CAPILLARY ELECTROPHORESIS ELECTROCHEMICAL

DETECTOR WITH NOBLE MICROCHANNEL STRUCTURE

FOR MINIATURIZATION

Development of a Capillary Electrophoresis Microchip Format Electrochemical

Detector for Endocrine Disruptors Sensing

Kon Ha

1*

, Gi-sung Joo

2

, Grace Nisola

3

, Wook-Jin Chung

3

, C. J. Kang

1

and Yong-Sang Kim

1,2

1

Dept. of Nano Science and Engineering, Myongji University, Gyeonggi 449-728, Korea

2

Dept. of Electrical Engineering, Myongji University, Gyeonggi 449-728, Korea

3

Dept. of Environmental Engineering and Biotechnology, Myongji University, Gyeonggi 449-728, Korea

Keywords: Capillary electrophoresis, Electrochemical detector, Lab-On-a-Chip, Miniaturization, Endocrine disruptors,

PDMS, ITO, bisphenol A (BPA).

Abstract: Numerous researches have been focused on capillar

y electrophoresis (CE) and amperometric detection

(AD) using a double-T micro-channel configuration. The combination of these two techniques becomes a

powerful analytical tool due to enhanced features in terms of sensitivity and selectivity. The developed CE-

AD chip is low cost and requires less power consumption. Its high compatibility with micro-fabrication

technology has made it popular for analysis of different compounds. However, due to the need to further

miniaturize the CE-AD device, a twisted CE micro-channel configuration is fabricated and tested in this

study. Furthermore, enhanced analyte separation due to delayed response time can be achieved using a

serpentine CE separation micro-channel. Phenolic compounds were used as testing analytes to confirm the

results using different types of running buffers. Also, the data gathered from the new micro-channel

configuration is compared with the previously gathered results obtained from double-T separation micro-

channels.

1 INTRODUCTION

Established analytical methods require sophisticated

equipment in order to obtain accurate and reliable

results. However, available apparatuses are bulky,

expensive and require sample pre-treatment steps in

order to minimize interferences. In lieu of these

conventional techniques, the micro-scale lab-on-a-

chip (LOC) devices could provide better

performances and other benefits. One in particular is

analytical cost reduction due to LOC cheaper

production, lower reagent volume requirement and

shorter analytical time. Though micro-fabrication

has become successful to miniaturize capillary

electrophoresis amperometric detector (CE-AD)

LOC devices, numerous problems are yet to be

solved. One of the common predicaments is the poor

selectivity of the detector which is related to the

unsatisfactory separation at the CE component.

Double T configuration has been commonly used in

CE microchannels. However, the effective length of

a CE microchannel may not be sufficient to

complete the separation process or may require

longer channel in order to attain an effective

separation, which defies the goal of miniaturization.

Other ways include proper tuning of separation

fields in order to provide an appropriate migration

time for different analytes in the sample but this

technique could not aid in further miniaturization of

the device. Changing the microchannel

configuration is another way to resolve separation

problem. In this study, a twisted or serpentine CE

microchannel configuration is investigated. An LOC

device is fabricated with twisted microchannels with

equivalent length of the previously reported double

T configuration. In a twisted configuration, the size

of the device can be further reduced. The influence

of the separation field is much less at curved channel

regions hence it is expected to have a more effective

separation as it slightly increases migration time of

different analytes. Interest in the use of polymeric

materials such as poly-dimethylsilioxane (PDMS)

130

Ha K., Joo G., Nisola G., Chung W., J. Kang C. and Kim Y. (2008).

CAPILLARY ELECTROPHORESIS ELECTROCHEMICAL DETECTOR WITH NOBLE MICROCHANNEL STRUCTURE FOR MINIATURIZATION -

Development of a Capillary Electrophoresis Microchip Format Electrochemical Detector for Endocrine Disruptors Sensing.

In Proceedings of the First International Conference on Biomedical Electronics and Devices, pages 130-133

DOI: 10.5220/0001046901300133

Copyright

c

SciTePress

and poly-methylmethacrylate (PMMA) has

increased over the past few years. PDMS has been

widely discussed due to good optical transparency

for detection, to cure at low temperatures, easily

replicates molding and good adhesion. Many PDMS

applications in CE microchip and microfluidic

channel design have been reported. This study

utilized PDMS as a substrate for formulating the

twisted CE microchannel for CE-AD microchip

device. As previously reported, a 3-microelectrode

system was fabricated on a glass substrate using bare

indium tin oxide (ITO) and Prussian blue (PB) as

catalyst on the working electrode.

2 EXPERIMENTAL

2.1 Materials and Chemicals

The chemicals used for PB electroplating solution

were composed of ferric chloride hexahydrate

(97%), potassium ferricyanide (99%), potassium

chloride, and hydrochloride acid (32%). The testing

analyte bisphenol A (BPA) was supplied by Wako.

All of which were diluted to get the desired

concentrations. Reagents used for microchannels

include Sylgard 184 PDMS from Dow Corning

Corp. (Midland, MI, USA). In order to mold PDMS

microchannels, negative photoresist SU-8 and XP

SU-8 developer from MicroChem Company were

used. Throughout the study, deionized water (DIW)

was used.

2.2 Microchip Fabrication

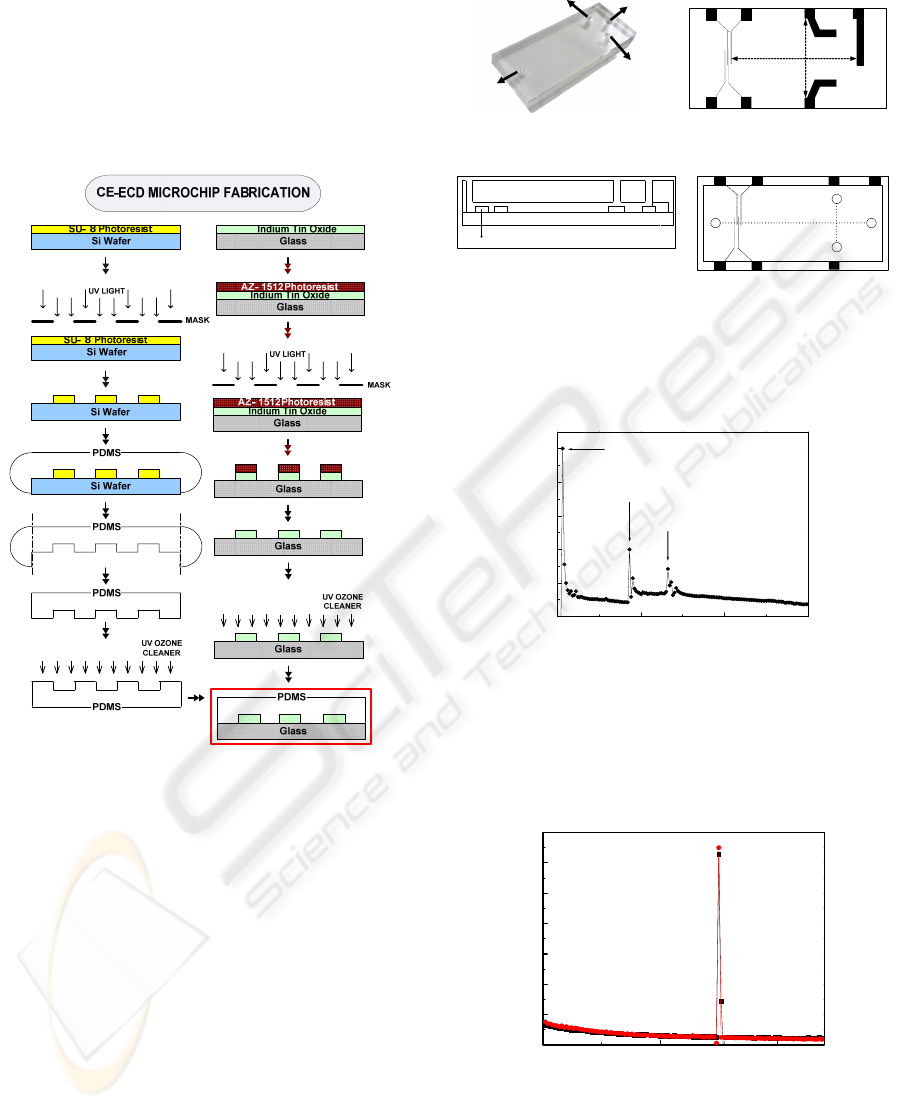

Figure 1 shows the simple process flow diagram for

the fabrication of the CE/ECD microchip. For the

electrodes in CE/ECD system, the ITO layer was

deposited on a glass substrate by R.F. magnetron

sputtering system. The thickness of the ITO film is

3400 Å. The 1.8 µm thick photoresist (AZ1512) was

spin-coated on the ITO-coated glass and patterned

for ITO electrodes. The sputter deposited ITO layer

was etched with FeCl

3

/HCl solution. In order to

avoid the interference of a high electric field with

EC detection, one decoupling-ground electrode as

the cathode of CE electric field was positioned in

front of the three-electrode electrochemical system.

The PB film was electrodeposited on the working

electrode. Electroplating solution is consisted of 20

mM FeCl3, 20 mM K

3

[Fe(CN)

6

], 0.2 M KCl and 0.1

M HCl. All the PB electrode surfaces were cleaned

with acetone and dried with N

2

gas. In order to

fabricate microchannels, 40 µm thick photoresist

(SU-8) was spin-coated and patterned on the silicon

wafer. The height of the positive patterns on the

moulding masters, which is equal to the channels

depth created on the PDMS layer, was 40 µm when

measured with a surface profiler. The PDMS layers

were fabricated by pouring a degassed mixture of

Sylgard 184 silicone elastomer and curing agent

(10:1) onto a molding master, followed by curing for

at least 1 hour at 72 °C. The cured PDMS was

separated from the mold, and reservoirs were made

at the end of each channel using a 3 mm circular

punch. The channel width is 80 µm. The double-T

injector channel had an offset of 170 µm with 5 cm

long separation channels and 1 cm long injection

channel. Also, the channel width is 80 µm. The

twisted injector channel had an offset of 170 µm

with 7 cm long separation channels and 1 cm long

injection channel. Before bonding the PDMS layer

to ITO-coated glass substrate containing the

electrodes, the two components were UV-Ozone

exposed to improve their bonding strengths.

2.3 Microchip Configuration

The microchip consists of four reservoirs and micro-

channels from PDMS (Fig. 2(a)), three electrodes

and electrodes for applying injection / separation

electric field on the glass substrate (Fig. 2(b)). The

width of the working electrode (W) is 100 µm, 50

µm for reference electrode (R) and 200 µm counter

electrode (C). In order to lower noise level, the

working electrode is surrounded by the reference

electrode.

2.4 CE/ECD Procedure

Each microchannel was preconditioned prior to use.

Acetone solution was flushed through the

microchannel for about 40 min to clean the

microchannels. Next, DIW and buffer solution were

flushed through the capillary for an hour

respectively. The running buffer solution was 10

mM 2-(N- morpholino) ethanesulfonic acid (MES)

fixed to pH 6.5 using 10 N NaOH. After

preconditioned, the entire microchannels would be

full of buffer solution. For CE process, no bubbles in

the capillary were permitted. The testing analytes

were injected by applying electric field of + 50 V/cm

from sample reservoir to sample waste reservoir.

With this process, the testing analytes are placed at

the head of the separation channel after about 7 sec

and buffer solution is still inside the microchannels.

Separation of the analytes was performed by

applying electric field of + 60 V/cm between buffer

CAPILLARY ELECTROPHORESIS ELECTROCHEMICAL DETECTOR WITH NOBLE MICROCHANNEL

STRUCTURE FOR MINIATURIZATION - Development of a Capillary Electrophoresis Microchip Format

Electrochemical Detector for Endocrine Disruptors Sensing

131

and detection reservoir. Amperometric detection was

performed in a three-electrode configuration. The

potential between working and reference electrode

was +700 mV DC in case of ECD for PB/ITO

electrode and +600 mV DC for bare ITO and Au

electrodes. When redox reaction between electrodes

and testing analytes happened, peak currents were

detected, recorded and stored directly on a computer.

Figure 1: Process flow for the fabrication of the CE/ECD

microchip.

3 RESULTS AND DISCUSSION

BPA was used to demonstrate the performance of

CE-AD microchip. Measurements were repeated for

several times. Figure 3 shows electropherogram of 1

mM BPA and butylphenol mixture by PB/ITO

electrode using double-T channel. Figure 4 shows

electropherogram of 1 mM BPA by PB/ITO

electrode using twisted channel. Especially figure 4

shows reproducibility of BPA detection. At the same

flow rates, the transport of ionic species to the

working electrode by double-T channel is slightly

faster than the twisted channel. Due to the curved

corners in twisted channels, the ionic transport rate

is slightly decreased. These zones are generally not

Sample Waste

Reservoir

Buffer

Reservoir

Sample

Reservoir

Detection

(a) (b)

(c) (d)

Figure 2: Configuration of (a) PDMS molding containing

microchannels and reservoirs and (b) electrodes on the

glass substrate. (c) Microchip side view and (d) Microchip

top view.

0 50 100 150

0

200

400

600

800

1000

Switching Peak

1 mM Butylphenol (64 sec, 146 nA)

1 mM Bisphenol A (41 sec, 315 nA)

Current (nA)

Time (sec)

Figure 3: Electropherogram of ECD using double-T

channel. Analytes are 1 mM BPA and 1 mM butylphenol

mixture. (PB/ITO electrode); Condition: Separation

voltage, 300 V; injection time, 7 sec; injection voltage, 60

V; detection voltage, 0.7 V

0 50 100

0

50

100

150

200

250

300

350

1 mM Bisphenol A (76 sec, 320 nA)

1 mM Bisphenol A (76 sec, 327 nA)

Current (nA)

Time (sec)

Figure 4: Electropherogram of ECD using twisted channel.

Analytes are 1 mM BPA. (PB/ITO electrode); Condition:

Separation voltage, 300 V; injection time, 7 sec; injection

voltage, 60 V; detection voltage, 0.7 V.

Reservoir

Sample Waste

Reservoir

Buffer

Reservoir

Sample

Reservoir

Detection

ervoir

R

C

W

Separation

E-field

Injection

E-

field

Res

C W

R

S

S

I

I

GLASS

ITO

PDMS

MICROCHANNEL

BIODEVICES 2008 - International Conference on Biomedical Electronics and Devices

132

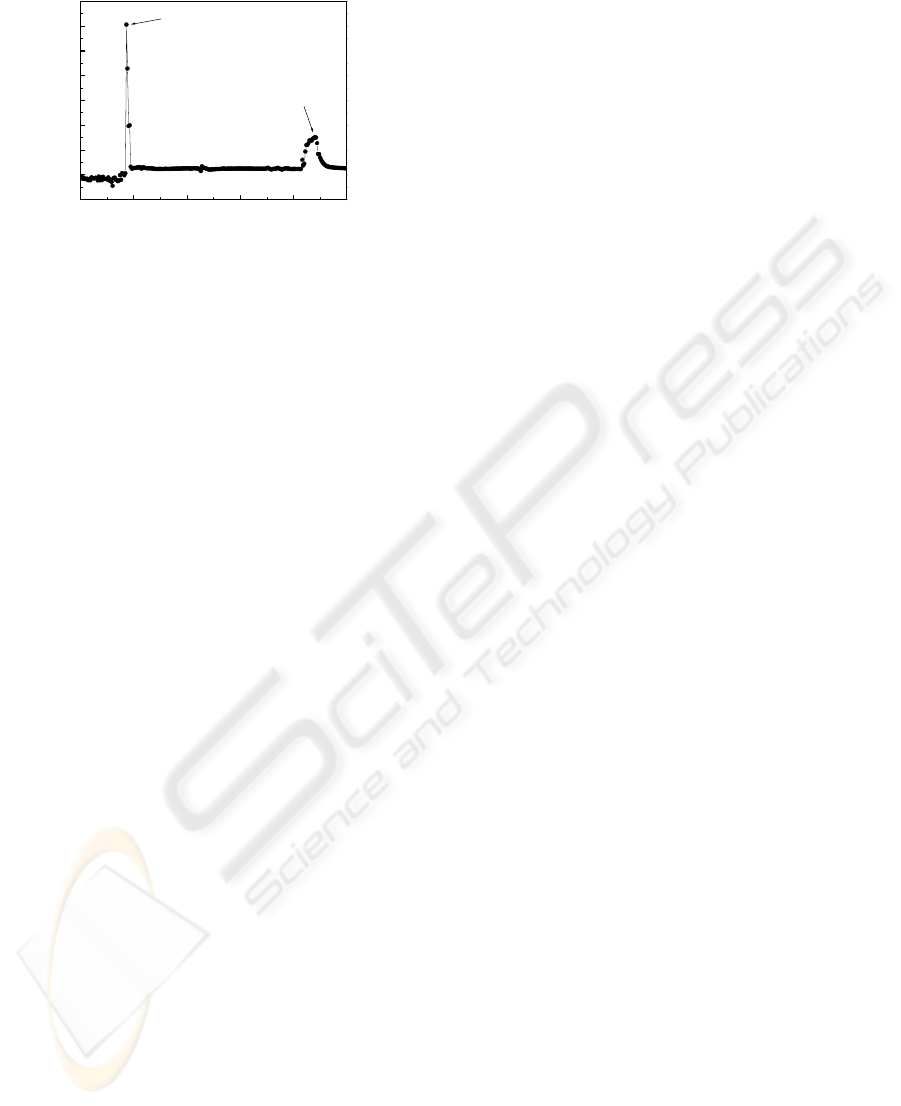

0 50 100 150 200 250

-100

0

100

200

300

400

500

600

700

1 mM Bisphenol A (208 sec, 130 nA)

Swiching Peak

Current (nA)

Time (sec)

Figure 5: Electropherogram of ECD using sodium-borate

buffer (pH 8.5). Analytes are 1 mM BPA. (bare ITO

electrode); Condition: Separation voltage, 300 V; injection

time, 40 sec; injection voltage, 60 V; detection voltage,

0.6 V.

affected by the separation electric field. The new

CE-AD chip is a fused PDMS-glass substrate. With

the CE-AD chip using twisted channel, 1 mM BPA

was detected. Results revealed that twisted channels

are effective to further miniaturize the exiting

double-T channel CE-AD chip; it also has a more

distinguished selectivity or analyte separation. After

a sample injection, the EC detector current rapidly

reached its steady-state background level with the

pH 6.5 buffer solutions and the BPA was easily

separated. The flat baseline and low noise level

indicate an effective isolation from the driving

voltage. Figure 5 show electropherogram of 1 mM

BPA by bare ITO electrode using sodium-borate

buffer. CE-AD using basic buffer is slower to flow

than CE-AD using acid buffer. Even if working

electrode is different, amperometric detector has

same channel structure.

4 CONCLUSIONS

The performance of our CE-AD microchip using

twisted channel was compared with those of

conventional CE-AD microchip using double-T

channel. Moreover, our device has several benefits

such as fast separation, high sensitivity, and simple

fabrication, which makes our CE-AD microchip a

good candidate to substitute the conventional CE-

AD devices. Our results demonstrate that twisted

channel is an effective technique to further reduce

the size of the current CE-AD LOC devices.

ACKNOWLEDGEMENTS

This work was supported by grant No. ROA-2006-

000-10274-0 from the National Research Laboratory

Program of the Korea Science & Engineering

Foundation.

REFERENCES

Y. Watabe, K. Hosoya, N. Tanaka, T. Kondo, H. Imai, M.

Morita, 2003. “ng/l Level of BPA Determination

Existing in Natural Water with HPLC-Electrochemical

Detection”, Japan analyst, Vol. 52, pp. 1167-1172

A. D'Antuono, V. C. Dall'Orto, A. L. Balbo, S. Sobral, I.

Rezzano, 2001. “Determination of Bisphenol A in

Food-Simulating Liquids Using LCED with a

Chemically Modified Electrode”, Journal of

agricultural and food chemistry, Vol. 49, pp. 1098-

1101

J. H. Kim, C. J. Kang and Y. S. Kim, 2004. “A disposable

polydimethylsiloxane-based diffuser micropump

actuated by piezoelectric-disc”, Microelectronic

Engineering, Vol. 71, pp. 119-124

J. H. Kim, C. J. Kang and Y. S. Kim, 2004. “A disposable

thermopneumatic-actuated microvalve stacked with

PDMS layers and ITO-coated glass”, Microelectronic

engineering, Vol. 73/74, pp. 864-869

R. S. Martin, A. J. Gawron, S. M. Lunte, C. S. Henry,

2000. “Dual-Electrode Electrochemical Detection for

Poly(dimethylsiloxane)-Fabricated Capillary

Electrophoresis Microchips”, Anal.Chem. Vol. 72, pp.

3196–3202

A. J. Gawron, R. S. Martin, S. M. Lunte, 2001.

“Fabrication and evaluation of a carbon-based dual-

electrode detector for poly(dimethylsiloxane)

electrophoresis chips”, Electrophoresis, Vol. 22 , pp.

242-248

J. Wang, M. P. Chatrathi, B. Tian, 2001.

“Microseparation Chips for Performing ultienzymatic

Dehydrogenase/Oxidase Assays: Simultaneous

lectrochemical Measurement of Ethanol and Glucose”,

Anal. Chem., Vol. 73, pp. 1296-1300

CAPILLARY ELECTROPHORESIS ELECTROCHEMICAL DETECTOR WITH NOBLE MICROCHANNEL

STRUCTURE FOR MINIATURIZATION - Development of a Capillary Electrophoresis Microchip Format

Electrochemical Detector for Endocrine Disruptors Sensing

133