NONLINEAR MODEL PREDICTIVE CONTROL OF A LINEAR

AXIS BASED ON PNEUMATIC MUSCLES

Harald Aschemann and Dominik Schindele

Chair of Mechatronics, University of Rostock, Justus-von-Liebig-Weg 6, D-18059 Rostock, Germany

Keywords:

Mechatronics, predictive control, flatness-based methods, pneumatic muscle.

Abstract:

This paper presents a nonlinear optimal control scheme for a mechatronic system that consists of a guided

carriage and an antagonistic pair of pneumatic muscles as actuators. Modelling leads to a system of nonlinear

differential equations including polynomial approximations of the volume characteristic as well as the force

characteristic of the pneumatic muscles. The proposed control has a cascade structure: the nonlinear norm-

optimal control of both pneumatic muscle pressures is based on an approximative solution of the corresponding

HJB-equation, whereas the outer control loop involves a multivariable NMPC of the carriage position and the

mean internal pressure of the pneumatic muscles. To improve the tracking behaviour, the feedback control

loops are extended with nonlinear feedforward control based on differential flatness. Remaining model un-

certainties as well as nonlinear friction can be counteracted by an observer-based disturbance compensation.

Experimental results from an implementation on a test rig show an excellent control performance.

1 INTRODUCTION

Pneumatic muscle actuators are tension actuators con-

sisting of a fiber-reinforced vulcanised rubber tubing

with connection flanges at both ends. Due to a spe-

cial fiber arrangement, the pneumatical muscle con-

tracts with increasing internal pressure. This effect

can be used for actuation purposes. Pneumatic mus-

cles offer major advantages in comparison to classi-

cal pneumatic cylinders: significantly less weight, no

stick-slip effects, insensitivity to dirty working envi-

ronment, and a larger maximum force. The nonlinear

characteristics of the muscle, however, demand for

nonlinear control, e.g. flatness-based control (Fliess

et al., 1995), (Aschemann and Hofer, 2004). For the

practical investigation of control approaches the test

rig shown in figure 1 has been built. Two guide-

ways with roller bearing units allow for rectilinear

movements of a carriage with small nonlinear friction

forces. On opposite sides of the carriage, pneumatic

muscles are arranged in an antagonistic configuration

between the carriage and the rigid frame. The mass

flow of air of each pneumatic muscle is controlled by

means of a proportional valve. The in-flowing air is

provided at a maximum pressure of 7 bar, whereas

the out-flowing air is discharged at atmospheric pres-

sure, i.e. 1 bar. Pressure declines in the case of large

commanded mass flows are counteracted by using

compensator reservoirs, which maintain an approxi-

mately constant pressure supply level for each pneu-

matic muscle. Similarly, an additional compensator

reservoir in combination with a sound absorber re-

duces the noise caused by discharged air. The pa-

per is structured as follows: first, the modelling of the

mechatronic system is addressed. Second, a nonlinear

cascade control scheme is proposed: nonlinear H

2

-

optimal control loops, which can be realised with high

bandwidth, guarantee a specified internal pressure in

each pneumatic muscle (Aschemann et al., 2006).

The outer control loop involves nonlinear model pre-

dictive trajectory control of the carriage position and

the mean muscle pressure as controlled variables and

provides the reference pressures for the inner pressure

control loops. Aiming at good tracking behaviour,

feedforward control based on differential flatness is

considered in the control structure as well. A distur-

bance force resulting from remaining modelling er-

rors w.r.t. the force characteristic of the pneumatic

92

Aschemann H. and Schindele D. (2007).

NONLINEAR MODEL PREDICTIVE CONTROL OF A LINEAR AXIS BASED ON PNEUMATIC MUSCLES.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 92-99

DOI: 10.5220/0001649200920099

Copyright

c

SciTePress

Figure 1: Linear axis test rig.

muscles as well as the friction characteristic of the

carriage is estimated by a reduced-order disturbance

observer and used for compensation in the nonlinear

control scheme. By this, desired trajectories for both

carriage position and mean pressure can be tracked

with high accuracy as shown by experimental results

from an implementation at the test rig.

2 SYSTEM MODELLING

As for modelling, the mechatronic system is divided

in a pneumatic subsystem and a mechanical subsys-

tem, which are coupled by the tension forces of the

two pneumatic muscles. In contrast to the model

of (Carbonell et al., 2001) the dynamics of the pneu-

matic subsystem is also included. The tension force

F

Mi

≥ 0 and the volume V

Mi

of the pneumatic mus-

cle i, i = r, l, nonlinearly depend on the according

internal pressure p

Mi

as well as the contraction length

∆ℓ

Mi

. The origin of the generalised coordinate x

S

(t)

of the carriage is defined as the position where the

right muscle is fully contracted. Then, the constraints

∆ℓ

Ml

(x

S

) = x

S

, ∆ℓ

Mr

(x

S

) = ∆ℓ

M, max

− x

S

(1)

hold. Consequently, the contraction lengths of both

pneumatic muscles are related to the carriage posi-

tion.

2.1 Modelling of the Pneumatic

Subsystem

The dynamics of the internal muscle pressure follows

directly from a mass flow balance in combination with

the energy equation for the compressed air in the mus-

cle. As the internal muscle pressure is limited by

a maximum value of p

Mi,max

= 7 bar, the ideal

gas equation represents an accurate description of the

thermodynamic behaviour. The thermodynamic pro-

cess is modelled as a polytropic change of state with

n = 1.26 as identified polytropic exponent. The iden-

tified volume characteristic of the pneumatic muscle

can be described by a polynomial function

V

Mi

(∆ℓ

Mi

, p

Mi

) =

3

X

j=0

a

j

· ∆ℓ

j

Mi

·

1

X

k=0

b

k

· p

k

Mi

.

(2)

with the contraction length ∆ℓ

Mi

and the muscle

pressure p

Mi

. The resulting state equation for the in-

ternal muscle pressure in the muscle i is given by

˙p

Mi

=

n

V

Mi

+ n ·

∂V

Mi

∂p

Mi

· p

Mi

[R

L

· ϑ(·) · ˙m

Mi

−

∂V

Mi

∂∆ℓ

Mi

·

∂∆ℓ

Mi

∂x

S

· p

Mi

· ˙x

S

, (3)

where R

L

denotes the gas constant of air. The func-

tion ϑ(n, T

S

, T

Mi

, sign( ˙m

Mi

)), which depends on

the polytropic exponent n, the air supply tempera-

ture T

S

, the internal temperature T

Mi

, and the sign

of the mass flow rate ˙m

Mi

, can be approximated with

good accuracy by the constant temperature T

0

of the

ambiance. Thereby, temperature measurements can

be avoided, and the implementational effort is signif-

icantly reduced.

2.2 Modelling of the Mechanical

Subsystem

The mechanical subsystem is related to the motion of

the carriage with mass m

S

= 30 kg on its guideways.

The nonlinear force characteristic F

Mi

(p

Mi

, ∆ℓ

Mi

)

of a pneumatic muscle represents the resulting ten-

sion force for given internal pressure p

Mi

as well as

given contraction length ∆ℓ

Mi

. It has been identified

by static measurements and, then, approximated by a

polynomial description

F

Mi

(∆ℓ

Mi

, p

Mi

) =

¯

F

Mi

(∆ℓ

Mi

)·p

Mi

−f

Mi

(∆ℓ

Mi

).

(4)

The equation of motion follows directly from New-

ton’s second law as a second order differential equa-

tion for the carriage position

m

S

· ¨x

S

= F

Ml

(·) − F

Mr

(·) − F

U

. (5)

At this, remaining model uncertainties are taken into

account by the disturbance force F

U

. These uncer-

tainties stem from approximation errors concerning

the static muscle force characteristics, non-modelled

viscoelastic effects of the vulcanised rubber material,

and viscous damping as well as friction forces acting

on the carriage.

NONLINEAR MODEL PREDICTIVE CONTROL OF A LINEAR AXIS BASED ON PNEUMATIC MUSCLES

93

3 NORM-OPTIMAL CONTROL

OF THE MUSCLE PRESSURES

In the sequel, the nonlinear norm-optimal control de-

sign is presented (Lukes, 1969). The design approach

applies to the following class of systems

˙

x(t) = Ax(t) + Bu(t) + f (x(t), u(t)) ,

y = h (x(t), u(t)) = Cx(t) + Du(t),

(6)

with the affine control input u ∈ U ⊂ R

m

, the

state vector x ∈ X ⊂ R

n

and the output vector

y ∈ Y ⊂ R

p

. The non-linearity f (x, u) can be

stated as f (x, u) = f

(2)

(x, u) + f

(3)

(x, u) + ...,

where f

(m)

(x, u) denotes a polynomial of degree m

in terms of x and u. The H

2

-optimal control aims at

calculating a nonlinear state feedback law u(x) with

u(0) = 0 such that the nonlinear cost function

J(u) = inf

u∈L

m

2

[0,∞)

Z

∞

0

Λ

2

(x, u)dt (7)

with

Λ

2

(x, u) =

1

2

y

T

Qy + u

T

Ru

+ l(x, u)

=

1

2

x

T

˜

Qx +

1

2

u

T

˜

Ru + x

T

N u + l(x, u)

(8)

is minimized. The symmetric, positive definite

weighting matrix Q = Q

T

> 0 accounts for the

output variables, whereas the symmetric, positive

definite weighting matrix R regards the control in-

puts. The nonlinear term l(x, u) = l

(3)

(x, u) +

l

(4)

(x, u) + ... consists of expressions of third or

higher degrees in terms of x and u. In the case of

l(x, u) = 0 the cost function becomes quadratic. The

solution of the above stated optimization problem is

given by the positive definite solution J (x) : X →

R

+

of a nonlinear partial differential equation, the

Hamilton-Jacobi-Bellman-equation (HJB-equation)

min

u

H (x, J

x

(x), u) = 0, (9)

with the corresponding Hamiltonian

H = J

x

(x) [Ax + Bu + f(x, u)] + Λ

2

(x, u).

(10)

In the considered unconstrained case, the optimal so-

lution u

∗

is obtained from the stationary condition

H

u

= 0. Consequently, the two equations

H =J

x

(x) [Ax + Bu + f(x, u)] +

1

2

x

T

˜

Qx

+ x

T

Nu +

1

2

u

T

˜

Ru + l(x, u) = 0

(11)

and

H

u

= J

x

(x) (B + f

u

(x, u)) + x

T

N

+ u

T

˜

R + l

u

(x, u) = 0

(12)

need to be solved. These equations are approximately

solved by an approach according to (Lukes, 1969)

based on power series expansions of the involved non-

linear functions . The gradient of the optimal solution

J (x) and the control law are recursively determined

by a step-by-step solution of both equations for a con-

sidered degree k of the according polynomials in x

and u.

3.1 Feedback Control Design

The control design for both internal muscle pressures

is identical (Aschemann et al., 2006). For the sake of

simplicity, the internal muscle pressure as state vari-

able is denoted as x := p

Mi

, i = {r, l}, and the con-

trol input as u := u

pi

= R

L

· T

0

· ˙m

Mi

. Then, the

state equation (3) can be rewritten as

˙x =

n ·

u − k

1

(x

S

, ˙x

S

) · x − k

2

(x

S

, ˙x

S

) · x

2

k

3

(x

S

) + k

4

(x

S

) · x

,

(13)

According to the continuous dependence of the coef-

ficients k

i

(x

S

, ˙x

S

) on x

S

and ˙x

S

, the resulting feed-

back control law is adapted by gain-scheduling. Af-

ter a truncated Taylor series expansion with respect to

x = p

Mi

, the nonlinear state space description for the

muscles pressure becomes

˙x = a(u) + b(u) · x + c(u) · x

2

+ d(u) · x

3

+ e(u) · x

4

+ g(u) · x

5

,

y = x,

(14)

The quadratic cost function with l(x, u) = 0 is given

by

J(u) =

1

2

Z

∞

0

q

p

x

2

+ r

p

u

2

dt, (15)

where the scalar r

p

serves as a weighting factor for

the input variable u = u

pi

and the scalar q

p

as weight-

ing factor for the state variable, i.e. the muscle pres-

sure x = p

Mi

. The H

2

-optimal control laws for these

fast inner control loops are calculated up to the degree

k = 3, i.e. u

pi,F B

(x) =

P

3

j=1

u

0(j)

. The resulting

nonlinear feedback control law u

pl,F B

(p

Ml

, x

S

, ˙x

S

)

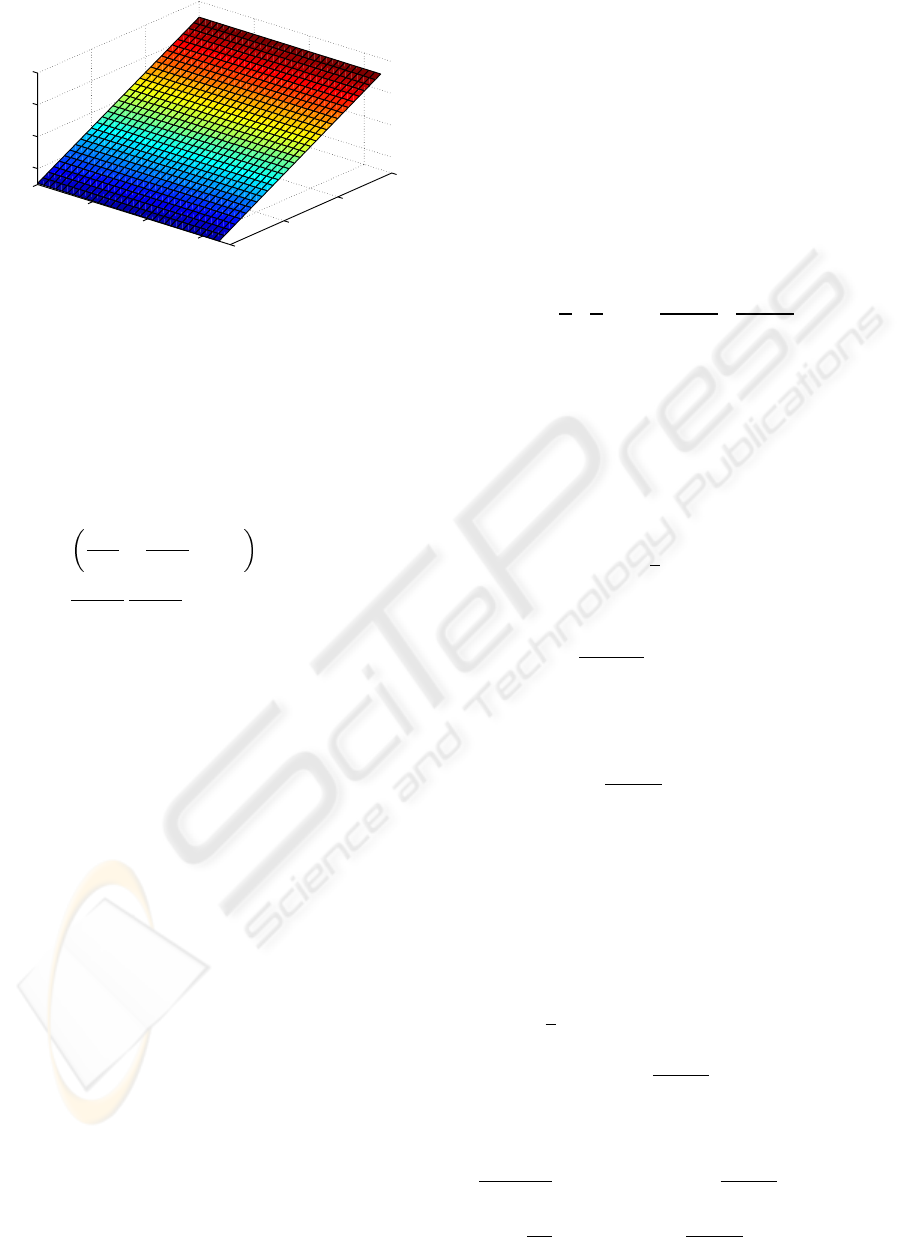

for the left muscle is depicted in Fig. 2 for ˙x

S

=

0.1 m/s. Obviously, the linear part dominates the non-

linear terms.

3.2 Feedforward Control Design

As for feedforward control design, differential flat-

ness can be exploited for the system under consid-

eration (Fliess et al., 1995). The muscle pressure

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

94

1

3

5

7

0

0.1

0.2

0.3

−6

−4

−2

0

x 10

4

p

Ml

in N/m

2

x 10

5

x

S

in m

u

pl,FB

in J/s

Figure 2: Nonlinear H

2

-optimal feedback control law

u

pl,F B

(p

Ml

, x

S

, ˙x

S

) for the left pneumatic muscle for the

gain-scheduling parameters x

S

and ˙x

S

= 0.1 m/s.

y = p

Mi

, i = {r, l}, obviously represents a flat out-

put of the corresponding inner control loop. Evaluat-

ing the state equation (3) for the muscle pressure with

desired values for the flat output y

d

= p

Mid

as well

as its time derivative ˙y

p

= ˙p

Mid

and solving for the

feedforward control part u

pi,F F

result in

u

pi,F F

=

V

Mi

n

+

∂V

Mi

∂p

Mi

· p

Mid

˙p

Mid

+

∂V

Mi

∂∆l

Mi

∂∆l

Mi

∂x

S

· ˙x

S

· p

Mid

− u

pi,F B

(p

Mid

).

(16)

Note that the measured values x

S

and ˙x

S

are used for

a gain-scheduled adaptation of the feedforward con-

trol law. As a result, the overall control law for the

inner control loops becomes u

pi

= u

pi,F F

+ u

pi,F B

.

4 NONLINEAR MPC

The main idea of the control approach consists in a

minimization of a future tracking error in terms of the

predicted state vector based on the actual state and

the desired state vector resulting from trajectory plan-

ning (Lizarralde et al., 1999), (Jung and Wen, 2004).

The minimization is achieved by repeated approxi-

mate numerical optimization in each time step, in

the given case using the Newton-Raphson technique.

The optimization is initialised in each time step with

the optimization result of the preceeding time step in

form of the input vector. The NMPC-algorithm is

based on the following nonlinear discrete-time state

space representation

x

k+1

= f (x

k

, u

k

) , y

k

= h(x

k

, u

k

) , (17)

with the state vector x

k

∈ R

n

, the control input u

k

∈

R

m

and the output vector y

k

∈ R

p

. The constant M

specifies the prediction horizon T

P

as a multiple of

the sampling time t

s

, i.e. T

P

= M · t

s

. The predicted

input vector at time k becomes

u

k,M

=

u

(k)

1

T

, ..., u

(k)

M

T

T

, (18)

with u

k,M

∈ R

m·M

. The predicted state vector at

the end of the prediction horizon φ

M

(x

k

, u

k,M

) is

obtained by repeated substitution of k by k + 1 in the

discrete-time state equation (17)

x

k+2

= f (x

k+1

, u

k+1

) = f(f(x

k

, u

k

), u

k+1

)

.

.

.

x

k+M

= f (· · · f

|

{z }

M

(x

k

, u

k

), · · · , u

k+M −1

|

{z }

M

)

= φ

M

(x

k

, u

k,M

) .

(19)

The difference of φ

M

(x

k

, u

k,M

) and the desired

state vector x

d

leads to the final control error

e

M,k

= φ

M

(x

k

, u

k,M

) − x

d

, (20)

i.e. to the control error at the end of the prediction

horizon. The cost function to be minimized follows

as

J

MP C

=

1

2

· e

T

M,k

e

M,k

, (21)

and, hence, the necessary condition for an extremum

can be stated as

∂J

MP C

∂e

M,k

= e

M,k

!

= 0 . (22)

A Taylor-series expansion of (22) at u

k,M

in the

neighbourhood of the optimal solution leads to the

following system of equations

0 = e

M,k

+

∂φ

M

∂u

k,M

∆u

k,M

+ T.h.O. (23)

The vector ∆u

k,M

denotes the difference which has

to be added to the input vector u

k,M

to obtain the

optimal solution. The n equations (23) represent an

under-determined set of equations with m · M un-

knowns having an infinite number of solutions. A

unique solution for ∆u

k,M

can be determined by

solving the following L

2

-optimization problem with

(23) as side condition

J =

1

2

· ∆u

T

k,M

∆u

k,M

+ λ

T

e

M,k

+

∂φ

M

∂u

k,M

∆u

k,M

.

(24)

Consequently, the necessary conditions can be stated

as

∂J

∂∆u

k,M

!

= 0 = ∆u

k,M

+

∂φ

M

∂u

k,M

T

λ,

∂J

∂λ

!

= 0 = e

M,k

+

∂φ

M

∂u

k,M

∆u

k,M

,

(25)

NONLINEAR MODEL PREDICTIVE CONTROL OF A LINEAR AXIS BASED ON PNEUMATIC MUSCLES

95

which leads to e

M,k

:

e

M,k

=

∂φ

M

∂u

k,M

∂φ

M

u

k,M

T

|

{z }

S(φ

M

,u

k,M

)

λ . (26)

If the matrix S (φ

M

, u

k,M

) is invertible, the vector λ

can be calculated

λ = S

−1

(φ

M

, u

k,M

) e

M,k

. (27)

An almost singular matrix S (φ

M

, u

k,M

) can be

treated by a modification of (27)

λ = [µI + S (φ

M

, u

k,M

)]

−1

e

M,k

, (28)

where I denotes the unity matrix. The regularisation

parameter µ > 0 in (28) may be chosen constant or

may be calculated by a sophisticated algorithm. The

latter solution improves the convergence of the op-

timization but increases, however, the computational

complexity. Solving (25) for ∆u

k,M

and inserting

λ according to (27) or (28), directly leads to the L

2

-

optimal solution

∆u

k,M

= −

∂φ

M

∂u

k,M

T

S

−1

(φ

M

, u

k,M

) e

M,k

= −

∂φ

M

∂u

k,M

†

e

M,k

.

(29)

Here,

∂φ

M

∂u

k,M

†

denotes the Moore-Penrose pseudo

inverse of

∂φ

M

∂u

k,M

. The overall NMPC-algorithm can

be described as follows:

Choice of the initial input vector u

0,M

at time k = 0,

e.g. u

0,M

= 0, and repetition of steps a) - c) at each

sampling time k ≥ 0:

a) Calculation of an improved input vector v

k,M

ac-

cording to

v

k,M

= u

k,M

− η

k

∂φ

M

∂u

k,M

†

e

M,k

. (30)

The step width η

k

can be determined with, e.g.,

the Armijo-rule.

b) For the calculation of u

k+1,M

the elements of the

vector v

k,M

have to be shifted by m elements and

the steady-state input vector u

d

corresponding to

the final state has to be inserted at the end u

d

u

k+1,M

=

0

(m(M−1)×m)

I

(m)

u

d

+

0

(m(M−1)×m)

I

(m(M−1))

0

m×m

0

(m×m(M−1))

v

k,M

.

(31)

In general, the steady-state control input u

d

can

be computed from

x

d

= f (x

d

, u

d

). (32)

For differentially flat systems the desired input

vector u

d

is given by the inverse dynamics and

can be stated as a function of the flat outputs and

their time derivatives.

c) The first m elements of the improved input vector

v

k,M

are applied as control input at time k

u

k

=

I

(m)

0

(m×m(M−1))

v

k,M

. (33)

In the proposed algorithm only one iteration is per-

formed per time step. A similar approach using sev-

eral iteration steps is described in (Weidemann et al.,

2004).

4.1 Numerical Calculations

The analytical computation of the Jacobian

∂φ

M

∂u

k,M

be-

comes increasingly complex for larger values of M .

Therefore, a numerical approach is preferred taking

advantage of the chain rule with i = 0, ..., M − 1

∂φ

M

∂u

(k)

i+1

=

∂φ

M

∂x

k+M −1

·

∂x

k+M −1

∂x

k+M −2

· · · ·

·

∂x

k+i+2

∂x

k+i+1

·

∂x

k+i+1

∂u

(k)

i+1

.

(34)

Introducing the abbreviations

A

i

:=

∂x

k+i+1

∂x

k+i

=

∂f

∂x

x

k+i

, u

(k)

i+1

, (35)

B

i

:=

∂x

k+i+1

∂u

(k)

i+1

=

∂f

∂u

x

k+i

, u

(k)

i+1

, (36)

the Jacobian can be computed as follows

∂φ

M

∂u

k,M

= [A

M−1

A

M−2

· · · A

1

B

0

,

A

M−1

· · · A

2

B

1

, ..., A

M−1

B

M−2

, B

M−1

] .

(37)

For the inversion of the symmetric and positive def-

inite matrix S (φ

M

, u

k,M

) =

∂φ

M

∂u

k,M

∂φ

M

∂u

k,M

T

the

Cholesky-decomposition has proved advantageous in

terms of computational effort.

4.2 Choice of the Nmpc Design

Parameters

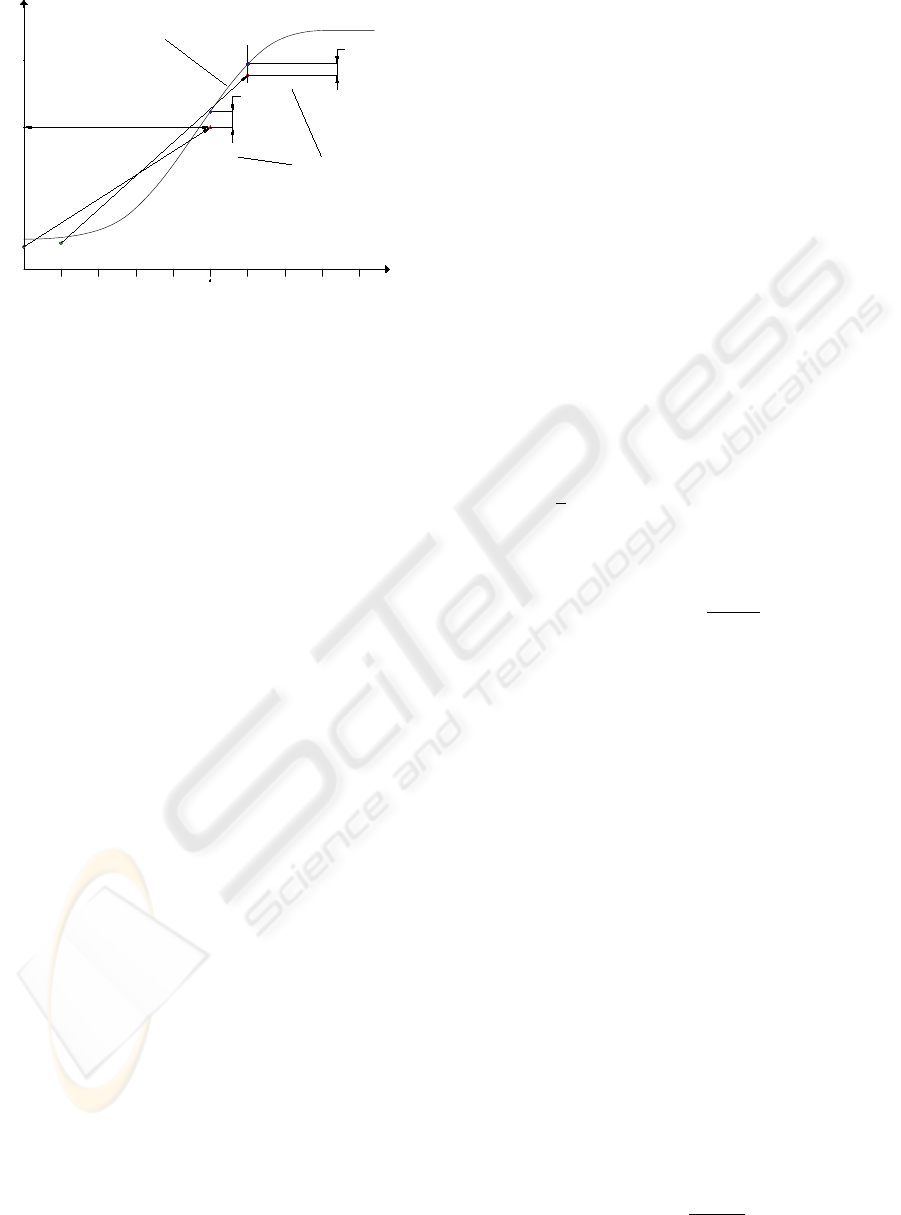

The most important NMPC design parameter is the

prediction horizon T

P

, which is given as the prod-

uct of the sampling time t

s

and the constant value

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

96

T

P

e

M,0

x

0

φ

M

(x , u )

0

0,M

Desired Trajectory

x

t

t

s

φ

M

(x , u )

1

1,M

x

1

e

M,1

t

s

M

Predicted state

x

d,0

x

d,1

Figure 3: Design parameters.

M. Large values of T

P

lead to a slow and smooth

transient behaviour and result in a robust and stable

control loop. For fast trajectory tracking, however,

a smaller value T

P

is desirable concerning a small

tracking error. The choice of the sampling time t

s

is crucial as well: a small sampling time is neces-

sary regarding discretization error and stability; how-

ever, the NMPC-algorithm has to be evaluated in real-

time within the sampling inverval. Furthermore, the

smaller t

s

, the larger becomes M for a given pre-

diction horizon, which in turn increases the compu-

tational complexity of the optimization step. Conse-

quently, a system-specific trade-off has to be made

for the choice of M and t

s

. This paper follows the

moving horizon approach with a constant prediction

horizon and, hence, a constant dimension m · M of

the corresponding optimization problem in constrast

to the shrinking horizon approach (Weidemann et al.,

2004).

4.3 Input Constraints

One major advantage of predictive control is the pos-

sibility to easily account for input constraints, which

are present in almost all control applications. To this

end, the cost function can be extended with a corre-

sponding term

h(u

(k)

j

) =

0 u

min

≤ u

(k)

j

≤ u

max

g

1

(u

(k)

j

) for u

(k)

j

> u

max

g

2

(u

(k)

j

) u

(k)

j

< u

min

,

(38)

which has to be evaluated componentwise, i.e. for

each input variable at each sampling time. Thus,

the contribution of the additional input constraints

depending on u

k,M

is given by

z(u

k,M

) =

M

X

j=1

h(u

(k)

j

) (39)

Instead of e

M,k

the vector

h

e

T

M,k

, z

i

T

has to be min-

imized in the NMPC-algorithm.

5 MODIFICATIONS OF THE

ALGORITHM

To improve trajectory tracking behaviour, the NMPC-

algorithm can be modified as follows:

(1) Instead of a minimization of the control error at

the end of the prediction horizon given by the dif-

ference of the predicted value φ

M

(x

k

, u

k,M

) and

the according reference value x

d

, the minimization

could take into account additional predicted errors

e

Mi,k

= φ

Mi

(x

k

, u

k,M i

) − x

di

, i ∈ N , Mi < M .

Thus, the cost function (21) is modified as follows

J

MP C

=

1

2

(e

T

M1,k

e

M1,k

+ ... + e

T

M,k

e

M,k

) (40)

The required values φ

Mi

are already known from

the calculation of φ

M

and, hence, do not further

increase the computational effort. Unfortunately,

the additional computation of

∂φ

Mi

∂u

Mi,k

as well as the

increased dimension of the matrix to be inverted

S(φ

M1

, ..., φ

M

, u

k,M 1

, ..., u

k,M

) have a significant

impact on the computation time. Therefore, the num-

ber of expressions in the cost function should be kept

as small as possible, especially in the given case of a

fast higher-dimensional system.

(2) A further improvement of the trajectory tracking

behaviour can be achieved if an input vector resulting

from an inverse system model is used as initial vector

for the subsequent optimization step instead of the last

input vector. Since the system under consideration is

differentially flat (Aschemann and Hofer, 2004), the

required ideal control input can be derived for a given

reference trajectory. The slightly modified algorithm

can be stated as follows

a) Calculation of the ideal input vector u

(d)

k,M

by

evaluating an inverse system model with the spec-

ified reference trajectory as well as a certain num-

ber β ∈ N of its time derivatives

u

(d)

k,M

= u

(d)

k,M

y

d

, ˙y

d

, ...,

(β)

y

d

. (41)

b) Calculation of the improved input vector v

k,M

based on the equation

v

k,M

= u

(d)

k,M

− η

k

∂φ

M

∂u

k,M

†

e

M,k

. (42)

NONLINEAR MODEL PREDICTIVE CONTROL OF A LINEAR AXIS BASED ON PNEUMATIC MUSCLES

97

c) Application of the first m elements of v

k,M

to the

process

u

k

=

I

(m)

0

(m×m(M−1))

v

k,M

. (43)

If the reference trajectory is known in advance, the ac-

cording reference input vector u

(d)

k,M

can be computed

offline. Consequently, the online computational time

remains unaffected. Of course, all the proposed mod-

ifications could be combined.

5.1 Nmpc of the Carriage Position

The state space representation for the position control

design can be directly derived from the equation of

motion for the carriage

˙

x =

˙x

S

¨x

S

=

˙x

S

F

Ml

(x

S

,p

Ml

)−F

Mr

(x

S

,p

Mr

)

m

S

.

(44)

The carriage position x

S

and the carriage velocity ˙x

S

represent the state variables, whereas the input vector

consists of the left as well as the right internal muscle

pressure, p

Ml

and p

Mr

. The discrete-time representa-

tion of the continous-time system (44) is obtained by

Euler discretisation

x

k+1

= x

k

+ t

s

· f(x

k

, u

k

) (45)

Using this simple discretisation method, the compu-

tational effort for the NMPC-algorithm can be kept

acceptable. Furthermore, no significant improvement

was obtained for the given system with the Heun dis-

cretisation method because of the small sampling time

t

s

= 5 ms. Only in the case of large sampling times,

e.g. t

s

> 20 ms, the increased computational effort

caused by a sophisticated time discretisation method

is advantageous. Then, the smaller discretisation er-

ror allows for less time integration steps for a speci-

fied prediction horizon, i.e. a smaller number M. As a

result, the smaller number of time steps can overcom-

pensate the larger effort necessary for a single time

step. The flat output variables of (44) are given by

y =

x

S

p

M

=

x

S

1

2

· (p

Ml

+ p

Mr

)

. (46)

Using the desired trajectories for the carriage position

x

Sd

and the mean muscle pressure p

Md

, the corre-

sponding desired input values result in

u

d

=

p

Mld

p

Mrd

=

1

¯

F

Ml

(·) +

¯

F

Mr

(·)

·

f

Ml

(·) − f

Mr

(·) + 2

¯

F

Mr

(·)p

Md

+ m

S

¨x

Sd

f

Mr

(·) − f

Ml

(·) + 2

¯

F

Ml

(·)p

Md

− m

S

¨x

Sd

.

(47)

5.2 Compensation of the Valve

Characteristic and Disturbances

The nonlinear valve characteristic (VC) is compen-

sated by pre-multiplying with its inverse valve char-

acteristic (IVC) in each input channel. Here, the in-

verse valve characteristic depends both on the com-

manded mass flow and on the measured internal pres-

sure. Disturbance behaviour and tracking accuracy in

view of model uncertainties can be significantly im-

proved by introducing a compensating control action

provided by a reduced-order disturbance observer,

which uses an integrator as disturbance model. The

observer design is based on the equation of motion for

the carriage (5), where the variable F

U

takes into ac-

count both the friction force F

RS

and the remaining

model uncertainties of the muscle force characteris-

tics ∆F

M

, i.e. F

U

= F

RS

− ∆F

M

. Moreover, the

disturbance observer is capable of counteracting im-

pacts of changing carriage mass ∆m

S

as well, which

results in F

U

= F

RS

+ ∆m

S

· ¨x

S

− ∆F

M

. As the

complete state vector x = [x

S

, ˙x

S

]

T

is forthcom-

ing, the reduced-order disturbance observer yields a

disturbance force estimate

ˆ

F

U

. Disturbance compen-

sation is achieved by using the estimated force

ˆ

F

U

as additional control action after an appropriate input

transformation.

6 EXPERIMENTAL RESULTS

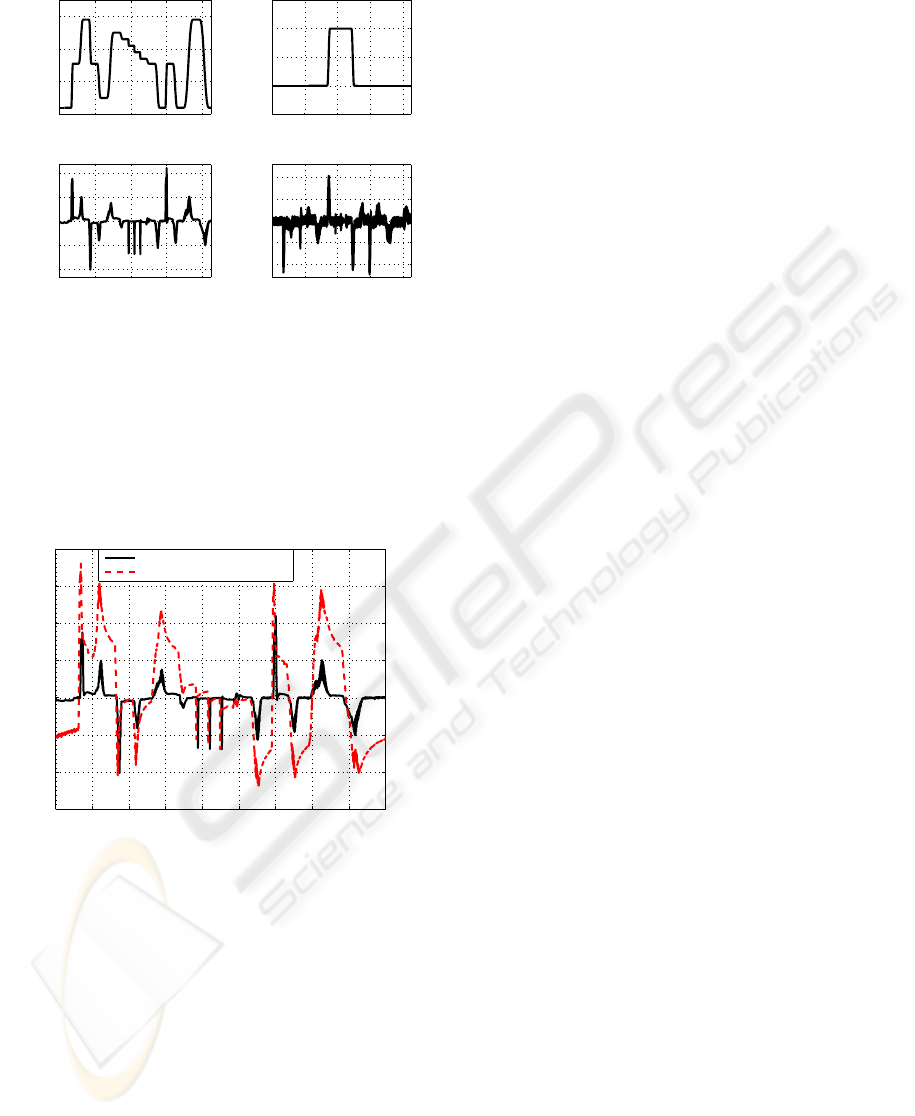

For the experiments at the linear axis test rig the syn-

chronized reference trajectories for the carriage po-

sition as well as the mean muscle pressure depicted

in the upper part of fig. 4 have been used. First, sev-

eral changes are specified for the carriage position be-

tween 0.02 m and 0.29 m at a constant mean pressure

of 4 bar. Second, the mean pressure is increased up

to 5 bar and kept constant during some subsequent

fast position variations by −0.02 m. Third, several

larger position changes are performed with a constant

mean pressure of 4 bar.

During trajectory tracking the number M is set to

small values. The sampling time has been kept con-

stant at t

s

= 5 ms. Fig. 4 shows the results obtained

with the choice M = 15, i.e. T

P

= 75 ms. Smaller

prediction horizons would lead to a tendency towards

increasing oscillatory behaviour and, finally, to insta-

bility. During the acceleration and deceleration in-

tervalls a maximum position control error e

x,max

of

approx. 4 mm occurs. The maximum control error

of the mean pressure e

p

is only slightly above an ab-

solute value of approx. 0.12 bar. The importance of

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

98

0 20 40 60 80

0

0.1

0.2

0.3

t in s

x

Sd

in m

0 20 40 60 80

−4

−2

0

2

4

x 10

−3

t in s

e

x

in m

0 20 40 60 80

3.5

4

4.5

5

5.5

t in s

p

Md

in bar

0 20 40 60 80

−0.1

−0.05

0

0.05

0.1

t in s

e

p

in bar

Figure 4: Reference trajectories and according tracking er-

rors for carriage position and mean pressure (T

P

= 75 ms).

the observer-based disturbance compensation is em-

phasized by Fig. 5. Without this control part the

maximum position control error increases up to ap-

prox. 7 mm.

0 10 20 30 40 50 60 70 80 90

−6

−4

−2

0

2

4

6

8

x 10

−3

t in s

e

x

in m

with disturbance compensation

without disturbance compensation

Figure 5: Position control error e

x

with and without distur-

bance observer (T

P

= 75 ms).

7 CONCLUSIONS

In this paper, a cascaded trajectory control scheme us-

ing nonlinear optimal design is presented for a car-

riage driven by pneumatic muscles. The modelling

of this mechatronic system leads to a system of four

nonlinear differential equations. The nonlinear char-

acteristics of the pneumatic muscles are approximated

by polynomials. The nonlinearity of the valve is lin-

earised by means of a pre-multiplication with its ap-

proximated inverse characteristic. The inner control

loops of the cascade involve a norm-optimal control

of the internal muscle pressure with high bandwidth.

The outer nonlinear model predictive control loop is

responsible for trajectory tracking with carriage po-

sition and mean pressure as controlled variables. Re-

maining model uncertainties are taken into account by

a disturbance force estimated by means of a distur-

bance observer. Experimental results from an imple-

mentation on a test rig emphasise the excellent closed-

loop performance with maximum position errors of

4 mm during the movements, negligible steady-state

position error and steady-state pressure error of less

than 0.02 bar.

REFERENCES

Aschemann, H. and Hofer, E. (2004). Flatness-based tra-

jectory control of a pneumatically driven carriage with

model uncertainties. Proceedings of NOLCOS 2004,

Stuttgart, Germany, pages 239 – 244.

Aschemann, H., Schindele, D., and Hofer, E. (2006). Non-

linear optimal control of a mechatronic system with

pneumatic muscles actuators. CD-ROM-Proceedings

of MMAR 2006, Miedzyzdroje, Poland,.

Carbonell, P., Jiang, Z. P., and Repperger, D. (2001). Com-

parative study of three nonlinear control strategies for

a pneumatic muscle actuator. Proceedings of NOL-

COS 2001, Saint-Petersburg, Russia, pages 167–172.

Fliess, M., Levine, J., Martin, P., and Rouchon, P. (1995).

Flatness and defect of nonlinear systems: Introduc-

tory theory and examples. Int. J. Control 61, 6:1327 –

1361.

Jung, S. and Wen, J. (2004). Nonlinear model predictive

control for the swing-up of a rotary inverted pendu-

lum. ASME J. of Dynamic Systems, Measurement and

Control, 126:666 – 673.

Lizarralde, F., Wen, J., and Hsu, L. (1999). A new model

predictive control strategy for affine nonlinear control

systems. Proc of the American Control Conference

(ACC ’99), San Diego, pages 4263 – 4267.

Lukes, D. (1969). Optimal regulation of nonlinear dynami-

cal systems. SIAM Journal Control, 7:75 – 100.

Weidemann, D., Scherm, N., and Heimann, B. (2004).

Discrete-time control by nonlinear online optimiza-

tion on multiple shrinking horizons for underactuated

manipulators. Proceedings of the 15th CISM-IFToMM

Symposium on Robot Design, Dynamics and Control,

Montreal.

NONLINEAR MODEL PREDICTIVE CONTROL OF A LINEAR AXIS BASED ON PNEUMATIC MUSCLES

99