NOVEL HAPTIC TOOL AND INPUT DEVICE FOR BILATERAL

BIOMANIPULATION ADDRESSING ENDOSCOPIC SURGERY

K. Houston, O. Tonet, C. Eder, A. Menciassi, P. Dario

CRIM Laboratory, Scuola Superiore Sant’Anna, Pisa, Italy

A. Sieber

Profactor Research & Solutions GmbH, Austria

Keywords: Microhandling, sensorised, microgripper, teleoperation, haptic, force feedback.

Abstract: In this paper a teleoperation system is presented which consists of a sensorised polymer microgripper as a

suitable end effector on an endoscopic microinstrument which is controlled by a novel tweezer-like haptic

input device. This tweezer device gives the operator the ability to remotely feel these forces generated by

grasping operations with the microgripper. This feedback is used to control the amount of force applied in

manipulation of tissues during the procedure. The mechanical and electronic design of the microgripper,

microinstrument and haptic tweezers is also presented and preliminary results detailed.

1 INTRODUCTION

Thanks to technological advances, an increasing

number of precision operations are nowadays

possible through key hole surgery interventions.

However, during key hole surgery sensory feedback

information is reduced, distorted or even absent,

which is the case of visual, force and tactile

information, respectively. These sensorimotor

limitations also reduce dexterity in manipulation

tasks. In this context, microengineering and

microrobotics can help providing the surgeons with

a new generation of smart instruments. Research

efforts have been devoted to restoration of haptic

(force and tactile) feedback (Kazi, A. et al, 2001).

Forces exerted during surgery and the role of haptic

perception have been investigated in many papers

(Sheridan, T.B. et al, 1992, Kitagawa, M et al).. In

traditional key hole surgery procedures, the

attenuated haptic sensation still plays an important

role (Bholat, O. S. et al, 1999), but it cannot be

further restored or enhanced. In the case of

mechatronic or robotic instruments, however, the

interaction forces and torques between instrument

and tissue can be measured and fed back to the

surgeons hand by means of actuators and dedicated

interfaces. Recent surgical instruments (Rosen, J. et

al, 1999, Tavakoli, M. et al, 2005) and telerobotic

systems used for research (Cavusoglu, M. C. et al,

2001, Mayer, H. et al, 2005) incorporating haptic

interfaces have been developed (Menciassi, A. et al,

2001, Menciassi, A., 2003). The telesurgery concept

has been enhanced and brought to a commercial

stage, e.g. da Vinci Surgical System by Intuitive

Surgical, Inc. (Guthart, G. S. et al, 2000), which

however does not yet incorporate force feedback.

There are also several authors which have

produced working prototype manipulation system

with force feedback tools (Howe, R.D. et al, 2006,

Pillarisetti, A. et al, 2006, Mitsuishi, M. et al, 2005)

Howe, R.D. et al, 2006, Pillarisetti, A. et al, 2006,

Mitsuishi, M. et al, 2005). This paper aims to present

an entire teleoperation system which consists of an

endoscopic tool with a microgripper end-effector

and a novel haptic force sensing tweezers which can

together give a remote force sensing ability during

key hole surgery procedures, for example in

laparoscopy or endoscopy . All of these new tools

are connected to a user interface with micro-

controller communication to dynamically display

microscopic video, gripper force values and also

modes to change the haptic behaviour of the tools in

real-time.

64

Houston K., Tonet O., Eder C., Menciassi A., Dario P. and Sieber A. (2008).

NOVEL HAPTIC TOOL AND INPUT DEVICE FOR BILATERAL BIOMANIPULATION ADDRESSING ENDOSCOPIC SURGERY.

In Proceedings of the First International Conference on Biomedical Electronics and Devices, pages 64-69

DOI: 10.5220/0001047100640069

Copyright

c

SciTePress

2 METHODS

2.1 Microgripper

The sensorised microgripper used as end-effector for

the endoscopic microinstrument is an SMA (shape

memory alloy) wire actuated polymer type and has

been detailed in previous work (Houston, K. et al,

2007). The SMA actuation principle is based on a

simple SMA wire applying a tensile force through

the centre of the symmetrical microgripper structure,

thus causing the tips of the device to move inward

(Figure 1). The advantages of this microgripper are

that it is robust, has a large gripper tip span, is made

primarily of polymer, and is low cost, as it can be

mass-fabricated by SDM (shaped deposition

manufacturing. The first polyurethane microgripper

prototype measures 22 mm length in total, with a

width of 6 mm. Figure 2 showing a FEMLAB 3.0

structural strain displacement simulation to verify

the design.

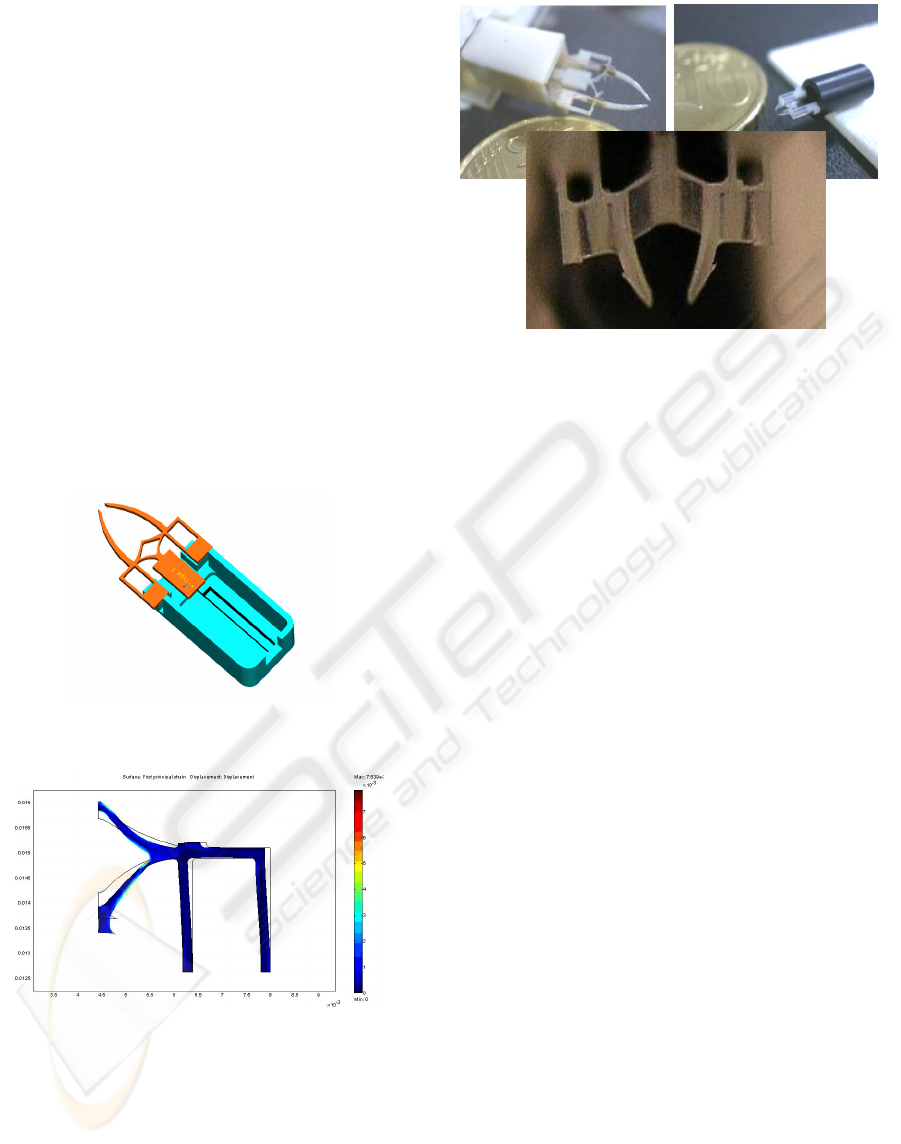

Figure1: SMA actuated microgripper.

Figure 2: FEMLAB strain due to SMA wire force.

As an added part of this work, a further miniaturised

SMA actuated microgripper shown in Figure 3

(right) was designed and fabricated using the same

techniques, Figure 3 (left) shows the first sensorised

prototype.

Figure 3: First gripper prototype (top left) and

miniaturized version (top right, bottom).

To name a few advantages of the smaller

microgripper, this device is less than half the total

length of the first prototype (11 mm), half the width

(3 mm), has a gripper tip maximum span of 500 μm

and requires a lower operating power. Figure 8

shows a design of the device attached to the

endoscopic tool. The microgripper itself is fabricated

by the SDM process which has been implemented

and detailed in many previous works with success

(Eisinberg, A. et al, 2005). The four micro strain

gauges are embedded in the microgripper at the

points of maximum structural strain. In one version,

all eight micro strain gauge wires and two SMA

power supply wires are embedded in the polymer

microgripper housing for robustness and a silicone

membrane covers the opening of the actuator

housing where the SMA wire connects with the

moving microgripper structure. This allows the

device to be used in fluid environments. Figure 4

shows another version where the moulded gripper

structure is mounted on a glass substrate with a

copper/polyamide flexible electrical connector. This

allows all 8 strain gauge connections to be

accessible inside the housing- in practical terms this

means that there are no fragile wires coming from

the microgripper, and makes the gripper assembly

more modular and robust. There is then also the

possibility of integrating electronics onto the

substrate.

NOVEL HAPTIC TOOL AND INPUT DEVICE FOR BILATERAL BIOMANIPULATION ADDRESSING

ENDOSCOPIC SURGERY

65

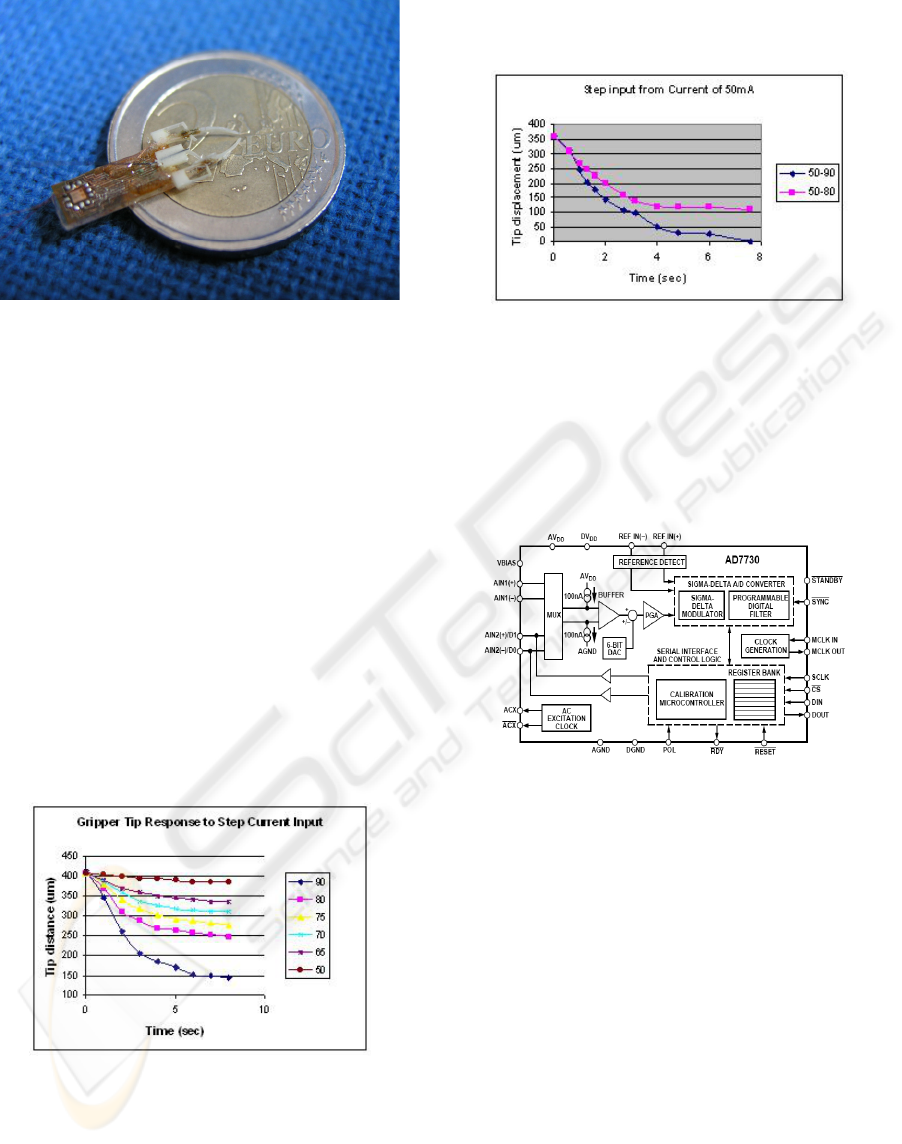

Figure 4: Modular design of the gripper structure on glass

substrate with flexible circuit.

The microgripper requires a current of 70 mA for

total tip closure. A step current input applied to the

SMA actuator demonstrates the dynamic behaviour

of the device (step response plotted for six current

steps from 40 to 90 mA) in Figure 5. The calculated

time constant is 8 seconds, while although quite high

is normal for SMA mechanisms. In order to decrease

the time constant and thus the speed of grasping, a

preheating control strategy was used which

maintained the SMA wire heated with a current of

40 mA; this was below the actuation current of the

wire. In order to actuate the gripper, the current was

then increased above 40 mA, and this makes the

actuator more responsive. Using this strategy, the

time constant was reduces to 2 s, a substantial

improvement in the dynamic response of the

microgripper. Figure 6 shows the improvement in tip

displacement of the microgripper against time.

Figure 5: Response of SMA microgripper to step current

input.

The signal of the strain gages in the microgripper is

sampled with an Analog Devices AD 7730 analog to

digital converter as shown in Figure 7. Offering a

programmable input stage (±80 mV to ± 10 mV) and

24 bit resolution this device is suitable for

bridge/transducer applications.

Figure 6: Improved response of SMA microgripper due to

preheating.

Further signal processing is then done by a separate

Atmel microcontroller (ATMEGA8) connected via

USB to PC. The software for the microcontroller is

programmed in C++, while the visualisation of the

data is performed under National Instruments

LabView.

Figure 7: AD7730 strain gauge signal processing circuit.

2.2 Endoscopic Device

The microgripper is mounted on the tip of the

endoscopic device (Figure 8), which can be bent in

two degrees of freedom up to ±90˚. Bending of the

tip is performed by pulling on steering wires. The

principle of the mechanism is described in detail in

(Harada, K. et al, 2005). For precise actuation of the

4 steering wires two high precision servo drives with

a theoretical resolution of 13 bit are used. The tube

is made of hard Delrin plastic, machined using

traditional turning techniques, while the rolling

spheres are of polyurethane, procured from off-the-

shelf stock. The smaller micro parts for passage of

wires and location of the spheres were machining

using a precision CNC milling machine. The all-

plastic assembly is finished with the controlling

wires which can be any type of strong wire-for the

prototype, a fishing line wire was used .

BIODEVICES 2008 - International Conference on Biomedical Electronics and Devices

66

Figure 8: CAD drawing of the endoscopic instrument with

the gripper as end-effector.

2.3 Interfacing the Heptic Input Device

In the lower arm of the tweezers like input device

two strain gauges are integrated to allow a force

measurement, as shown in Figure 9. The signal of

these two strain gauges is processed in a half

Wheatstone bridge configuration and then amplified

by a factor of 100. To digitize the signal the first

channel AD0 of the Atmel ATMEGA8

microcontroller is used. Analogue channel 1 is used

to acquire the signal of the potentiometer integrated

in the Servo (Graupner 381) giving real feedback of

the position of the servo. One digital output is used

to drive the Servo with pulses in the length of 1 to

2 ms with a resolution of 0,5 µs. Figure 12 shows

the haptic tweezers being used in a

micromanipulation task with force feedback. Figure

10 shows the actual haptic tweezers prototype in the

users hand.

Figure 11 show the flow diagram for the haptic

tweezers in active mode. The AD7730 ADC is

continuously updating the microgripper tip force. As

this is happening, the ATMEL ADC is updating the

strain gauge voltage which relates to the actual

haptic tweezer force that the user perceives. The

microcontroller then compares the perceived and

actual forces and updates the new haptic tweezer

servo value to reflect the force changes, if any.

R10

10k

Servo

R11

10k

R12

10k

R13

10k

0

Atmel ATMEGA8

Dout0

Ain1

Ain 0

+5V

A

Figure 9: Haptic tweezers circuit.

Figure 10: Hepatic tweezers in users hand.

Thus in real life, when one grasps a pair of tweezers,

as the tips close, the force perceives on the finger

tips increases linearly. This is exactly how the haptic

tweezers behaves, in that when the user picks up the

tweezers, there is initially no movement.

Figure 11: Force feedback flow diagram.

When the user then applies a force with the finger

tips to close the tweezer tips, the strain gauge on the

device detects this force and activates the servo

motor-the position of the servo is always such as to

follow the finger tips of the user, while all the time

giving the sensation of a natural spring.

In the active mode (when there is an actual force

on the tips of the microgripper tool), the scheme in

Figure 11 is followed: the difference between the

force on the microgripper tips and the force

perceived by the user is used to update the haptic

tweezer servo value-this is done continuously.

Microgripper

force value (actual

force at microgripper

Haptic Tweezer strain

value (force that user perceives)

Update servo to

continue feedback force

Calculate new tweezer

servo value

NOVEL HAPTIC TOOL AND INPUT DEVICE FOR BILATERAL BIOMANIPULATION ADDRESSING

ENDOSCOPIC SURGERY

67

Figure 12: Haptic tweezers being used for

micromanipulation task with force feedback under

microscope.

2.4 Software

The current, and thus the actual position of the

microgripper, is set according to the actual position

of the control device. The feedback parameter is the

force sensed by the microgripper. This parameter

together with the position of the actuator and the

signal of the strain gauges integrated in the lower

arm of the device are used to drive the input devices

actuator (PID control). Figure 13 shows the software

flow scheme for the system.

Figure 13: Software scheme.

be used for surgical or biomanipulation task in a

haptic environment. At 3 mm in diameter, the tool is

suitable for keyhole surgery and can achieve ±90

degrees rotations around both axes.

The prototype sensorised microgripper has a tip

distance of 500-800 µm, and can be set to any

distance in the assembly process. The maximum tip

force is approximately 1 mN. The tip of the

sensorised microgripper is a flat edge of 100 µm,

however this geometry can be tailored in the design

of the mould according to the task. The tool length is

22 mm and is 6 mm wide.

Figure 14: Prototype haptic biomanipulation tool.

The smaller microgripper has a smaller tip distance

of 400 µm and again can be set during assembly.

The diameter is 3 mm, the tip has a right angled

point edge which is useful for precision grasping of

small particle without minimisation of adhesive

forces.

The prototype haptic tweezers has the

dimensions of a normal off-the-shelf pair of plastic

tweezers used in a medical lab (length of approx.

150 mm, width can be set by software, but as with a

normal pair of tweezers, a maximum tip distance of

approx. 40 mm is optimum). This prototype has a

working tweezer angle of 90 degrees, however only

about 20 degrees of movement is necessary to

simulate a pair of tweezers-a larger angle is not very

comfortable for the fingers when used for long

periods. Because the servo is a 13 bit model of high

resolution, the 20 degree angle sweep of opening

and closing the tweezers has a resolution of over 40

increments per degree, giving a very smooth

movement with no vibrations. The position of the

tweezer tips is updated at a frequency of 50 Hz. The

maximum torque of the input device is approx.

190 g/cm and the device is designed so that one arm

of the tweezers will snap off easily before the

maximum torque is reached.

3 CONCLUSIONS

Nowadays robot aided key hole surgery and

teleoperated surgical techniques lack devices able to

provide haptic feedback to the surgeon, particularly

in the small scale. This paper presented a new

teleoperation system with a novel endoscopic tool,

force sensing microgripper and haptic tweezers

which allows the surgeon to feel the gripping force

at the tip of a microgripper instrument, even if as in

the case of teleoperated surgery, they are miles

away.

BIODEVICES 2008 - International Conference on Biomedical Electronics and Devices

68

The authors are convinced that these first

promising results are one step closer to a new era of

surgical instruments giving "reality-like feelings" in

endoscopic and teleoperated surgery.

ACKNOWLEDGEMENTS

The work described in this paper was supported by

the ASSEMIC project, a Marie Curie Research &

Training Network (MRTN-CT- 2003-504826) and

PROFACTOR Research and Solutions GmbH –

Austria. A special mention to Mr. C. Filippeschi for

his continuous and invaluable help.

REFERENCES

Bholat, O. S. , Haluck, R. S., Murray, W. B., Gorman, P.

J. and Krummel, T. M., 1999, “Tactile feedback is

present during minimally invasive surgery”, J Am

Coll Surg,, 189(4):349–55.

Cavusoglu, M. C., Williams, W., Tendick, F. and Sastry,

S.S., 2001 “Robotics for telesurgery: second

generation Berkeley/UCSF laparoscopic telesurgical

workstation and looking towards the future

applications” In Proceedings of .the 39th Allerton

Conference of Communication, Control and

Computing.

Guthart, G. S. and Salisbury, J. K., 2000 “The Intuitive

TM

telesurgery system: overview and application”, in

Proceedings of ICRA 2000, pages 618–621, DaVinci.

Wagner,C.R., Perrin,D.P., Howe,R.D., “Force Feedback

in a Three-Dimensional Ultrasound-Guided Surgical

Task”, Symposium on Haptic Interfaces for Virtual

Environment and Teleoperator Systems 2006, March

25 - 26, Alexandria, Virginia, USA

Pillarisetti,A.,Pekarev,M., Brooks,A.D., Desai, J.P.,

“Evaluating the Role of Force Feedback for

Biomanipulation Tasks” Symposium on Haptic

Interfaces for Virtual Environment and Teleoperator

Systems 2006 March 25 - 26, Alexandria, Virginia,

USA

Pitakwatchara,P., Warisawa,S.,Mitsuishi, M., “Force

Feedback Augmentation Modes in the Laparoscopic

Minimal Invasive Telesurgical System” Aug. 2007,

IEEE /ASME Transactions on Mechatronics Volume:

12, Issue: 4, pages: 447-454

Kazi, A., 2001, “Operator performance in surgical

telemanipulation. Presence”, 10:495– 510.

Kitagawa, M., Okamura, A.M., Bethea, B.T., Gott, V.L.,

and Baumgartner, A.A., “Analysis of suture

manipulation forces for teleoperation with force

feedback”, /Lect. Not. Comp. Sci./, vol. 2488, pp.

155–162.

Mayer, H., N´agy, I., Knoll, A., Schirmbeck E. U., and

Bauernschmitt, R., 2005 “An experimental system for

robotic heart surgery” in IEEE 18th International

Symposium on Computer-Based Medical Systems

(CBMS), Dublin, Ireland.

Menciassi, A., Eisinberg, A., Carrozza, M.C. and Dario.

P., 2003, “Force sensing microinstrument for

measuring tissue properties and pulse in

microsurgery”, IEEE/ASME Transactions on

Mechatronics, 8(1):10–17.

Menciassi, A., Eisinberg, A., Scalari, G., Anticoli, C.,

Carrozza,M.C. and Dario, P., 2001 ,“Force feedback-

based microinstrument for measuring tissue properties

and pulse in microsurgery”, in Proc. IEEE

International Conference on Robotics and Automation

(ICRA).

Rosen, J., Hannaford, B., MacFarlane, M., and Sinanan,

M., 1999 “Force controlled and teleoperated

endoscopic grasper for minimally invasive surgery –

experimental performance evaluation”, IEEE

Transactions on Biomedical Engineering,

46(10):1212–1221.

Sheridan, T.B., 1992, “Telerobotics, automation and

human supervisory control”, MIT Press, Cambridge,

MA, USA.

Tavakoli, M., Patel, R.V. and Moallem, M. , 2005 ,

“Haptic interaction in robot-assisted endoscopic

surgery: a sensorized end-effector”, International

Journal of Medical Robotics and Computer Assisted

Surgery, 1(2):53–63.

Houston, K., Eder, C., Sieber, A., Menciassi, A. Carrozza,

M. C., Dario, P., 2007 “Polymer sensorised

microgrippers using SMA actuation”, ICRA 2007.

Eisinberg, A., Izzo, I., Menciassi, A. Houston, K. ,

Valdastri, P., Dario, P., Gustafsson., R., Simu, U.,

Johansson S., 2005 , “Design and shape deposition

manufacturing (SDM) fabrication of a PZT-actuated

tool for micromanipulation”, Computational

Intelligence in Robotics and Automation, CIRA 2005.

Harada, K., Tsubouchi, K., Fujie, M. G., Chiba, T., 2005,

“Micro Manipulators for Intrauterine Fetal Surgery in

an Open MRI”, Proceedings of the 2005 IEEE

International Conference on Robotics and Automation

Barcelona, Spain.

NOVEL HAPTIC TOOL AND INPUT DEVICE FOR BILATERAL BIOMANIPULATION ADDRESSING

ENDOSCOPIC SURGERY

69