AUTOMATIC GENERATION OF EXECUTABLE CODE FOR

A ROBOT CELL USING UPNP AND XIRP

Alexander Verl and Martin Naumann

Fraunhofer Institute for Manufacturing Engineering and Automation

Nobelstr. 12, 70569 Stuttgart, Germany

Keywords: Plug’n’Produce, High-Level Programming, Automatic Code Generation.

Abstract: This paper deals with the concept of a control architecture for robot cells that enables Plug’n’Produce

according to Plug’n’Play in the office world. To achieve this, the cell controller needs special functionality

located in a software module called “P’n’P-Module”. This module takes as input descriptions of devices and

processes. These descriptions are then automatically evaluated in order to offer the user device-independent

high-level commands to define a task for the robot cell. Based on this task definition an executable code has

to be generated. The focus of this paper lies on the descriptions and algorithms necessary to generate this

executable code. The presented method will be realized as a test bed within a bin picking cell using UPnP

and XIRP.

1 INTRODUCTION

In Germany, 45% of all robots in 2006 have been

shipped to the automotive industry, not counting

other industry sectors with mass production 0. The

tasks robots have to fulfil there are mostly highly

repetitive and do not change over an extended period

of time. Therefore, the main requirements for robots

used in mass production are short cycle times. The

goal of the european project SMErobot

TM

0 is to

broaden the field of applications for robots from

mass production to small lot size production, as it is

typically encountered in small and medium sized

enterprises (SMEs). Because of small lot sizes, fast

adaptability of robot and surrounding cell to new

products and processes is much more important for

SMEs than short cycle times. To make this possible

the programming of applications for robot cells and

the integration of new devices into these robot cells

must be adapted to these new requirements.

2 APPROACH AND SCOPE OF

THIS PAPER

In the office world it is very easy to install and use

new devices. For example, to install a printer to your

PC, you just plug it in. The entire configuration is

then done automatically and your application will

offer you the service “print”. This automatic

configuration is called “Plug’n’Play”. Carried

forward to a production environment this would

mean that you would connect e.g. a robot to a cell

controller and it would offer you the service

“move_to” on a HMI. Even more advanced, it

could mean that you connect e.g. a robot and a

gripper to a cell controller and the cell controller

would recognize the new possibilities enabled

through the combination of two or more devices and

offer you the service “

pick and place”. To

achieve this, the cell controller needs to know about

the functionality of the connected devices and must

be able to draw conclusions which services it can

offer to a user. The approach pursued in this paper is

based on device- and process-descriptions evaluated

in order to offer services representing the

functionality of the robot cell to a user.

The ability to add devices to a robot cell and to

use the functionality of these devices without the

need of configuration is called “Plug’n’Produce”,

according to “Plug’n’Play” in the office world and is

provided by a so called “Plug’n’Produce-Module”.

Plug’n’Produce (P’n’P) can be broken down into

three layers depending on the amount of

configuration done automatically:

Communication Plug’n’Produce: deals with

communication protocols. Automatic setup of a

242

Verl A. and Naumann M. (2008).

AUTOMATIC GENERATION OF EXECUTABLE CODE FOR A ROBOT CELL USING UPNP AND XIRP.

In Proceedings of the Fifth International Conference on Informatics in Control, Automation and Robotics, pages 242-248

DOI: 10.5220/0001504602420248

Copyright

c

SciTePress

basic means of communication between cell

controller and devices includes discovery and

addressing of devices.

Configuration Plug’n’Produce: automatically

configures all the settings the users should not

need to care about, e.g. bandwidth

requirements, default values, …

Application Plug’n’Produce: automatically

offers services to the user corresponding to the

functionality of the robot cell.

The focus of this paper lies on the Application-

P’n’P-layer. Of course, this layer depends on the

Configuration- and the Communication-P’n’P-layers

in order to get to know which devices are available,

to communicate with these devices and to get to

know the descriptions of these devices 0. However,

the two lower layers will not be within the scope of

this paper as they are already realized in available

communication protocols like XIRP and UPnP that

will be used.

3 STATE OF THE ART

UPnP 0 and XIRP 0are both XML-based client-

server communication protocols that both support

eventing and in the case of XIRP also cyclic

communication. UPnP was mainly developed by

Microsoft® for the PC-world while XIRP (XML

Interface for Robots and Peripherals) was developed

by a consortium of companies within the German

public funded project ARIKT.

Both protocols support the definition of device

profiles as do also many other communication

protocols 0. These device profiles define

programming interfaces that have to be supported by

a device in order to belong to a certain device

category. The functionality of the device can partly

be inferred from the programming interface, but it is

not itself part of a device profile. Therefore, device

profiles do not contain enough information to allow

detailed assumptions about the functionalities of

devices.

In the domain of knowledge representation,

languages have been developed that can be used to

describe functionalities of devices in form of a

taxonomy plus additional attributes. The most

popular of these languages is OWL (Web Ontology

language). It was developed as a key technology of

the Semantic Web 0 with the goal to add meaning to

the information that is today merely displayed in the

internet. This additional information can be used to

enable knowledge based services that contain

several entities.

In the context of home entertainment systems, a

function planning module was developed within the

SmartKom project. This module tries to serve

complex user requests by first determining which

devices are necessary and then determining how to

control devices based on abstract descriptions of the

functionalities of devices 0, 0.

In this paper, the concept of device profiles

augmented by a detailed description of the device’s

functionality with a knowledge representation

language is used to infer the functionality of a robot

cell within the Plug’n’Produce-Module that adapts

concepts of the function planning module of the

SmartKom project to the robotic domain to generate

executable code for UPnP- and XIRP-devices thus

enabling Application-P’n’P.

4 APPLICATION-P’N’P

OVERVIEW

Application-P’n’P as the highest P’n’P-layer has the

goal to offer the user as easy as possible means of

using the functionality of a robot cell. In the context

of SMErobot

TM

this means offering the user as easy

as possible means of adapting robot cells to new

tasks.

State of the art of defining the sequence for robot

cells is to enter commands in the dialog of some sort

of a programming system. The entered commands

are then uniquely mapped to devices. This is an

appropriate way of programming as long as the user

has detailed knowledge about the control structure of

devices as well as about programming itself. In the

context of a SMErobot

TM

-application this cannot be

granted. Users of robot cells in SME environments

normally know a lot about the processes they have to

perform in order to achieve the desired result, but

have only minor knowledge about programming

devices (a robot is a special kind of device).

Therefore, the definition of sequences for robot cells

in SME environments should be possible without the

need of device programming. Instead, programming

should be focused on the processes the user wants to

execute. In this paper, this will be called “process-

oriented programming” and the corresponding

commands will be called “process commands” as

opposed to traditional “device commands”.

Process commands trigger whole processes like

drilling a hole or gripping a part, while device

commands trigger a state change in a single device

like setting a digital output or moving a robot from

AUTOMATIC GENERATION OF EXECUTABLE CODE FOR A ROBOT CELL USING UPNP AND XIRP

243

point A to point B. Process commands are a much

more general approach than subroutines because

they define the sequence of actions for a process and

the required functionalities. They abstract

programming interfaces and communication and are

therefore independent of specific device properties

or communication protocol properties.

The mapping of specific device commands to a

process command in order to generate executable

code will be described in detail in the following

chapters.

The introduction of process commands imposes

the following requirements on the robot cell

controller:

The robot cell controller needs information

about the functionality of the available devices

and must be able to infer the subset of available

process commands that can be executed by the

current setup of the cell.

The robot cell controller must be able to

automatically generate code to execute the

sequence of process commands defined by the

user.

To fulfil these requirements the “P’n’P-Module” is

introduced. It acts as an intermediate between user

and devices. The operating mode of the P’n’P-

Module will be described in detail in the following

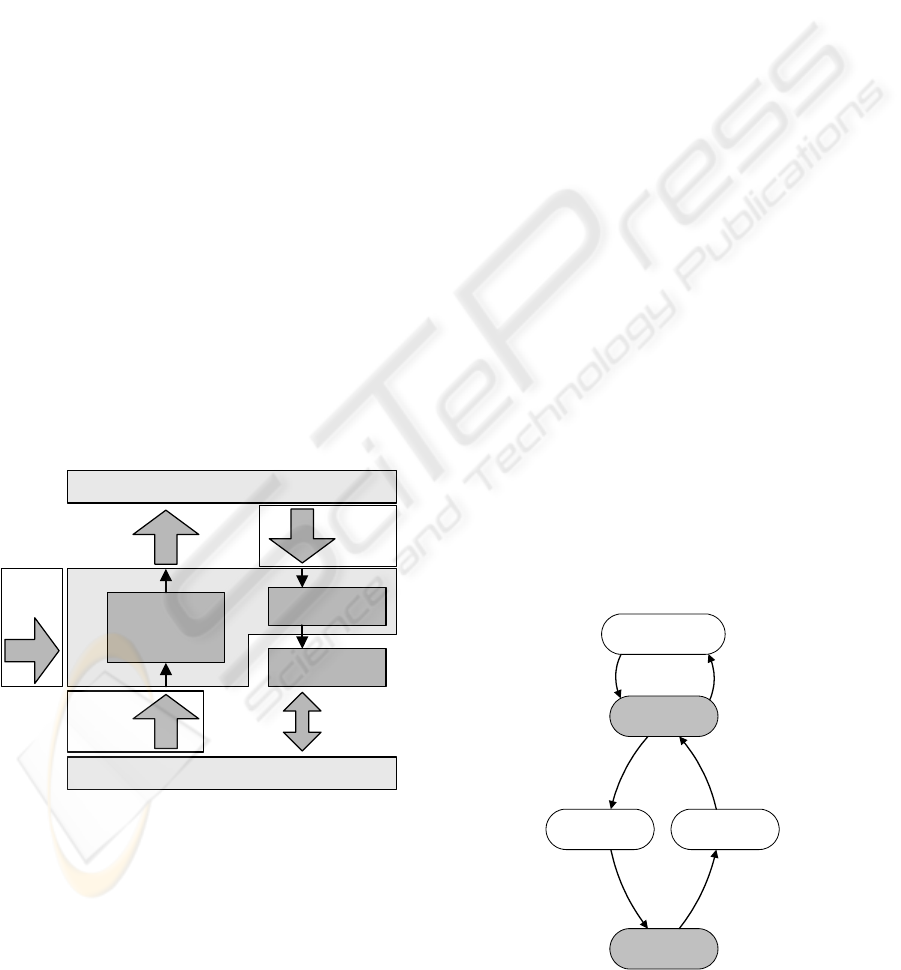

chapters. Figure 1 shows a block diagram of the

P’n’P-Module and its environment.

Generic HMI

data/

commands

device

descriptions

determine

functionality of

robot cell

executable

processes

generate

executable code

task

description

process

descriptions

Communication-Layer

P’n’P-Module

code executor

Figure 1: Block diagram of the P’n’P-Module and its

environment

5 DESCRIPTIONS

As shown in figure 1, three types of descriptions are

necessary:

Device Descriptions containing information

about the functionality and the programming

interface of devices.

Process Descriptions containing information

about the required functionality of a process

and the sequence of actions.

One user-defined task description containing

information about the sequence of processes

and according process parameters.

Information on the determination of the functionality

of the robot cell can be found in 0. Therefore, this

paper concentrates on the generation of executable

code out of descriptions of programming interfaces

of devices, the description of the sequence of actions

of processes and the user-defined task description.

5.1 Device Descriptions

The description of programming interfaces of

devices is realized in form of state charts, called

“Device State Charts”. Device State Charts can have

as many states as necessary, but depending on the

functional description of a device certain states are

mandatory. If the functional description of a device

contains a certain skill, the state chart must contain

certain mandatory state(s), e.g. if the functional

description of a gripper contains the skill “CanGrip”,

the Device State Chart of this device must contain

the states “open” and “closed”. Apart from these

mandatory states, the Device State Chart may have

other additional states that replicate special

properties of the device controller. Figure 2 shows

an exemplary Device State Chart of a gripper. The

states “configuring”, “opening” and “closing” are

additional states.

open

closed

opening closing

WaitFor:

XIRP:Request

<Open>

Send:

XIRP:Event

<gripper closed>

WaitFor:

XIRP:Request

<Close>

Send:

XIRP:Event

<gripper opened>

configuring

WaitFor:

XIRP:Request

<SetAngle>

Send:

XIRP:Event

<angle set>

Figure 2: Device State Chart of a simple gripper.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

244

The transitions of the state chart describe the

device commands that triggers the state changes. In

the case of the bin picking test bed described in

chapter 7 UPnP and XIRP will be used as

communication protocols. Therefore the transitions

of the Device State Charts describe device specific

UPnP and XIRP communication to control the

devices.

Several languages exist to describe state charts.

One of them is SCXML 0. SCXML allows the

concurrent execution of parallel state charts and their

synchronization and is therefore well suited for the

use in Device State Charts.

Device State Charts are a mandatory part of

device descriptions in order to generate the

necessary sequence of commands to reach certain

states – that means, to execute a certain task.

5.2 Process Descriptions

General Process State Charts describe the states the

involved devices have to reach, their order and

synchronizations that must be taken into account.

They are the counterpart of Device State Charts.

General Process State Charts have the purpose of

describing the sequence of actions of a certain

process. “General” means that they describe this

sequence independent of the devices actually used

and therefore independent of their specific

programming interfaces. Therefore, they must

describe which states must be reached by the devices

in which order to execute a certain action, but they

must not describe how these states can be reached as

this depends on the devices actually used. General

Process State Charts consist of separate state

machines for each involved devices. These separate

state machines are synchronized where necessary,

e.g. to assure that a gripper is closed only after the

robot has reached the gripping position. Figure 3

illustrates the General Process State Chart of a

picking process.

General Process State Charts are expressed in

SCXML, too.

5.3 Task Description

The task description is defined by the user of the

robot cell on the Generic HMI as sequence of

process commands. The Generic HMI displays all

executable processes to the user. The user defines a

sequence of processes and enters the corresponding

gripper state chartrobot state chart

open

closed

idle

move

idle

move

idle

Figure 3: General Process State Chart of a picking process.

process parameters like e.g. gripping force, picking

position or robot speed. For that purpose dialogs are

automatically generated out of the process

descriptions. It is either possible to enter the required

process parameters directly on the HMI or, if

available, with the help of input devices. Positions

could e.g. be taught with lead through programming

if the robot is equipped with a force torque sensor

and the controller supports lead through

programming.

6 GENERATION OF

EXECUTABLE CODE

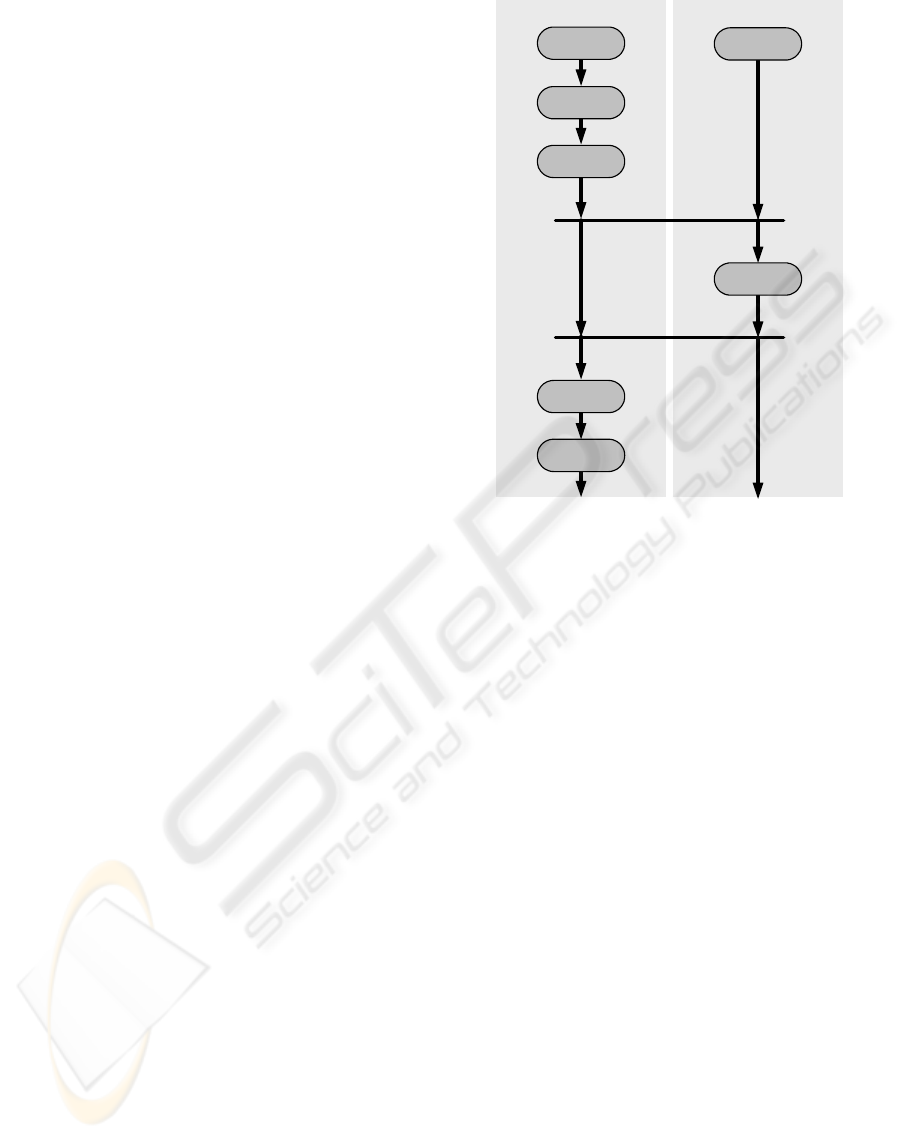

In order to run the task defined by the user code has

to be generated that can be executed by the code

generator (see figure 1). This code generation

consists of two steps. First, General Process State

Charts and Device State Charts are combined to

(device-) Specific Process State Charts. Second, the

Specific Process State Charts are concatenated

according to the user-defined task description to a

Task State Chart. In this Task State Chart, the user-

defined process parameter values are included.

Figure 4 illustrates the workflow.

AUTOMATIC GENERATION OF EXECUTABLE CODE FOR A ROBOT CELL USING UPNP AND XIRP

245

Generation

of Task State

Chart

Task State

Chart

(executable)

Specific

Process

State Charts

Task

Description

Device

State

Charts

General

Process

State Charts

Generation of

Specific

Process

State Charts

Figure 4: Workflow to generate executable code.

6.1 Generation of Specific Process

State Charts

Specific Process State Charts are generated out of

General Process State Charts by adding device

commands to the transitions.

Therefore, the states of the General Process State

Chart are mapped to states of the Device State

Charts of the used devices. The mapping is possible

because the states of the General Process State

Charts and the states of the Device State Charts are

related by an ontology. The device commands are

then added stepwise by searching a path in the

Device State Chart for each Transition in the

General Process State Chart. This path including all

states, transitions and device commands in between

is then inserted into the General Process State Chart.

Once this path-search has been done for a whole

General Process State Chart, the result is a (device-)

Specific Process State Chart. Figure 5 illustrates this

approach exemplary using the Device State Chart

shown in figure 2 and the Process State Chart in

figure 3.

Part of resulting

Specific Process

State Chart

open

closed

opening

Extract from

General Process

State Chart

open

closed

Extract from

Device State

Chart

closed

opening

open

+=

Send:

XIRP:Request

<Open>

Send:

XIRP:Event

<gripper closed>

WaitFor:

XIRP:Request

<Open>

WaitFor:

XIRP:Event

<gripper closed>

Figure 5: Generation of Specific Process State Chart out of

Device State Chart and General Process State Chart.

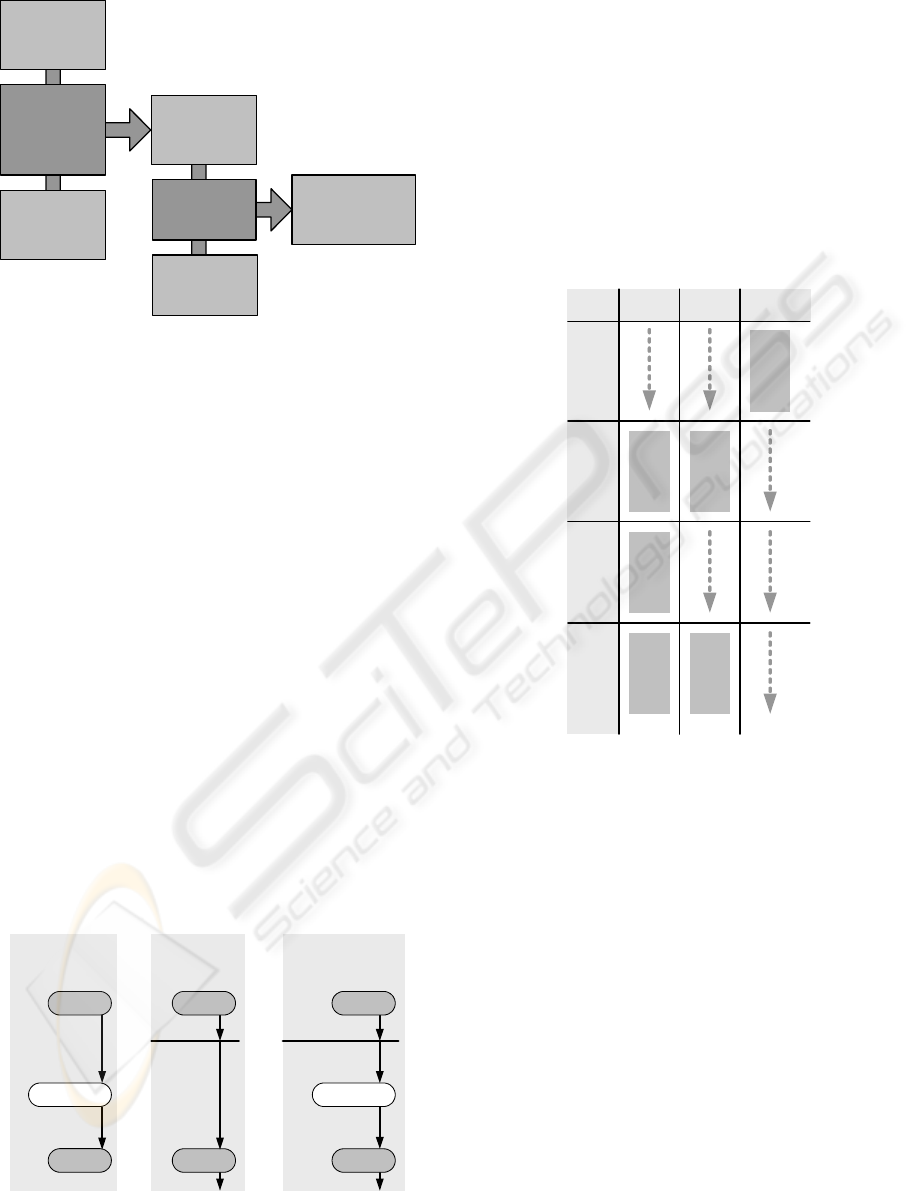

6.2 Generation of Task State Chart

To generate the Task State Chart, the Specific

Process State Charts are concatenated according to

the task description. If a process does not involve a

device, this device stays in the last state of the

previous process. Finally, the user-defined process

parameters are included. Result is a state chart

containing device commands of the used devices

that can be executed. Figure 6 shows an example of

a Task State Chart.

Place

process

Move

process

Pick

process

GetPartPos

process

State chart

of robot

State chart

of gripper

State chart

of camera

State chart

of robot

State chart

of robot

State chart

of gripper

robot gripper camera

Figure 6: Generation of Task State Chart by concatenating

processes.

While concatenating the processes, a basic

plausibility check is performed to assure that only

processes with matching final and start states are

attached. This plausibility check assures e.g. that the

gripping process shown in figure 3 cannot be used

without in between opening the gripper again in

some other process. In this way some errors of the

user defined Task Description can be detected.

6.3 Executing the Task State Chart

The execution of the Task State Chart is done by the

code executor in the cell controller (see figure 1).

For each involved device, a state machine is

initialized with the start state of the first process.

From then on these state machines check cyclically

if the condition of a transition is fulfilled. If yes, a

state change is triggered and the state machines

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

246

switch to the next state. State changes of a device

can either be triggered by an incoming message

from that device, by a state change of another device

or by a transition without a transition condition.

7 TEST BED BIN PICKING

The presented concept will be realized as test bed in

a bin picking robot cell. This cell consists of the

following devices:

Robot

Gripper

3D-Sensor

PC that runs the bin picking algorithms

All these devices are connected to a cell controller.

The cell controller runs the P’n’P-Module with the

described functionality. Figure 7 illustrates the

underlying control architecture.

Figure 7: Control Architecture of the bin picking cell.

All devices have their own controller that offers a

programming interface to access their functionality.

This programming interface is accessible either via

XIRP or the UPnP communication protocol.

Because both protocols support automatic discovery

and initialization of communication, the devices are

integrated into the cell controller without manual

configuration effort. Then, description files

containing the Device State Chart are loaded into the

P’n’P-Cell-Controller. The P’n’P-Cell-Controller

uses these descriptions to evaluate the cell

functionality and – after the user has defined a task –

generate and execute code as described in this paper.

8 CONCLUSIONS AND

OUTLOOK

The presented concept allows programming of a

robot cell without knowing details about the

underlying programming interfaces and

communication protocols and therefore permits

users with little knowledge of (robot) programming

to use robots. The user has to combine and

parameterize the processes but does not need to use

device commands. To facilitate the parameterization,

intuitive input devices can be integrated into the cell

controller.

The abstraction layers introduced to achieve this

goal furthermore allow easy exchange of devices

with different programming interfaces and

communication protocols as long as they offer the

same functionality.

The concept should help users in a SME

environment to define typical machine tending or

part handling tasks that do not require closed control

loops extending over several devices as the present

concept cannot cope with real time requirements.

One possible solution would be to include

mechanisms into the communication layer to support

real-time provided that real-time communication

protocols are used. Another, more advanced

approach would be to establish direct real-time

connections between devices that need to exchange

time-critical data. This approach would impose new

requirements on the devices and the underlying

network.

Another possibility to further advance the

presented concept is to upgrade the plausibility

check described in chapter 6.2. The available

information about the meaning of processes and

states could be used to not only detect task definition

errors, but also make suggestions to the user on how

to correct them.

A third advancement of the presented concept

could be an upgrade of the code executor. At the

moment it executes the generated Task State Chart

sending single commands to devices to trigger

actions. Because state charts are a very general way

of representing programs, the Device State Chart

could be used to generate complete programs for

single devices using transformation rules. This

would allow generating e.g. a program for a robot,

downloading it and running it on the robot controller

thus significantly reducing the communication

effort.

The bin picking test bed will give the opportunity

to prove the presented concept, to draw conclusions

about its strengths and weaknesses and by this

means decide about the next steps.

AUTOMATIC GENERATION OF EXECUTABLE CODE FOR A ROBOT CELL USING UPNP AND XIRP

247

ACKNOWLEDGEMENTS

This work has been funded by the European

Commission’s Sixth Framework Program under

grant no. 011838 as part of the Integrated Project

SMErobot

TM

.

REFERENCES

World Robotics 2007, IFR Statistical Department.

http://www.smerobot.org

Papas homepage: http://www.projekt-papas.de

UPnP Device Architecture; Version 1.0; 8.6.2000.

Downloadable from the UPnP-Forum: http://

www.upnp.org

VDMA Einheitsblatt 66430-1: XML-basiertes

Kommunikationsprotokoll für Industrieroboter und

prozessorgestützte Peripheriegeräte (XIRP) - Teil 1:

Allgemeine Vereinbarungen.

Riedl, M.; Simon, R.; Thron, M.: EDDL – Electronic

Device Description Language. München, Oldenburg

Industrieverlag, 2002.

OWL Web Ontology Language Overview, 10.4.2004.

Downloadable from W3C: http://www.w3.org/

TR/owl-features/

Berners-Lee, T.; Hendler, J.; Lassili, O.: The Semantic

Web, Scientific American, 17.1.2001.

SmartKom homepage: http://www.smartkom.org/

Torge, S., Hying, C.: Realizing Complex User Wishes

With a Function Planning Module. In: SmartKom:

Foundations of Multimodal Dialogue Systems. Berlin.

Heidelberg. Springer Verlag, 2006.

Naumann, M.; Wegener, K.; Schraft, R. D.: Control

Architecture for Robot Cells to Enable

Plug’n’Produce. In: Proceedings of ICRA 2007.

State Chart XML (SCXML): State Machine Notation for

Control Abstraction 1.0, W3C Working Draft,

24.1.2006. Downloadable from W3C: http://

www.w3.org/TR/scxml/

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

248