IMPROVEMENTS IN THE FIELD OF DEVICE INTEGRATION

INTO AUTOMATION SYSTEMS WITH EMBEDDED WEB

INTERFACES

1

Anton Scheibelmasser,

2

Jürgen Menhart

1

Department of Automation Technology, CAMPUS 02, Körblergasse 126, 8021 Graz, Austria

2

Test Bed Automation and Control Systems, AVL List GmbH, Hans List Platz 1, 8020 Graz, Austria

Bernd Eichberger

Department of Electronics, Technical University Graz, Inffeldgasse 12, 8010 Graz, Austria

Keywords: Measurement device, automation system, device integration, embedded web interface, automotive test bed.

Abstract: Web-Technologies which came up in many fields of automation seem to be a solution which improves

device integration in many ways. On the one hand the used Ethernet improves the installation techniques

with reliable and approved network cables and routing devices. On the other hand the used internet

protocols provide several services for the application software development. With the introduction of those

services, the local controller of the measurement devices has to execute complex communication protocols

in addition to the device specific tasks. This fact has serious influences on the measurement device

instrumentation and the execution of the device firmware. Concerning new developments and compatible

adaptations of existing instruments several ways for the integration of web technologies are available. The

following article is intended to explain the architectural aspects of device integrations using Industrial

Ethernet by means of an embedded web server. As a practical example to this architecture, concepts and

results of a new developed communication module called EWI (embedded web interface) are given to

demonstrate the improvements in measurement device integration in the field of automotive test bed

automation.

1 INTRODUCTION

Automation systems like test beds in the automotive

industry are used for the development and the

quality control of combustion engines. In order to

evaluate the interesting quantities, a lot of

measurement devices have to be controlled to

acquire the data during a test run. From the

automation system’s point of view these

measurement devices can be seen as automata

incorporating a finite state machine. Integrating such

devices in an automation system means to

synchronise the states of the measurement device

with the states of the automation system. As those

devices are physically separated from the test bed,

synchronisation has to be performed by means of

communication lines. From this point of view device

integration can be split into software aspects like

device driver development and hardware parts like

network design and installation. Concerning the

network aspect, web technologies have spread over

in many fields of application. As the components

have become cheap and reliable, the well defined

Ethernet (Metcalfe, Boggs, 1976) was introduced in

the field of automation technology. Because of the

standardized bus system, network cables and

components like plugs, transceiver, switches, routers

and gateways, Industrial Ethernet (Hirschmann,

2007) has established in several fields of automation

technology. In many applications it was extended to

real time derivates (Powerlink, 2003) of this

standard. Particulary automation systems in the field

of combustion engine development, called test beds,

are a potential field for the use of Industrial

Ethernet.

94

Scheibelmasser A., Menhart J. and Eichberger B. (2008).

IMPROVEMENTS IN THE FIELD OF DEVICE INTEGRATION INTO AUTOMATION SYSTEMS WITH EMBEDDED WEB INTERFACES.

In Proceedings of the Fifth International Conference on Informatics in Control, Automation and Robotics - ICSO, pages 94-99

DOI: 10.5220/0001479100940099

Copyright

c

SciTePress

As the test bed automation system has to

control a lot of measurement devices, there are high

requirements concerning the communication. A

central task of the system in this context is the

synchronisation of the used measurement devices.

Synchronisation is needed in order to drive the

internal state machine of the devices in the desired

state of the automation system (e.g. measurement).

On a typical test bed the measurement devices are

seperated from the automation system. Therefore

synchronisation is only feasable by means of

communication lines. So measurement device

integration into automation systems can be split up

into two parts.

The first one is the network part. A lot of

measurement devices have to be connected to the

test bed by means of communication lines. Typically

existing test bed measurement devices are connected

by means of peer to peer connections (e.g. RS232).

This causes problems concerning the available

connectors at the automation system and problems

related to the available data acquisition rate. Based

on traditional master/slave communication protocols

and low data rate connections (e.g. 9600 Baud),

timing requirements for high dynamic combustion

engine tests are not met. So improvements in these

directions are required.

The second part of device integration is the

software part. Based on generic device drivers

(Scheibelmasser, Traussnigg, Schindin, Derado,

2004) the protocol layer integration can be managed

generically. Based on a Measurement Device

Description (MDD) a flexible and efficient way for

the device driver development is applicable.

Concerning the appropriate graphical user interface

(GUI) a similar methode is not available. Typically,

a lot of software components have to be developed

for different plattforms to provide the user with the

appropriate visualisation for every measurement

device. This implies high efforts and an economical

disadvantage.Therefore new concepts in terms of

device visualisation are needed. In both parts of

measurement device integration Industrial Ethernet

promises an improvement. In case of network

problems, Industrial Ethernet provides the user with

a high speed bus system. This avoids the connector

problems and the data rate restrictions. Concerning

the software part, the available Ethernet protocols

enables a lot of services (e.g. http, ftp) which are

available for implementing economical and high

quality user interfaces and additional improvements

in the field of service and maintenance.

2 INDUSTRIAL ETHERNET

If we introduce the Ethernet in an automation

system, we provide the user with a lot of new

capabilities. This chapter is intended to summarize

the characteristics of such communication lines.

2.1 Bus Features

In contrast to the traditional peer to peer connections

between the automation system and the

measurement device, a bus system like Ethernet

provides the capability to connect several devices to

one line (network). Additionally, Ethernet increases

the useable bandwidth in high ranges (e.g. GHz).

Therefore existing restrictions concerning the

connectors on the host system or the data rate

acquisition problems could be easily solved. A

possible disadvantage of this solution lies in the fact

that the bus feature implies the need of a bus

arbitration which is responsible for loosing a

deterministic bus response time. Therefore an

extension of the classical standard is necessary if

hard real-time is required. In most cases the user

interfaces require only soft real-time. So the

standard Ethernet protocol is sufficient to support

these applications.

2.2 Network Capability

Based on the standard and the defined network

protocol stack, measurement devices which are

connected to the Ethernet are able to communicate

not only in the local network with the automation

system but worldwide in the web. This feature

enables on the one hand improvements in the area of

remote control, remote maintenance and updating

parameters or software in the field. On the other

hand the security aspects will conquer against these

features and lead to protected small subnets locally

to the automation system. Depending on the required

application the security aspect has to be taken into

consideration and should be adjusted to the needed

level.

2.3 Service Aspects

If we use the Ethernet with the standardized

protocols (e.g. TCP/IP, UDP, HTTP) to connect the

measurement devices, a lot of services are available

to improve the human machine interface. Using

these services, the challenges of the measurement

device visualisation could be improved in many

ways by means of embedded web-server.

IMPROVEMENTS IN THE FIELD OF DEVICE INTEGRATION INTO AUTOMATION SYSTEMS WITH

EMBEDDED WEB INTERFACES

95

Technologies like JAVA or .NET are available to

program the appropriate user interface. The

graphical user interface (GUI) of such a device is

shown within a web-browser window independent

from the computer platform. The respective program

instructions (e.g. JAVA Applet) for the visualisation

and control are stored in this scenario in the

measurement device. In addition to this, user

manuals, service instructions or electronical data

sheets are available inside the device and accessible

by means of Ethernet protocols (e.g. ftp). The

challenge of implementing this method lies in the

appropriate hardware and software design of

measurement device.

3 SYSTEM ARCHITECTURE

In contrast to the traditional measurement device

visualisation, the development of additional PC-

Programs for control and visualisation could be

avoided if we are using the Ethernet technology. As

mentioned, the required human machine interface is

implemented by means of applets which are stored

in the respective device and are executed within a

web browser. The details of the applets and the

methods used for the implementation should not be

part of this work. The main focus of this paper

concerns the communication aspects of an

embedded web server solution. Using the Ethernet

protocols for the measurement device

communication increases the efforts for the

communication task in the device. This fact has two

consequences. Existing devices are not able to carry

out this additional task because of their limited

resources. New device developments have to

introduce additional hardware which is capable to

execute not only the application program but an

operating system with the Ethernet protocol stack. In

addition to the protocol stack, a files system and a

multitasking support are necessary to support the

desired web-services. Concerning the control aspects

of the measurement device, we have to take care not

to loose the real time aspects. From the economical

point of view we have to consider the side effects of

introducing an operation system (e.g. licences) and

the consequences in terms of additional hardware

(e.g. memory). Never the less a compatible solution

for existing measurement devices is required

additionally. A further aspect lies in the fact that the

introduction of a fast bus connection will not

automatically yield to a higher data acquisition rate.

Typically, existing firmware and protocols limit the

performance of the system. So a appropriate

hardware architecture is necessary to support the

demanded improvements.

Based on a principle which was already

implemented in a density meter (Röhrer, 1991) there

exists a trade off concerning the improvement of the

device communication. If we separate the non real-

time tasks like human machine interface from the

real-time control tasks of a system with the

introduction of two independent execution units (e.g.

computers), we can achieve a solution which

provides a lot of advantages. Using this concept, we

can use even existing small and economical

controller solutions without any modifications to

carry out the real time control task. In contrast to

this, improved communication or human machine

interaction is done by an additional device computer

which communicates with the real time controller on

a proprietary and efficient protocol (e.g. SPI). This

architecture provides the system not only with real

time advantages but also with economical benefits.

4 TEST BED INTEGRATION

Based on the above mentioned considerations the

device integration of measurement devices in an

automotive test-bed automation system should be

shown. An additional computer called EWI is

introduced which works as a gateway between the

traditional RS232 lines of the measurement device

and the Ethernet. Based on this component, a new

integration concept was developed.

4.1 EWI Definition

The main part of the integration concept is a

standalone working EWI (embedded web interface).

According to the different aspects of the

measurement devices (e.g. version, protocol,

hardware, technology), this system offers an overall

and compact solution for a new and standardized

integration concept for measurement devices in

automotive automation systems. The EWI was

development on the basis of a few important

concepts:

- An increase of the data communication rate

- A multi user access from the client systems

- Introduction of a new visualisation concept

The EWI offers different solutions for data

communication and exchange and is implemented as

an additional hardware component. Therefore it is

even applicable for existing devices. The highest

priority is set on the communication between the

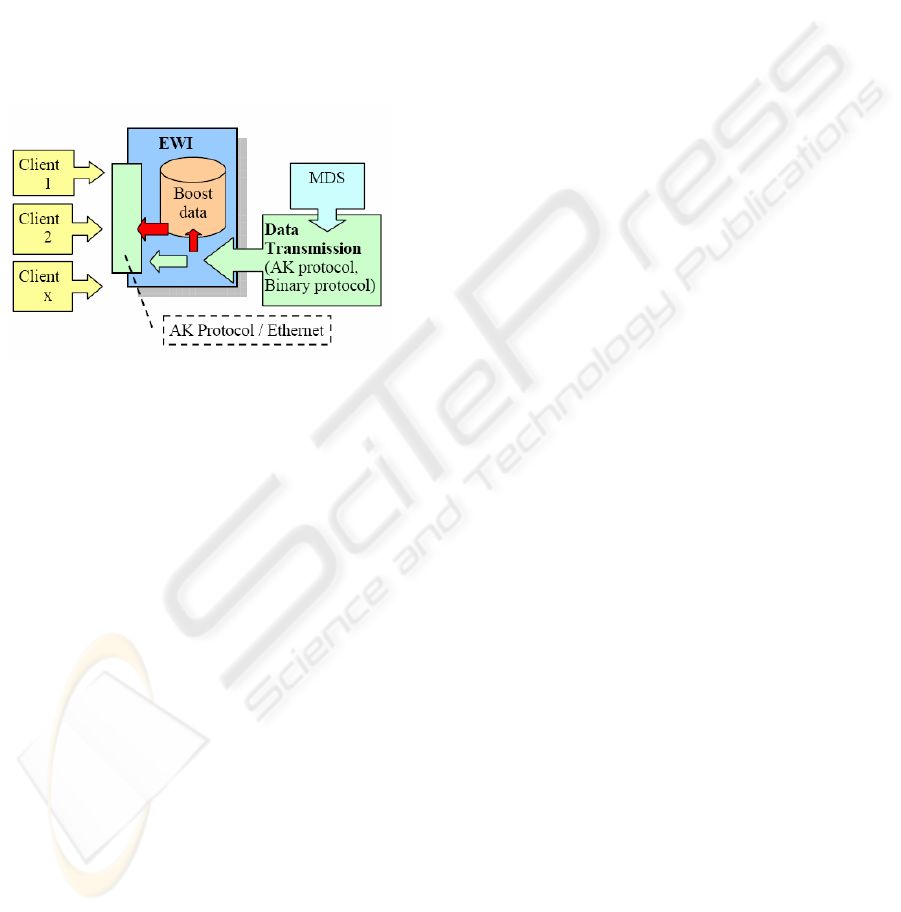

different users. As shown in Figure 1, it takes care of

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

96

the direct communication between the measurement

devices (MDS) and different client systems (e.g. test

bed system, personal computer, handheld system).

The web interface provides the user on the one hand

with a gateway function (Ethernet to RS232), on the

other hand it offers a data storage for a device

specific user interface (GUI), directly stored in an

extended memory.

Figure 1: EWI integration concept (AVL, 2007).

Depending on the hardware version of the

measurement device, the EWI hardware supports

two integration concepts. The first scenario supports

existing devices and provides the user with an

external component, equipped with a serial

connection to the device and a power supply. In

contrast to this, the EWI-integration in current

measurement devices is done in the system. In this

case the communication will be done directly

between the microcontroller and the EWI using a

high speed serial connection (e.g. SPI). So there is

no need for an additional power-supply.

4.2 Economical Aspects

One of the first steps in the EWI-development was

the consideration of economical aspects. In order to

make a decision, available technologies on the

market were checked against aspects like initial

costs, time to market or training efforts for the

development team. To reach a high reuse of the

module, the EWI should be customized by means of

text-based configuration files. The following

characteristics are configurable:

- Communication protocol definition/settings

- Multi-user access handling

- Automatic device detection

- Boost data handling

Based on this text file and the generic structure the

EWI firmware allows the use of the system even

with different kinds of ASCII based protocols on the

RS232-line. A further economical aspect of the EWI

development was the intention to improve the device

user interface including the visualization. Currently

a lot of different device user interfaces have to be

offered to the customer. Depending on the supplier

of the test bed system, the operating system on the

client, software versions or languages appropriate

software have to be provided. Every component of

such an interface has to be maintained, bug fixed

and released separately. The user has to be trained

on each of the user interfaces because the integration

into the customer’s test bed has to be done always in

a different way. So a main goal was to implement

the user device interface as a web-page inside the

EWI and to use a standard web-browser instead of

proprietary PC-programs.

4.3 EWI Hardware Platform

In consideration of the above mentioned aspects the

OEM-module solution was chosen. The EWI

hardware acts as a communication co-processor

solution. It is implemented as an additional hardware

component and could be used without any influence

on existing controller solution. Therefore it is

applicable even for existing devices in the field.

Concerning initial- and development time and costs,

easy integration of software modules, functionality,

licenses and RTOS features the OEM-module was

the best trade-off. So the EWI was build up on the

IPC@CHIP SC13. The system is based on a 80186

single chip computer and offers a maximum

flexibility and availability for individual

applications. The module incorporates a real time

operating system, RAM, FLASH-Disk, serial and

Ethernet controller and a large number of I/Os. The

EWI software and architecture was built up on the

preinstalled real time operating system. By means of

the generic application software it is now possible to

integrate the EWI in the different measurement

systems, to store and manage the device user

interface and to communicate with the measurement

devices via multiple access.

4.4 Performance Considerations

Members of the automotive industry and their

customers use a common known communication

protocol called AK-Protocol (Arbeitskreis, 1991).

This protocol is based on ASCII and provides an

easy way to communicate with the measurement

IMPROVEMENTS IN THE FIELD OF DEVICE INTEGRATION INTO AUTOMATION SYSTEMS WITH

EMBEDDED WEB INTERFACES

97

devices on the test bed. It has been used for a long

time and is described in user manuals of test bed

devices. The communication is typically done via a

point to point serial line connection in a master/slave

mode. As the test bed devices are typically equipped

with two serial lines, a connection for a maximum of

two users is feasible. The AK protocol offers the

user several commands, to switch the device into

another mode (set), to acquire data (acquire) or setup

new parameters (store) on the system. The

interpretation of the AK protocol for a customer is

very complex and varies between several

measurement devices. To present an easier control

mechanism for the user, the supplier of such a

measurement system includes device user interfaces

on his test bed systems or PCs. These software

components are in communication with the

measurement devices and offer the user a simplified

view of the system. The communication rate

between the participants depends on the client

system. It varies between 1 Hz up to 10 Hz on

current systems in the field. The communication

rate, the operating systems and the software

platforms are totally different. According to these

differences, the standardized EWI integration

concept has to consider the different communication

rates in order o offer an overall solution in terms of

test bed integration. A closer look to the protocol

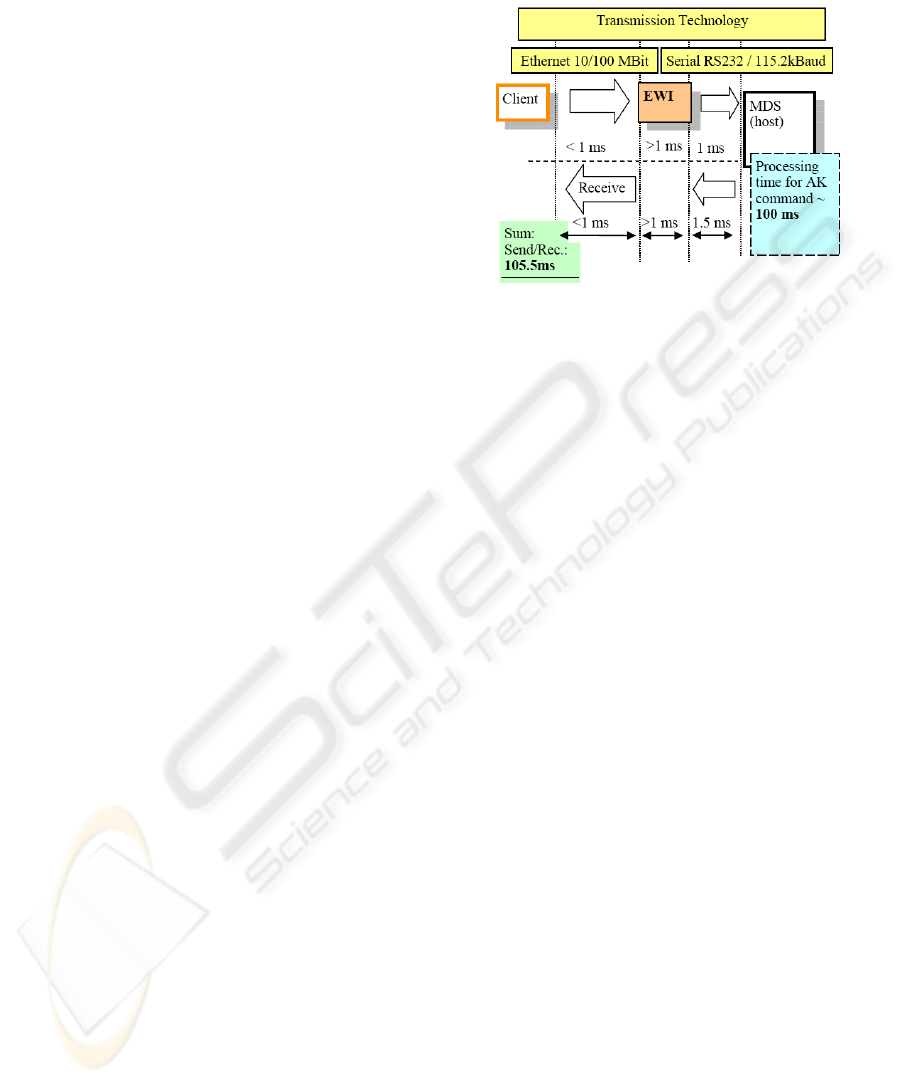

timing shows that the bottleneck of the

communication can be found in the measurement

devices itself. In current measurement devices the

processing time takes about 100 ms. Due to the used

hardware this time is necessary to receive the serial

line string of the ASCII protocol, to interpret the

frame, to calculate the data and to send it back to the

client on the serial line. In comparison to this time,

the communication of a command on the serial line

between the client and the measurement device takes

about 25 ms. It must be considered that the EWI is

now a third partner in the communication line

between the host and the client, and should not

decrease the data rate between these communication

partners. To improve the communication between

the client and the host system, the EWI concept is

split up into two parts.

The first part is the increase of the

communication data rate between the client and host

system by means of changing the physical layer and

the protocol to Ethernet and TCP/IP.

The second part of the concept increases the

communication data rate between the EWI module

and the measurement device system. Instead of 9600

Baud the communication was increased to a data

rate up to 115.2 kBaud. In this case the elapsed time

can be decreased to 5.5 ms instead of 25 ms (Figure

2). The new communication schema offers now an

overall communication time of about 105.5ms

between the client and the host system.

Figure 2: Transmission rates (Menhart, 2007).

Without changing the existing controller hardware in

the measurement device, no further improvement of

the transmission time is possible. Due to this fact the

data rate for existing devices is limited up to 10Hz.

But a main demand of the integration concept was

the ability to process incoming data from the

measurement device with a data rate of 50 Hz. In

order to achieve this, the communication schema

was extended with a so called Boost mode which

was implemented in parallel to the ASCII based

communication between the host and the client.

4.5 Data Acquisition/Boost Mode

As mentioned, it will be hardly possible to reach a

data rate up to 50 Hz based on an ASCII based AK

protocol without a change directly in the

measurement device. The bottleneck between the

communication structure – client, EWI, host - is the

processing and interpretation time of the AK strings

in the measurement devices itself.

The solution for this problem is a concept

based on a mixed mode of communication. A

transparent standardized ASCII mode and a fast

binary data mode called “boost mode”. To achieve

the requirement of a measurement data rate up to 50

Hz the communication will be done via this boost

data mode in form of binary data sent from the

measurement devices to the EWI. The data

communication will be started and controlled from

the measurement device, independent which client is

in communication. The goal of the solution is to

relieve the device from processing ASCII based AK

data acquisition frames. Therefore the most

important data of the measurement devices – the

measurement data – will be sent to the EWI via

binary data. In case of a client data acquisition the

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

98

data are taken from the EWI and no AK frame to the

device is invoked.

In parallel the standard communication like

parameter settings or service/maintenance

commands will be done via the standard AK

protocol. By means of this concept a dual

communication is established. The processing time

of the measurement device is not influenced and the

client receives the AK data with a transmission rate

up to 50 Hz. Due to the fact that the communication

between the clients and EWI is now done via

Ethernet, a multiple access from the clients to this

boost data and the standard AK commands is

possible. (Figure 3).

Figure 3: Multiple client access via EWI (Menhart, 2007).

5 CONCLUSIONS

In general the embedded web interface (EWI)

represents a uniform and excellent solution for the

integration of measurement devices into automotive

test bed systems. It offers a complete support of the

Ethernet technology as well as a standardized

solution to overcome the problems of existing data

transmission and communication modes. Providing

the user with an Ethernet connection on the

measurement device solves a lot of problems. As the

peer to peer connections of RS232 lines are replaced

with high speed, low cost and high reliable bus

connections, the network problems are sufficiently

solved. The used TCP/IP protocol offers the

application software a lot of services. These services

are able to improve not only the communication rate

but even the user interface by means of embedded

web-server technologies. Implementing such server

in a measurement device enables the devices to

provide their data not in traditional protocol frames

but as web-service on a graphical web-page

accessible with a standard web-browser.

The EWI concept, implemented as a

communication co-processor has shown excellent

results in the field tests. The used EWI principles

and methods are able to establish a standardized way

of measurement device integration into test bed

automation systems.

REFERENCES

AVL List GmbH, 2007, Embedded Web Interface,

Test Bed Instrumentation Systems, www.avl.com

Röhrer, R., 1991. Intelligente Instrumentierung von

Messgeräten, Berichte der Informationstagung ME91,

pp.46-50, Fric-Verlag

Scheibelmasser A., Traussnigg U., Schindin G., Derado I.,

2004, Device Integration into automation systems with

Configurable Device Handler, ICINCO 04

Conference, Setubal

Metcalfe R.,Boggs R., 1976, Ethernet: Distributed

Packet, Switching for Local Computer Networks,

Association for Computing Machinery, Vol19/No5

Hirschmann, 2007, Industrial Ethernet, http://

www.hirschmann-ac.de/Deutsch/industrial-ethernet/

index.phtmlww.hirschmann.com

Menhart J., 2007, Measurement device integration via

Embedded Web Interface, Diploma Thesis

CAMPUS02 University of Applied Sciences, Graz

Arbeitskreis der deutschen Automobilindustrie, 1991,

V24/RS232 Schnittstelle – Grundsätzliches, UA

Schnittstelle und Leitrechner

Powerlink, 2003, Ethernet Powerlink Standardisation Group,

www.ethernet-powerlink.org/

IMPROVEMENTS IN THE FIELD OF DEVICE INTEGRATION INTO AUTOMATION SYSTEMS WITH

EMBEDDED WEB INTERFACES

99