REAL-TIME SYSTEMS SAFETY CONTROL CONSIDERING

HUMAN MACHINE INTERFACE

José Machado and Eurico Seabra

Mechanical Engineering Department, University of Minho, Campus of Azurém, 4800-058 Guimarães, Portugal

Keywords: Real-Time Systems, Safety Control, Human Machine Interface, Dependable Systems.

Abstract: In this paper it is presented the analysis of real-time industrial controllers when it is taken into account

human behavior in the use of fully automated industrial systems. It is intended to develop safe controllers

for these systems and make them robust against inappropriate utilizations by human operators. For the

attainment of our goals it is used a case study, where, based on a IEC 60848 specification, is deduced the

controller program. Further, it is elaborated the controller model, the Plant model and the Human Machine

Interface Model of the automated system. The obtained results are generalized for other similar systems

with the presented case study.

1 INTRODUCTION

Since the early eighties, the influence of the human

role and of the degree of the human implication in

the human-machine global performance (production,

safety,…) has been studied. Tom Sheridan defined

(Sheridan, 1984) the well-known degrees of

automation and their consequences. These defined

three degrees of automation and their consequences

are:

• In fully manual controlled systems, safety

totally depends on the human controller

reliability;

• An intermediate, state allows a task sharing

between the human operators and the

automated controlled systems; and,

• Fully automated systems reject the human

operator out of the control and that can

produce a lack of vigilance, a loss of skill and

can prevent him to assume all the

responsibility on the system. Therefore, the

system safety is almost totally linked to the

technical reliability.

In the study presented on this paper we will

focus on the third point related with the fully

automated systems. In the industrial controllers

analysis, it will be used simulation and formal

verification techniques to increase, together, the

safety of industrial controllers.

Among the several available techniques for the

industrial controllers analysis, Simulation (Baresi et

al. 2000, Baresi et al. 2002) and Formal Verification

(Moon 1994, Roussel and Denis 2002), can be

distinguished due to their utility. In the research

works on industrial controllers’ analysis, these two

techniques are rarely used simultaneously. In our

work, here presented, these two techniques are used

together and it is shown that exist some limitations

in the use of Simulation when compared with

Formal Verification. These limitations are

demonstrated in a context of studying the Human

Machine Interface (HMI) of real time industrial

systems. Some results that seam to be correct, using

Simulation, may not be correct when using Formal

Verification. This paper is focused in giving an

overview in the limitations of Simulation when

compared with Formal Verification in a context of

the HMI.

To accomplish our goals, in this work, the paper

is organized as follows. In Section 1, it is presented

the challenge proposed to achieve in this work.

Section 2 presents a general presentation of the case

study involving a system with two tanks filled and

emptied by the control of some on-off valves.

Further, it is presented the methodology to obtain the

controller program deduced from an IEC 60848 SFC

specification of the system’s desired behaviour.

Sections 3 and 4 are, respectively, devoted to the

modelling the plant and HMI. In section 5 are

presented the system behaviour analysis results and

269

Machado J. and Seabra E. (2008).

REAL-TIME SYSTEMS SAFETY CONTROL CONSIDERING HUMAN MACHINE INTERFACE.

In Proceedings of the Fifth International Conference on Informatics in Control, Automation and Robotics - SPSMC, pages 269-274

DOI: 10.5220/0001498602690274

Copyright

c

SciTePress

finally, in section 6 are presented some conclusions

and future work.

2 CASE STUDY

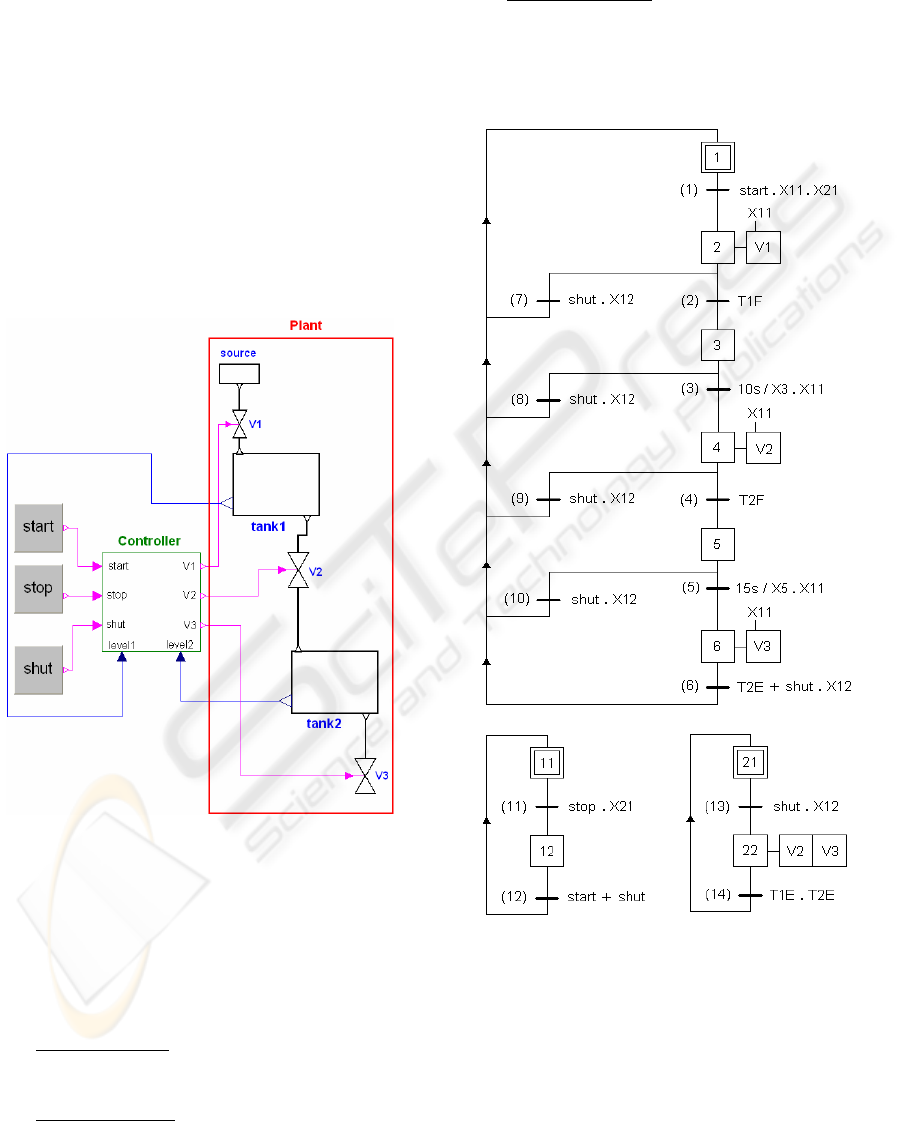

The case study, composed by two tanks and filling

and emptying on-off valves, is presented in figure 1.

Tank1 is filled by opening valve V1. When the level

of the tank1 becomes high, the valve V1 is closed.

After a waiting time of ten time units, valve V2 is

opened and the fluid flows from tank1 into tank2.

When tank1 is empty, valve2 is closed and, after

a waiting time of fifteen time units, valve3 is opened

and the fluid flows out of tank2. Finally when tank3

is empty, valve V3 is closed. In this work we

consider that one time unit is equal to one second.

Figure 1: Evaporator system: Closed-loop system

composed by controller and plant and start, stop and shut

buttons to interact with human behaviour.

Three buttons can influence the above normal

operation: start, stop and shut. In order to guarantee

the desired functioning of the system it is necessary

to simulate the following desired behaviors, traduced

by three system behavior properties:

• Property 1 (P1)

: In the beginning, when the

start button is pressed the system must start,

immediately, filling the tank 1.

• Property 2 (P2)

: Button “shut” is used to

shutdown the process. When the shut button is

pressed the system controller must reach the

initial state or the system must begin emptying

immediately the two tanks, in simultaneous.

• Property 3 (P3):

When the stop button is

pressed the system must stand in its actual

situation.

2.1 IEC 60848 Controller Specification

Figure 2: SFC specification of the controller.

As we use the Simulation and Formal Verification,

using different tools and intending to conciliate the

obtained results, we adopted a controller

specification that is the same for the basis of the

controller program in the two analysis techniques.

Thus, the controller specification was developed

in IEC 60848 SFC because it can be used as the

basis for the development of the Programmable

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

270

Logic Controller program (PLC), to be verified with

UPPAAL based on timed automata (Alur and Dill,

1990), and also it is the basis for the controller

program to be used by StateGraphs Modelica library

(Otter et al. 2005).

Table 1: Input/Output variables of the controller.

Inputs Outputs

Start – system start

stop – system stop

shut – system

shutdown

T1E – tank1 empty

T1F – tank1 full

T2E – tank1 empty

T2F – tank1 full

V1 – open valve1

V2 – open valve2

V3 – open valve3

The input and output variables of the controller

model are summarized on Table 1; minimum and

maximum level sensors of the tanks and the human-

machine interface buttons (start, stop and shut) are

controller program inputs and the on-off valves (V1,

V2 and V3) are controller program outputs.

In order to guarantee the desired behaviour for

the described system, a IEC 60848 SFC

specification is presented in Figure 2. As IEC 60848

SFC is a specification language (and not a

programming one), it is necessary to translate the

SFC specification, first to a StateGraph program,

presented in (Seabra and Machado, 2007) and,

second, to translate it into a program written in a

PLC programming language (in this case it will be

used the ladder language). This translation is done

using a methodology, having as base the

specification algebraic representation and

considering also the controller program behavior

presented at (Machado, 2006).

3 MODEL OF THE PLANT

In the plant modeling, first, the plant is modeled

with the Modelica programming language (Elmqvist

and Mattson, 1997) and simulated with the Dymola

software and, second, it is modeled by timed

automata to be used as input of the UPPAAL

software (David et al. 2003). The delays obtained, in

the simulation with the Dymola software, are used to

create the timed automata that are used on Formal

Verification with the UPPAAL tool.

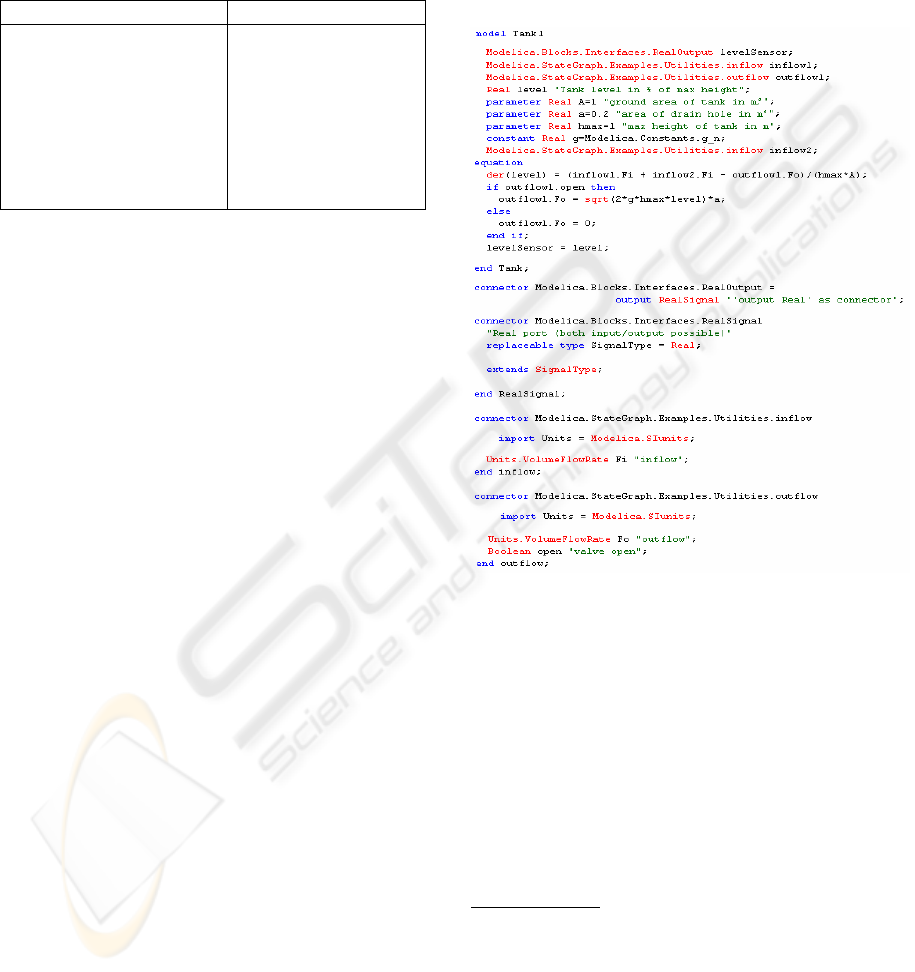

3.1 Plant Modelling for Simulation

Purposes

All the system was modeled. The tank1 model is

presented on this sub-chapter. Lets consider the case

of the tank 1 we have, for the Modelica

programming language the model presented in

Figure 3.

Figure 3: Modelica code for tank1 model.

The other physical parts of the system were

modeled (Seabra and Machado, 2007) but not

presented in this paper because is not part of the

goals of this paper.

3.2 Plant Modelling for Formal

Verification Purposes

For modeling the plant with formal verification

purposes there are considered the following modules

for the plant modeling: Tank1 and Tank2.

Model of tank1:

The obtained delays on simulation were used on

formal verification with UPPAAL. The

corresponding model of the tank developed in

UPPAAL for formal verification purposes is

presented in Figure 4.

REAL-TIME SYSTEMS SAFETY CONTROL CONSIDERING HUMAN MACHINE INTERFACE

271

Figure 4: UPPAAL model of tank1.

We consider four states: empty models that tank1

is empty; filling models that the liquid is entering in

tank1; full models that tank1 is full; state overflow is

also considered, this is a possible state for the tank,

but describes an undesired behaviour. In this model,

it is also considered that the tank1 is emptied in a

very short time, when compared with the filling

time. We have considered this time null. It is for that

reason that the model goes from the full state

directly to the empty state, without an intermediate

state. The Boolean variables T1E and T1F are

associated with tank1.empty and tank1.full,

respectively. These variables represent the level

sensors’ signals sent by the sensors from the plant to

the controller. The maximum time for filling tank1 is

six time units.

Model of tank2:

The model of tank2 is presented in figure 5 and

the reasoning followed to obtain this model was the

same as presented before for obtaining the tank1

model. As empting tank1 is considered to take a

short (null) time, the filling of the tank2 is done in

the same conditions, since the liquid is transferred

from tank1 to tank2.

Figure 5: UPPAAL model of tank2.

Four states are considered: empty, full, emptying

and overflow which is a possible state for the tank,

but describes an undesired behavior. The variables

T2E and T2F have the same behavior on the tank2

model as the T1E and T1F described above on the

tank1 model. Empty tank2 takes, at maximum,

twenty-six time units.

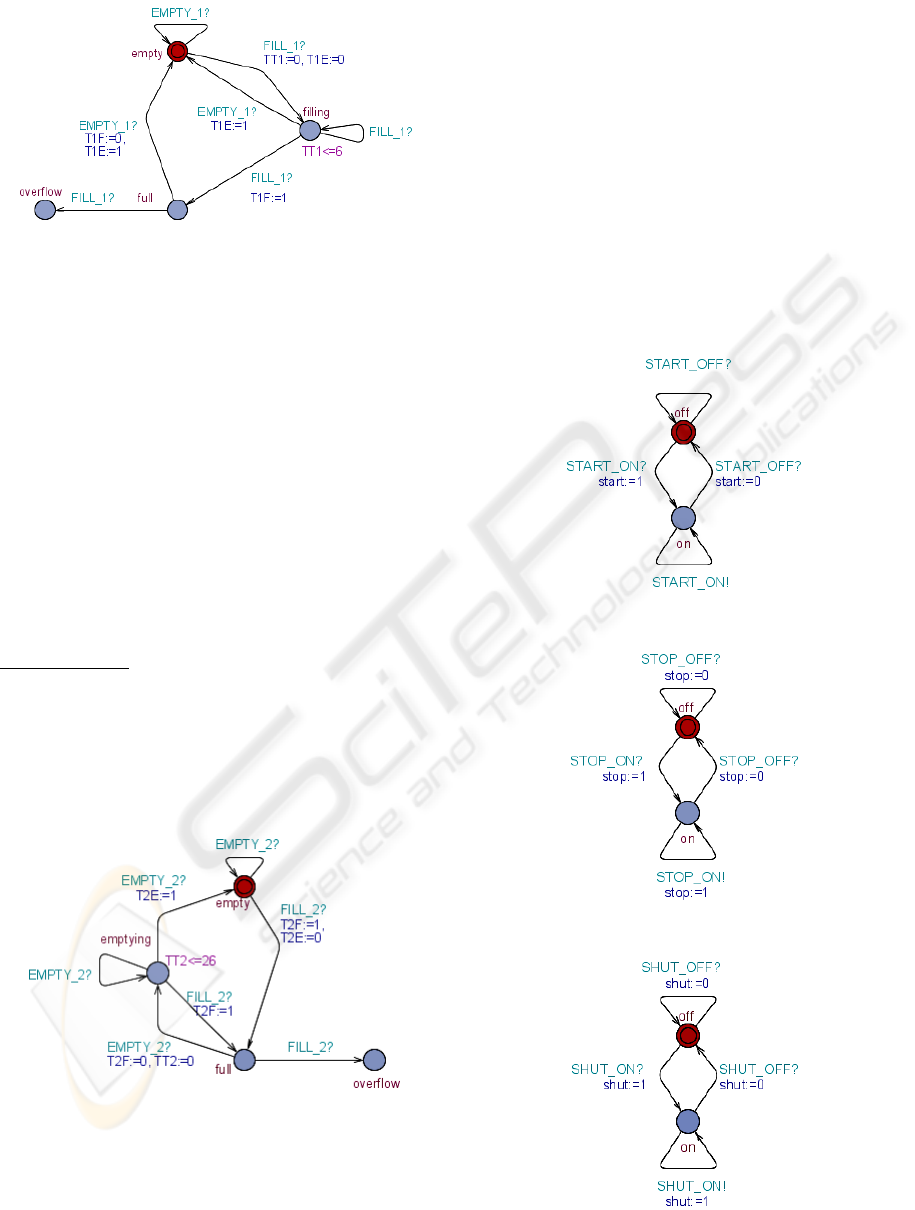

4 MODELLING THE HUMAN

MACHINE INTERFACE

In this chapter are modelled the three buttons: start,

stop and shut. The models for these elements of the

(HMI) are presented in figures 6, 7 and 8.

For each HMI button the considered behaviours

are that each one can be in the state off or on. They

can change of state at any time, according the human

behaviour.

Figure 6: Model of the start button.

Figure 7: Model of the stop button.

Figure 8: Model of the shut button.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

272

In the evolutions of the controller model it is

considered that it will be implemented into a PLC

with a scan cycle composed by three distinct phases:

Controller Inputs Reading (CIR), Controller

Computing (CCO) and Controller Outputs Updating

(COU).

The evolution of the controller model takes into

account the state changing of the HMI buttons at

each moment that it is in the CIR state. Any

changing of the HMI buttons state during the

evolution of the controller behaviour is not detected

by the controller model (as it is in the real behaviour

of the controller). Taking into account the

characteristics of the controller behaviour, the

characteristics of the plant behaviour and the

characteristics of the HMI behaviour, the properties

must be proved in the end of the evolution of the

controller model, after the Controller Outputs

Updating states.

5 SYSTEM BEHAVIOUR

ANALYSIS RESULTS

In the analysis of the system behaviour there were

used the two indicated techniques: the Simulation

and the Formal Verification.

It is pointed out that the system behaviors that

we intend to analyze, in this paper, are directly

related with possible human behaviors (correct or

incorrect) in the use of the automated system. There

are allowed, in the HMI models all possible human

behaviors with the three considered buttons.

The work presented here is a small part of a

larger developed work in the proof of properties in

real-time systems. The developed work in the

context of the controller behavior properties and the

global system behavior properties were presented,

respectively, in (Machado et al. 2007-a) and

(Machado et al. 2007-b).

The properties to prove, related with HMI, are:

• Property 1 (P1)

: In the beginning, when the

start button is pressed the system must start,

immediately, filling the tank 1.

• Property 2 (P2)

: Button “shut” is used to

shutdown the process. When the shut button is

pressed the system controller must reach the

initial state or the system must begin emptying

immediately the two tanks, in simultaneous.

• Property 3 (P3):

When the stop button is

pressed the system must stand in its actual

situation.

5.1 Simulation Results

Considering Simulation all properties are true.

As in this paper it is intended to show the

advantages of Formal Verification related with

Simulation, we will focus on Formal Verification

results discussion.

5.2 Formal Verification Results

Before presenting the formal verification results the

properties must be formalized using the UPPAAL

syntax, and, for that, we need a small part of TCTL

formalism (Alur et al. 1993 ). In the formulas below

which are all (possibly timed) invariants, A is the

universal quantifier on paths: for any path…, and [ ]

means always… The combination A [ ] means for

all states in the future…

There are considered, for the properties

formalization, the input and output variables of the

controller, the step variables of the controller SFC

program and the state of the controller model, where

are verified the properties according some rules

defined in (Machado, 2006). The considered state of

the controller model for the properties verification is

the Controller Outputs Updating state, COU.

For the properties formalization we have:

• P1: A[] !(COU && X1 && start)

• P2: A[] !((COU && !X22 && shut) || (COU

&& !X1 && shut))

• P3: A[] !(COU && X11 && stop)

After the formal verification tasks, the obtained

results are that all the properties are false.

5.3 Discussion of the Obtained Results

All the results, that are false in Formal Verification

analysis, are related with the controller behaviour

(Cyclic scan monitor of the PLC).

Indeed, in Simulation, this detail is not taken into

account but, in Formal Verification (because it is an

exhaustive technique!), these undesired behaviours

are detected and we can show that, with this

technique, the obtained results are exhaustive and

precise.

Detailing the results obtained for the Property 1

we can interpret the obtained trace with the

following sequence of human operator actions (see

figure 2):

In the initial situation, of the system, if the

human operator does not press the start button (as

expected!) but presses the stop button, the step 12 is

activated;

REAL-TIME SYSTEMS SAFETY CONTROL CONSIDERING HUMAN MACHINE INTERFACE

273

If, after that, the human operator presses the shut

button the step 22 is activated too;

Further, if the human operator presses the start

button the system does not start its normal behaviour

because the variable step X21 is not activated and

the step 1 remains active at least during a PLC

internal cycle.

For all the other properties the obtained results

(false) may be explained in the same way, when

analyzing the respective traces.

To solve this problem, there are many

possibilities. The simpler one seems to consider

actuation priorities for the three buttons considered.

These priorities must be included on the controller

program specification and, consecutively, in the

controller program implementation.

6 CONCLUSIONS AND FUTURE

WORK

With our study it has been possible to show that

some problems can occur if the development of safe

industrial controllers, for fully automated systems,

are not developed taking into account some possible

incorrect behaviours of human operators.

These possible undesired system behaviours can

be detected, only, if it is used the Formal

Verification technique; the Simulation technique is

not sufficient.

The fully automated systems safety is almost

totally linked to the technical reliability of the

system and it must be guaranteed that some incorrect

possible behaviours of the human operators do not

compromise these systems’ safety and

dependability.

ACKNOWLEDGEMENTS

This research project is carried out in the context of

the SCAPS Project supported by FCT, the

Portuguese Foundation for Science and Technology,

and FEDER, the European regional development

fund, under contract POCI/EME/61425/2004 that

deals with safety control of automated production

systems.

REFERENCES

Alur R., Dill D. L., 1990. Automata for Modeling Real-

Time Systems. Proceedings of the 17th Int. Coll.

Automata, Languages, and Programming (ICALP'90),

Warwick University, England, July 1990, Vol. 443,

Lecture Notes in Computer Science, Springer.

Alur R., Courcoubetis C., Dill D. L, 1993. Model-

Checking in Dense Real-Time. Information and

Computation, vol. 104, n_ 1, p. 2-34.

Baresi L., Mauri M., Monti A., Pezzè M., 2000.

PLCTOOLS: Design, Formal Validation, and Code

Generation for Programmable Controllers. Special

Session at IEEE Conference on Systems, Man, and

Cybernetics. Nashville USA.

Baresi L., Mauri M., Pezzè M., 2002. PLCTools: Graph

Transformation Meets PLC Design. Electronic Notes

in Theoretical Computer Science 72 No. 2.

David A., Behrmann G., Larsen K. G., Yi W., 2003. A

Tool Architecture for the Next Generation of

UPPAAL. Technical Report n. 2003-011, Department

of Information Technology, Uppsala University, Feb.

20 pages.

Elmqvist E., Mattson S., 1997. An Introduction to the

Physical Modelling Language Modelica. Proceedings

of the 9th European Simulation Symposium, ESS'97.

Passau, Germany.

Machado J., 2006. Influence de la Prise en Compte d’un

Modèle de Processus en Vérification Formelle des

Systèmes à Evénements Discrets. PhD Thesis in

cooperation between the University of Minho and

École Normale Supérieure de Cachan; School of

Engineering, University of Minho, June.

Machado J., Seabra E., Campos J., Soares F., Leão C.,

Silva J., 2007-a. Simulation and Forml Verification of

Industrial Systems Controllers. Proceedings of 19

th

Edition of the International Congress of Mechanical

Engineering (COBEM’2007), Brazilia, Brazil, 5-9

th

November.

Machado J., Seabra E., Soares F., Campos J., 2007-b. A

new Plant Modelling Approach for Formal

Verification Purposes. Proceedings of the 11

th

IFAC/IFORS/IMACS/ IFIP Symposium on Large Scale

Systems: Theory and Applications. Gdansk, Poland.

Moon I. 1994. Modeling programmable logic controllers

for logic verification. IEEE Control Systems, 14, 2,

pp. 53-59

Otter M., Årzén K., Dressler I., 2005 StateGraph - A

Modelica Library for Hierarchical State Machines.

Modelica 2005 Proceedings.

Roussel M., Denis B., 2002. Safety properties verification

of ladder diagram programs. Journal Européen des

Systèmes Automatisés, vol. 36, pp. 905-917

Seabra E., Machado J., 2007. Simulation of Real Time

Systems Behavior Considering Human-Machine

Interface. In Proceedings of the 6

th

EUROSIM

Congress on Modelling and Simulation, Federation of

European Simulation Societies, September 9-13,

Ljubljana, Slovenia.

Sheridan, T. B., 1984. Supervisory Control of Remote

Manipulators Vehicules and Dynamic Processes:

Experiments in Command and Display Aiding, In

Advances in Man-Machine Researches, Vol.1.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

274