SURFACE DEFECTS DETECTION ON ROLLED STEEL STRIPS

BY GABOR FILTERS

Roberto Medina, Fernando Gayubo, Luis M. González, David Olmedo

CARTIF Foundation, Boecillo (Valladolid, Spain

Jaime Gómez, Eduardo Zalama, José R. Perán

ETSII, University of Valladolid, Valladolid, Spain

Keywords: Machine vision, surface inspection, defect detection, thresholding, Gabor filters.

Abstract: Product material integrity and surface appearance, in steel flat products manufacturing and processing, are

important attributes that will affect product operation, reliability and customer confidence. Automated

visual inspection has to be envisaged, but five major problems have to be overcome: (i) The variable nature

of the defects, (ii) The high reflective nature of the metallic surfaces, (iii) The oil presence, (iv) The huge

amount of visual data to be acquired and processed, and (v) The high speed in the section where inspections

are performed. We have developed an automated cellular visual inspection system of flat products in a flat

steel cutting factory. Among the approaches that the system uses to detect defects, we have included the

two-dimensional Gabor filters. In this paper a detection procedure of defects in flat steel products based on

Gabor filters is presented. The traditional methods based on the study of the grey-level histogram and shape

analysis, have shown quite good results, but there are not good enough to achieve the level of success

required. Experimental results show that a greater number of defects can be readily detected using the

proposed approach.

1 INTRODUCTION

The steel coils produced by the iron and steel

industry are rarely directly usable by the end users.

Therefore, they must be reprocessed in cutting lines

or processes to more manageable products with

dimensions and features that the customer desires,

but always with the highest quality.

Figure 1: Automatic surface defect visual inspection

system developed by CARTIF Foundation for

GONVARRI Industrial (Spain).

Automated visual inspection is the obvious

alternative to the human inspector (Gayubo et al.,

2006a; Gayubo et al, 2006b). An automatic surface

inspection system provides the following advantages

(Obeso et al., 1997):

Uniform quality control.

Programmable quality control oriented to

different acceptance levels for different

standards.

Possibility of assigning different quality

products to different customers, based on their

requirements.

We have developed an automated cellular visual

inspection system of flat products in a flat steel

cutting factory (Figures 1 and 2). Among the

approaches that the system uses to detect defects, we

have included the two-dimensional Gabor filters. In

this work a detection procedure of defects in flat

steel products based on Gabor filters is presented.

479

Medina R., Gayubo F., González L., Olmedo D., Gómez J., Zalama E. and Péran J. (2008).

SURFACE DEFECTS DETECTION ON ROLLED STEEL STRIPS BY GABOR FILTERS.

In Proceedings of the Third International Conference on Computer Vision Theory and Applications, pages 479-485

DOI: 10.5220/0001088504790485

Copyright

c

SciTePress

Figure 2: User interface.

Automated visual inspection has to be envisaged,

but five major problems have to be overcome: (i)

The variable nature of the defects, (ii) The high

reflective nature of the metallic surfaces, (iii) The oil

presence, (iv) The huge amount of visual data to be

acquired and processed, and (v) The high speed in

the section where inspections are performed (Fig. 3).

Figure 3: Coil slitting line (images courtesy of

GONVARRI Group).

The practice of detecting, analysing and

classifying abnormal structures in a surface is called

surface inspection (Chin, 1992). Deviations form the

surrounding surface can be either design elements

that must have been adequately fabricated or

fabrications faults that ought not have been present.

It is clear the immediate detection of surface defects

is important.

The number of surface defect types is large. Also

the naming of similar defect may differ from plant to

plant. Figure 4 shows examples of defect images.

One of the main problems of this application is

the huge amount of visual data to be acquired and

processed. The development of electronics and

information technology have made the actual image

applications possible. However the on-line

inspection is not an easy task due to the subtle

characteristics of the defects, high reflective nature

of the metallic surfaces, and the oil presence.

A surface of flat steel products may be defined in

terms of shape and reflectance, a defect may be

described as a local aberration in shape and/or

reflectance. The key is the ability to determine a

deviation in the expected shape and reflectance of

the surface.

Figure 4: Surface defects. Pattern-type and roughness-type

surface defects (rust, coat-less...).

Among the approaches that the system uses to

detect defects, we have included the two-

dimensional Gabor filters (Fig. 5). A two-

dimensional Gabor filter consists of a sinusoidal

wave modulated by a gaussian envelope. It performs

a localized and oriented frequency analysis of a two-

dimensional signal (Kamarainen, 2003).

Experimental results show that a number of defects

can be readily detected using the proposed approach.

Figure 5: 2D-Gabor filters interface.

2 DEFECT DETECTION

2.1 Introduction

Many methods have been proposed to extract

features either directly from the spatial domain or

from the spatial-frequency domain. In the spatial

domain, the more simple features are first-order

statistics such as mean, variance, skewness and

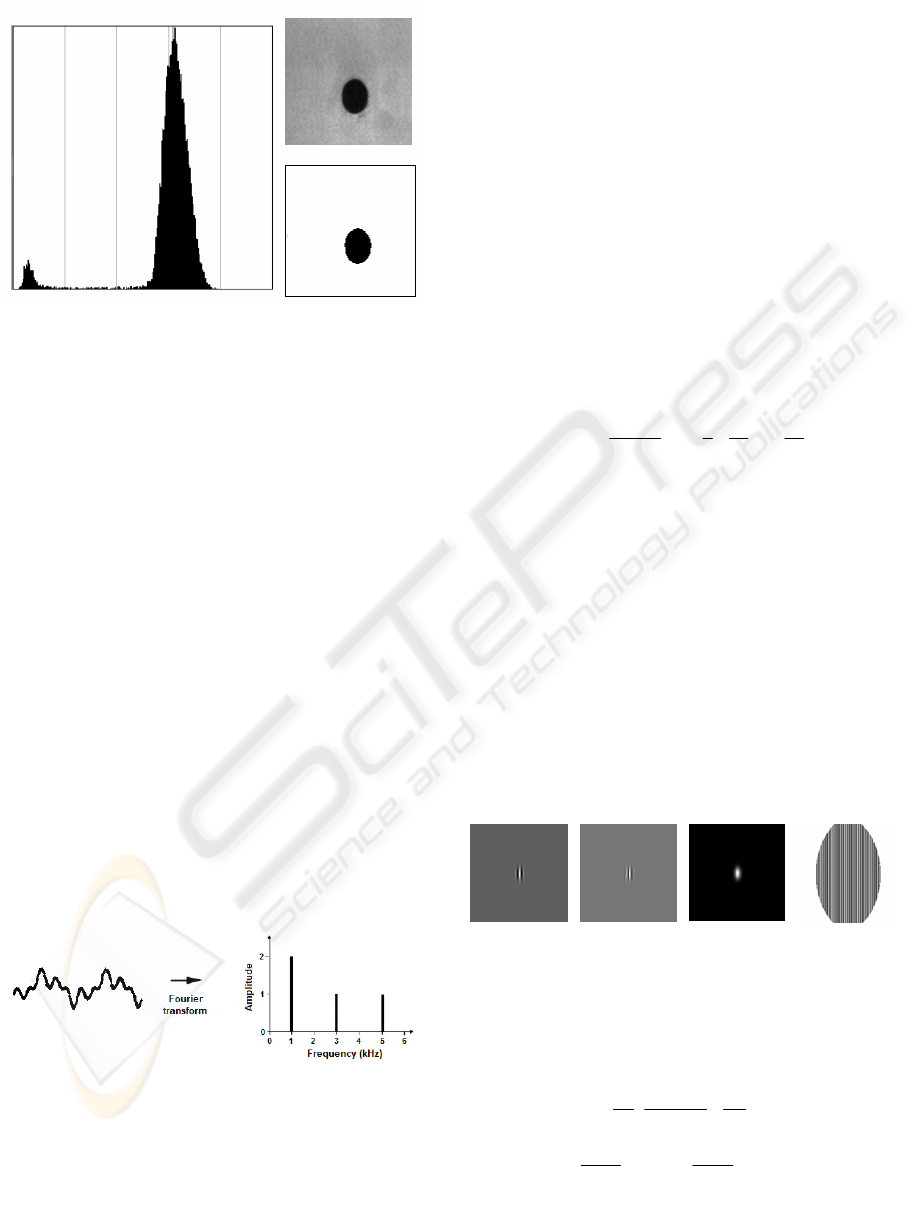

kurtosis from the grey-level histogram (Fig. 6) of an

image (Ramana and Ramamoorthy, 1996).

VISAPP 2008 - International Conference on Computer Vision Theory and Applications

480

Figure 6: Thresholding.

Thresholding is a very fast and simple method,

but there are two major problems. First, it is often

difficult to determine, automatically or even

manually, the optimal threshold. Second, only in

very simple images can a threshold segment all

objects correctly. To perform local thresholding, an

approach is to divide the image into square sub-

regions and calculate the threshold independently for

each one. However, there may be some

discontinuities between edges of different regions.

To determinate the threshold there are two methods:

consider it equal to the mean minus three standard

deviations or choose the threshold according to the

valley points and inflexion points of the histogram

(Sahoo et al., 1988).

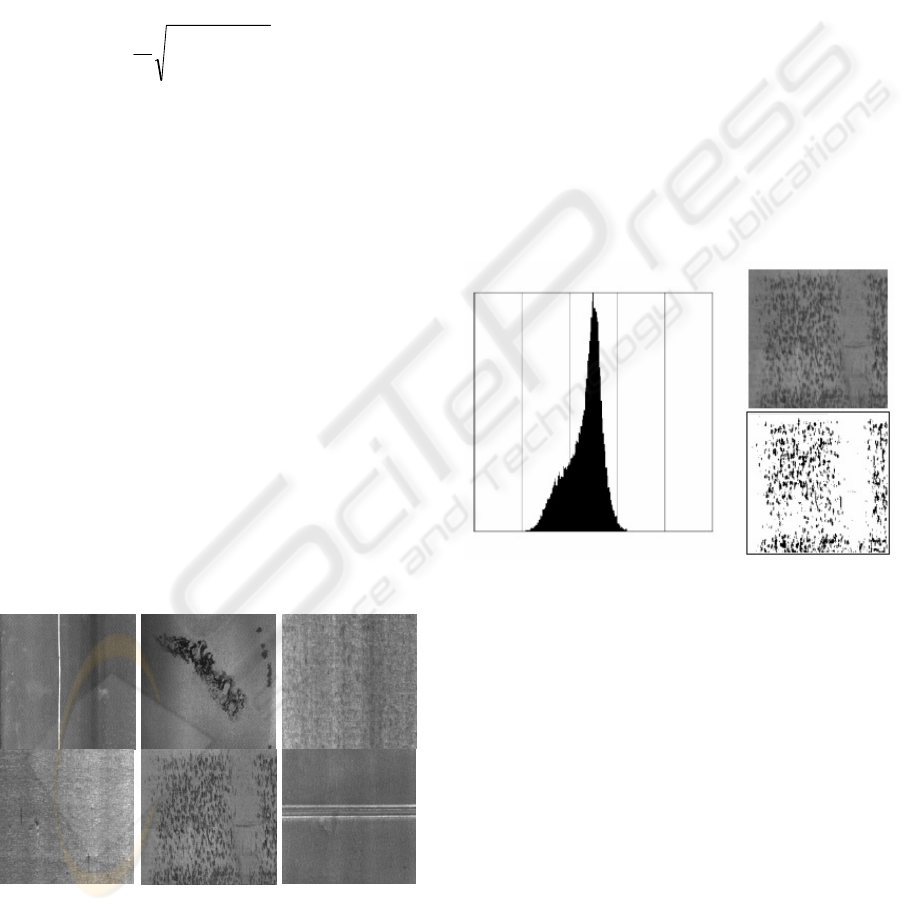

Many work suggested that it may be possible to

find better features, which are less sensitive to noise

and intensity variation, in the spatial-frequency

domain than those features extracted from the spatial

domain (Wechsler, 1980). Measures of the shape of

the spatial frequency spectrum such as location, size,

and orientation of peaks in regions of spatial

frequency using the 2D Fourier transform can be

used to design the textural features.

Figure 7: Fourier transform of a signal.

The Fourier methods characterise the spatial-

frequency distribution, but they do not consider the

information in the spatial domain. In the recent past,

Gabor filters have been well recognised as a joint

spatial/spatial-frequency representation for analysing

images containing highly specific frequency and

orientation characteristics. Daugman (Daugman,

2002) showed that Gabor filters have optimal joint

localisation in both the spatial and the spatial-

frequency domains. In addition, they are bandpass

filters, which are inspired by a multichannel filtering

theory for processing visual information in the early

stages of the human visual system (Beck et al.,

1986).

2.2 2D Gabor Filters Bank

A two-dimensional Gabor filter consists of a

sinusoidal wave modulated by a gaussian envelope.

It performs a localized and oriented frequency

analysis of a two-dimensional signal. The

formulation in the spatial domain is the following:

[

]

θθθθ

σσσπσ

π

σ

σϑσ

cossinsincos

2

1

exp

2

1

),(

2exp),(),(

2

2

,,

yxyyxxwith

yx

yxgwhere

xFjyxgyxG

yxyx

F

+−=

′

+=

′

⎥

⎥

⎦

⎤

⎢

⎢

⎣

⎡

⎟

⎟

⎟

⎠

⎞

⎜

⎜

⎜

⎝

⎛

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

′

+

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

′

−=

′

⋅

=

(1)

where F is the central frequency of the filter, θ is the

angle between the direction of the sinusoidal wave

and the x axis of the spatial domain, σ

x

and σ

y

the

standard deviations of the gaussian envelope

respectively in the direction of the wave and

orthogonal to it. These last two parameters

(sometimes referred to as the smoothing parameters)

represent the shape factor of the gaussian surface:

they determine the greater or less selectivity of the

filter in the spatial domain (Fig. 8). In the

above

formulation it is assumed that the angle between the

wave direction and the axis of the gaussian envelope

is zero

Figure 8: Real part, imaginary part, magnitude and phase

of Gabor filter in the spatial domain. F=0.09375; θ=0º;

σx=6; σy=10.

In frequency domain the Gabor filter can be written

as follows (Fig. 9):

()

θθθθ

πσ

σ

πσ

σ

σσ

θσ

cossinsincos

2

1

,

2

1

2

1

exp),(

2

2

2

2

,,

vuvyvuuwith

where

vFu

vuG

y

v

x

u

vu

F

+−=

′

+=

′

==

⎥

⎥

⎦

⎤

⎢

⎢

⎣

⎡

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

′

+

−

′

−

=

(2)

SURFACE DEFECTS DETECTION ON ROLLED STEEL STRIPS BY GABOR FILTERS

481

Figure 9: Real part, imaginary part, magnitude and phase

of Gabor filter in the frequency domain. F=0.09375; θ=0º;

σ

x

=6; σ

y

=10.

Gabor filters seem to have important relations

with the vision system of mammals. It has been

shown that the response of cortical simple cells

devoted to the processing of visual signal can be

approximated with Gabor functions (Daugman,

1985).

A defect detection procedure based on Gabor filters

is usually carried out through the following steps:

1. design of a filter bank with filters at different

frequencies and orientations;

2. computation of the transformed images;

3. extraction of a set of synthetic parameters

(features) from the transformed images

(definition of the feature space);

4. definition of a proper distance in the feature

space;

5. detection through a suitable pattern detection

algorithm.

The design of the filter bank consists in the

selection of a proper set of values for the filter

parameters: F, θ, σx and σy. The possible

combinations of the various parameters determine

how the filter bank analyses the spatial and

frequency domain. In frequency domain it is

common practice to display the zones covered by the

various filters by plotting the half-peak magnitude

iso-curves, as shown in the figure 10.

Figure 10: Half-peak iso-curve of the filter.

The design of a proper Gabor filter bank is a key

aspect of the problem, and it is also controversial.

Various authors proposed different values of the

parameters, based on mathematical and

physiological considerations. In order to simplify the

selection the Gabor filter bank, we made the

following assumptions: uniform separation in

orientation; constant ratio between the central

frequency of two adjacent filters:

•

the central frequency of the filter at the highest

frequency F

M

•

the total number of frequencies n

F

•

the total number of orientations n

O

•

the ratio between the central frequencies of two

adjacent filters k

F

• the value of the parameters σ

x

and σ

y

.

In general the highest central frequency of the

filter at the highest frequency is chosen such as that

the half-peak iso-curve of the filter reaches the value

of 0.5, which represents the Nyquist frequency.

Setting G(u,v) = 1/2 in (2), it gives the equation of

the half-peak magnitude iso-curve:

()

1

2ln

2

2ln

2

2

22

2

22

=

′

+−

′

vFu

y

x

σπ

σπ

(3)

This is an ellipse of semiaxes

yx

ba

πσπσ

2

2ln

2

2ln

==

(4)

The maximum frequency value reached by the

half-peak magnitude iso-curve of the filter at the

highest frequency (F

M

) is:

x

M

FF

πσ

2

2ln

max

+=

(5)

Setting F

max

= ½

x

x

M

F

πσ

πσ

2

2ln2−

=

(6)

The smoothing parameters, σ

x

and σ

y

, can be set

of such way that the half peak magnitude iso-curve

overlaps in greater or smaller measurement

modifying in (7) the parameters K

x

and K

y

, called

radial overlap and circumferencial overlap. Setting

this values to one makes adjacent filters touch each

other.

(

)

()

()

2tan2

2ln

122

122ln

ϑ

π

σ

π

σ

BF

K

F

K

yy

B

B

xx

F

F

=

−

+

=

(7)

being B

F

and B

θ

the frequency and orientation

bandwitch, in octaves and radians respectively. The

central frequency is affected by the value of σx, so

the central frequency must be calculated as in (8).

(

)

()()

()

1122

12

−++⋅

+

=

xx

B

B

x

M

KK

K

F

F

F

(8)

So, first of all, we must set the radial overlap

value and the frequency bandwitch, and then we

calculate de central frequency and smoothing

parameters.

To compute the transformed images we have

used the Convolution theorem, which says that the

Fourier transform of a convolution is the point-wise

product of Fourier transforms:

()

),(),(),(),(

1

vuGvuFyxgyxf

−

ℑ=⊗

(9)

VISAPP 2008 - International Conference on Computer Vision Theory and Applications

482

There are several features of the filter response

we could measure. We could use the real part, the

imaginary part, the magnitude or the phase. We have

chosen the magnitude because it contains more

information and it is more robust.

The detection method used is based on the

concept of distance, as a measure of closeness of

two points in the feature space. There several

methods to measure the distance. The type of

distance we adopted is called euclidean distance and

can be calculated as follows:

()

∑

=

−=

N

i

sirirs

xx

N

1

2

1

δ

(10)

x

r

and x

s

represent two generic points in the feature

space of dimension N.

2.3 Implementation

The main objective of defect detection is to

determinate if there is a defect inside an image. To

carry out this objective we have divide the images

into two groups: defected and non-defected images,

and evaluate the response of the filters.

The number of frequencies selected is eight and

the number of orientations is also eight, so the filter

bank is composed of 64 Gabor filters. We have

adopted the approach to design the filter such as the

half-peak magnitude iso-curves of adjacent filters

touch each other and these iso-curves reaches the

value 0,5 at the highest frequency. The size of then

filter is 256x256, so the images acquired must be

divided into pieces of the same size. The frequency

bandwidth selected is ½ octaves. The tests carried

out show us that these parameters reach the

compromise between selectivity and dispersion.

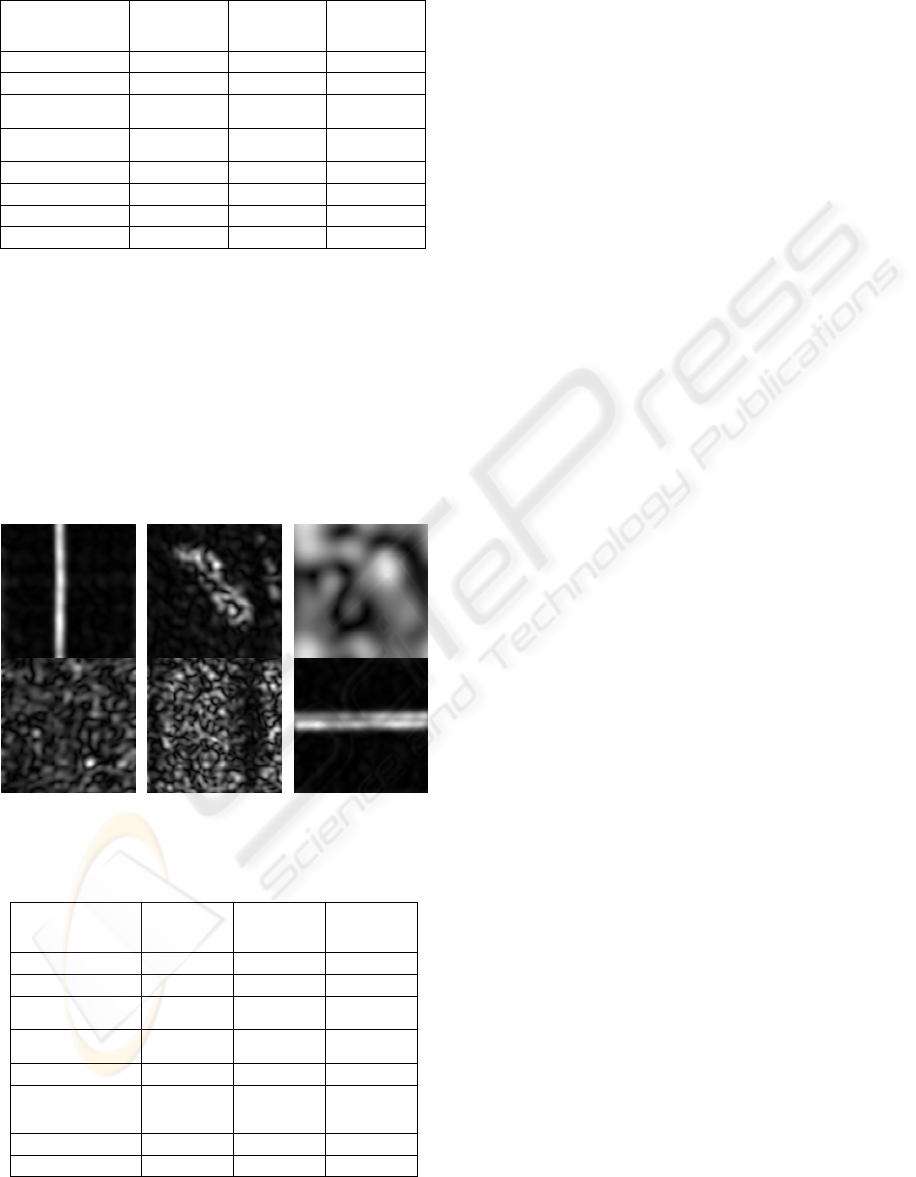

Figure 11: Defects types used in this paper.

In each image without defect we have calculated

the mean value response of each of the filters of the

bank. Then we have calculated the euclidean

distance between the mean value calculated and the

maximum value reached in every image use for

training. The defected images will have a higher

response to some filters in some part of the image

than the images without defects.

Establishing an appropriate limit between images

that contain defects and images with no defect we

can achieve our goal.

3 EXPERIMENTAL RESULTS

We have studied six types of the defects commonly

found in rolled steel: vertical scratch, rust, coat-less,

indents, settlement marks and weld (Fig. 11).

A total of 768 images were selected for training

and another 768 were used for testing. In both of the

groups half of the images contain a defect and in the

other half there was no defect. We have 64 images

of each type of defect resulting a total of 384 images

contain a defect in each group.

Figure 12: Segmentation based on the histogram for a

settlement mark defect.

The method used in segmentation of the images

is based in the idea that different objects or regions

in the image have significantly different grey levels.

Thresholds are usually determined from the grey-

level histogram of an image. We have search for two

thresholds, the upper and the lower, assuming that

the zone of the image with no defect has a medium

grey level. We have calculated the mean and

standard deviation of the number of pixel outside the

thresholds (Fig. 12).

SURFACE DEFECTS DETECTION ON ROLLED STEEL STRIPS BY GABOR FILTERS

483

Table 1: Mean and standard deviation of the percentage of

pixel outside the thresholds.

Mean

Standard

Deviation

Percentage

of detection

N

o defec

t

0.195165 0.081513 95.3125

D

efec

t

3.131472 2.639977 91.9270

Vertical scratch

2.340807

0.174513 97.6562

Rust

5.254671

4,546847

98.8281

Coat-less 0.264038 0.091215 78.5156

Indents 0.484261 0.146349 91,4062

Settlement marks 8.31251 2.541135 86.3281

Weld 2.132541 0.419870 98.8281

As we can see in the chart above (Table 1), there

are a 4.69 rate of false positives, and the defects are

correctly detected in 91.93%.

To improve the results obtained with the grey-

level histogram we have developed the Gabor filter.

Observing the response of the these filters for

training images (Fig.13), we have established the

limit that separate the defect images and the no

defect images. The test images have been used to

determinate the goodness of the method.

Figure 13: Some transformed images used in this paper.

Table 2: Mean and standard deviation of the euclidean

distance.

Mean

Standard

Deviation

Percentage

of detection

N

o defec

t

0.158103 0.035414 99.21875

D

efec

t

0.375900 0.101831 96.61458

Vertical scratch

0.395899

0.076832 97.6562

Rust

0.353493

0.130730 85.9375

Coat-less 0.264038 0.010007 98.82812

Indents 0.374794 0.046349

99.21875

Settlement marks 0.407765 0.068066 98.82812

Weld 0.459415 0.075339 99.21875

The measure of the distance can be observed in

the next chart (Table 2). We can see in this chart the

mean value and the standard deviation of the

euclidean distance between the mean value, obtained

with the training images without defect, and the

maximum value of then transformed image. In the

third column we can see the percentage of defect

detection obtained with the testing images. The first

two rows show the results for no-defect and defect

images. The rest of the rows show the results for

each type of defect studied.

We can see that we detect 96,61% of the defects,

obtaining only a 0,78% of false positives. The defect

of rust is the one that reaches the worst results,

obtained almost 86% of right detection. The rest of

defects are detected around 99%.

4 CONCLUSIONS

Quality control is a key process in steel flat products

manufacturing and processing. Coil slitting and

cutting is a paradigmatic process: often 200 meters a

minute process speed is reached, so than human

visual inspection is dramatically restricted.

We have developed an automated cellular visual

inspection system of flat products in a

flat steel

cutting factory (GONVARRI Burgos, Spain).

Among the approaches that the system uses to detect

defects, we have included the traditional methods

and two-dimensional Gabor filters.

The traditional methods based on the study of the

grey-level histogram and shape analysis, have shown

quite good results, but there are not good enough to

achieve the level of success required. It has been

necessary the implementation of new methods. The

application of Gabor filters seem to be a good

alternative to the traditional methods.

The results obtained in the detection of six of the

most common defects that appear over the surface of

the steel have reached a rate of 96,61% of right

detection, obtaining only a 0,78% of false positives.

ACKNOWLEDGEMENTS

This research is partially funded by GONVARRI

Group, the Spanish FIT-020400-2006-125 research

project, and the Agencia de Inversiones y Servicios

(ADE) of Castilla y León (Spain).

VISAPP 2008 - International Conference on Computer Vision Theory and Applications

484

REFERENCES

Beck, J., Sutter, A. and Ivry, R., 1987. Spatial frequency

channels and perceptual grouping in texture

segregation . Computer Vision. Graphics and Image

Processing. pp. 299–325.

Chin, R.T., 1992. Automated visual inspection algorihms.

In: Computer Vision: Theory and Insdustrial

Applications, Springer Verlag, New York, pp. 377-404.

Daugman, J.G., 1985. Uncertainty relation for resolution

in space, spatial frequency, and orientation optimized

by two-dimensional visual cortical filters, J. Opt. Soc.

Am., vol. 2, pp. 1160-1169.

Daugman, J.G., 2002. Gabor wavelets and statistical

pattern recognition. The Handbook of Brain Theory

and Neural Networks. 2nd ed.. MIT Press (M. Arbib.

editor). pp. 457-463.

Gayubo, F., González, J.L., de la Fuente, E., Miguel, F.,

and Perán, J.R., 2006. On-line machine vision system

for detect split defects in sheet-metal forming

processes. Conference on Pattern Recognition. ICPR

2006. vol. 1, pp. 723-726.

Gayubo F., González L.M., Olmedo D., Medina R. Goméz

J., González J.L. 2006. Inspección visual en línea de

defectos en piezas de chapa embutida. Proc. XVI

Congreso de Máquinas-Herramienta y Tecnologías de

Fabricación. vol. 1. pp. 715-728.

Hubel, D.H. and Wiesel, T.N., 1962. Receptive fields,

binocular interaction, and functional architecture in the

cat's visual cortex J Physiol. (Lond.), vol. 160, pp.

106-154.

Kamarainen, J.K., 2003. Feature extraction using Gabor

filters. PhD thesis.

Obeso, F., Gonzalez, J.A., Dominguez, S., Campoy, P. and

Mochon, J., 1997. Intelligent on-line surface

inspection on a skinpass mill. Iron and Steel Engineer.

Parker, J.R., 1997. Algorithms for Image Processing and

Computer Vision. Wiley Computer Publishing.

Phan, D.T. and Alcock, R.J., 2003. Smart Inspection

Systems. Techniques and applications if Intelligent

Vision. Ed. Academic Press.

Porat, M. and Zeevi, Y.Y., 1988. The generalized Gabor

scheme of image representation in biological and

machine vision. IEEE Transactions on Pattern

Analysis Machine Intelligence. pp. 452–468.

Ramana, K.V. and Ramamoorthy, B., 1996. Statistical

methods to compare the texture features of machined

surfaces. In: Pattern Recognition. pp. 1447–1459.

Sahoo P.K., Soltani S., Wong, A.K.C. and Chen Y.C.,

1988. A Survey of Threshonding Techniques.

Computer Vision, Graphics and Image Processing.

Vol. 41, pp. 233-260.

Tsai, D.M. and Wu, S.K., 2000. Automated Surface

Inspection Using Gabor Filters Int J Adv Manuf

Technol. pp. 474–482.

Wechsler, H., 1980. Texture analysis: a survey. Signal

Processing

. pp. 271–282.

SURFACE DEFECTS DETECTION ON ROLLED STEEL STRIPS BY GABOR FILTERS

485