Antecedents to RFID Adoption:

Perspectives of Retail Supply Chain Stakeholders

Stephen Waters

1

and Shams Rahman

2

1

School of Management, University of Western Sydney, NSW, Australia

2

School of Management, RMIT University, VIC, Australia

Abstract. This paper examines factors antecedent to the adoption of Radio

Frequency Identification (RFID) from the perspectives of three key retail

supply chain stakeholders: retailers, retailer suppliers, and technology providers

and develops a conceptual framework to explore the impact of RFID on retail

supply chain performance. Drawing on extant interorganisational information

system theory, this research identifies factors likely to impact on the adoption of

RFID. Four categories of factors such as technological, economic,

organisational and external are identified. The relationship between RFID

factors, RFID adoption and retail supply chain performance was developed as a

conceptual framework employing Analytical Hierarchy Process (AHP). The

proposed framework was validated by the results of two Australian pilot studies

and responses from stakeholders of two mini surveys. The study identifies

several gaps and proposes that each stakeholder group must be aware of, and

agree to the salient factors that effects an RFID adoption decision.

1 Introduction

There has been an increased interest in RFID due to advances in the RFID

technologies and improvements in Internet technologies. Equally, a notable reduction

in technology and associated costs has triggered a review of RFID capabilities.

Organisations within fast moving consumer goods (FMCG) supply chains are now

looking to replace barcodes with RFID tags [1]. More importantly, they want to

progress from established RFID closed system environments to RFID open system

environments [2]. Open systems operate when tags attached to products containing a

microprocessor chip are populated with identity information. As a pallet load of

products passes a reader, it picks up radio signals from the products and passes

information to the organisation’s enterprise system. Location information is

simultaneously circulated to supply chain partners via the Internet. EPCGlobal is the

principal institute involved in developing RFID technology. Currently EPCGlobal is

coordinating RFID efforts within the retail industry and endeavoring to provide the

infrastructure supporting an open system network [3].

The scope of the paper is restricted to RFID open system technology which has

the potential to radically change retail supply chains.

Waters S. and Rahman S. (2007).

Antecedents to RFID Adoption: Perspectives of Retail Supply Chain Stakeholders.

In Proceedings of the 1st International Workshop on RFID Technology - Concepts, Applications, Challenges, pages 35-49

DOI: 10.5220/0002434700350049

Copyright

c

SciTePress

Increased interest in RFID has resulted in a growth of literature, including books,

research articles and articles in trade and business journals [4-6]. However, much of

the information is anecdotal and the majority of articles are published in trade journals

[7] and newspapers [8]. Robust research of RFID in the context of supply chain

management is limited.

Implementation of RFID technologies are likely to result in benefits within supply

chains [6, 9, 10]. These benefits include improvements over current barcode

technology. For example, RFID technology will provide greater levels of inventory

visibility, increased accuracy, and lower labour costs [2, 6, 9]. These benefits provide

the incentive to investigate the value of RFID in supply chains. The potential benefits

of RFID are summarised in Table 1.

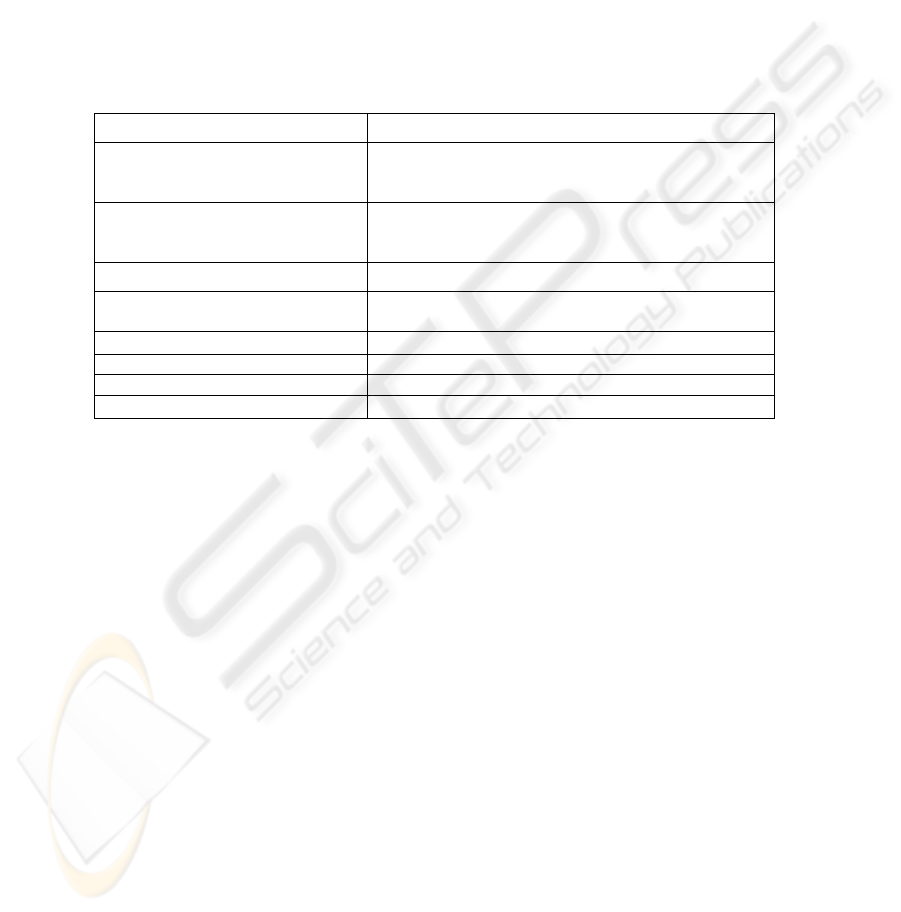

Table 1. Benefits from Adopting RFID.

Authors Major Benefits

[6]

• Faster processing - increased information

• Higher accuracy

• Increased tracking capability

[9]

• Increased inventory visibility

• Decreased inventory levels

• Decreased out of stock

[10]

• Increased inventory turnover

[2]

• Decreased shrinkage

• Lower labour costs

[11]

• Minimised bullwhip effect

[4]

• Prevention of counterfeiting

[12]

• Process freedom

[2]

• Improved customer service

To prove the benefits of RFID, Wal-Mart commissioned the University of

Arkansas to undertake a scientific study. The results concluded that stores using RFID

outperformed stores without RFID [7]. Supply chain measures such as ‘on-shelf

availability’ improved with a 14% reduction in out of stock (OOS) products. Also the

stockouts were replaced three times faster, and there was a decrease in manual orders

submitted by RFID enabled stores [7]. While the Wal-Mart study confirms some of

the benefits, it fails to mention other factors including offsetting costs.

The objective of this paper is to develop a conceptual framework for RFID

adoption based on extant literature and validate using responses from retail supply

chain stakeholders. This will assist in understanding the relationships between factors

impacting on the adoption of RFID and in turn its impact on the retail supply chain

performance. The structure of this paper is as follows. Section 2 reviews literature on

several interorganisational information systems, RFID, and performance measures of

retail business. Section 3 summarises supporting adoption theories and proposes a

conceptual framework employing analytical hierarchy process (AHP). Section 4 tests

the proposed framework against the perspectives of three key stakeholders using two

Australian pilot case studies and qualitative information collected through two mini

surveys. The paper is concluded with a discussion on the findings, limitations, and

future intentions.

36

2 Literature Review

2.1 Interorganisational Systems

Interorganisational systems [13] enable multiple organisations to communicate

through efficient electronic links. IOS facilitates integration resulting in higher levels

of collaboration and coordination [14]. Furthermore, higher levels of collaboration

and coordination leads to higher levels of supply chain performance [15]. We discuss

two widely researched IOS technologies such as Electronic Data Interchange (EDI)

and the Internet due to their prominence in literature [16, 17].

2.2 Electronic Data Interchange (EDI)

Electronic Data Interchange (EDI) is defined as the computer-to-computer transfer of

information between organisations in a structured format [16]. The primary drivers

for implementing EDI are operational gains, competitiveness, and improvements in

inter-organisational relationships [18]. Benefits from EDI including, quick response

and access to information, improving data control, improving customer service,

enhancing competitive capacity, faster inventory turnover, consistent flow of

information among trading partners, standardization of procedures, and improving

trading partner relationships have been reported in literature [19].

Initially, these reported benefits compelled organisations to consider adopting

EDI. However, claims of inevitable wide spread adoption did not eventuate. Apart

from fortune 1000 firms, only 2% of organisations in the US have implemented EDI

[20]. Factors impacting on adoption include high costs [21], technology complexity

[22] and the requirement for close cooperation by supply chain members [23]. Such

factors prompted the search for other technologies.

2.3 Internet

Organisations have adopted the Internet technology to conduct electronic business in

a dyadic framework [24]. Known as e-business, it has been demonstrated that higher

levels of web usage throughout supply chains leads to higher organisational

performance [25, 26]. Organisations including Dell, GE, Cisco have claimed

significant benefits from the adoption of e-business within their supply chains [27,

28].

It is apparent to businesses that the Internet makes sharing information easier and

cheaper [29], reduces response times, simplifies payments, extends supplier bases,

reduces the manual paperwork, and eliminates errors [30]. e-business applications

have advantages over EDI resulting in organisations switching across [31]. For

instance, compared to EDI, internet technology requires lower implementation and

operating costs and does not require close coordination between partners. There is

also a limited need for adjustments for compatibility [29]. Unlike EDI, the Internet

has the advantage of a common protocol (xml) [24] and operates in an open world-

wide-web system [32]. Internet is also being combined with technologies such as EDI

37

[33], electronic trading hubs [34], business process management systems [35], and

automatic data capture technologies [36] to create more effective electronic systems.

However, studies also identified factors that impact adversely on adoption of e-

business. These include technology competence, availability of IT professionals,

organisational size, global scope, integration, competitive intensity, and regulatory

environment [37]. There are increasing evidences of the Internet merging with other

technologies.

Both EDI and the Internet have reported benefits for organisations contemplating

adopting either of these technologies. Conversely, both technologies have a number of

factors that act as antecedents to adoption. These factors can be grouped into

categories: technological, economic, organisational and external. We assume that

similar factors will be found when we examine RFID technology.

2.4 RFID

Like EDI and the Internet, RFID is now classified as an interorganisational

information system [38]. There are two main reasons for current interest in RFID.

Firstly RFID has been designed to enhance the transfer of information between

organisations. This is achieved by taking information about a product directly from

tags placed on these products without line of sight. Secondly, designers provide a

network whereby this valuable information can be shared via the Internet [11].

However, RFID technologies have a number of factors that are currently

preventing wide spread adoption. RFID is a new technology and not compatible with

many of the existing technologies such as other RFID technologies and Enterprise

Resource Planning (ERP) systems [12]. RFID is prone to interference causing errors

in reading tags [10]. There are economic reasons as well. RFID is considered too

expensive [11]. Infrastructure costs, hardware costs, tag costs are all reasonably high

[11]. There are also organisational considerations in the adoption of RFID. Studies

indicate that only larger organisations are capable of committing considerable

resources required to adopt RFID [9]. Furthermore, there is a need for top

management support for successful implementation of RFID [6]. Finally there are

factors external to the organisation such as competitive pressures [39] and privacy

issues [40]. These factors all act as antecedent to adoption of RFID and will be

discussed in the following subsections in more detail.

2.4.1 Technological Factors

According to literature, the adoption of technology innovations is shaped by three

factors. If a technology is compatible with existing technology, and is not overly

complex, and has some relative advantage, then it is more likely to be adopted [41].

Despite advances in technology, RFID has both compatibility and complexity issues

that are currently acting as barriers to wide spread adoption. A substantial effort is

underway to overcome existing technological issues. Conversely one reason for

current attention in RFID is the relative advantage that RFID tags have over barcodes.

A comparison of RFID and barcode technologies results in RFID being considered as

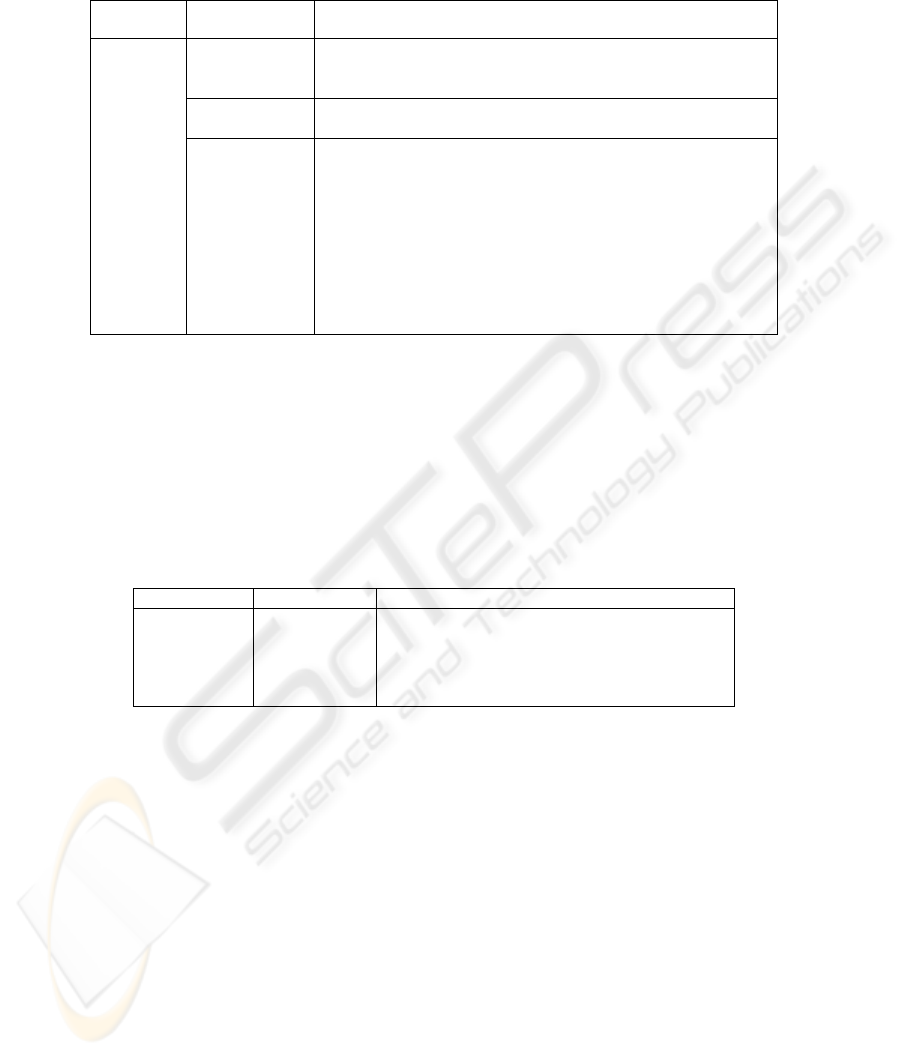

superior. A summary of technological factors is presented in Table 2.

38

Table 2. Technological Factors Affecting RFID Adoption. Source: [6, 10, 12, 42, 43].

2.4.2 Economic Factors

Our research also identifies economic factors as antecedent to adoption. Although the

costs associated with RFID technology are declining, they are still considered

unacceptably high [2]. The passive tags, which were used in supply chain trials in

2000, cost around $1.00. These tags can now be purchased for between 15 to 20 cents

[44]. Some studies suggest that a target cost of 5 cents is likely to be accepted by

industries [45]. Table 3 summaries the major issues concerning costs.

Table 3. Economic Factors Affecting RFID Adoption. Source: [2, 11, 44, 46].

2.4.3 Organizational

Literature acknowledges the importance of a number of organisational factors in the

adoption of RFID. In particular, the support and leadership of top management and

the size of the organisation impacts on the propensity to adopt an emerging

technology such as RFID [47]. Although top management support has not received

wide coverage in RFID literature, a study by Sweeney [6] highlights the need for

management involvement in the deployment of RFID. The size of the organisation is

reported to have an impact on RFID adoption. Studies show that at this early stage of

RFID implementation, mainly the larger retailers and manufacturers are involved in

RFID technology trials [2, 9, 12]. We argue that these organisational factors are

critical for the RFID adoption process. A summary of organisational factors are

presented in Table 4.

Cat.egory Factors Major issues

Compatibility

• Inability to integration with other RFID systems

• Incompatible with ERP systems

• Incompatible numbering, frequency and power standards

Complexity

• High levels of false reads

• High data volume

Technological

Relative

advantage

• Continuous information

• More accurate information

• Simultaneous tag reads

• Read without opening cartons

• More data stored on a tag

• Active tags can record data such as temperature and humidity

• Anti tampering capability

• Ability to write to active tags

• Operate in harsh conditions

• Does not require line of sight

Category Factor Major issues

Economic Costs

• RFID tag costs

• Hardware costs

• Software costs

• System integration costs

• Training and consulting costs

39

Table 4. Organisational Factors Affecting RFID. Source: [2, 9, 38].

Category

Factors Major issues

Firm size

• Large firms dominate

• Small firms not considered

Organisational

Top Management Support

• Wide adoption less likely

without support

2.4.4 External Factors

The adoption of technology is often shaped by the reaction of competitors, supply

chain partners and other stakeholders. A number of external factors such as pressure

from competitors, industry readiness, and privacy concern have been linked to the

adoption of RFID.

When high levels of uncertainty exist, organisations are often subject to coercion,

mimetic and/or normative pressures [48]. For example, Wal-mart has mandated

suppliers to adopt RFID. Suppliers are aware that failure to comply may result in lost

business [49].

Consumer are disturbed about unwanted access to information held in RFID tags

attached to products after they leave the store [40]. The issue of anonymity has caused

adverse reaction by consumers who object to the thought of being tracking via these

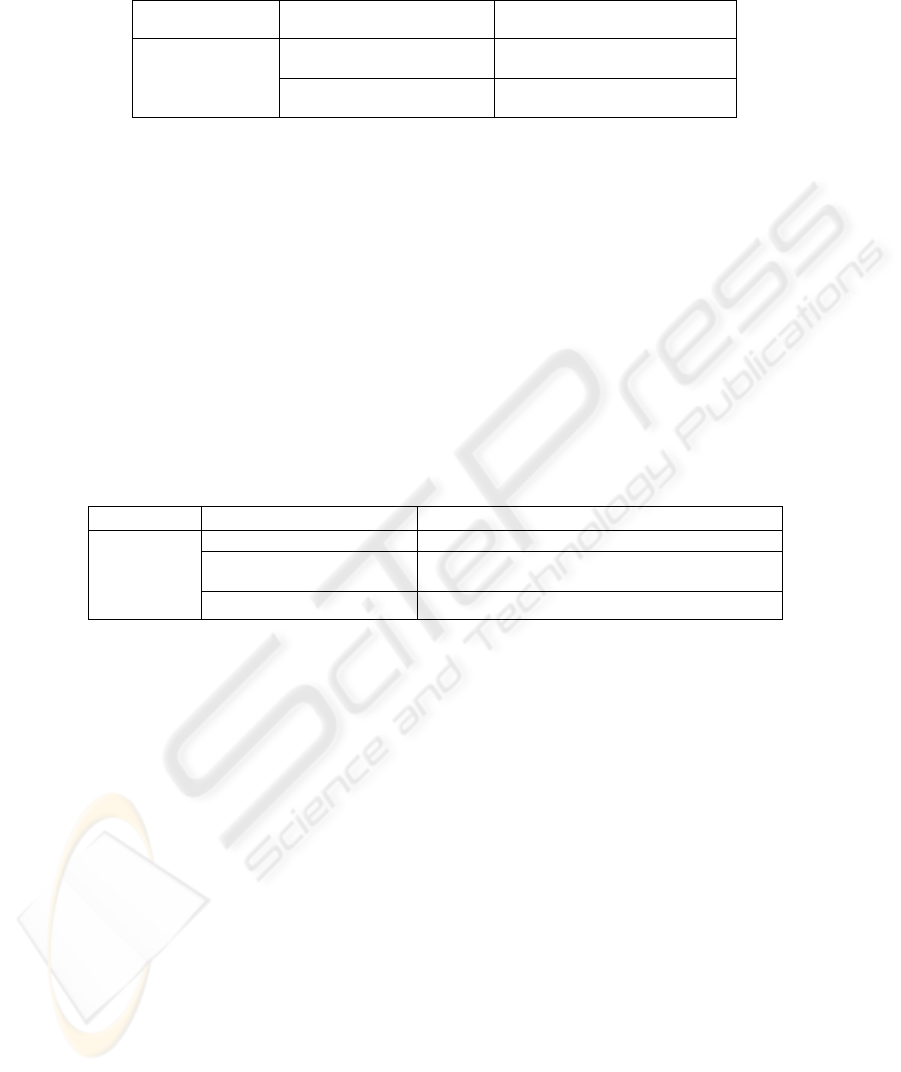

tags. [50]. A summary of external factors is presented in Table 5.

Table 5. External Factors Affecting RFID. Source: [38, 40, 49, 50].

Category Factors Major issues

Industry readiness

• Retailers and Department of Defence industries

Competitive forces

• Retailer mandates

• Mimetic behaviour

External

Privacy

• Consumers action groups against tags

2.5 Retailer Performance

Leading organisations have focused on adopting appropriate performance indicators

for supply chain performance [51]. These indicators assist in determining

improvements throughout the supply chain.

Retailers have recognised that improvements throughout the supply chain will

impact positively on their own performance [52, 53]. In particular, upstream

efficiencies will impact positively on product availability. Product availability has

become the accepted bottom line performance measure for retailers [52].

Retailers compete by offering a wide variety of products to customers. A typical

supermarket may manage as many as 30000 products at one time [54]. One issue with

such a large assortment is the likelihood of product being out-of-stock (OOS). A

recent world wide study reported that the average OOS is about 8.3%. Furthermore,

lost sales resulting from products not being on the shelf are reported to be 3.9% of

sales world wide [55]. The majority of OOS occurs due to store mismanagement such

as failure to order the product. Since OOS is a major concern when it comes to

customer service, it is argued that OOS should be completely eliminated [56].

40

3 Conceptual Framework

3.1 Adoption Theories

There are a number of theories acknowledging adoption and diffusion of emerging

technologies [41, 57, 58]. The adoption process has been recognised in terms of

initiation stages (agenda setting and matching) and implementation stages

(redefining/restructuring, clarifying, and routinizing) [41]. Initiation focuses on the

stages up to an adoption decision and is more relevant to emerging technologies such

as RFID. The adoption decision is dependent on an organisation’s knowledge about a

new technology [41]. Organisations continually scan the external environment for

new technology. This technology is then examined in the context of matching a

problem noted in the organisation’s agenda of problems requiring solutions [41].

Equally, knowledge of an emerging innovation can also lead to an investigation of its

value, regardless of problems. However, there is uncertainty with radical innovations

due to the considerable amount of knowledge an organisation must acquire[41]. This

knowledge reflects an organisation’s preparedness and the level of accessibility to

antecedent factors.

The decision to implement a new technology results in either acceptance or

rejection [41]. However, we propose that the decision may also include adoption

postponement. Emerging technologies, such as RFID are continually being developed

and as a result, organisations need to access all the latest information about antecedent

factors. Thus a feedback loop is required to be added between adoption and

organisational preparedness to account for uncertainty. Literature also describes how

retail performance is influenced by the effective execution of logistics activities

upstream in the supply chain. We have considered the term product availability as the

performance indicator to capture these factors. Increased product availability will lead

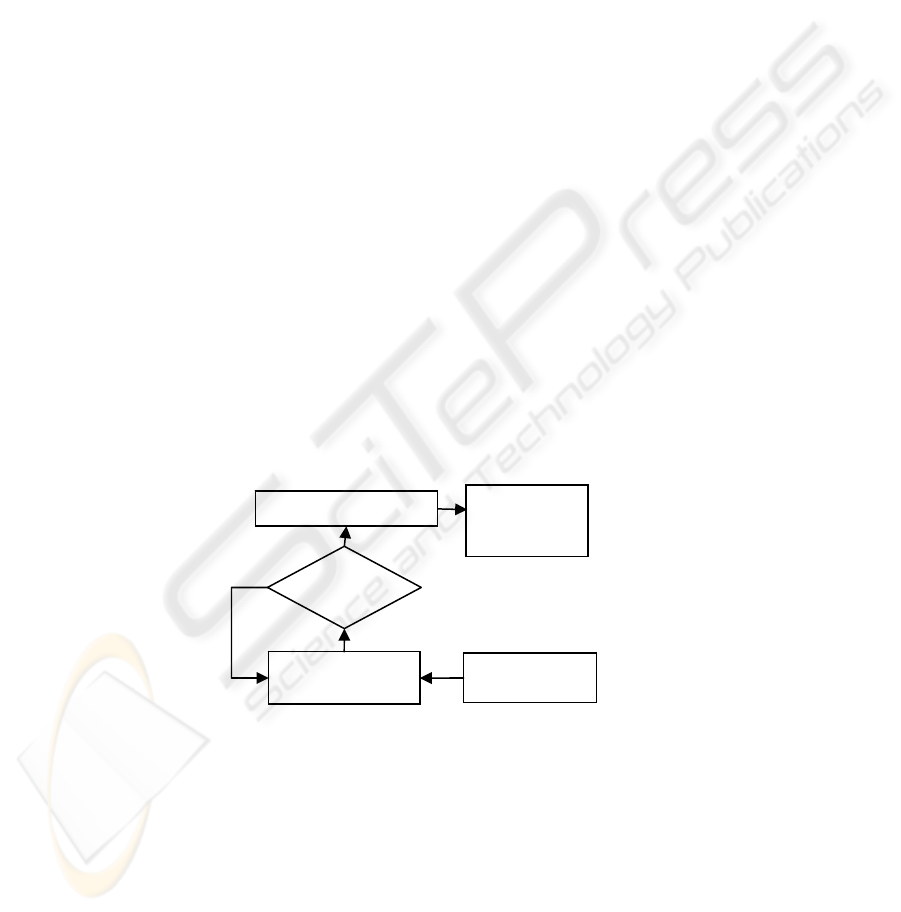

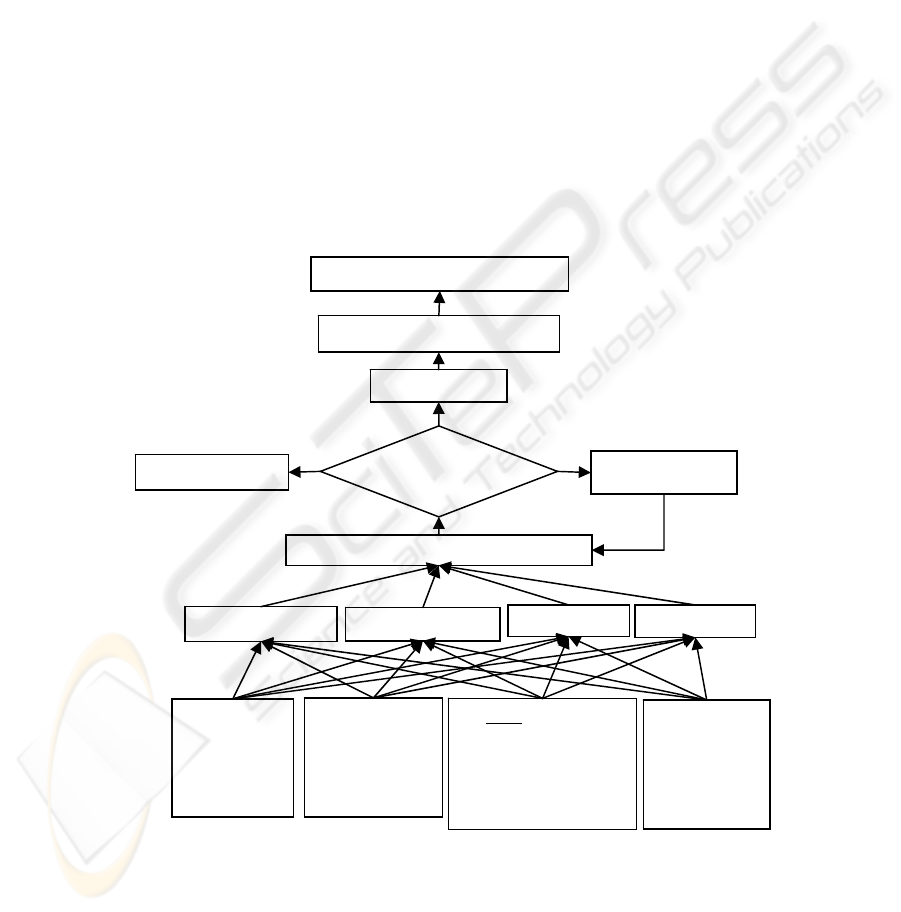

to improvements in retail performance. Our conceptual framework is represented in

Figure 1.

Fig. 1. RFID Adoption Framework.

3.2 Analytical Hierarchy Process

In order to ascertain the managers understanding on factors that affect the successful

adoption of RFID, this study develops a conceptual framework using the AHP

approach [59].

Retail

Supply Chain

Performance

Organisational

Preparedness

RFID

Ado

p

tion

Product availability

Antecedents

41

AHP is a decision-making approach which integrates simultaneously qualitative

and quantitative information for prioritising alternatives when multiple criteria must

be considered. According to Saaty [59], a decision making approach should have the

following characteristics:

• be simple in structure,

• be adaptable to both group and individual decision making environments,

• be natural to human intuition and general thinking,

• encourage compromise and consensus, and

• not require inordinate specialisation to master and communicate.

The decision making process of the AHP is consistent with these characteristics.

After comparing five different utility models for determining priorities, Schoemaker

and Waid [60]

concluded that the AHP was the easiest to use and produced the most

credible results. AHP has been used in a recent publications in the field of RFID [61].

3.2 The Modeling Process of the AHP

The modeling process involves four steps:

1. assessment of factors in the adoption of RFID

2. structuring the problem as a hierarchy and building the AHP model

3. collection and compilation of experts’ opinions and application of the

prioritisation procedure, and

4. determination of critical factors.

The first step involves identification of key factors that influence the level of RFID

adoption. Identification and classification of these factors have been discussed earlier

and are shown in Table 2 – Table 5.

The structuring step consists of breaking down any complex multiple criteria

decision-making problem into a series of hierarchies or set of integrated levels.

Generally, the problems are structured in at least three levels given in Table 6.

Table 6. Problem Structure and Definition.

Level Generic definition In the study

1 Goal

The overall objective of the decision

making process which is placed at the

apex of the hierarchy

The goal is to identify the

state of organisational

preparedness based on the

level of accessibility of

each of the factors.

2 Criteria

Bases on which the alternatives are

evaluated

Factors such as

technological, economic,

organisational and external

3 Alternatives The outcomes of the evaluation process

Importance of four

factors

The goal is to identify the state of organisational preparedness based on the level of

accessibility of each of the factors. This is shown at level 1 in Figure 2. Level 2 is

42

represented by the four antecedent categories: technological, organisational, economic

and external. Factors within each of these categories (Level 3) requires continous

refinement. Frequent advancements update an organisation’s knowledge about RFID.

For example, industry has been awaiting a 2

nd

generation of standards anticipating

enhanced capability [3]. Our framework indicates a flow from these four categories of

factors via updated knowledge to a decision point. The decision node is defined by

three outcomes, rejection, acceptance and postponement. While some organisations

may have rejected RFID outright, many have postponed their decision pending further

information. Postponement is therefore linked back to the state of organisational

preparedness. Continual postponement is likely to force organisations to reject RFID

altogether. On the other hand, there is considerable evidence that acceptance will lead

to significant supply chain improvement. This improvement is represented by product

availability. As discussed earlier product availability is now accepted as a bottom line

retail performance measure. The conceptual framework for RFID adoption developed

using AHP is shown in figure 2. This framework could be used to assess the State of

Organisational Preparedness using both quantitative and qualitative information.

However, in this paper our objective is to validate the proposed framework using only

the qualitative information collected from two pilot studies and two mini surveys. The

next section examines this validation process.

Fig. 2. Detailed RFID Adoption Research Framework.

Level 3

Retail Chain Performance

Product Availability

Technological

Economic

Or

g

anisational

External

Costs

• Hardware costs

• Software costs

• Implementation costs

• Infrastructure costs

•

Trainin

g

costs

• Top

Management

Support

• Organisation

size

•

Competitive

pressure

• Industry

readiness

• Privacy

issues

Acce

p

tance

Postponement

Level 1

• Compatibili

ty

• Complexity

• Relative

Advantage

Rejection

RFID Adoption

Decision

State of Organisational Preparedness

Level 2

43

4 RFID Stakeholder Perspectives

There are a number of stakeholders representing the current RFID environment. Three

major parties are retailers, suppliers to retailers, and RFID technology and service

providers. In this paper we gathered information from all three sources and compared

each stakeholder’s view of RFID implementation. This information was obtained

from two pilot studies in Australia and two mini surveys undertaken during the latter

half of 2005 and 2006.

4.1 Australian Demonstrator Project

The EPC Network Australian Demonstration Project was a trial undertaken in

Melbourne during 2006. A consortium of retailers, suppliers, technology providers,

transport providers and materials handling organisations in the fast moving consumer

goods industry (FMCG) conducted a pilot study of RFID technology.

Supply chain participants including Gillette, Proctor and Gamble, Chep Pallets,

Linfox, Metcash Retailer, and technology service institutions such as Commonwealth

Scientific Industry Research Organisation (CSIRO), and GS1 Australia. The

objectives of the trial objectives were to show that EPC Network could deliver

benefits to all members of supply chains through RFID adoption .

The trial also set out to encourage Australian companies to get involved rather

than wait for mandates[3]. CSIRO analysed each site and designed the RFID layout.

Technology service providers including Verisign and Sun Microsystems provided

hardware and software. A subsequent report outlined the results including integration

beyond 1

st

tier suppliers and customers with the adoption of a single set of global

standards resulted in higher levels of visibility and real time information. The trial of

EPC Network Project provided evidences that such collaborative affords can be

successfully applied[3].

This trial provides support for our framework. For example, all the participants of

the Network Project are of the opinion that technological factors have serious

implications on the adoption of RFID. RF interference, complexity of RFID, failure to

link with existing technologies, and false reads are some of the major technological

concerns expressed by these companies. Metcash identified the significant amount of

resources needed to adopt RFID, alluding to the fact that only larger organisations

would be capable of RFID adoption. Metcash also revealed external factors such as

the need for all parties to agree to adoption before it could be a success.

Gillette mentioned organisational factors such as top management support, while

P&G and Linfox both indicated the difficulty in justifying the return on investment.

Among the possible benefits of RFID adoption expressed by the companies are

improvement in sharing information (Gillette), process improvement (Capilano and

Nugan), improvement in supply chain visibility (P&G), and improvement in tracking

capabilities (Chep). Although there was no mention of improvements in product

availability, it is suggested that such improvements will invariably impact on the

product availability of the entire supply chain [3].

44

4.2 Patties and Montague’s EPC/RFID Pilot Study

Another trial was Patties and Montague’s EPC/RFID pilot study. Patties Pies, and

Montague Cold Storage are both suppliers to retailer outlets. Together with a number

of technology providers they examined RFID technology to determine the reliability

and integration capability in a business to business setting [62]. Montague’s cold

storage facility added a new dimension to the study of RFID technology. One

important finding of this study is that tags can be read successfully in sub-zero

temperatures. Results also indicated improved visibility, elimination of scanning,

reduced labour requirements and overall efficiency of the supply chain [62]. This

study also validates our proposed conceptual framework. For instance, technological

issue such as RF interference was expressed as a major concern.

4.3 RFID Australasia 2005 and 2006

Two mini surveys were conducted in 2005 and 2006. The first involved respondents

from a trade exhibition held in conjunction with ‘RFID Australasia 2005’ conference

in Sydney in August 2005. This venue provided an opportunity to gather information

from RFID technology suppliers. Suppliers of RFID technologies included senior

level representatives from both local and multinational organisations. These

executives were interviewed individually.

The exhibition displayed RFID related technologies which include identification

systems, contactless smart cards, middleware, RFID enabled supply chain

applications, RFID hardware, RFID software, RFID labels and label printers, RFID

readers, transponders and technology consultants. Respondents answered a structured

set of open-ended questions aimed at soliciting verbal responses.

The findings support our proposed framework for RFID adoption. Respondents

revealed that factors such as technological (infrastructure, standards, interference),

economic (costs), organisational (top management support), and external factors

(competitive pressures, and mandates) are likely to have profound impact on the

adoption of RFID. However, size of organisation was not mentioned as an issue. The

possible benefits of RFID expressed by the respondents include labour savings,

automation, advantages over barcodes and increased supply chain visibility.

Our 2005 survey was replicated at the 2006 exhibition and found similar results

with regards to factors impacting RFID adoption and benefits derived from adoption.

However, during this survey we also questioned respondents about changes to the

RFID environment in the last 12 months. These responses are summarised in Table 7.

It would seem that while some changes could support acceptance of the technology,

other responses indicate continuing postponement.

45

Table 7. Changes to the RFID Environment – 2006 Pilot Study Results.

5 Discussion and Conclusions

First this paper compares extant IOS literature with RFID technology and concludes

that the factors that generally impact the adoption of IOS also impact RFID adoption.

These were categorised as technological, economic, organisational and external

factors. Applying the adoption and diffusion theory [41], we concluded that adoption

of RFID would follow similar pattern as other IOS technologies. RFID adoption is

dependent on knowledge about the technology, and other antecedent factors. Our

research proposes that in the earlier stages of the innovation process involving radical

emerging technology there is considerable uncertainty. Thus organisations continually

seek the latest information about changes, developments and upgrades. We highlight

this point in our framework and define as ‘State of Organisational Preparedness’. We

suggest that under these conditions, organisations may decide to accept or reject the

technology, as well as postpone adoption.

We employed AHP to develop a conceptual framework for RFID adoption

presenting the relationships between the various factors. Three levels are identified in

the AHP process. The first level is the goal, characterized by state of organisational

preparedness. The second level is factors impacting on the goal, and the third level

defines alternatives which represent the importance attributed to factors.

Our research proposes that the organizational preparedness is linked to the RFID

adoption decision. Acceptance of RFID is likely to lead to improved supply chain

performance in terms of superior product availability.

We test the proposed framework by analysing information from two pilot studies

and two mini surveys conducted at RFID exhibitions in Australia. Information was

collected from three stakeholders such as retailers, suppliers to retailers, and

technology providers. The results from the case studies and mini surveys validated

our proposed framework.

It is worthy mentioning that the proposed framework validation process was

designed for a preliminary exploratory study. Thus there are two major limitations to

this study. First, the trials were localized (in Australia) and did not involve the two

major retailers (Coles and Woolworths). Second, the sample size was small and

Acceptance

• Significant improvement in ultra high frequency with generation 2 technology now available

• The ability to read and write to passive tags

• The relaxation of power regulations allowing organisations to gain 4 watt licenses for RFID

studies

• Greater levels of education have become apparent

• Consensus on the GS1 standard as the preferred standard for RFID

Postponement

• There has been a slowdown in RFID technology trials

• Decreased hype about the technology

• Significant resources required to undertake such a project

• No open systems have been adopted in Australia

• The two major retailers Woolworths and Coles have not adopted and do not intend to adopt

• RFID in the near future. Both are in touch with USA counterparts (WalMart and Target) and

therefore able to monitor this environment.

46

therefore may not be representative of the retail industry. Further research is required

to validate the framework using large sample size and utilizing quantitative data and

information.

References

1. Rousos, G., Enabling RFID in Retail. IEEEE, 2006. March.

2. Jones, P., et al., The Benefits, Challenges and Impacts of Radio Frequency Identification

Technology (RFID) for Retailers in the UK. Marketing Intelligence & Planning, 2005.

23(4): p. 395-402.

3. GS1, A., EPC Network Australian Demonstrator Project Report 2006, GS1: Melbourne.

4. Heinrich, C., RFID and Beyond. Growing Your Business Through Real World Awareness.

2005: Wiley Publishing.

5. Shepard, S., RFID Radio Frequency Identification. 2005: McGraw Hill.

6. Sweeney, P., RFID for Dummies. 2005: Wiley Publishing.

7. Materials Handling and Distribution, RFID Put to the Test, in Materials Handling and

Distribution. 2006. p. 45.

8. Sullivan, L., RFID Network Set to Launch in 2006. Tech Web News, 2005b.

9. Narsing, A., RFID and Supply Chain Management: An Assessment of its Economic,

Technical, and Productive Viability in Global Operations. The Journal of Applied Business

Research, 2005. 21(2).

10. Twist, D.C., The Impact of Radio Frequency Identification on Supply Chain Facilities.

Journal of Facilities Management, 2005. 3(3): p. 226.

11. Asif, Z. and M. Mandviwalla, Integrating the Supply Chain with RFID: A Technical and

Business Analysis, in http://ebi.temple.edu/programs/RFID/default.htm. 2004, The Fox

School of Business and Management.Temple University.

12. Angeles, R., RFID Technologies: Supply Chain Applications and Implementation Issues.

Information Systems Management, 2005. 22(1): p. 51 - 65.

13. Giaglis, G.M., et al., The Issue Methodology For Quantifying Benefits From Information

Systems. Logistics Information Management, 1999. 12(1/2): p. 50.

14. Goodhue, D.L., M.D. Wybo, and L.J. Kirsch, The Impact of Data Integration on the Costs

and Benefits of Information Systems. MIS Quarterly, 1992. 16(3): p. 293-311.

15. Lee, H.L., V. Padmanabhan, and S. Whang, The Bullwhip Effect in Supply Chains. Sloan

Management Review, 1997. 38(3): p. 93-102.

16. Hansen, J.V. and N.C. Hill, Control and Audit of Electronic Data Interchange. MIS

Quarterly, 1989. 13(4): p. 402-413.

17. Kumar, K. and E. Ellen Christiaanse. From Static Supply Chains To Dynamic Supply webs:

Principles For Radical Redesign In The Age Of Information. in International conference on

Information systems Proceeding of the 20th international conference on Information

Systems. 1999. Charlotte USA.

18. Cox, B. and S. Ghoneim, Drivers and Barriers to Adopting EDI: A Sector Analysis of UK

Industry. European Journal of Information Systems, 1996. 5(1): p. 24-33.

19. Ngai, E.W.T., et al., Mobile Commerce Integrated with RFIID Technology in a Container

Depot. Decision Support Systems, 2005. xxx xxx.

20. Densmore, B.,

EDI vs. the new kids. Emmerce. www.computerworld.com/home/

emmerce.nsf//all/980406edi, 1998.

21. Soliman, K.S. and B.D. Janz, An Exploratory Study to Identify the Critical Factors

Affecting the Decision to Establish Internet-based Interorganisational Information Systems.

Information and Management, 2004. 41: p. 697-706.

22. Haugen, R. and E. Behling, Electronic Data Interchange as an Enabling Technology for

International Business. Journal of Computer Information Systems, 1995: p. 13-16.

47

23. Premkumar, G., K. Ramamurthy, and S. Nilakanta, Implementation of electronic data

interchange: An innovation diffusion perspective. Journal of Management Information

Systems, 1994. 11(2): p. 157-187.

24. Easton, G. and L. Araujo, Evaluating the Impact of B2B e-commerce: A Contingent

Approach. Industrial Marketing Management, 2003. 32: p. 431-439.

25. Frohlich, M.T., E-Integration in the supply chain: Barriers and performance. Decision

Sciences, 2002. 33(4): p. 537-555.

26. Frohlich, M.T. and R. Westbrook, Demand chain management in manufacturing and

services: Web-based integration, drivers and performance. Journal of Operations

Management, 2002. 20: p. 729-745.

27. Lancioni, R.A., M. Smith, and T.A. Oliva, Role of the Internet in supply chain

management. Industrial Marketing Management, 2000. 29: p. 45-56.

28. Raghunathan, B. and T.S. Raghunathan., Planning Implications of the Information Systems

Strategic Grid: An Empirical Investigation. Decision Sciences, 1990. 21: p. 287-300.

29. Christiaansea, E., T.V. Diepenb, and J. Damsgaard, Proprietary versus Internet

Technologies and the Adoption and Impact of Electronic Marketplaces Journal of Strategic

Information Systems, 2004. 13: p. 151-165.

30. Min, H. and W.P. Galle, E-purchasing: Profiles of Adopters and Nonadopters. Journal of

Marketing Management, 2003. 32: p. 227-233.

31. Lee, S.C., B.Y. Pak, and H.G. Lee, Business Value of B2B Electronic Commerce: The

Critical Role of Inter-firm Collaboration. Electronic Commerce Research and Applications,

2003. 2: p. 350-361.

32. Dai, Q. and R.J. Kauffman, Business Models for Internet-Based B2B Electronic markets.

International Journal of Electronic Commerce, 2002. 6(4): p. 41-72.

33. Mireille, S.K. and B.C. Kavan, From Traditional EDI to Internet-based EDI: Managerial

Considerations. journal of Information Technology, 1999. 14: p. 347-360.

34. Sawhney, M., e-Hubs: The new B2B marketplaces. Harvard Business Review, 2000. 78(3):

p. 97-102.

35. Leymann, F., D. Roller, and M.T. Schmidt, Web Service and Business Process

Management. IBM Systems Journal, 2002. 41(2): p. 198-211.

36. Fisher, M.L., What Is the Right Supply Chain for Your Product?.’ Effective Supply Chains.

Harvard Business Review,, 1997. Mar-Apr: p. 106-116.

37. Xu, Zhu, and Gibbs, Global Technology, Local Adoption A Cross country invetigation of

Internet adoption by companies in US and China. Electronic Markets, 2004. 14(1): p. 13-

24.

38. Sharma, A., A. Citurs, and B. Knonsynski. Strategic and institutional perspectives in the

adoption and early integration of radio frequency identification (RFID. in Proceedings of

the 40th Hawaii International Conference on System Sciences. 2007. Hawaii.

39. Sullivan, L., RFID Enterprise Link. Information Week, 2004.

40. Knospe, H. and H. Pohl, RFID Security. Information Security Technical Report, 2004. 9(4):

p. `.

41. Rogers, E.M., Diffusion of Innovations. 2003: The Free Press NY.

42. Davenport, T.H. and J.D. Brooks, Enterprise Systems and The Supply Chain. Journal of

Enterprise Information Management, 2004. 17(1): p. 8-19.

43. Sheffi, Y., RFID and the Innovation Cycle. The International Journal of Logistics

Management, 2004. 15(1): p. 1 - 10.

44. Prater, E., G.V. Frazier, and P. Reyes, Future Impacts of RFID on e-Supply Chains in

Grocery Retailing. Supply Chain Management, 2005. 10(2): p. 134-142.

45. Donovan, J., RF Identification Tags: Show Me the Money, in Electronic Engineering Times.

2003. p. 41.

46. Chiesa, M., et al., RFID. A week long Survey on the Technology and its Potential, h.p.i.-

i.i.c.n.R.R.r.p.a.o.r.N. 2005, Editor. 2002, Harness Technology Project. Research

Interaction Design Institute Ivrea.

48

47. Premkumar, G., A Meta-Analysis of Research on Information Technology Implementation

in Small Business. Journal of Organizational Computing and electronic Commerce 2003.

13(2): p. 91-121.

48. DiMaggio, P.J. and W.W. Powell, The iron cage revisited: Institutional isomorphism and

collective rationality in organisational fields American Sociological Review, 1983. 48(2):

p. 147-160.

49. Sullivan, L., Wal-Mart Tests RFID with eight Suppliers. Information week, 2004b(987): p.

28.

50. Atkinson, W., Tagged: The Risks and Rewards of RFID Technology. Risk Management,

2004. 51(7): p. 12-17.

51. Keebler, J.S., et al., Keeping Score: Measuring The Business Of Logistics In The Supply

Chain. 1999: Council Of Logistics Management Butterfield Rd.

52. Taylor, H.D., Measurement and Analysis of Demand Amplification across Supply Chain.

International Journal of Logistics Management, 1999. 10(2): p. 55-70.

53. Gaur, V., M.L. Fisher, and A. Raman, An Econometric Analysis of Inventory Turnover

Performance in Retail Services Management Sciences, 2005. 51(2): p. 181-195.

54. Broniarczyk, S.M. and W.D. Hoyer, Retail Assortment: More ≠ Better, in Retailing in the

21st Century: Current and Future Trends, M. Krafft and M.K. Mantrala, Editors. 2006,

Springer publishers.

55. Corsten, D. and T. Gruen, Desperately seeking shelf availability: An examination of the

extent, the causes, and the efforts to address retail out-of-stocks International Journal of

Retail & Distribution Management. Bradford: , 2003. 31(11/12): p. 605-19.

56. Verhoef, P.C. and L.M. Sloot, Out-of-Stock: Reactions, Antecedents, Management

Solutions, and a Future Perspective, in Retailing in the 21st Century: Current and Future

Trends, M. Krafft and M.K. Mantrala, Editors. 2006, Springer publishers.

57. Cooper, R.B. and R.W. Zmud, Information Technology Implementation Research: A

Technological Diffusion Approach. Management Science, 1990. 36(2): p. 123-139.

58. Premkumar, G., K. Ramamurthy, and M. Crum, Determinants of EDI Adoption in the

Transport Industry. European Journal of Information Systems, 1997. 6: p. 107-121.

59. Saaty, T.L., How to make a decision: The analytic hierarchy process. Interfaces, 1994

24(6): p. 19-43.

60. Shoemaker, P.J., An Experimental Comparison of Different Approaches to Determining

Weights in Additive Utility Models. Management Sciences, Waid, C.C. 28: p. 182-196.

61. Lin, K. and C. Lin, Evaluating the decision to adopt RFID systems using analytic hierarchy

process. Journal of American Academy of Business, 2007. 11(1): p. 72-77.

62. GS1, A., Patties to Montague EPC/RFID Pilot - Case Study 2005, GS1: Melbourne.

49