A MULTI-MODEL APPROACH FOR BILINEAR GENERALIZED

PREDICTIVE CONTROL

Anderson Luiz de Oliveira Cavalcanti

Informatic and Industry Academic Department, CEFET, Natal/RN, Brazil

André Laurindo Maitelli

Department of Computation and Automation, UFRN, Campus Universitário S/N, Natal/RN, Brazil

Adhemar de Barros Fontes

Department of Electrical Engineering,UFBA, Rua Aristides Novis, 04, Salvador/BA, Brazil

Keywords: Model Predictive Control, Multi-Model, Distillation Column.

Abstract: This paper presents a contribution in multivariable predictive control. A new approach of multi-model based

control is presented. The controller used is the quasilinear multivariable generalized predictive control

(QMGPC). A metric based in 2-norm is presented in order to build a global model using local models.

Simulation results in a distillation column, with a comparative analysis, are presented.

1 INTRODUCTION

The multi-model approach has been presented as an

alternative method to be applied is systems that

operate in a long range (Aslan et al., 2004). When a

process operates in a long range, due to non-

linearities, usually the parametric variation of its

models is large. For this reason, usually, a controller

based in just one model has poor performance in

these kind of process.

The basic idea of multi-model approach is to

identify a set of models (one for each operating

regime in a chosen trajectory) and to interpolate

these models (through an interpolation function).

Other approach calculates a suitable control effort as

a wheighting sum of each control effort (in each

designed controller for each operating regime).

Some approches use space state models like

(Azimadeh et al., 1998) and (Foss et al., 1995). In

(Azimadeh et al., 1998) a set of linear space state

models is chosen in a given trajectory. In (Foss et

al., 1995) a set on nonlinear space state models is

chosen (and a nonlinear predictive controller is

designed).

A closed loop metric, that guarantee the global

stability, is proposed in (Aslan et al., 2004). In that

case, a set of PI controllers is projected and, for each

instant, the distance from the current point in a

chosen trajectory to a tabled operating regime is

calculated.

In this paper, a similar idea to (Foss et al., 1995)

is proposed. In this case, a set of local bilinear

models is identified. The global model is build with

a wheigthing sum of the identified local models. The

wheigthing factor is calculated based in a proposed

metric. This metric consists of use a 2-norm to

measure the distance from the current point (in a

chosen monotonic trajectory) and a tabled operating

regime. A case study in a debutanized distillation

column is presented in order to show an application

of the proposed controller.

The next step of this research is the stability and

robustness analisys (to presents a stable algorithm

proposal).

289

Luiz de Oliveira Cavalcanti A., Laurindo Maitelli A. and de Barros Fontes A. (2007).

A MULTI-MODEL APPROACH FOR BILINEAR GENERALIZED PREDICTIVE CONTROL.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 289-295

DOI: 10.5220/0001617202890295

Copyright

c

SciTePress

2 MULTIVARIABLE MULTI-

MODEL

The designed controller is based in quasilinear

multivariable generalized predictive control

(QMGPC). This controller is based in multivariable

bilinear NARIMAX (Non Linear, Auto-Regressive,

Moving Average, with exogenous input) models.

The basic idea of QMGPC algorithm is calculate

a control effort sequence, based in the minimization

of a multi-step objective function, in a defined

prediction horizon.

2.1 Multivariable Multi-Model

The multivariable multi-model bilinear NARIMAX

model with p-inputs and q-outputs is given by:

)()(

)1()()()]1([)(

)1()()()()()(

1)(

11

)(

1

)(

11)(11)(

keqC

kyqqDkuDqD

kuqqBkyqqA

k

q

k

d

k

e

p

k

q

k

−

−−−

−−−−

+−Δ−

+−Δ=Δ

(1)

where

q

Rky ∈)( is the process output vector,

p

Rku ∈)( is the process input vector and

q

Rke ∈)(

is the gaussian white noise with zero mean and

covariance

)(

2

σ

diag . The matrices )(

1)( −

qA

k

,

)(

1)( −

qB

k

and )(

1)( −

qC

k

are polynomials matrices in

shift operator

1−

q

and are defined by:

na

k

na

k

qq

k

qAqAIqA

−−

×

−

+++=

)(

1

)(

1

1)(

)( "

(2)

nb

k

nb

kk

k

qBqBBqB

−−−

+++=

)(

1

)(

1

)(

0

1)(

)( "

(3)

nc

k

nc

k

pp

k

qCqCIqC

−−

×

−

+++=

)(

1

)(

1

1)(

)( "

(4)

d

d

nd

k

ndd

k

d

k

d

k

d

qDqDDqD

−

−−

+++=

)(

,

1

)(

1,

)(

0,

1

)(

)( "

(5)

e

e

nd

k

nde

k

e

k

e

k

e

qDqDDqD

−

−−

+++=

)(

,

1

)(

1,

)(

0,

1

)(

)( "

(6)

where:

qqk

RqA

×−

∈)(

1)(

,

pqk

RqB

×−

∈)(

1)(

,

qqk

RqC

×−

∈)(

1)(

,

pq

k

e

RqD

×−

∈)(

1

)(

and

qp

k

d

RqD

×−

∈)(

1

)(

. The matrix

)]1([ −kuD is defined as:

⎥

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎢

⎣

⎡

−

−

−

=−

)1(00

0)1(0

00)1(

)]1([

2

1

ku

ku

ku

kuD

p

"

#%##

"

"

(7)

The generic polynomial matrix

)(

1)( −

qP

k

in (1)

represents this matrix in instant

k.

The first step to build (1) is decompose the

system's operating range into a number of operating

regimes that completely cover the chosen trajectory.

Second, for each operating regime, a local model

structure must be developed as showed in (Foss

et

al.

, 1995). In this case, the model structure is chosen

by using the Akaike criterion.

The last step is to identify the parameter's model

for each local model. The estimation algorithm is the

Multivariable Recursive Least Squares (MRLS).

2.2 Building the Global Model

The global model is built as a weighting sum of the

bilinear models in each chosen operating regime.

The generic polynomial matrix

)(

1)( −

qP

k

is built as:

∑

=

−−

=

NOR

i

kii

k

wqPqP

1

,

1

)(

1)(

)()(

(8)

where

)(

1

)(

−

qP

i

is the polynomial matrix in i

th

operating regime,

ki

w

,

is the i

th

weighting factor

calculated in instant

k, NOR is the number of

operating regimes. The computation of

ki

w

,

is

showed in the section 3 of this paper.

2.3 The Quasilinear Multivariable

Multi-Model

The nonlinear model presented in (1) is

quasilinearized to be used in QMGPC (Quasilinear

Multivariable Generalized Predictive Control). The

multivariable quasilinear multi-model must be

obtained by rewriting the expression (1) of the

following form:

)()()1()()(

)()(),(

1)(1)(1

11)(

keqCkuqqB

kyquqA

k

p

k

q

k

−−−

−−

+−Δ

=Δ

(9)

where:

)()]1([)(

)(),(

1

)(

1

)(

1)(1)(

−−

−−

−

−=

qDkuDqD

qAuqA

k

d

k

e

kk

(10)

The polynomial matrix

),(

1)(

uqA

k −

is calculated

considering its parameters as constant in prediction

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

290

horizon. The polynomial matrix )(

1)( −

qA

k

is

considered diagonal in this paper.

2.4 The Predictor

The output prediction i-step ahead may be calculated

multiplying the expression (1) for

i

q

as in the

following expression:

)()()1()()(

)(),(

~

1)(11)(

1)(

ikeqCikuqqB

ikyuqA

k

p

k

k

++−+Δ

=+

−−−

−

(11)

where

)(),(),(

~

11)(1)( −−−

Δ= quqAuqA

q

kk

.

In this case, the polynomial matrix

pp

IqC

×

−

=)(

1

is uncorrelated (white noise). Considering the

following Diophantine equation:

),(),(

~

),(

1

)(

1)(1

)(

uqFquqAuqEI

k

i

ik

k

ipp

−−−−

×

+=

(12)

where:

)1(

)(

1,

)(

,

1

)(

)()(),(

−−

−

−

++=

i

k

ii

k

oi

k

i

quEuEuqE "

(13)

na

k

nai

k

oi

k

i

quFuFuqF

−−

++= )()(),(

)(

,

)(

,

1

)(

"

(14)

Pre-multiplying (11), with

pp

IqC

×

−

=)(

1

, for

),(

1

uqE

i

−

we obtain:

)(),(

)1()()(),(

)(),(

~

),(

1

)(

11)(1

)(

1)(1

)(

ikeuqE

ikuqqBuqE

ikyuqAuqE

k

i

p

k

k

i

k

k

i

+

+−+Δ

=+

−

−−−

−−

(15)

Rewriting (12) of the following form:

),(),(

~

),(

111

uqFqIuqAuqE

i

i

ppi

−−

×

−−

−=

(16)

Substituting (16) in (15) we obtain:

+−+Δ

++=+

−−−

−−

)1()()(),(

)(),()(),()(

11)(1

)(

1

)(

1

)(

ikuqqBuqE

ikeuqEkyuqFiky

p

k

k

i

k

i

k

i

(17)

As the degree of

),(

1

)(

uqE

k

i

−

is 1−i , then the

sub-optimal prediction of

)( iky + is:

)1()()(),(

)(),()(

ˆ

11)(1

)(

1

)(

−+Δ

+=+

−−−

−

ikuqqBuqE

kyuqFiky

p

k

k

i

k

i

(18)

Make:

),(),()(),(

1

)(

1

)(

1)(1

)(

uqHquqHqBuqE

k

ipa

i

k

i

k

k

i

−−−−−

+=

(19)

As the degree of

),(

1

uqH

i

−

is less than 1

−

i ,

the predictor may be written as:

)1()(),(

)1()(),()(),()(

ˆ

11

)(

11

)(

1

)(

−+Δ

+−Δ+=+

−−

−−−

ikuquqH

kuquqHkyuqFiky

p

k

i

p

k

ipa

k

i

(20)

The last term of (20) considers the future inputs

(forced response) and the two first terms consider

only past inputs (free response). Define:

)(

11

)(

)1()(),()(

ˆ

k

lip

k

i

YikuquqHiky +−+Δ=+

−−

(21)

where:

)1()(),()(),(

11

)(

1

)()(

−Δ+=

−−−

kuquqHkyuqFY

p

k

ipa

k

i

k

li

(22)

2.5 The Objetive Function

The objective function is given by:

∑∑

==

−+Δ++−+=

NU

i

Q

NY

Ni

R

k

k

ikuikyikrJ

1

2

2

)(

1

)(

)1()(

ˆ

)(

(23)

where

1

N is minimum prediction horizon, NY is

prediction horizon,

NU is the control horizon,

)(k

R

and

)(k

Q are weighting matrices of error signal and

control effort in instant

k in the chosen trajectory,

respectively,

)(

ˆ

iky

+

is the sub-optimum i-step

ahead predicted output,

)( ikr + is the future

reference trajectory.

2.6 The Control Law

The control effort is obtained, without constraints,

by the minimization of the objective function. This

minimization is obtained by the calculation of its

gradient (making it equals zero), of the following

form:

0=

∂

∂

u

J

(24)

Consider the predictions set:

)(

)(

1

1

1

k

ylNNU

N

k

N

YuHy

yu

y

+=

(25)

A MULTI-MODEL APPROACH FOR BILINEAR GENERALIZED PREDICTIVE CONTROL

291

where:

[]

T

N

NYkyNkyNkyy

y

)(

ˆ

)1(

ˆ

)(

ˆ

11

1

++++= "

(26)

⎥

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎢

⎣

⎡

=

−−−

−+−

−−−

NUNY

k

NY

k

NY

k

NUN

k

N

k

N

k

NUN

k

N

k

N

k

k

N

HHH

HHH

HHH

H

yu

)(

2

)(

1

)(

1

)(

1

)()(

)(

2

)(

1

)(

)(

111

111

1

"

#%##

"

"

(27)

⎥

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎢

⎣

⎡

−+Δ

+Δ

Δ

=

−

−

−

)1()(

)1()(

)()(

1

1

1

NUkuq

kuq

kuq

u

p

p

p

NU

#

(28)

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎣

⎡

=

+

lNY

lN

lN

lN

Y

Y

Y

y

y

#

1

1

1

1

(29)

The objective function (23) may be rewritten of

the following form:

NUk

T

NUlNNUNk

T

lNNUN

uQuyuHRyuHJ

yyuyyu

)()(

)()(

1111

+++=

(30)

where:

],,[

)()(

1

)(

k

NYq

k

k

RRdiagR

×

= "

(31)

],,[

)(

)(

1

)(

NUp

k

k

k

QQdiagQ

×

= "

(32)

The computation of an element

)(k

i

x

of

)(k

R and

)(k

Q is given by:

∑

=

=

NOR

j

kjji

k

i

wxx

1

,,

)(

(33)

where

ji

x

,

is the i

th

element of weigthing matrix

(

)(k

R

or

)(k

Q ) for the j

th

operating regime and

ki

w

,

is the

i

th

weighting factor calculated in instant k.

The minimization of (30) produces the following

control law:

)()(

1111

1

yyuyuyu

lN

T

NN

T

N

yrRHQHHu −+=

−

(34)

Because of the receding control horizon, only the

first

p rows of (34) are computed.

3 THE PROPOSED METRIC

The proposed metric is based in a 2-norm. Norms, in

general, gives a notion of distance in a vectorial

space. In multivariable case, in a process with p-

inputs and q-outputs, the output is

q

Rky ∈)( and the

input is

p

Rku ∈)(

. In a known trajectory of process

output, the distance of the process’s output from the

first operating regime to the last operating regime is

given by:

2

1,1

yyd

NORNOR

−=

(35)

where

NOR

y is the process's output in last operating

regime and

1

y is the process's output in the first

operating regime.

To measure the distance from the current

process's output (in instant

k) to the i

th

operating

regime, we can use the expression:

NORi

yky

d

i

NOR

ki

,,1;

)(

2

,1

,

"=

−

=

δ

(36)

where

)(ky is the process's output in instant k and

i

y is the process's output to the i

th

operating regime.

The weighting factor for the

i

th

operating regime

in instant

k is given by:

NORiw

NOR

j

kj

ki

ki

,,1;

1

,

,

,

"==

∑

=

δ

δ

(37)

4 APPLICATION OF THE

MULTI-MODEL APPROACH

4.1 Distillation Column

In this paper, an application in a debutanizer

distillation column is showed. Debutaziner

distillation column is usually used to remove the

light components from the gasoline stream to

produce Liquefied Petroleum Gas (LPG). The

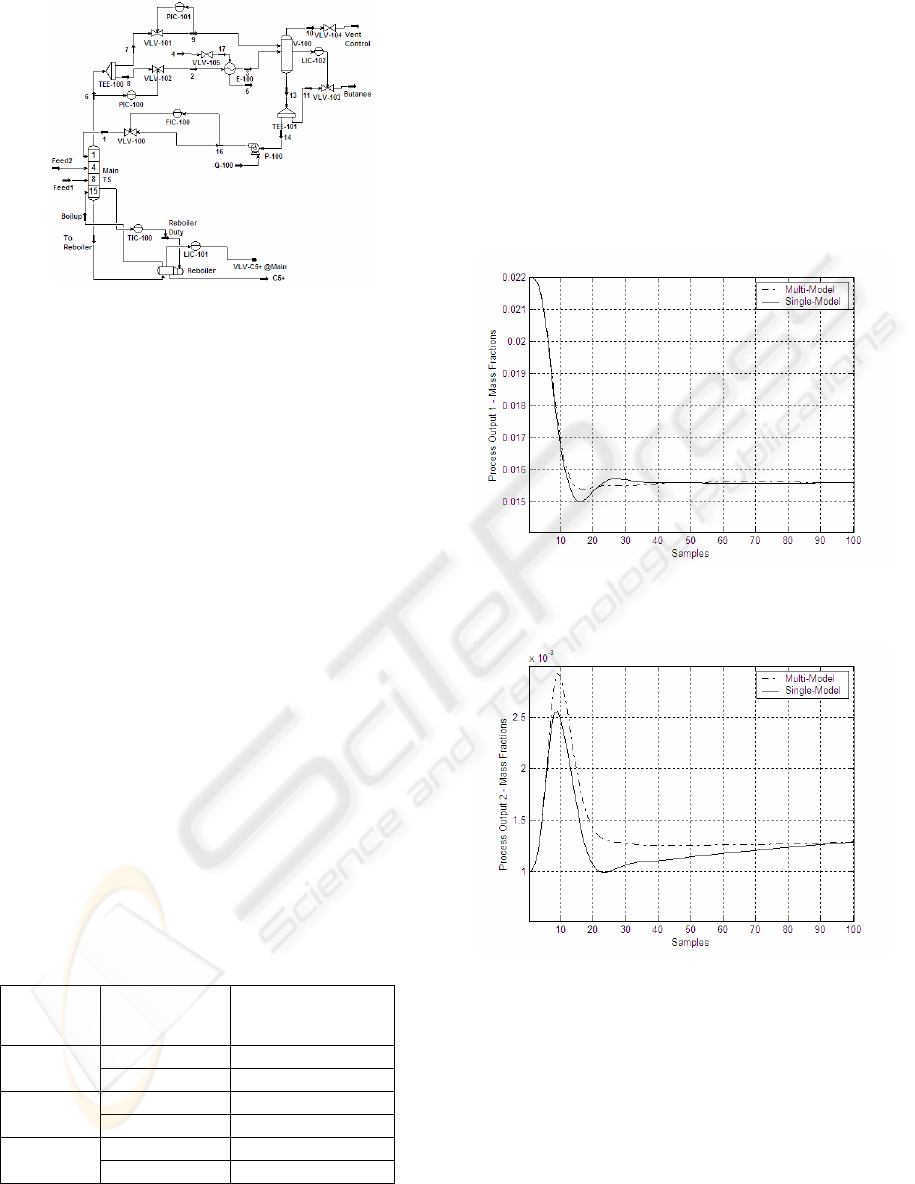

column is showed in Figure 1.

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

292

Figure 1: Distillation Column simulated in Hysys

Software.

The most common control strategy is to

manipulate the reflux flow rate and the temperature

in column's bottom and, to control the

concentrations of any product in

butanes stream and

in C5+ stream as showed in (Almeida,

et al., 2000)

and (Fontes, et al., 2006). The chosen process

variables are: concentration of i-pentane in butanes

stream (

y

1

) and concentration of i-butene in C5+

stream (

y

2

).

The reflux flow rate (

u

1

) is manipulated through

the FIC-100 controller and the temperature of

column's bottom (

u

2

) is manipulated through the

TIC-100 controller. The reflux flow rate is given in

m

3

/h and the temperature of column's bottom is

given in

o

C.

In this case study, three operation regime were

chosen, as showed in Table 1. The identified bilinear

models were obtained using the multivariable

recursive least squares algorithm and the model's

structure has been chosen by using the Akaike

criterion. In all models, the chosen sample rate is 4

minutes.

The trajectory of

1

y is monotonically increasing

and the trajectory of

2

y is monotonically

decreasing.

Table 1: Chosen Operating Regimes.

Operation

Regime

Input

Output

(Mass Fractions)

u

1

= 40 m

3

/h y

1

= 0.014413

1

u

2

= 147

o

C y

2

= 0.001339

u

1

= 37 m

3

/h y

1

= 0.017581

2

u

2

= 147.5

o

C y

2

= 0.001161

u

1

= 34 m

3

/h y

1

= 0.021994

3

u

2

= 148

o

C y

2

= 0.001004

The operating regimes must be chosen based in a

knowledge of the process.

4.2 Results

In this simulation, the process is in the 3

rd

operating

regime and a deviation in reference is applied in the

proposed controller. With this reference deviation,

the process will come to close to the 1

st

operating

regime. The proposed quasilinear multi-model is

compared with quasilinear single-model (using the

model of the 3

rd

operating regime). Figures 2 and 3

show the output comparison.

Figure 2: Process Output 1. Comparison between single-

model and multi-model approach.

Figure 3: Process Output 2. Comparison between single-

model and multi-model approach.

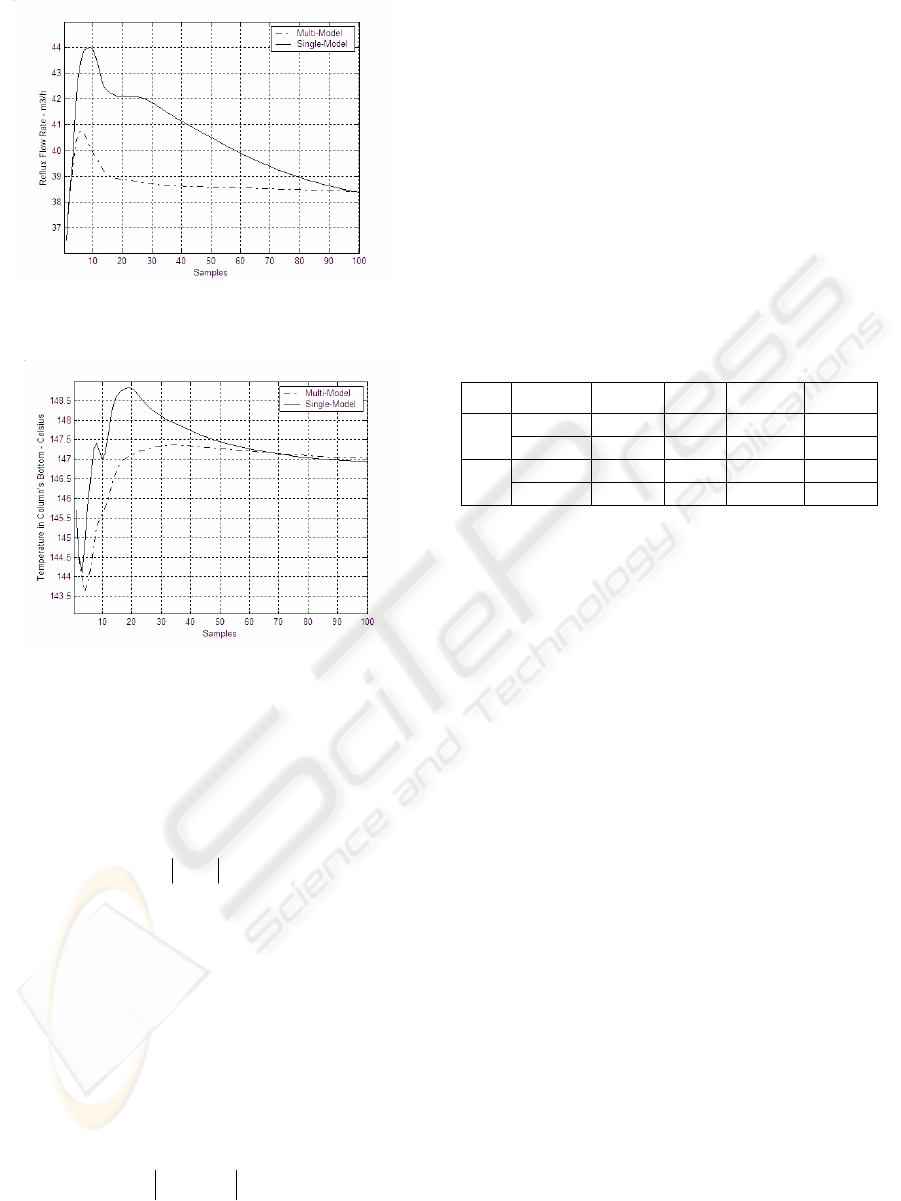

Figures 4 and 5 show the control effort

comparison between the quasilinear single-model

and multi-model approaches.

The figures show the better performance of

multi-model approach when compared with single-

model approach.

A MULTI-MODEL APPROACH FOR BILINEAR GENERALIZED PREDICTIVE CONTROL

293

Figure 4: Reflux Flow rate. Comparison between single-

model and multi-model approach.

Figure 5: Temperature in column's bottom. Comparison

between single-model and multi-model approach.

In order to quantitatively asses the performance

of multi-model quasilinear GPC, some indices like

showed in (Goodhart,

et al., 1994) are calculated.

Theses indices may be extended to multivariable

case, of the following form:

Nku

ii

/)(

,1

∑

=

ε

(38)

where

pi ,,1 "= and N is the amount of control

effort applied in the process to achieve the desired

response. The index showed in (38) is the account of

total control effort to achieve a given response. The

variance of controlled actuators is:

Nku

iii

/))((

2

,1,2

∑

−=

εε

(39)

The deviation of the process of integral of

absolute error (IAE) is:

Nykr

jjj

/)(

,3

∑

−=

ε

(40)

where

qj ,,1 "= .

The overall measure of effectiveness is defined

as:

j

p

i

jiiiij ,3

1

,2,1

)(

ερεβεαε

∑

=

++=

(41)

where

qj ,,1 "

=

. The factors

i

α

,

i

β

and

j

ρ

are

weightings chosen to reflect the actual financial cost

of energy usage, actuator wear and product quality,

respectively. In this case, we consider

1.0

=

i

α

,

15.0

=

i

β

and 5.0

=

j

ρ

.

Table 2: Comparison of Performance indices between

Quasilinear single-model and Quasilinear multi-model

with N=100.

I/O Model

1

ε

2

ε

3

ε

ε

Single 40.47 2.61 499.46 269.00

1

Multi 38.72 0.31 486.20 261.80

Single 147.38 0.63 242.40 140.47

2

Multi 146.88 0.62 197.71 117.56

Table 2 shows the performance of quasilinear

multi-model approach in terms of less energy usage,

less actuator wear and better product quality in

relation to quasilinear single-model performance.

5 CONCLUSIONS

The multi-model approach is a good alternantive of

controller to systems that operate in a large

operation range. The indices has shown that this

approach presents better performance in relation of

quasilinear single model.

REFERENCES

Almeida, E., Rodrigues, M.A., Odloak, D., 2000. Robust

Predictive Control of a Gasoline Debutanizer Column.

Brazilian Journal of Chemical Engineering, vol. 17,

pp. 11, São Paulo.

Arslan, E., Çamurdan, M. C., Palazoglu, A. and Arkun,

Y., 2004. Multi-Model Control of Nonlinear Systems

Using Closed-Loop Gap Metric. Proceedings of the

2004 American Control Conference, Vol. 3, pp. 2374-

2378.

Azimadeh, F., Palizban, H.A. and Romagnoli, J. A., 1998.

On Line Optimal Control of a Batch Fermentation

Process Using Multiple Model Approach. Proceedings

of the 37

th

IEEE Conference on Decision & Control,

pp. 455-460.

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

294

Fontes, A., Maitelli, A.L., Cavalcanti, A. L. O. and

Angelo, E., 2006. Application of Multivariable

Predictive Control in a Debutanizer Distillation

Column. Proceedings of SICOP 2006 – Workshop on

Solving Industrial Control and Optimization

Problems, pp. 1-5.

Foss, B.A., Johansen, T.A. and Sorensen, A.V., 1995.

Nonlinear Predictive Control Using Local Models –

Applied to a Batch Fermentation Process. Control

Eng. Practice, pp. 389-396.

Goodhart, S. G., Burnham, K. J., James, D.J.G., 1994.

Bilinear Self-tuning Control of a high temperature

Heat Treatment Plant. IEEE Control Theory Appl.:

Vol. 141, no 1, pp. 779-783.

A MULTI-MODEL APPROACH FOR BILINEAR GENERALIZED PREDICTIVE CONTROL

295