A DECISION SUPPORT SYSTEM FOR FACILITY LOCATION

SELECTION BASED ON A FUZZY HOUSE OF QUALITY

METHOD

R. Tavakkoli-Moghaddam

1

and S. Hassanzadeh-Amin

2

1

Department of Industrial Engineering, Faculty of Engineering, University of Tehran, P.O. Box: 11365/4563, Tehran, Iran

2

Department of Industrial Engineering, Graduate School, Islamic Azad University - South Tehran Branch, Tehran, Iran

Keywords: Decision support systems, Location selection, House of Quality, Fuzzy logic.

Abstract: Companies investigate decision supports systems (DSSs) for facility location selection to reduce cost and

manage risk. In this paper, a decision support system for location selection is proposed based on a house of

quality (HOQ) method, adopting an analysis to fuzzy logic and triangular fuzzy numbers. Special attention

is also paid to the subjective assessment in the HOQ concept. Further, the differences between decision

makers are taken into account. Finally, a case study is presented to demonstrate the procedure of the

proposed algorithm and identify the suitable location.

1 INTRODUCTION

Facility location selection is a multi criteria

decision-making problem. Location problems

involve the determination of the location of one or

more new facilities in one or more of several

potential sites. Obviously, the number of sites must

be at least equal to the number of new facilities

being located (Heragu, 2006).

Researchers applied a quality function deployment

(QFD) technique for a facility location selection

problem. This technique is a planning tool used to

fulfill customer expectations. It is disciplined

approach to product design, engineering, and

production and provides in-depth evaluation of a

product. QFD focuses on customer expectations or

requirements, often referred to as the voice of

customer. The primary planning tool used in QFD, is

the house of quality (HOQ), whose basic structure is

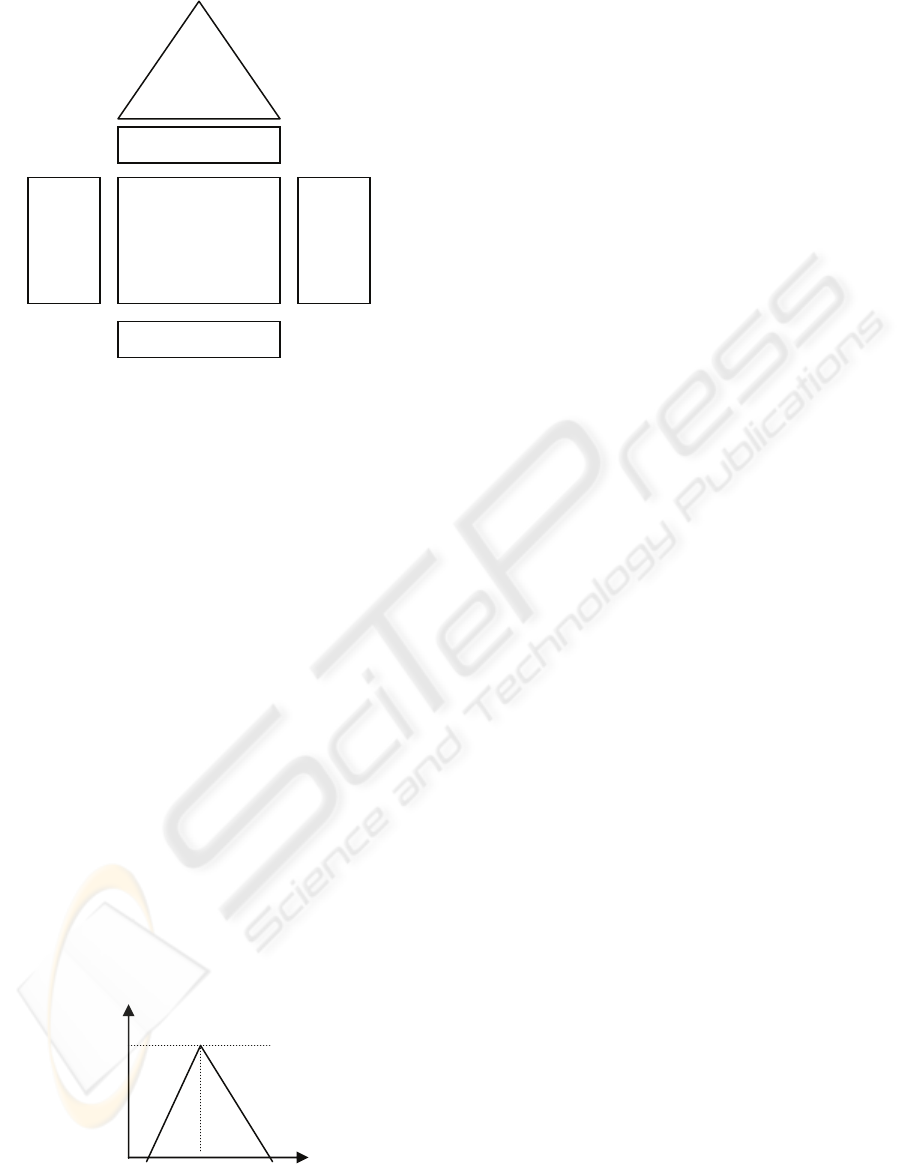

shown in Figure 1 (Besterfield et al., 2003).

Some researchers also applied the QFD approach

for facility location decisions. For instance, Chuang

(2002) presented approaches including a single QFD

matrix for relating customer wants to facility

location. Further, Partovi (2006) presented a

strategic solution to a facility location problem by

using the QFD, AHP, and ANP, simultaneously. He

considered internal and external criteria. However,

these models do not take into account the impression

and vagueness of humans’ judgments. Temponi et

al. (1999) developed a fuzzy logic-based extension

to the HOQ to capture imprecise requirements to

both facilitate communication of team members and

have a formal representation of requirements.

Recently, Bevilacqua et al. (2006) suggested a new

method that transfers the HOQ approach, typical of

QFD problems to the supplier selection process.

In this paper, we develop a decision support

system (DSS) for location selection on the basis of

the HOQ concept, adopting an analysis based on

fuzzy logic and triangular fuzzy numbers. It has

been assumed that there are some locations

(alternatives) and we want to select the best one

according to significant criteria. To deal with

vagueness of human thought, a fuzzy method is

suggested to convert the location linguistic attributes

into fuzzy numbers. The decision support system

can be easily implemented with a spreadsheet

package, such as MS Excel.

The rest of this paper is as follows: In Section 2

fuzzy sets are presented. Sections 3 and 4 present the

proposed model and case study, respectively.

Finally, conclusions are discussed in Section 5.

403

Tavakkoli-Moghaddam R. and Hassanzadeh-Amin S. (2008).

A DECISION SUPPORT SYSTEM FOR FACILITY LOCATION SELECTION BASED ON A FUZZY HOUSE OF QUALITY METHOD.

In Proceedings of the Tenth International Conference on Enterprise Information Systems - AIDSS, pages 403-406

DOI: 10.5220/0001674304030406

Copyright

c

SciTePress

Figure 1: House of quality.

(A) Customer requirements (voice of the customer).

(WHATs)

(B) Prioritized customer requirements.

(C) Technical descriptors (HOWs) (Voice of the

organization).

(D) Relationship between requirements and descriptors.

(E) Interrelationship between technical descriptors.

(F) Prioritized technical descriptors.

2 FUZZY SETS THEORY

To deal with vagueness of human thought, Zadeh

(1965) first introduced the fuzzy set theory, which

was oriented to the rationality of uncertainty due to

imprecision or vagueness. A major contribution of

the fuzzy set theory is its capability of representing

vague data. To deal with this type of uncertainty

correctly, we can resort to fuzzy logic that is based

on fuzzy sets (Zadeh, 1965). There are various types

of fuzzy numbers, each of which may be suitable

than others for analyzing a given ambiguous

structure, the present analysis uses triangular fuzzy

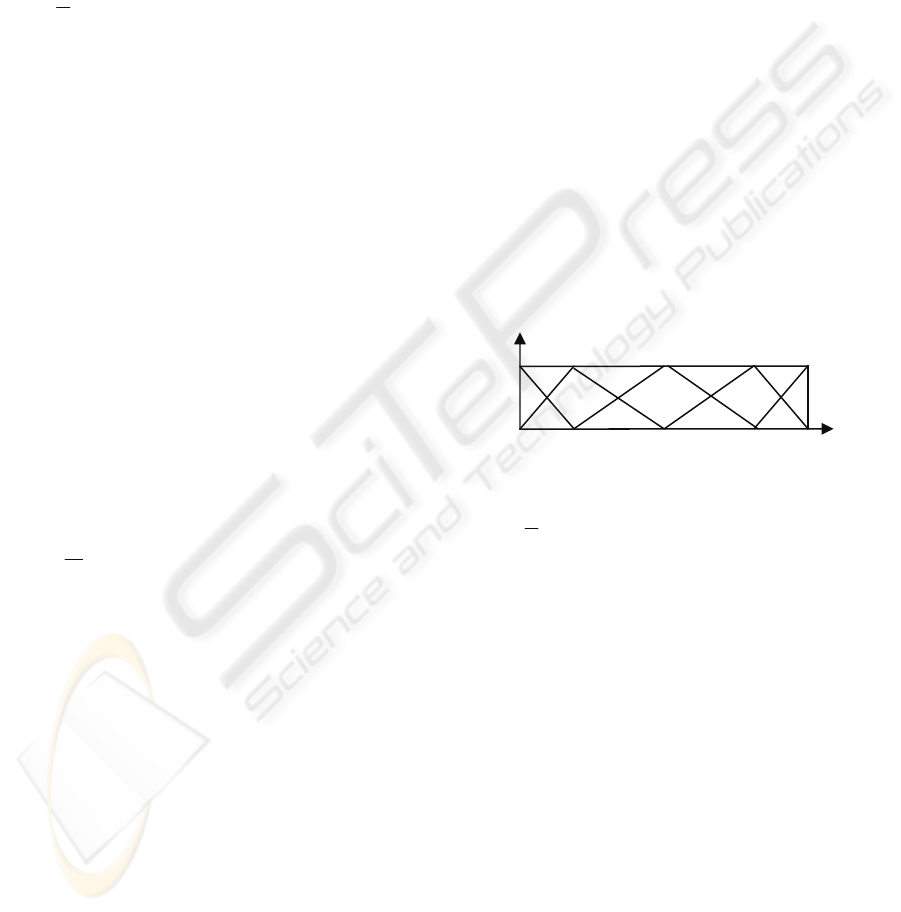

numbers. Figure 2 depicts a triangular fuzzy number

Ã= (l, m, u) (Klir and Yuan, 1995).

μ

(x)

1

l m u

x

Figure 2: Triangular fuzzy number.

If we want to use fuzzy sets in applications, we

will deal with fuzzy numbers operations. Let Ã= (a,

b, c), Ẽ = (d, e, f), denote fuzzy numbers followed

by Eqs. (1) and (2)

(, , )Eadbecf

Α

⊕= + + +

%%

(1)

(, , )

E

adbec f

Α

⊗= × × ×

%%

(2)

3 PROPOSED MODEL

Suppose that there are a number of locations

(alternatives) and we want to select the best one

according to the given significant criteria. The main

steps of our proposed model are as follows:

Step 1: List the customer requirement (i.e., product

criteria, or WHATs).

Step 2: List the technical descriptors (i.e., location

criteria, or HOWs).

Step 3: Determine prioritized customer requirement.

The decision maker determines a weight by

linguistic variables. Triangular fuzzy numbers are

used to quantify the linguistic variables.

Step 4: Determine a weight of each decision maker

(DM), in which r

i.

is the weight of DMi. This

parameter can be determined by a manager of a

company. These variables are designed according to

authority, experience, and the responsibilities of

different DMs. In addition, Eq. (3) should be

satisfied.

Step 5: Calculate an aggregated weight for WHATs:

The weights assigned by the decision-makers for

customer requirement should be aggregated.

Aggregated weight (w

i

) is computed by the

following equation:

where, k is the number of WHATs, and n is the

number of decision-makers (i = 1,…,k).

Step 6: Determine the relationship between

requirements and descriptors: Every DM was asked

to express an opinion by using the linguistic

variables on the impact of each HOWs on each

WHATs. It is worthy noting that triangular fuzzy

numbers are used to quantify the linguistic variables.

Step 7: Compute the aggregated weight, (a

ij

),

between WHATs and HOWs by Eq. (5).

(E)

(

C

)

(D)

(B)

(A)

(

F

)

)4()(...)()(

2211 inniii

wrwrwrw ⊗⊕⊕

⊗

⊕

⊗

=

)5()(...)()(

2211 ijnnijijij

ararara ⊗⊕⊕

⊗

⊕

⊗

=

)3(1

1

=

∑

=

k

i

i

r

ICEIS 2008 - International Conference on Enterprise Information Systems

404

where, k is the number of WHATs, n is the number

of decision-makers, (i = 1,…,k), (j = 1,…,m), and m

is the number of HOWs.

Step 8: Determine prioritized technical descriptors.

Now we can complete the HOQ, calculate the

weights of the HOWs (f

i

), average the aggregated

weight for WHATs (w

i

), with the aggregated weight

between WHATs and HOWs (a

ij

), according to Eq.

(6).

Again, these variables are triangular fuzzy numbers.

Step 9: Determine the impact of each location on the

attributes considered. It is necessary to assess each

location vis-à-vis the attribute in question and

combine said assessments with the weight of each

attribute in order to establish a final ranking. In the

same way as before, the linguistic variables are used

quantified by means of triangular fuzzy numbers,

then the DMs

,

assessment or LR (LR = Location

Rating), are aggregated according the following

equation:

h = 1,…,p , j = 1,…,m

where, m, p, and n are the number of attributes,

locations, and decision makers, respectively.

Step 10: Calculate the FSI index that expresses the

degree to which a location satisfies a given

requirement. This index is a triangular fuzzy number

obtained from the previously calculated scores by

Eq. (8).

Step 11: Defuzzify the FSI index and Ranking. The

simple and popular method is adopted to defuzzify

the FSI index. A defuzzified triangular fuzzy

number, Ã= (l, m, u), is obtained by Eq. (9).

Finally, the final scores can be ranked.

4 CASE STUDY

In this section, we consider a real-case study. A

famous company in Iran that manufactures bicycle

components, such as cranks, hubs, rims, and so forth

wants to establish another factory to expand its

supply chain. Therefore, this company should focus

on product design during location selection process.

Because customer service is very important, the

company wants to be as close its customers as

possible. Preliminary investigation is shown that

three big sites, namely Isfahan, Tabriz, and Yazd,

are considered as the three most desirable locations

in this study. The data are collected by means of

interviews with three company buyers.

Step 1: Reasonable Cost, Nice Finish, Lightweight,

Strengthm and Durable are five customer

requirements.

Step 2: The customer needs and expectations are

expressed in terms of the customer requirement, and

the QFD team must come up with location criteria

(HOWs). Five location criteria are: Economic (EC),

Technological (TE7), Social (SO), Political (PO),

and Environmental (EC) criteria.

Step 3: Let U = {VL, L, M, H, VH} be the linguistic

set used to express opinions on the group of

attributes (VL = Very Low, L = Low, M = Medium,

H = High, VH = Very High). The linguistic variables

of U can be quantified by using triangular fuzzy

numbers as shown in Figure 3: VL = (0, 0, 2); L =

(0, 2, 5 ) ; M = (2, 5, 8); H = (5, 8, 10); VH = (8, 10,

10). Each of the three decision-makers establishes a

level of the importance or weight of each of WHATs

by means of a linguistic variable.

VL L M H VH

1

0 2 5 8 10

Figure 3: Linguistic scale.

Step 4: The manager of this company determines a

weight for each decision maker (DM). In this case,

there are three decision makers. However, one of

these DMs has more experience. Therefore, the

manager devotes the weights as follows:

r

1

=0.4, r

2

=0.3, r

3

=0.3

Step 5: By using Eq. (4), the aggregated weights are

calculated. In our case, k=5, m=5, and n=3.

Step 6: The opinion expressed by three decision-

makers, on the impact of each HOWs on each

WHATs are determined.

Step 7: The aggregated weights between WHATs

and HOWs are calculated by Eq. (5). Again, a

ij

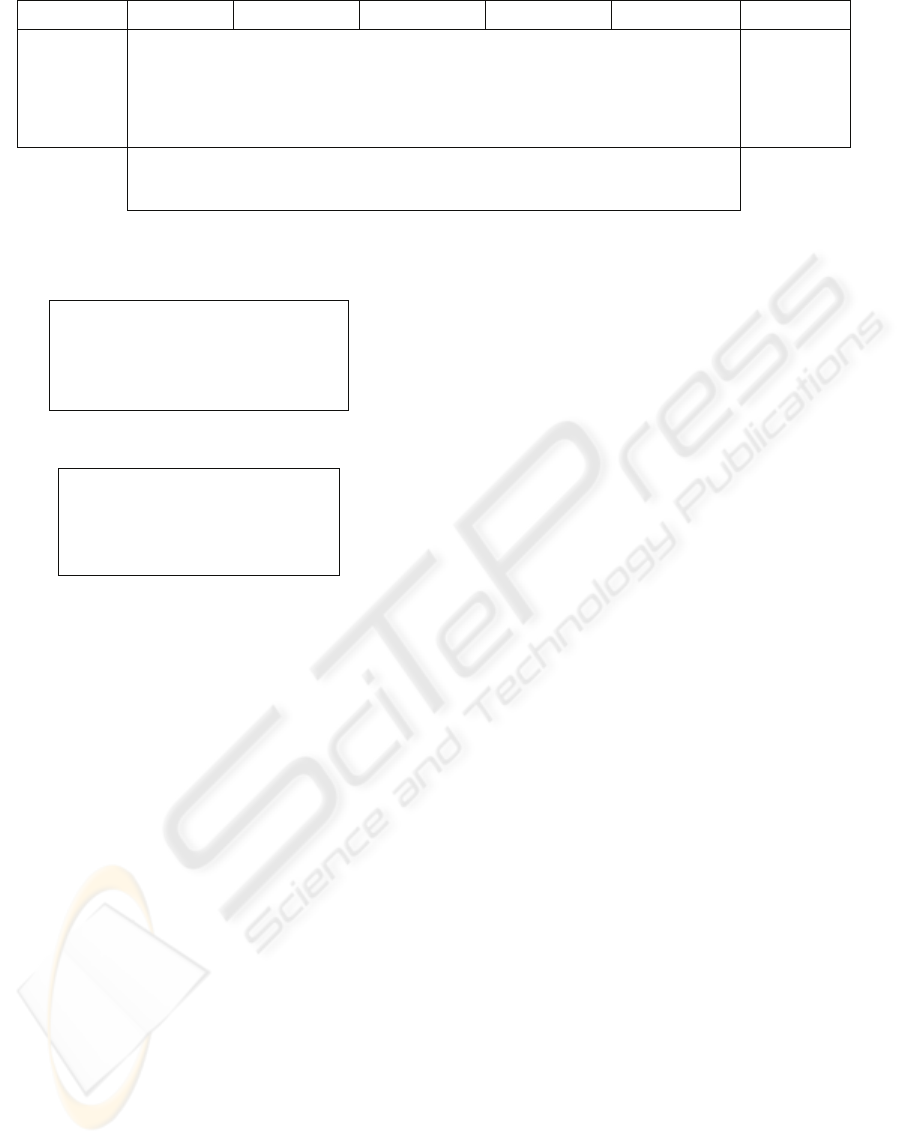

elements are triangular fuzzy numbers, as shown in

Figure 4.

Step 8: Prioritized technical descriptions are

calculated by Eq. (6). The fuzzy values are shown in

matrix F of Figure 4.

)6()](...)[(

1

11 kjkjj

awaw

k

f ⊗⊕⊕⊗⊗=

)7()(...)()(

2211 hjnnhjhjhj

lrrlrrlrrLR ⊗⊕⊕⊗⊕⊗=

)8()](...)[(

1

11 mhmhh

fLRfLR

m

FSI ⊗⊕⊕⊗⊗=

)9()2(

4

1

UmLFSI ⊕⊕⊗=

A DECISION SUPPORT SYSTEM FOR FACILITY LOCATION SELECTION BASED ON A FUZZY HOUSE OF

QUALITY METHOD

405

Economic Technical Social Political Environmental

Cost

Nice finish

Lightweight

Strength

Durable

(6.2,8.8,10) (3.8,6.8,9.2) (5,8,10) (1.2,3.8,6.8) (4.1,7.1,9.4)

(2.9,5.9,8.6) (2.6,5.3,7.9) (0.6,2.9,5.9) (5.9,8.6,10) (0.1.4,4.1)

(2.3,5,7.7) (7.1,9.4,10) (0.6,1.5,3.8) (4.1,7.1,9.4) (0,2,5)

(3.8,6.8,9.2) (2.9,5.9,8.6) (0.6,2.9,5.9) (6.2,8.8,10) (0,1.2,3.8)

(1.2,3.8,6.8) (5,8,10) (1.2,3.8,6.8) (5.9,8.6,10) (0.6,2.9,5.9)

(2.6,5.3,7.9)

(2.1,4.7,7.4)

(5.9,8.6,10)

(4.1,7.1,9.4)

(0.8,3.2,6.2)

f

1

f

2

f

3

f

4

f

5

(52.3,177.8,348.2) (21.2,101,6,258.2) (11.1,79.2,211.8)

(73.1,209.2,373.9) (69.8,211.6,377.7)

Figure 4: Completed fuzzy-HOQ.

Table 1: Calculation of the FSI index.

L M U

Isfahan 187.2 324.2 440.3

Tabriz 109.8 248.9 392.2

Yazd 187.2 322.2 437.2

Table 2: Defuzzification.

Alternative Score Ranking

Isfahan 319 1

Tabriz 250 3

Yazd 317 2

Step 9: In this step, the impact of each potential

location on the attributes considered. By using Eq.

(6), location ratings are calculated.

Step 10: The FSI index is calculated by using Eq.

(8). Table 1 illustrates the related results.

Step 11: Triangular fuzzy numbers are defuzzified

by Eq. (9). Now, the alternatives can be ranked.

Ultimate ranking and scores are given in Table 2.

According to this table, Isfahan is the best

alternative for establishing a new factory.

5 CONCLUSIONS

Facility location selection in any industry is a multi

criteria decision-making process. Expertise,

experience, authority, and the responsibilities of

different decision makers (DMs) influence on the

results. The fuzzy logic can overcome the vagueness

of human opinion. In this paper, a decision support

system was proposed based on total quality

management (TQM) tools, such as house of quality

(HOQ) adopting an analysis to the fuzzy logic and

triangular fuzzy numbers. The linguistic variables

were used to quantify variables. The problem can be

solved by our proposed algorithm very quickly. We

conclude that this algorithm can be useful for

practitioners. Further research may be investigated

to determine the DMs’

weights by another method,

such as a fuzzy data envelopment analysis (DEA).

Besides, our proposed algorithm can be applied

effectively to various issues, such as performance

assessment, business strategies, policy making, and

other selection problems.

REFERENCES

Chuang, P., 2002. A QFD approach for distribution’s

location model. International Journal of Quality &

Reliability Management 19 (8/9) 1037–1054.

Besterfield, D.H., Michna, C.B., Besterfield, G.H., Sacre,

M.B., 2003. Total Quality Management. Third Edition,

Pearson Education. New Jersey.

Bevilacqua, M., Ciarapica, F.E., Giacchetta, G., 2006. A

fuzzy QFD approach to supplier selection. Journal

Purchasing and Supply Management 12 (1) 14-27.

Heragu, S.S., 2006. Facilities Design, Second Edition,

iUniverse Publishing Co., Lincoln, NE.

Klir, G.J., Yuan, B., 1995. Fuzzy sets and fuzzy logic:

theory and applications. Englewood Cliffs. NJ:

Prentice-Hall Co.

Partovi, F.Y., 2006. An analytic model for locating

facilities strategically. Omega 34 (1) 41-55.

Temponi, C., Yen, J., Tiao, W.A., 1999. House of quality:

a fuzzy logic based requirements analysis. European

Journal of Operational Research 117 (2) 340–354.

Zadeh, L.A., 1965. Fuzzy sets. Information and Control 8

(1) 338-353.

ICEIS 2008 - International Conference on Enterprise Information Systems

406