WWW++

Adding

Why to What, When and Where

Paris Pennesi, Mark Harrison

University of Cambridge, Distributed Information and Automation Laboratory and the Auto-ID Lab, U.K.

Chaithanya Rao

Indian Institute of Technology, India

Chien Yaw Wong, Srilakshmi Sivala

RedBite Solutions Ltd., U.K.

Keywords:

Context aware systems, rfid middleware, business process, business context addition.

Abstract:

RFID technology can be used to its fullest potential only with software to supplement the hardware with

powerful capabilities for data capture, filtering, counting and storage. The EPCglobal Network architecture

encourages minimizing the amount of business logic embedded in the tags, readers and middleware. This

creates the need for a Business Logic Layer above the event filtering layer that enhances basic observation

events with business context - i.e. in addition to the (what, when, where) information about an observation,

it adds context information about why the object was there. The purpose of this project is to develop an

implementation of the Business Logic Layer. This application accepts observation event data (e.g. from

the Application Level Events (ALE) standard interface), enriches them with business context and provides

these enriched events to a repository of business-level events (e.g. via the EPC Information Services (EPCIS)

capture interface). The strength of the application lies in the automatic addition of business context. It is quick

and easy to adapt any business process to the framework suggested and equally easy to reconfigure it if the

business process is changed. A sample application has been developed for a business scenario in the retail

sector.

1 INTRODUCTION

Automatic Identification (Auto-ID) technologies such

as Radio-Frequency Identification (RFID) and bar-

codes, combined with architectures (such as the EPC

Network) for processing and exchange of event data,

provide plenty of data and create the opportunity for

an information rich business environment. One of

the main challenges to achieve an information rich

business environment is to link event data automat-

ically created by the EPC Network infrastructure to

the Enterprise Information System, and to contextual-

ize those data into the business process. The ultimate

objective is to infer the business semantics from the

automatic collection of data.

To achieve this objective we need to fill the gap

between the EPC Network and the Enterprise Infor-

mation System. The idea is to create a methodology

which automatically detects the business logic from

the data and links them in the context of the business

process. Ideally, we want to have an adaptive mech-

anism to keep the system running despite changes in

the business process.

The main objective of this paper is to develop

a methodology and a sample application that would

process the observation events (e.g. output from the

ALE interface) and infer business context from the

unique IDs (EPCs), timestamp and reader location be-

fore putting each event into an EPC Information Ser-

vice (EPCIS) repository. We want to add the ‘why’ to

the ‘what’, ‘when’ and ‘where’, dimensions already

present in an observation event from the Application

Level Events (ALE) layer.

Our main contribution is a mechanism that links

data from the ALE component of the EPC Network,

to the business process. That mechanism is highly and

304

Pennesi P., Harrison M., Rao C., Yaw Wong C. and Sivala S. (2008).

WWW++ - Adding Why to What, When and Where.

In Proceedings of the Tenth International Conference on Enterprise Information Systems - DISI, pages 304-309

DOI: 10.5220/0001710403040309

Copyright

c

SciTePress

easily configurable to accommodate different busi-

ness process and to allow changes on time without

requiring IT expertise.

To build our sample application we use input from

the SMART project. SMART (Intelligent Integra-

tion of Supply Chain Processes and Consumer Ser-

vices based on Unique Product Identification in a

Networked Business Environment) is a EU funded

project looking at possible ways of extracting maxi-

mum benefits from a full scale deployment of RFID

technology. The SMART project plans to exploit

unique identification and automatic process monitor-

ing to improve decision making within the retail sec-

tor. The top level goals of the SMART project can be

listed as

• Dynamic pricing

• Promotion Management

• Shelf Replenishment

2 BUSINESS SCENARIO

To illustrate our methodology we focus, without loss

of generality, on a particular business scenario. The

business scenario considered is that of a retailer who

receives stocks from a distribution centre and stores

products in a backroom. The backroom has prede-

fined areas for holding products found to be non-

sellable due to expiry, damage or other reasons as also

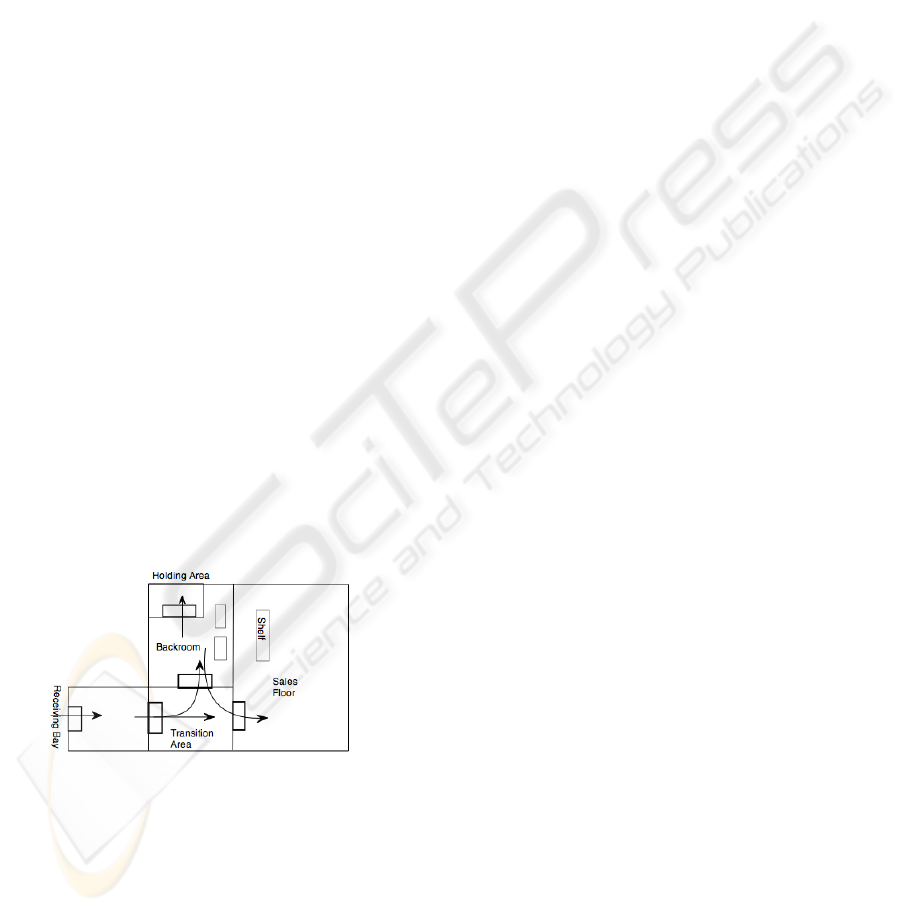

the ones returned by customers. Fig. 1 shows the floor

plan of a hypothetical retailer.

Figure 1: Floor plan of a retailer.

The flow of events at this retailer can be traced as be-

low:

• The Retailer receives an advance shipmment

notice indicating the dispatch of the requested

goods. This transaction includes the unique iden-

tifiers (EPCs) of the goods being shipped.

• The goods are received through the receiving bay

within the receiving area.

• Initial test on the integrity of the product and ex-

istence of tags might be carried out using a hand-

held reader

• It is then taken through the sales transition area,

where it now has two possible destinations:

– The Sales Floor: this might be to meet the ur-

gent requirement for replenishment of stocks

on the sales floor

– The Backroom: the Backroom is the storage

area as well as the holdings area for damaged

goods and goods to be returned.

• In the Backroom , the product might go to the

Holding area. The product might be held back

here for various reasons such as damage, no

matching pedigree etc.

• If the product is perfect with no flaws, it is likely

to be stored on the storage shelves

• The products on the storage shelf might be moved

to the sales floor at a later time or might be moved

to the holding area if they expire during their stor-

age on the shelf.

• The products in the holding area might then be

returned to the manufacturer or the distributor.

The purpose of choosing the above mentioned struc-

ture of the Shop floor or the flow as mentioned above

is to cover almost all possible business steps and dis-

positions available as a part of an EPCglobal vocab-

ulary that has so far been defined by members of the

Fast Moving Consumer Goods sector.

3 METHODOLOGY

Before describing our methodology, we need to

define the Business Logic context. The Business

Logic/Semantics referred to in this report are states or

qualifiers associated with a group of EPCs or a group

of objects of a given EPC class that give more infor-

mation about why those objects were seen by a reader

at a specific location. The business semantics used in

this project can be listed as below

• Business Step is a vocabulary whose elements de-

note steps in business processes. An example is an

identifier that denotes “shipping”. The business

step field of an event specifies the business context

of an event: what business process step was taking

place that caused the event to be captured (EPC-

Global, b)?

• Disposition is a vocabulary whose elements de-

note a business state of an object. An example

is an identifier that denotes “available for sale”.

WWW++ - Adding Why to What, When and Where

305

The disposition field of an event specifies the busi-

ness condition of the event’s objects, subsequent

to the event. The disposition is assumed to hold

true until another event indicates a change of dis-

position. Intervening events that do not specify a

disposition field have no effect on the presumed

disposition of the object (EPCGlobal, b).

• The Action type says how an event relates to

the lifecycle of the entity being described. For

example, Aggregation Event is used to capture

events related to physical aggregations of objects,

such as cases aggregated to a pallet. Through-

out its life, the pallet load participates in many

business process steps, each of which may gen-

erate an EPCIS event. The action field of each

event says how the aggregation itself has changed

during the event: have objects been added to

the aggregation, have objects been removed from

the aggregation, or has the aggregation simply

been observed without change to its membership?

The Action type is an enumerated type having

three possible values namely ADD, OBSERVE

and DELETE. For more details check out EPCIS

standards (EPCGlobal, b).

To link data to the business process we use the au-

tomata framework. An automaton is a model of be-

havior for a system composed of a finite number of

states, transitions between those states, and actions

( (Hopcroft et al., 2007)).

More formally, an automaton is a sixtuple

(E, X, x

0

, F, Γ, X

m

), where:

• E is the event set (a finite non empty set of sym-

bols).

• X is a finite non empty set of states.

• x

0

is an initial state, an element of S.

• F is the state transition function: F : X x E → X

• Γ is the active event function defined as Γ : X →

2

E

• X

m

is the set of final states, a (possibly empty) sub-

set of S.

The finite non empty set of states, X

m

, is defined as an

ordered pair of two values namely Business step and

Business disposition. It could be extended to include

more fields than the ones listed. These are the ones

specified in the EPCglobal data standards for event

data. All the states are referred to by number in the

transition table or the state diagram. The state table

listing the business steps and dispositions for the busi-

ness scenario discussed in this section is shown in Ta-

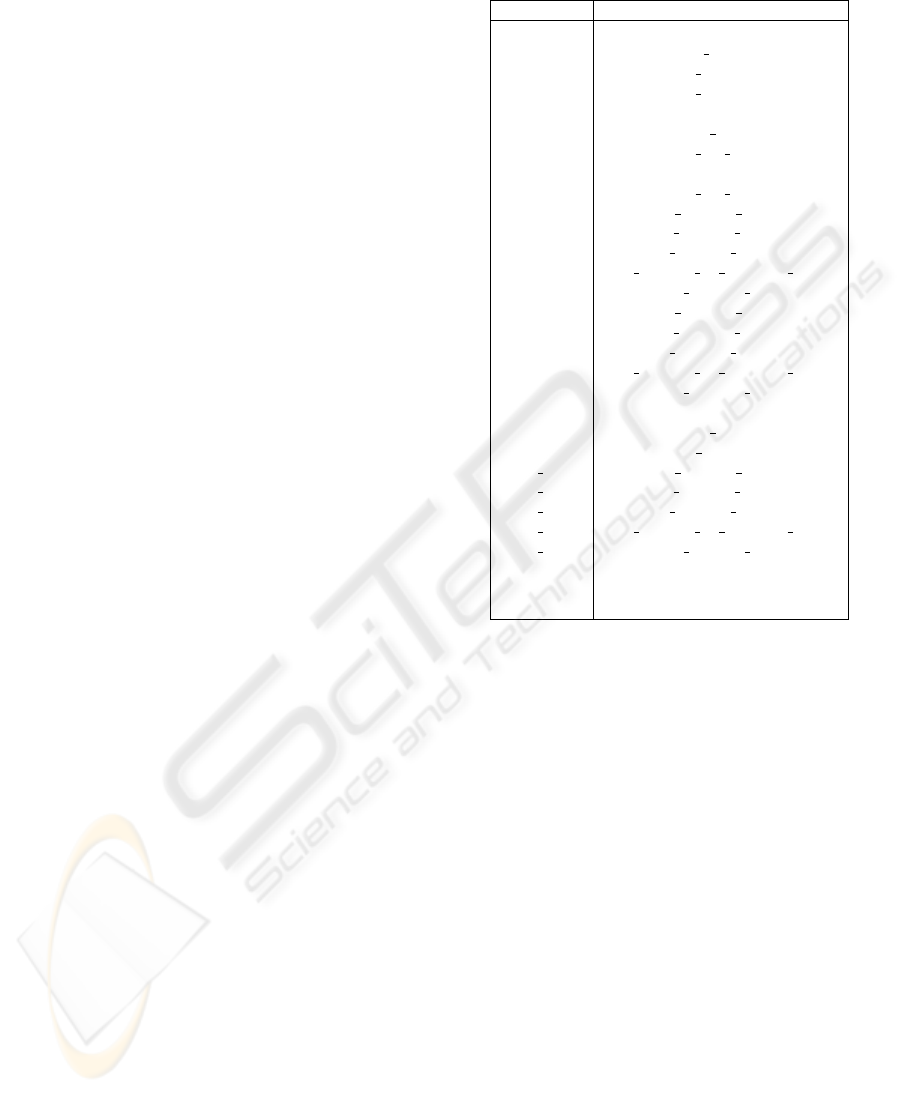

ble 1.

It is not necessary to use the same definition of

states, although it is advisable to make use of standard

Table 1: State Definition Table.

BizStep BizLogic

- -

shipping in transit

accepting in progress

receiving in progress

- inspecting

receiving sellable accessible

receiving sellable not accessible

- receiving

storing sellable not accessible

storing non sellable expired

storing non sellable recalled

storing non sellable damaged

storing non sellable no pedigree match

storing non sellable other

holding non sellable expired

holding non sellable recalled

holding non sellable damaged

holding non sellable no pedigree match

holding non sellable other

holding returned

Stocking sellable accessible

Picking In progress

Stag Outb non sellable expired

Stag Outb non sellable recalled

Stag Outb non sellable damaged

Stag Outb non sellable no pedigree match

Stag Outb non sellable other

Loading

Sold

Destroying Destroyed

vocabularies for business steps and business disposi-

tions specified by the EPCglobal or by other industry

standards bodies. Note that the initial state x

0

is ‘-1’.

It denotes a wait state. When a uniquely identifiable

object (or EPC) is seen for the first time, its initial

state is set to ‘-1’. When it is seen once again, its ex-

istence is confirmed and it is assigned a state number.

There could be additional wait states which have not

been included. The set of the wait states and the set

X

m

define the set X.

The event set E consists of the following:

• Tags being read at a location.(e.g. 1000 EPCs

were observed at the receiving bay)

• Transaction events.(An advance shipment notice

is sent listing the EPCs that are being shipped)

• Timed checking events(e.g. Every day a check

is performed if a product has exceeded its expiry

date)

• Checking events about the integrity of the pro-

ducte.g. Pedigree checks

A list of possible event sets for the business scenario

in discussion is given in Table 2.

ICEIS 2008 - International Conference on Enterprise Information Systems

306

Table 2: Event Set.

Event No Description

1 Advance Shipment notice is sent

2 Product seen at receiving bay

3 Product seen at Transition Area door

4 Inspection on handheld device

5 Product seen at Backroom door

6 Product seen at Salesfloor door

7 Recall demanded on a product

8 Product seen at Holding area door

9 Product seen on Backroom shelf

10 Product seen on sales floor shelf

11 Product seen at POS

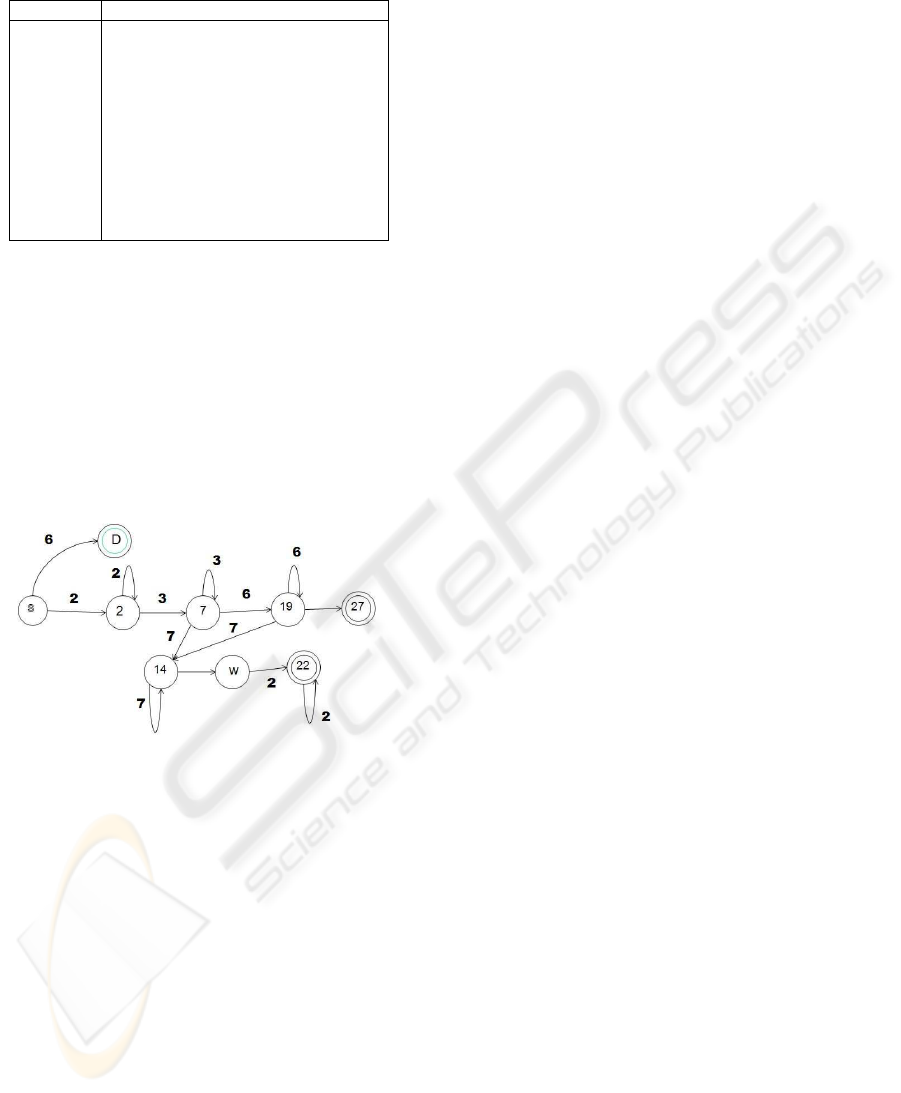

The transition diagram in Fig. 2 includes the states in

discussion and for each given state, the correspond-

ing transitions for each of the event sets. Note for

our case, the consistent and required transitions are

very small considered to the total possible transitions.

Therefore the sample state transition diagram for the

case in consideration shows only the essential and

meaningful transitions. All others are inconsistent

and have to be handled using wait states, doubtful

states and flagged-off danger states.

Figure 2: State transition diagram.

The numbers encircled denote the state numbers and

their description can be checked from the State Def-

inition Table, Table 1. The numbers on the arrows

denote the event set and their description is as pro-

vided in Table 2. The states marked with 2 circles are

marked states. As an example, let us focus on state

‘14’, a wait state. If an object is being returned to

the distributor through the receiving bay and passes

through the backroom door, then there is not much

significance with the products crossing the backroom

and they could be confirmed to be leaving the facility

only when they are seen through the transition area

door. Wait states can be used generously and EP-

CIS events linked with them are recorded without any

business context.

A specific state not included in the state defini-

tion list can be used as the flagged-off state to denote

any inconsistencies like a product that should have be

been returned being seen on the sales floor. All doubt-

ful cases may be dealt with using a default wait state

that just records the event.

4 WWW++ APPLICATION

4.1 Architecture

For the implementation of our sample application we

use as a starting point the Accada project (Accada, ).

Accada is an open source software RFID prototyping

platform that implements the EPC Network specifi-

cations. Accada provides implementations which are

platform independent under GPL. The requisite mod-

ules of Accada which have been used in the project

are listed below:

• ALE(Application Level Events): The ALE soft-

ware has two main components, namely the filter-

ing and counting server and the client. All events

from the physical reader are directed towards the

ALE server. The server then filters the reads based

on event definitions and logical reader classifica-

tions. It then prepares an XML report that can be

displayed online or sent to a TCP address speci-

fied in a client’s subscription. The report format

and the event cycle specifications need to be set by

a system administrator. These specifications can

be uploaded using the ALE client. It gives the user

the ability to set event cycle start and stop times,

as well as the periodicity of reporting. Event cy-

cles can also be triggered by other actions. The

specification is set using XML files and the corre-

sponding schema can be found in the ALE stan-

dard version 1.0 (EPCGlobal, a)

• EPCIS Repository: EPC Information Services

(EPCIS) is a standard for exchange and retrieval

of business-level events. An EPCIS event repos-

itory can store reads from radio frequency identi-

fication (RFID) tags and readers, with additional

business context annotations per event.

• Capture Client: The capture client is an interface

that pushes data into an EPCIS repository. It ac-

cepts manual input of data including the EPCs and

business semantics.

• Query Client: The query client queries the EPCIS

repository for events that match specified query

criteria, which may include the EPC, time, busi-

ness disposition, transaction id etc.

The Accada implementation of the EPCIS capture ap-

plication requires manual input and does not interface

with the ALE. When all parts of the Accada software

WWW++ - Adding Why to What, When and Where

307

are put together there still lies an application gap be-

tween the output of the ALE layer and the input to the

EPCIS repository via the capture interface. Though a

capture client is available, it requires manual input of

meaning as well as the basic event data like the EPCs

and the event time.

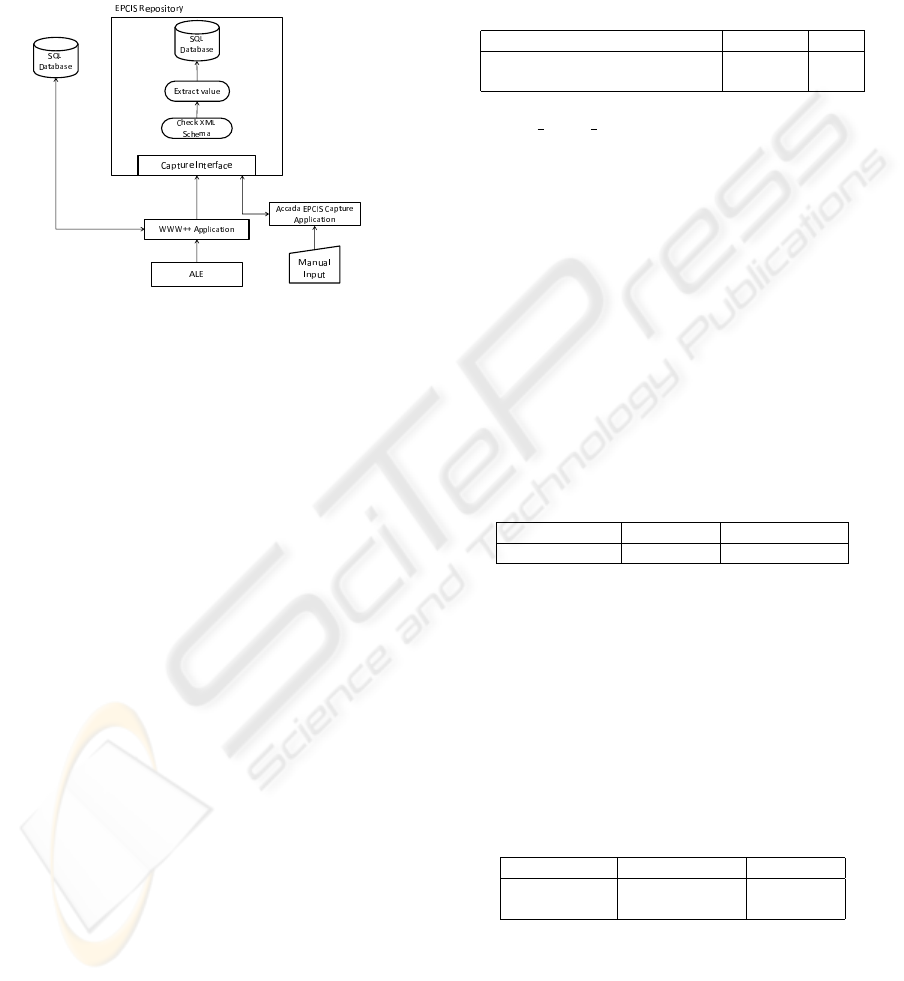

Figure 3: Structure.

Fig. 3 shows the architecture of the system. WWW++

refers to the application in discussion. WWW++ as-

sumes a position in between the ALE and the EP-

CIS repository acting as a controller which decides

the business semantics to be added. This decision is

based on the automaton described in Sec. 3. The ap-

plication does not post the data itself but uses the EP-

CIS repository server’s capture interface.

The ALE layer sends its reports in XML format

according to a standard schema ((EPCGlobal, a)).

The WWW++ acts as a tcp server listening at a given

port address. On receiving the report the WWW++

application uses JAXB to unmarshal the document

and extract the three essential values (what, when and

where). The ‘where’ is not explicitly mentioned but a

spec name is included which indicates the specifica-

tion that generated the report. This specification cor-

responds to a logical reader location. If the ‘what’ is

a list of EPCs, then object events are noted.

The business context dection algorithm depends

on the level of tagging. The best possible results can

be achieved with the use of item level tagging. This

makes it possible to isolate an object at each stage

of its life and hence associate a State to it. In this

case an automaton is used. The automaton is defined

by its elements. All the elements are stored as SQL

tables, some of which are loaded at the beginning of

the application while others are referred to throughout

the operation of the application.

A state definition table similar to the one in Ta-

ble 1 is stored in SQL tables and loaded at the be-

ginning of the application.The application maintains

a State table as shown in Table 3. It maintains a field

called a flag that can take binary values 0 or 1

0 means Consistency.

1 means an Inconsistency

Table 3: The State Table.

EPC State No Flag

urn:epc:tag:gid-96:10.50.1000 2 0

urn:epc:tag:gid-96:10.50.1001 3 1

The Spec Event Link table is used to link the Spec-

Name with a reader location. The reports from the

ALE layer contain the name of the specification that

was used to create the report. Since the ALE report

is generated for the logical readers listed in the spec-

ification file, the SpecName corresponds to a location

marked by the intersection of a few readers.

Manual events have to be entered through a cap-

ture application like Accada’s implementation for the

EPCIS capture interface. Any other data, for exam-

ple ERP data or barcode data can be handled by the

WWW++ application provided that the data is refor-

matted to conform to the XML schema provided for

ALE reports

The structure of the table is as follows

Table 4: Spec Event Link Table.

SpecName ReadPoint Event Number

ReceivingBay x:y:z:t.h.k 5

Table 3 defines the event set for finite state machine.

The transition function can be described by the

state diagram or by the transition table. The transition

table consists of three fields, namely Present State,

Event Number and Next State. A sample transition

table is shown in Table 5. It is stored as an SQL ta-

ble that is loaded at the start of the application. The

transition table should handle all possible cases i.e.

number of states x number of events.

Table 5: Transition Table.

Present State Event Number Next State

-1 1 0

0 2 4

4.2 Configuration

Configuration of the SQL tables is very essential to

the proper working of the application. First a list of

all the logical readers must be made. Then an event

ICEIS 2008 - International Conference on Enterprise Information Systems

308

should be associated with it. Once the spec files for

the logical readers are uploaded they should all be

subscribed to by the client machine that is running the

WWW++ application on an appropriate port address.

A State definition table should be made, as shown in

previous section. It is also necessary to create the ta-

ble that links spec names with events. in the appendix,

we provide SQL scripts to generate the tables and link

them. The transition table is the most important table

and utmost care must be taken while configuring it.

When a new event is added, then for all the existing

states the transition for the given state should be de-

fined. Triggers have been associated to perform this

task. However, the trigger initializes the table with the

default ‘-1’ (start state). It is the responsibility of the

system administrator to have a well defined transition

table and to update the transition table when events

are added. Also when a new state is added then all the

transitions from that state to all existing events must

be added. This is also implemented using SQL trig-

gers, although the default value of ‘-1’ should be up-

dated to the required value. The state definition table

must be ordered in an ascending order according to

the state numbers. Also the first two states (denoted

‘-2’ and ‘-1’) are reserved for the flagging state and

the start state. The User may define his own states

starting from ‘0’.

5 CONCLUSIONS

In this paper we proposed a new methodology to inte-

grate information and event from the enterprise infor-

mation system and the ALE component of the EPC

Network, adding business context to them before to

feed the EPCIS Repository, to provide an informa-

tion rich business environment. The methodology is

based on automata theory and a sample application

for a specific business scenario has been provided.

The ability to easily configure it for any business

process is one of its strengths. It is also equally easy

to reconfigure for further changes in the process.

ACKNOWLEDGEMENTS

The work has been partially supported by the Euro-

pean Commission trough the SMART, “Intelligent In-

tegration of Supply Chain Processes and Consumer

Services based on Unique Product Identification in a

Networked Business Environment” (European Sixth

Framework Project ST5034957STP).

REFERENCES

Accada. http://www.accada.org.

EPCGlobal. Application level events (ale).

http://www.EPCglobalinc.org/standards/Application

Level Event ALE Standard Version 1.0.pdf.

EPCGlobal. Epc information services.

http://www.EPCglobalinc.org/standards/EPCglobal

EPCIS Ratified Standard 12April 2007 V1.0.pdf.

Hopcroft, J., Motwani, R., and J.D. Ullman, J. (2007). In-

troduction to Automata Theory, Languages, and Com-

putation, Third Edition. Addison-Wesley.

WWW++ - Adding Why to What, When and Where

309