TEMPORAL MATCH OF MULTIPLE SOURCE DATA IN AN

ETHERNET BASED INDUSTRIAL ENVIRONMENT

Daniela Hossu and Andrei Hossu

University Politehnica of Bucharest, Faculty of Control and Computers

313 Spl. Independentei, sector 6, RO-77206, Bucharest, Romania

Keywords: Industrial Robotic Application, Ethernet-based communication, Data transfer consistency, Artificial Vision

System, Control Management System, Routing Control System.

Abstract: The actual stream in automation control systems is to distribute the control tasks among different modular

and easy to integrate processing cells. It is part of this trend the increase of the use of Ethernet technology

for machine-machine data communication inside this distributed based architecture. The paper presents a

robotic handling application of industrial parts transferred by a transport conveyor. Data representing a set

of parameters of the parts to be handle from the conveyor is provided by a Routing Control System (RCS).

The Control Management System (CMS), which controls a number of robotic cells is receiving this data

from RCS and merge it with the information provided by an Inspection System (Artificial Vision System).

The communication between these two Control Systems (RCS and CMS) is Ethernet-based. Ethernet

technology is good, reliable and fast for large amount of data, but because of its non-deterministic character,

it has a lack of tools for data synchronization. The paper includes an analysis of the experimental results of

the measurements of the non-deterministic factor of the existing network. The "worst case scenario" of the

largest communication delay caused by Ethernet traffic and the minimum time between two consecutive

data commands, reveals that application requirements could not be achieved without recovering data

transfer time-consistency. The paper is presenting a mechanism developed at protocol level, in order to

guarantee the consistency in time, at CMS level (data consumer), of the merging process of the data

provided by the two application partners, RCS and Vision System as the data producers.

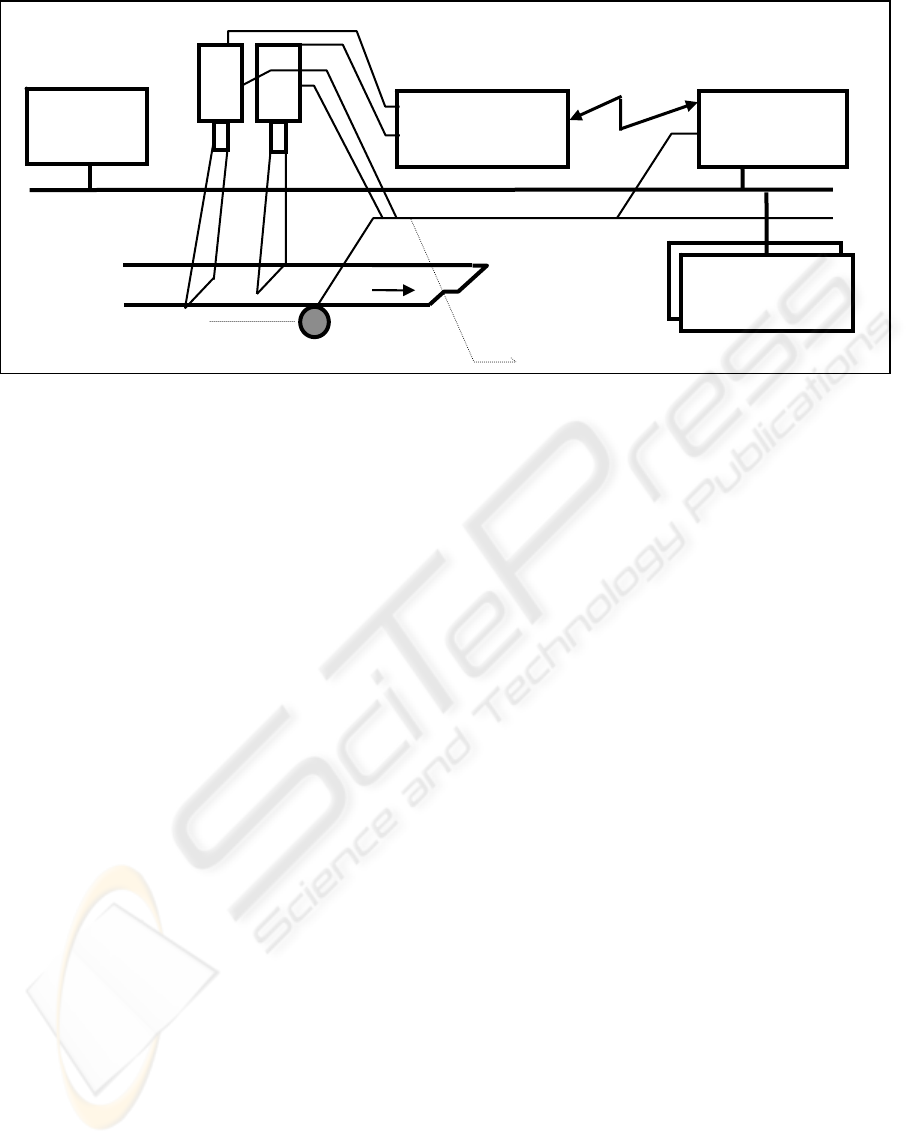

1 THE DESCRIPTION OF THE

ROBOTIC APPLICATION

The system described in the paper is dedicated for

the robot-based automation of the unloading and

packing stages in the flat glass industry. In Figure 1

it is presented the architecture of the proposed

automation system. This architecture is often utilized

in industrial applications (in palletizing of moving

objects systems).

1.1 The Structural System

Architecture

Active Elements:

Control Management System (CMS), Routing

Control System (RCS), Vision System and Robotic

Cells.

Passive Elements:

Conveyor, glass plates.

Infrastructure:

Communicational Link between Vision System

and CMS;

Communicational Link between CMS and

Robots Controllers;

Communicational Link between CMS and RCS.

General assumptions:

The plates are connected to the conveyor (the

same speed and direction).

1.2 The Functional System

Architecture

The Routing Control System has to provide for CMS

the Routing Data - a description of the possible

destinations (one or more of the robotic cells) of

each plate in the moment the plate is passing the

Decision Point of the Vision System. The role of the

Vision System is to inspect the cutting accuracy and

the shape parameters of every plate. The Vision

140

Hossu D. and Hossu A. (2008).

TEMPORAL MATCH OF MULTIPLE SOURCE DATA IN AN ETHERNET BASED INDUSTRIAL ENVIRONMENT.

In Proceedings of the Fifth International Conference on Informatics in Control, Automation and Robotics - RA, pages 140-144

DOI: 10.5220/0001476301400144

Copyright

c

SciTePress

System is analyzing the information provided by a

Line Scan Acquisition System (a dual line scan

camera system) in conjunction with the information

provided by an encoder connected to the transport

conveyor. The Vision Data, containing the data

resulted from the inspection process, together with

the data describing the location of the plate, are

transmitted to CMS in the moment the Vision

System processing time ended.

The moment (time-based) is called Vision

Decision Point. Both sets of data (Routing Data and

Vision Data) are merged by CMS. CMS will take

the decision to send the pick the plate command to a

certain robotic cell only if Vision Data describe the

plate having cutting accuracy and shape parameters

inside the accepted tolerances for a certain packing

destination AND the plate is routed to that certain

destination.

2 THE DESCRIPTION OF THE

INFORMATIONAL SYSTEM

ARCHITECTURE

The communication between Vision System and

CMS is a dedicated connection. Some of the reasons

for choosing this type of communication is the

geographical neighborhood of these two systems and

the fact the structure of the data transferred between

Vision System and CMS could be very tight

specified (no need for using a general type of

protocol). Another reason is the concept that Vision

System is an intelligent sensor of the Robotic

Application, which means the Vision System will be

not “visible” on the higher automation level, but

only on the Robotic Automation Level (the Vision

System is “visible” only for CMS). This

communication channel has a serial support. This

type of connection is providing a deterministic

character of the Vision System – CMS

communication. For the communication between

CMS and RCS it was adopted an Ethernet-based

topology. The main reason of choosing this type of

topology is the fact CMS is an automation entity

visible on the high automation level (CMS includes

all the automated stacking capabilities of the whole

production line). Industrial Protocol on Ethernet is a

very good and reliable support for modern

configurations on industrial automations, but

because it’s non-deterministic character, it is poor in

data time-synchronization (Marshall, et al., 2004).

The time-synchronization between the Routing Data

(data coming from RCS) and the Vision Data (data

coming from Vision) in the merging process in CMS

it is a key factor of achieving the requirements of the

automation application.

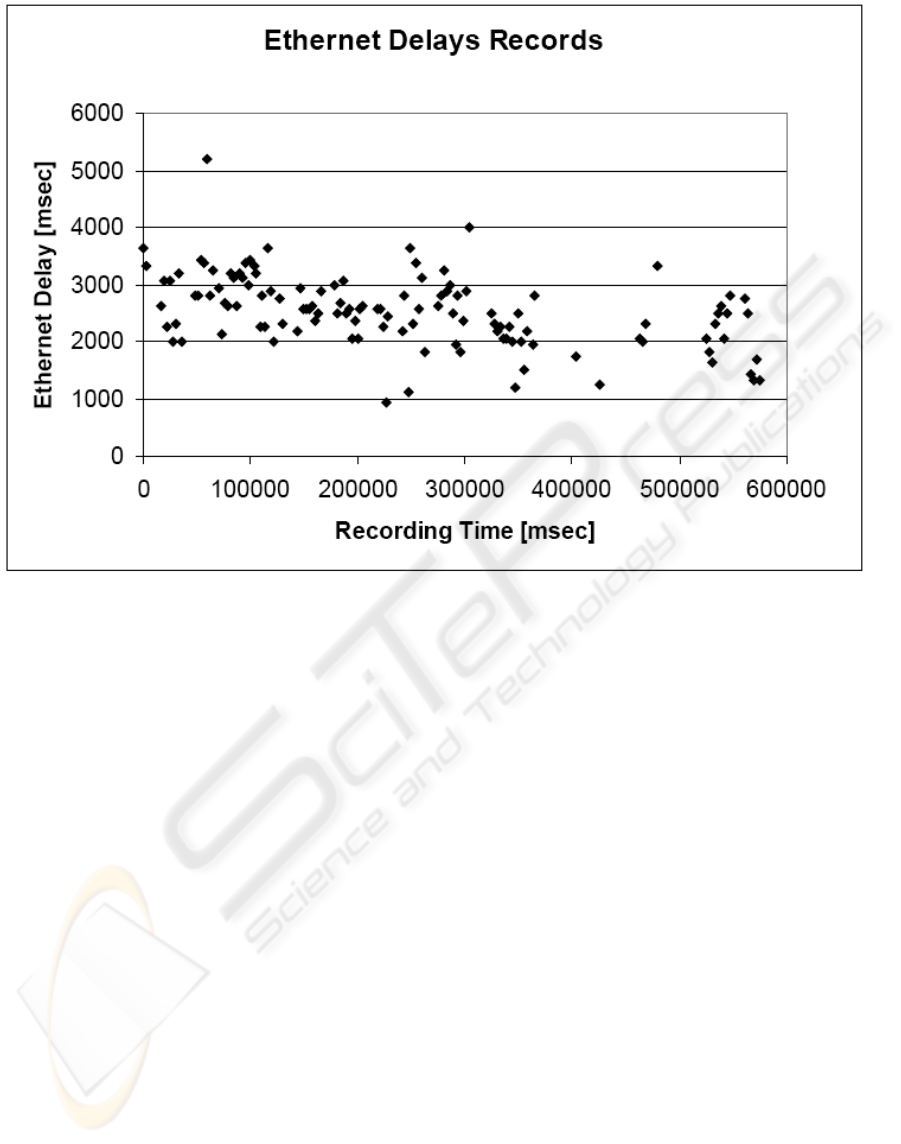

3 EXPERIMENTAL RESULTS

In Figure 2 are presented the experimental results of

recording Ethernet Delays over around 10 minutes

on the analyzed network. The Ethernet Delays are

estimated as the differences between the CPU time

of receiving Routing Data (sent over a non-

deterministic communication channel) and the CPU

time of receiving Vision Data (sent over a

deterministic communication channel). A lost in

Artificial Vision

System

CMS

Encoder

Encoder Pulses

LAN

Conveyor

Robot

Controller

Dedicated connection

RCS

Figure 1: The robot-based automation system for handling glass plates from a moving conveyor.

TEMPORAL MATCH OF MULTIPLE SOURCE DATA IN AN ETHERNET BASED INDUSTRIAL ENVIRONMENT

141

synchronization will occur only if the variation of

the Ethernet Delay value from the average value of

the Ethernet Delay is greater than the minimum time

between two consecutive sets of Routing Data.

Analyzing the manufacturing process we can

identify what is the minimum time between two

consecutive sets of Routing Data.

This is the minimum time between two glass plates

coming on the conveyor (this is called “snapping

period”). The actual glass manufacturing process has

the minimum snapping period of 1.44 seconds.

Analyzing the experimental results we could see the

necessity of implementing a method for recovering

data transfer time-consistency.

4 RECOVERING DATA

TRANSFER

TIME-CONSISTENCY

A few solutions were analyzed in order to solve this

problem (Marshall, et al., 2004).:

- Use a more powerful Ethernet board

(instead of using 10MB/s type of board, to use a

100BT Ethernet module)

- Replace the communication software

support (RSLinx) with another one with a better

response time (a software module dedicated

only for a specific protocol would provide a

better response time related to a general

software package like RSLinx, which is coming

with a large CPU overhead).

The above two solutions could improve the

Ethernet behavior, but the non-deterministic

character of this type of communication is not

eliminated.

- Install another dedicated Ethernet module

in the RCS and an additional dedicated Ethernet

module in the CMS PC. These modules would

be connected to a separate isolated Ethernet

switch. In this case, most of the delays

experienced on the current Ethernet link would

be eliminated since the only traffic on the link

would be between the routing system and the

CMS cell PC.

- Use an ASCII serial (RS-232, RS-485,

etc.) connection rather than using Ethernet. This

would make the communication time between

the Routing and CMS systems deterministic.

- Use a dedicated digital signal from RCS to

the CMS in addition of the Ethernet connection

in order be used to re-synchronize the Routing

Data in CMS. This would be implemented by

energizing a digital output that would indicate

to the CMS cell in the moment of sending

current Routing Data. When the input was seen

by the CMS system, the CMS system would

capture its own internal time and it will use this

time value in the moment the Routing Data is

received over Ethernet.

These last three solutions could solve the time-

synchronization problem, but any of these solutions

wouldn’t be accepted because of a dramatic

aggression on the network topology previously

agreed on the design time of the application

(Mackay, et al., 2003), (Stenerson, et al., 2002).

The solution proposed in the paper is based on

inserting a “timestamp parameter” in any set of

Routing Data transmitted from the Routing System

to the Control Management System.

This timestamp parameter will be the Routing

System CPU time in millisecond representation.

This timestamp parameter value will be a

wraparound counter representing the least significant

two bytes (one Word) of the CPU time (in

milliseconds).

This timestamp parameter will be used by CMS

to estimate with a “good enough” approximation, the

offset between the CPU time values of the producer

of the message (RCS) and the consumer of the

message (CMS). This estimated offset would be

used for time synchronization of the current

message. It means CMS will add the estimated CPU

time values offset to the current timestamp

parameter value contained in the current received

message.

In order to provide a “good enough”

approximation of the offset between the CPU time

values of the producer (RCS) and the consumer

(CMS) the algorithm has to estimate the minimum

value of the statistical population containing all the

offsets estimated for a large number of

transmitted/received messages.

This minimum is a “moving minimum” (it will

be estimated from a statistical population collected

on a certain time window) because we expect a

slippage between the clocks of the two CPU (this

slippage is accumulative and will become significant

in time).

For the support of building this statistical

population of offset values is used an existing

message from RCS to CMS, called “Request Status

Message”.

This message is sent by RCS every half a second

in order to check the communication with CMS and

also to obtain from the CMS the status of the

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

142

Figure 2: The experimental results of recording Ethernet Delays over around 10 minutes on the analyzed network.

availability of each possible plate destination

stations (of each Robotic Cell).

The proposed solution requires the Routing

System to move the CMS cell data hand-off point

(the point where it is transmitting the Routing Data

to CMS) more upstream the conveyor.

The CMS has to receive the Routing Data

message of a plate before the Vision Systems ends

the process of analyzing that plate (even on the

highest Ethernet traffic). But the method is not

anymore affected by receiving Routing Data in

advance. CMS will build a buffer of all the Routing

Data received from the RCS describing plates will

come in time, and it will be able to recover the

consistency in time of these data on the merging

process with the Vision Data.

5 CONCLUSIONS

The paper presented an algorithm developed at

protocol level, in order to guarantee the recovering

of data transfer consistency in time, at CMS level,

for merging of the data provided from RCS over an

Ethernet communication channel with the data

provided by the Vision System over a deterministic

communication channel.

This solution proposed in this paper is based on the

following assumptions:

- The actual slippage of the clocks on either

the RCS or the CMS processors would be very

minimal. This assumption is not a restrictive

one, being normal to accumulate a significant

slippage value around one second in much more

that days or even weeks.

- In the time the slippage value of the clocks

would become significant, the network

connection would have a period of relative low

traffic. This assumption is also not restrictive

one, because in those days or weeks that the

slippage value of the clocks is becoming

significant, it is more likely a relative calm

moment to occur in the net traffic.

- The number of collected messages

transmitted by the producer/received by the

consumer (till the slippage of the CPU clocks

will accumulate a significant value) will be

large enough to build a statistical population.

This assumption is also not a restrictive one

because the statistical population main support

is the “Request Status Message” which is set to

TEMPORAL MATCH OF MULTIPLE SOURCE DATA IN AN ETHERNET BASED INDUSTRIAL ENVIRONMENT

143

be transmitted every half second (most of the

statistical population members are coming from

collecting the estimated offsets for this type of

message).

REFERENCES

Mackay S., Wright E., Reynders D., Park J., 2003,

Practical Industrial Data Networks, Elsevier.

Marshall P.S., Rinaldi J.S., 2004, Industrial Ethernet (2

nd

Edition), ISA – The Instrumentation, Systems, and

Automation Society.

Stenerson J., 2002, Industrial Automation and Process

Control, Prentice Hal.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

144