COOPERATIVE LOCALIZATION

Self-configuring Procedure of a Multi-robot Localization System with Passive

RFID Technology

Mikko Elomaa, Aarne Halme

Automation Technology Laboratory, Helsinki University of Technology, Espoo, Finland

François Vacherand

Laboratoire d’Electronique et de Technologie de l’Information, CEA, Grenoble, France

Keywords: RFID, Multi-robot, cooperative, localization.

Abstract: This preliminary simulation study introduces methods to configure a low cost localization system based on

existing passive RFID technology. A group of small robots work together in order to configure the system

autonomously. Probabilistic estimation methods are used for data fusion. The robots should be able to build

and expand the localization system without human aid. When properly configured the system is able to offer

positioning information with bounded error. The use of passive RFID tags as beacons makes the cost of

expanding the robots' working area negligible.

1 INTRODUCTION

For a successful task execution a mobile robot has to

know its position and heading. Different kinds of

localization methods have already been developed.

There are systems where all the needed equipment

for the localization (wheel encoders, gyroscopes,

laser scanner, etc.) is on board the robot. One

problem with this kind of localization system is that

over time the robot's estimate of its absolute location

can get too erroneous for effectively continuing the

mission. Also the cost of the high precision

equipment can be considerable.

Another approach is to use external references

such as beacons or landmarks for localization. The

mobile robot can use absolute position data provided

by measurements and calculations involving these

external objects in order to obtain a better position

estimate. The main problem with this kind of system

is that the installation of the required external

objects can be costly and time consuming.

The system introduced in this paper uses passive

RFID tags as beacons. A passive RFID tag contains

an antenna and an IC with small (0-1kbit) memory

capacity. It operates on the power obtained from the

reader antenna. A typical operating range for a

900MHz system is up to 2 meters. The cost of one

tag is only a few cents and it does not need external

connections or a power supply. Also the sticker-like

tags are light to carry and a robot can place them on

suitable spots when moving to new working areas.

A multi robot approach is used for the system

configuration in order to replace the need of highly

accurate sensors for robot's localization in the initial

phase. Using a group of robots instead of one robot

also gives better fault tolerance as a single fault will

not endanger the whole mission.

2 RELATED WORK

Several studies have already been made on passive

RFID localization in robotics using a mobile RFID

reader (Hightower et al. 2000; Hähnel et al. 2004;

Bohn 2006; Kulyukin et al. 2004 and Kleiner et al.

2006). All of these are very different from each

other. Kulyukin et al. use a RFID system for

recognition of specific places inside a building. The

system is intended to help visually impaired people

recognise specific office doors, elevators, etc.

Kleiner et al. have been successfully using RFID

tags for sharing mission related information in a

99

Elomaa M., Halme A. and Vacherand F. (2008).

COOPERATIVE LOCALIZATION - Self-configuring Procedure of a Multi-robot Localization System with Passive RFID Technology.

In Proceedings of the Fifth International Conference on Informatics in Control, Automation and Robotics - RA, pages 99-102

DOI: 10.5220/0001493800990102

Copyright

c

SciTePress

rescue scenario involving both robots and humans.

Bohn introduces a super-distributed RFID tag

infrastructure, where mobile objects may leave

virtual traces in the physical space they traverse by

writing an ID to the tags in the floor (up to 120

tags/m

2

) while passing directly above them.

Hightower et al. have designed a system to help

people to localize objects equipped with passive

RFID tags in their vicinity.

Hähnel et al. study the problem of localizing

RFID tags with a mobile platform equipped with a

laser scanner and a pair of fixed RFID antennas. A

probabilistic sensor model of each antenna is used to

estimate location of a detected tag. When a tag is

detected for the first time a set of 1000 randomly

chosen positions around the robot are chosen for

initial estimates of the location of the tag. With each

measurement the probability of these locations is

calculated according to the sensor model. This is a

single robot approach where the robot builds a

database of tag positions. When localizing a robot

with the RFID tags and odometry the position error

was about 1 m.

The system proposed in this paper is based on

similar technology as the aforementioned system by

Hähnel et al. However, there are three major

distinctions. Our approach uses several simple

robots instead of one sophisticated robot. Instead of

one database, the localization data is distributed to

the tags. Also the relative displacement between the

robot and a tag is based on measured bearing angles

and not on a simple sensor model.

3 OPERATING PRINCIPLE

Our key interest is in developing a self configuring

localization system using a group of simple,

inexpensive robots. The idea is that even if the

robots have only wheel encoders and an RFID

reader for localization purposes they should be able

to localize themselves within bounded error. An

RFID reader is placed on each robot and stationary

tags are placed around the working area of the robot

group. The tags can be distributed by humans or by

robots if they are equipped with an appropriate

system (Kleiner et al. 2006)

The cooperative localization is based on a simple

Kalman filter. When the robots are configuring the

system and localizing the tags the main source of

error is the accumulated odometry error which, on a

group of robots, is assumed to follow roughly a

Gaussian distribution. Thus when the location

estimates of several independent robots on a

common object are combined, the location estimate

of the object converges towards the correct position.

3.1 System Operation

In the beginning the passive RFID tags contain no

data. The robots start at some chosen reference

location. A robot uses wheel encoders in order to

keep track of its current position. When a robot

detects an RFID tag it calculates an estimate for the

location of the tag. The estimate of the tag's location

has an uncertainty, which is calculated each time the

tag's location is estimated. The necessary algorithms

are explained in chapter 3.2.

The location estimate and the uncertainty are

stored in the memory of the tag. The next robot that

detects the tag reads the information found on the

tag and calculates a new estimate for the location of

the tag by combining the information stored in the

tag with the new measurements.

As soon as there is a position estimate stored in

the tag's memory the robots can use the tag as a

beacon in order to correct their own position. When

exploring new areas the robots have to return often

to areas with well localized beacons in order to

maintain reasonable estimate of their own position.

3.2 RFID Localization

The RFID localization is based on the measured

bearing angle to a beacon represented by a passive

RFID tag. The antenna of the RFID reader is turned

one full circle while trying to contact tags near the

robot. For each detected tag a bearing angle is

calculated based on the sector where the tag

responded to the calls of the RFID reader.

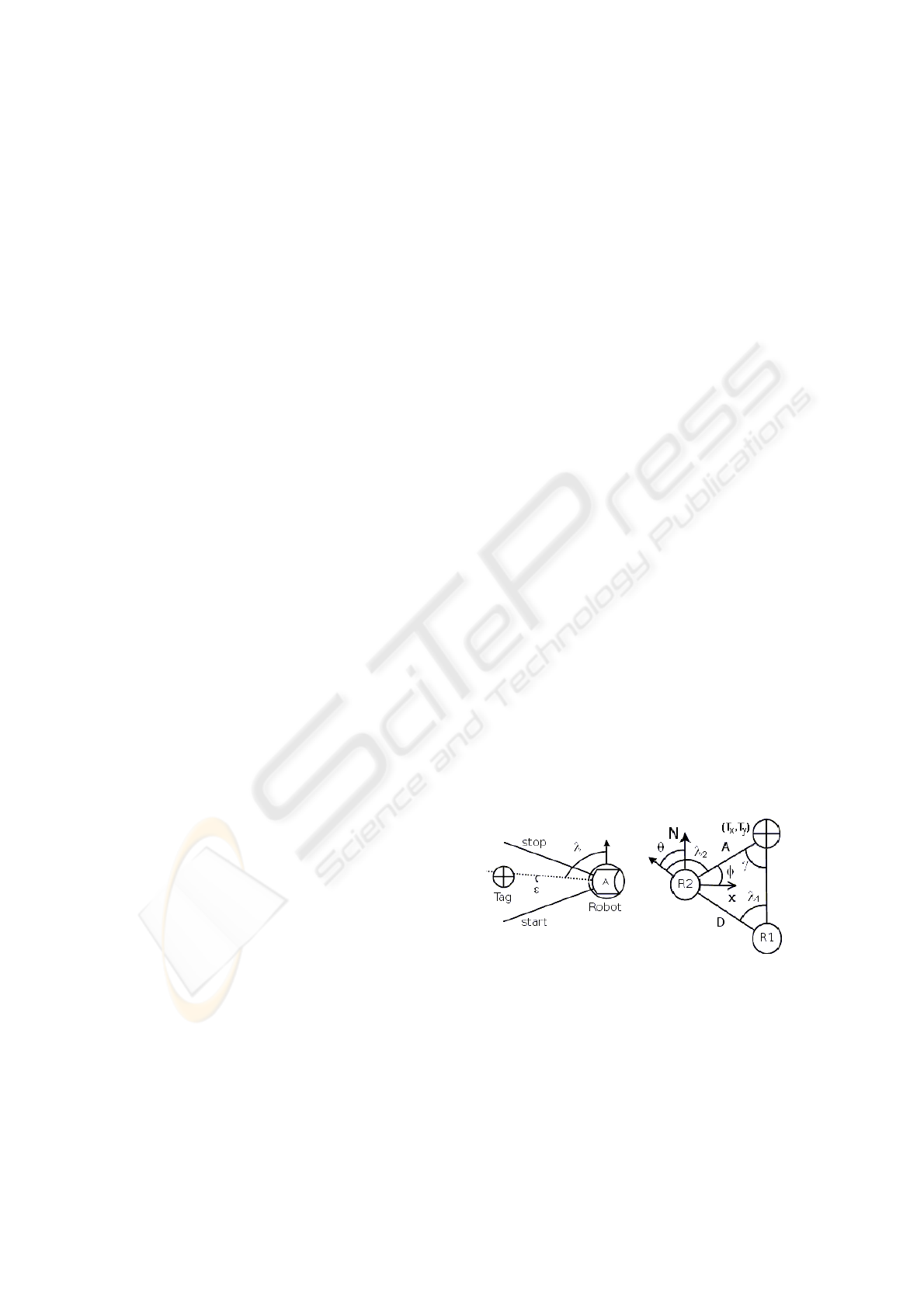

Figure 1a: Bearing angle estimation for a single RFID tag.

1b: Tag localization method.

The Figure 1a shows how the bearing angle of the

tag is estimated. The start and stop angles define a

sector where the tag responded to the readers calls.

The bearing angle estimate λ is obtained by solving

for the middle of the sector and subtracting the

a)

b

)

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

100

systematic error ε. The systematic error depends on

the geometry of the antenna and the immediate

surroundings of the antenna's mounting place. It

must be defined separately on each robot unless the

robots and the antennas are exactly alike.

3.2.1 Tag Localization

The robot uses bearing angle measurements and

odometry data in order to estimate the tag location

(E

x

,E

y

). In Figure 1b places R1 and R2 represent two

places where the robot has measured a relative

bearing angle to the tag. The distance A to the tag is

solved from the displacement D between the

measurement places and the gamma angle. The

absolute bearing angle φ is calculated as a function

of the measured relative bearing angle λ

2

and the

robot's estimated heading angle θ. A variance is

calculated for each tag location estimate. The x- and

y-coordinates have different variances which depend

on the angle φ. The C and G are parameter constants

||

12

λλ=γ −

(1)

(

)

γ

λD

=A

sin

sin

1

⋅

(2)

2

2

λ+θ

π

=φ −

(3)

()

()

φa+r=E

φa+r=E

yy

xx

sin

cos

⋅

⋅

(4)

2

21

2

21

2

sin

2

cos

γ

λλ

+φG

+C=var

γ

λλ

+φG

+C=var

y

x

⏐

⏐

⏐

⏐

⏐

⏐

⎟

⎠

⎞

⎜

⎝

⎛

−

⋅

⏐

⏐

⏐

⏐

⏐

⏐

⎟

⎠

⎞

⎜

⎝

⎛

−

⋅

(5)

With each new angle measurement the robot

calculates location estimates for the tag using all the

previous angle measurement. Thus after two

measurements the robot has one estimate for the tag

location and n measurements give 1+2+3+...+(n-1)

estimates.

Each estimate is fused with the previous estimate

of the tag location using a simple Kalman filter. It is

a recursive estimator, so all the prior information is

contained in the previous estimate (Maybeck, 1979).

The calculated variance P

k

represents the uncertainty

in the location of the tag. The equations for the

Kalman filter are shown below.

()

(

)

()

var+kP

kP

=kK

1

1

−

−

(6)

(

)

(

)

(

)()

[]

11 −−

⋅

−

kxEkK+kx=kx

(7)

(

)

(

)

(

)( )

11 −⋅

−

−

kPkKkP=kP

(8)

Odometry error and angle measurement error

may both cause significant deviation from the

correct position. Thus several estimates from

different robots are needed in order to properly

localize the tag.

4 RESULTS

Simulation models for the multi-robot localization

system were built in order to get an idea of the

effects of different measurement errors. The

simulations were run on Matlab. The system

presented here simulates a scenario where a single

tag is localized by a group of robots passing the tag

one by one. Each robot has random error on its own

position and heading angle estimate. Each bearing

angle measurement also contains a random error.

After each bearing angle measurement the robot

calculates new estimate of the location of the tag.

The result is then written on the tag's memory. A

robot is able to detect the tag inside a circular area

(r=50cm) in front of the tag. If the tag already

contains an estimate of its position, the robot tries

also to correct it's own position.

4.1 Effects of Inaccuracies

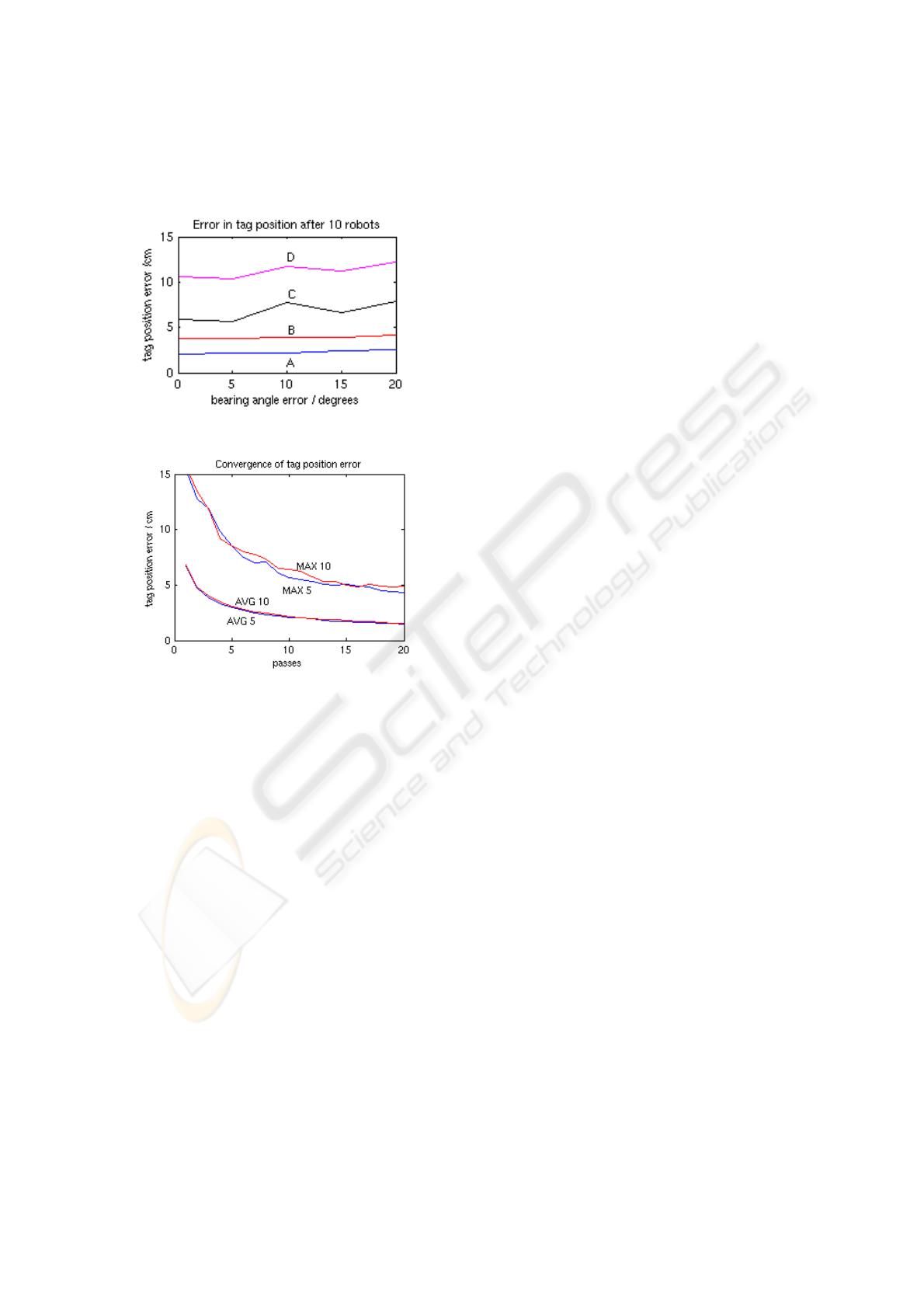

Several simulations were run with different

parameters in order to discover the effects of

inaccuracies in different estimates. First simulation

contained 500 independent groups of ten robots

passing the tag and localizing it cooperatively. The

Figure 2 shows the average and maximum error in

the estimated location of the tag as a function of the

error in the bearing angle measurement for two

different runs.

The curves A and C represent average and

maximum error when the robots' position error was

at most ±8 cm on each axis. The curves B and D

represent a run where robot's position error was

doubled to ±16 cm. The maximum heading angle

COOPERATIVE LOCALIZATION - Self-configuring Procedure of a Multi-robot Localization System with Passive RFID

Technology

101

error was ±4° on both runs. The simulation results

show that the bearing angle error is a lot smaller

factor than the error in robot's position.

Figure 2: Effect of the bearing angle error.

Figure 3: Convergence of tag position estimate.

The Figure 3 shows the convergence of tag's

position estimate when 1000 independent groups of

20 robots pass a tag. Two runs with different bearing

angle error factors (5 and 10) were made. The curves

show average and maximum error in tag position

after each robot. The increase in bearing angle error

does not have significant effect on the position error.

Also a smaller group of robots can localize a tag

when they pass the tag multiple times.

5 CONCLUSIONS

The simulations indicate that the tags can be

localized with certain accuracy even if the angle

measurement to the tag is not very accurate. The

error in the tag’s position depends on several

different factors, such as errors in robot's position

and heading angle estimate. When several robots

participate in the localization the position error

settles on an acceptable level.

This study suggests that it is possible to build a

localization system that offers a bounded error after

it has been autonomously configured by simple,

inexpensive robots with readily available RFID

technology.

6 FUTURE WORK

Initial tests for the bearing angle measurements in

the office environment are under way. The first

RFID localization modules for laboratory tests will

be designed according to the information obtained

from the angle measurement tests. The system will

be tested with a group of small robots. In order to

obtain accurate localization information further

research is required in tag positioning and filtering

of the bearing angle measurements in an office

environment.

ACKNOWLEDGEMENTS

I want to thank CEA-LETI for offering the research

facilities during my visit in France and Finnish

Cultural Foundation for the funding.

REFERENCES

Bohn J., 2006. Prototypical Implementation of Location-

Aware Services based on Super-Distributed RFID

Tags., 19th International Conference on Architecture

of Computing Systems, LNCS No. 3894, Springer-

Verlag, pp. 69-83, Frankfurt am Main, Germany.

Hightower J., Borriello G. ,Want R., 2000. SpotON: An

Indoor 3D Location Sensing Technology Based on RF

Signal Strength, UWCSE Technical Report 2000.02.02

Hähnel D., Burgard W., Fox D., Fishkin K., Philipose M.,

2004. Mapping and Localization with RFID

Technology., Proc. IEEE Int. Conf. on Robotics and

Automation (ICRA), New Orleans, USA

Kleiner A., Prediger J., Nebel B., 2006. RFID

Technology-based Exploration and SLAM for Search

And Rescue, Proc. of International Conference on

Intelligent Robots and Systems, Beijing, China, 2006

Kulyukin V., Gharpure C., Nicholson J., Pavithran S.,

2004. RFID in Robot-Assisted Indoor Navigation for

the Visually Impaired, Proceedings of Intelligent

Robots and Systems,. Volume: 2, page(s): 1979- 1984

Maybeck, Peter S., 1979. Stochastic Models, Estimation

and Control, Vol.1 Academic Press, Inc., 1979

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

102