NONLINEAR FUZZY SELFTUNING PID CONTROL

TECHNOLOGY AND ITS APPLICATIONS IN AUTOMATED

PROGRAMMING ROBOTICS

Ganwen Zeng

Data I/O Corporation, 6464 185

th

Ave NE, Readmond, WA 98052, USA

Qianglong Zeng

Dartmouth University, Hanover, NH, 03755, USA

Keywords: Fuzzy control, Fuzzy sets, Fuzzy self-tuning control, Fuzzy PID control, Robotics, Distributed control,

Programming systems, Control algorithm, Control system, DSP, ADC/DAC, Servo motor control, FPGA,

Microcontrollers, PowerPC, ARM9, COM, CAN, ETHERNET, Multi-core architectures, Embedded control

system, Bios, RTOS, kernel, OOP, Nested ISR, Fast IO, Firmware, Embedded software, Control

applications, Programming technology, ONFI (Open NAND Flash Interface), Flash devices, Flash cards,

Flash disks, USB2.0 host/Flash Media Controller for SmartMedia (SM), xD, CF, MS, SD and

MultimediaCard (MMC).

Abstract: The paper presents an advanced Fuzzy self-tuning PID controller theory and it implement its applications on

Data I/O’s automated robotic programming systems. Considerable programming technology shift occurred

in recent device programmer industry; programming density have been constantly fast growing from low-

volume to high-volume programming for all kinds of non-volatile flash memory devices such as NOR flash,

NAND flash, and MMC cards, SD flash cards, serial flash device, serial flash cards, flash-based

microcontrollers and flash disks as high performance M-systems DiskOnChip. Device programming mode

is more demanding an automatic programming than manual operation mode. It drives the creation and

implementation of a high-performance automated programming robotic systems. This paper shows how this

proposed advanced Fuzzy self-tuning PID controllers work on these automated programming robotic

automation systems.

1 INTRODUCTION

Automated programming systems available today

are able to fully automate device programming and

to fully integrate programming testing, how to

obtain a high control performance and good control

system stability in these automated robotic system is

one key of the success in long-term device

operations in the programmer systems. It improves

the productivity, quality and flexibility of a

semiconductor production process.

High performance motor motion control precision

and high level of integration is continuously

increasing, and the clear trend is towards completely

integrated intelligent programming system. This

paper describes an embedded intelligent

programming automation system. The robotic

automated programmer system is shown in the

Figure 1.

The robotic automated programmer system is

implement in multiple microcontrollers, DSP and

embedded processors, for an complex control

motion and control task control, a multi-core

architecture is used for a high-performance motion

control and optimal marshalling control of multiple

control tasks. The multi-core can easily assist a

control task marshalling that implements a task-on-

task control communication. The control block

diagram of the robotic automated programmer

system is shown in the Figure 2.

372

Zeng G. and Zeng Q. (2007).

NONLINEAR FUZZY SELFTUNING PID CONTROL TECHNOLOGY AND ITS APPLICATIONS IN AUTOMATED PROGRAMMING ROBOTICS.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 372-375

DOI: 10.5220/0001647303720375

Copyright

c

SciTePress

Figure 1: Data I/O FLX500.

The robotic automated programmer system is

implement in multiple microcontrollers, DSP and

embedded processors, for an complex control

motion and control task control, a multi-core

architecture is used for a high-performance motion

control and optimal marshalling control of multiple

control tasks. The multi-core can easily assist a

control task marshalling that implements a task-on-

task control communication. The control block

diagram of the robotic automated programmer

system is shown in the Figure 2.

It is composed of one host commander and two

main motion control subsystems DPCS (Device

Positioning Control System) and DIOC (Device

Input Output Control System). The DPCS is

composed by 5 control units of robotic task space

configuration, X-gantry motion robotic control, y-

gantry motion robotic control, head dynamic motion

control, head rotation robotic control, device pick-

and-place robotic control. The DIOC is composed

by two control units of device feeding tape control

and device transportation belt motion control.

Synchronous communications can rely on the bus

Ethernet and TCP/IP protocol in a multi-core

architecture.

Figure 2: Control Block Diagram of Data I/O FLX500.

Asynchronous communications between the

host commander and the motor control systems for

the Nonlinear and Linear Brushless Servo Motors,

AC Speed Motors with fractional HP, and

Piezoelectric motors can be based on the TouCAN

bus or Motorola 68376 Com Ports to guarantee the

space loop closure for the main axes of the robotic

control system. Based on the CAN architectures, a

disturbed intelligent control structures is proposed in

this multiple robotic axis configurations in the

programmer automation system. This means the use

of single-axis intelligent DSP motion controllers for

both DPCS and DIOC which can handle local

robotic axis control function independently from the

multi-core processor host. Robust real-time OS

kernel codes are used into the controllers to

implement optimal interrupt service routines, fast

IO, multi-threading, PWM generating units, current

and motor torque control, speed/position control,

and fuzzy control self-tuning PID control algorithms

and integrated robotic motion solutions. Simulation

has been done in LabVIEW 7.0 Professional

Development System (PDS) and the MathWorks

Matlab and Simulink. The real-time performances

are shown in the conclusions.

2 CONTROL SYSTEM DESIGN

AND RESEARCH

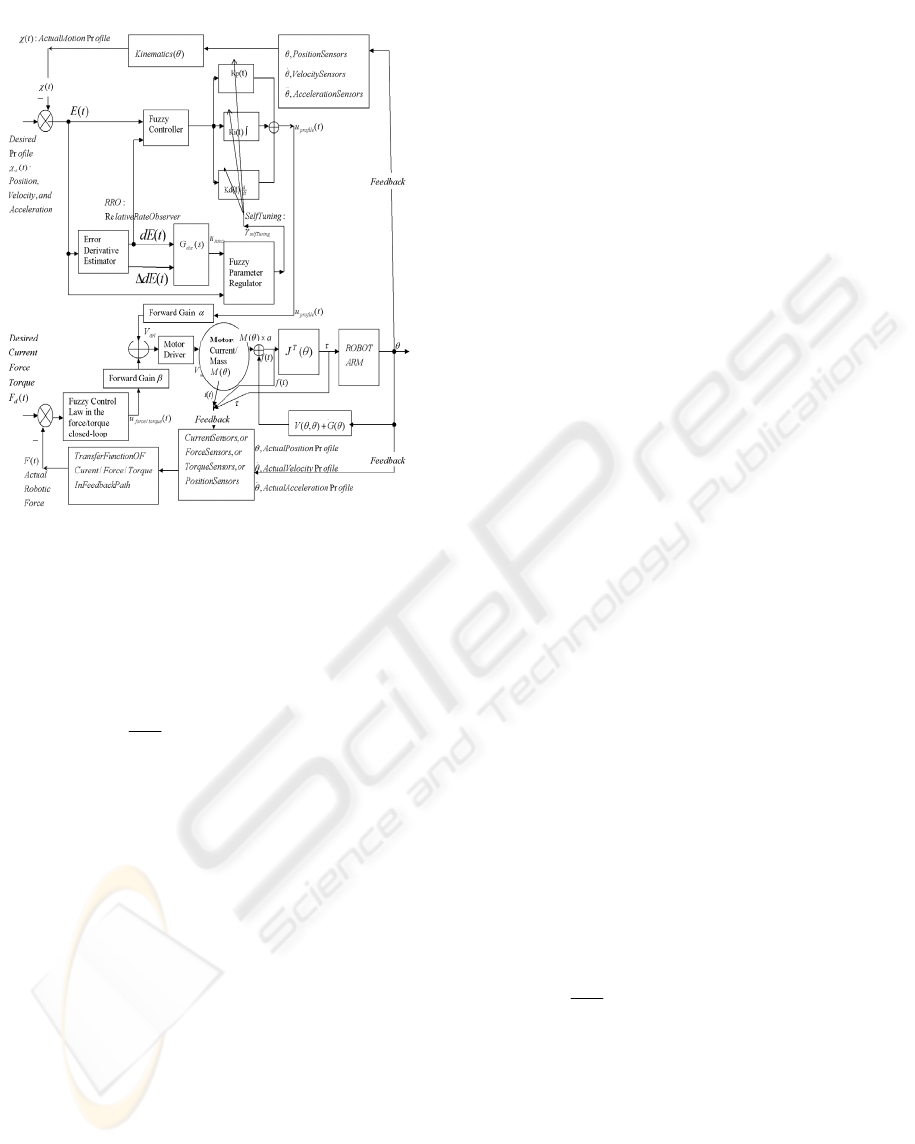

The control system design is shown in the Figure 3.

NONLINEAR FUZZY SELFTUNING PID CONTROL TECHNOLOGY AND ITS APPLICATIONS IN AUTOMATED

PROGRAMMING ROBOTICS

373

Figure 3: The control system design of nonlinear fuzzy

self-tuning PID robotic controller.

The robotic control object to obtain a steady

torque and high performance motion profiles, the

robotic control system transfer function

)(

θ

robot

G

is:

))(),(),(),(()(

)(

)(

ttttfsG

r

s

s

robot

τθθ

τ

Θ==

Θ

And

)(),())(()()(

..

θϑθθχθ

χχχ

GVtMtf ++=

Where

)(tf

is a fictitious force-moment acting on

the end-effectors of the robot arm,

)(

θ

χ

M

represents the mass matrix of the distributed robotic

joint in Cartesian space,

))(( t

θ

χ

is an appropriate

Cartesian vector representing position and

orientation of the end-effectors in Cartesian space.

),(

ϑθ

χ

V

is the Coriolis term of the robotic system

in Cartesian space,

)(

θ

χ

G

is the gravity term of the

robotic system in Cartesian space.

θ

is the angular

position of motor, the vector of joint angles of the

robotic arm.

ϑ

is the angular velocity of the motor,

θ

is the angular acceleration of the motor.

The advanced fuzzy self-tuning PID controller

provide a current/voltage control output variable

ctrl

ν

to a motor driver, the different motor drivers

have been designed in this control systems, for

instance, a switch-mode (chopper), constant-current

driver with multiple channels is designed in one

control unit; its current control inputs are low

current, high impedance inputs, which allows the use

of un-buffered DAC or external high resistive

resistor divider network. Each driver in the control

system contains a clock oscillator, which is common

for all the driver channels, a set of comparators and

flip-flops implementing the switching control, and

two output H-bridges for each motor, including

recirculation diodes. Maximum output current is

controlled at 750mA per channel. The DSP scales

and then generates PWM using the 68376’s TPU

from the control output

)(tV

ctrl

, The velocity control

is achieved through varying the voltage across the

terminals of a motor by the Pulse Width Modulation

that is the continuous fast switching of motor

voltage. By varying the duty cycle from 0% to

100%, the effective voltage across a motor can be

established from a set input of PMW duty cycle

(

motor

V

). The PWM duty cycle

motor

ν

is fed into the

motor drive to drive the DC servo motors; the

motors output the force

)(tf

, which support and

control the robotic operations in robotic Cartesian

based control space including robotic displacements

and robotic rotations.

The robotic torqueses come from the input

force

)(tf

. In Cartesian robotic task space, it can be

represented as

)()( tfJ

T

×=

θτ

Here

)(

θ

J

are Jacobians, a time-varying linear

transformations,

)(

θ

T

J

is the transpose Jacobian

transformation; only once in the case of a strictly

Cartesian robot arm, we can simplify the

)(

θ

T

J

to

the Jacobian’s inverse transformation

)(

1

θ

−

J

.

The voltage output

)(t

υ

of the motor driver and

motor current

)(ti

supplied by motor driver, input to

the robotic motors, the transfer function from the

driver input to the robotic force is

))(( sG

i

τ

.

))(),(()(

)(

)(

ttfsG

i

s

sf

i

υτ

υ

==

The desired control voltage

ctrl

V

, supplied by the

advanced Fuzzy self-tuning PID robotic controller,

consists of two components: robotic motion profile

voltage control component

)(tu

profile

and the robotic

force/torques/current voltage Fuzzy control

component

)(

/

tu

torqueforce

; i.e. the combined control

input is:

)(tV

ctrl

= (

α

)(tu

profile

+

β

)(

/

tu

torqueforce

)

Where

α

and

β

are forward control gains

coefficients. In the profile nonlinear fuzzy self-

tuning PID controller, the nonlinear fuzzy control

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

374

algorithm is implemented on the control DSP, based

on the Fuzzy control algorithm, the desired control

gains K

p(t), Ki(t), and Kd(t) for the motors are sel-

tuning on line in the control systems, and thus, the

equivalent control components of the fuzzy PID

controller are varied on line, it can be represented as

follows:

)(tu

profile

= Kp(t)

)(tUΔ

+ Ki(t)

dttU )(Δ∫

+

K

d(t)

dt

tUd

))(( Δ

Here:

Proportional gain control is Kp(t)

)(tUΔ

Integral gain control is Ki(t)

dttU )(Δ∫

Derivative gain control is Kd(t)

dt

tUd

))(( Δ

There is a RRO (relative rate observer) to estimate

the error derivative

)(tdE

, and construct

)(tdE

Δ

,

the derivative of

)(tdE

.

Here the motion profile control error is:

)()()()( tttEtE

dp

χ

χ

−==

And the RRO outputs the control variable

)(tu

RRO

to the PID parameter regulators; such that

regulator produce the regulation control output

)(t

selfTuning

γ

, which make the PID have a best-

performance control gains for the robotic systems.

3 NONLINEAR FUZZY

CONTROLLER

As shown in Figure 3, the error input for the motion

profile is

)()()( tttE

dp

χ

χ

−=

The error input for the force profile is:

)()()( tFtFtE

dF

−=

The desired voltage control of the nonlinear Fuzzy

PID is:

)(tV

ctrl

= (

α

)(tu

profile

+

β

)(

/

tu

torqueforce

)

This control output variables from the advance

Fuzzy control PID control the robotic systems, it has

achieved a high-performance actual profile in

robotic Cartesian space. The fuzzy control is not

only responsible to regulate the PID control gains, it

also provide the control variables for the

current/force/torque control closed-loop. The Fuzzy

control principle is show in Figure 4.

Figure 4: Nonlinear Fuzzy Controller.

Where the time continuous variables

q

VΔ

and

i

V

Δ

are the whole set of the control errors in the

control systems; which are the error set of

{

)(tE

p

, )(tE

F

}.

Basically, the nonlinear fuzzy controller consists

of three parts: the fuzzy discretization by use of the

fuzzy membership functions, the fuzzy control based

on the fuzzy control rules, and fuzzy decision

through the weighting meaning calculation.

4 CONCLUSIONS

The real-time performance results demonstrates that

the maximum Euler distance error of the Fuzzy self-

tuning PID equals to 0.0005239 inches, the PID

control accuracy is 0.175565 inches. The control

accuracy using a Fuzzy self-tuning PID controller is

improved compared a traditional PID controller in

Cartesian space

)}(),(,,,,{

2121

θ

μ

θ

μ

axisZaxisZYaxisXaxis .

REFERENCES

Shin, K. G: “Trajectory Planning for Robot Control: A

Control System Perspective, Control and Dynamic

System Series, Advances in Robotics System, “

Academic Press Inc.1991, pp. 105–146.

Yasuhiko Dote, Servo motor and motion control using

signal processors, TJ216.D68, Prentice Hall,:

Englewood Cliffs, N.J. 1990.

Bill Drury, The control techniques drives and controls

handbook, TK4058.D78, Stevenage: Institue of

Electrical Engineers, 2001.

Sakae Yamamura, AC motors for high-performance

applications: analysis and control, TK2791.Y35, New

York: Dekker, 1986.

Ganwen Zeng and Ahmad Hemami, “An overview of

robot force control,” Robotica, 1997, pp. 473-482.

NONLINEAR FUZZY SELFTUNING PID CONTROL TECHNOLOGY AND ITS APPLICATIONS IN AUTOMATED

PROGRAMMING ROBOTICS

375