THE BENEFITS OF ACCURATE, AND TIMELY DATA IN LEAN

PRODUCTION ENVIRONMENTS

RFID in Supply Chain Management

Vijay K. Vemuri

C.W. Post Campus, Long Island University, 720 Northern Blvd., Brookville, NY 11548, USA

Keywords: Radio Frequency Identification, Inventory Management, Supply Chain Management, Simulation.

Abstract: The usefulness of information systems critically depends on the accuracy of the data contained within it.

Errors in capturing data into the information systems are particularly vexing since these errors permeate the

entire information system(s), affecting every aspect of information use. The direct and indirect

consequences of unreliable data did not attract much attention as there were few alternatives to reduce them.

Newer technologies, especially Radio Frequency Identification (RFID), are enabling virtual elimination of

data entry errors in inventory management. We investigate the effect of accurate data on the performance of

supply chains utilizing lean production systems. Our simulation results indicate that time to fulfil a purchase

order (cycle time) is significantly reduced by improving the quality of the inventory data. The simulation

model we developed will enable us to examine other performance characteristics of a supply chain. We will

also investigate the sensitivity of supply chain performance due to changes in the parameters of the model.

1 INTRODUCTION

Advances in information technology have led us to

expect the availability of accurate, reliable, and

timely information at a reasonable cost. Indeed,

synergies between microprocessor, fiber-optics,

satellite, and related technologies have increased the

promise of information systems further. However,

data capture still remains the weakest link in the

chain of information technology tasks needed to

provide accurate and timely information. A 1980’s

study of data capture error rates by the U.S.

Department of Defence (DoD) shows that in

entering 30 million characters; 250,000 errors in

handwritten, 100,000 errors in keyboard, 1,000

errors in OCR, and 10 errors in barcode entries were

made (Taylor, 2004). Despite the astonishing

advances in information technology since the DoD

study, inaccurate data still remains an elusive

problem. The level of data inaccuracies in patient

health care and the resulting dire consequences are

startling (up to 98,000 patients die in the U.S. die

every year due to medical errors (Kohn, et al,

2000)). Medical data errors are a leading cause of

these preventable errors. Information technology can

offer solutions in reducing the data errors - for

example, in one study, direct data entry by

physicians reduced errors by 55 percent (Wendel,

2000).

Although not to the extent those patients do,

businesses also bear the consequences of inaccurate

data. Due to handling of their records by many

functional areas within an organization, the high

volume of items, large number of transactions and

exchanges of information and goods with value

chain partners, inventories are especially vulnerable

to data errors. Kang and Gershwin (2005) report that

for a large global retailer, for an average of 49% of

its Stock Keeping Units (SKUs) its inventory

records did not exactly match with the physical

inventories. The error rate remains high at 24% if an

error of ± 5 units is tolerated.

1.1 Causes and Effects of Inventory

Inaccuracy

There are many causes of inventory inaccuracies. 1)

Stock loss due to obsolete inventory and theft by

employees, customers and others, 2) transaction

errors, 3) inaccessible inventory, and 4) incorrect

product identification are often cited as the most

common causes of incorrect inventory records. In

retail sector, customer, employee, and customer theft

is a major source of stock loss accounting for about

221

K. Vemuri V. (2006).

THE BENEFITS OF ACCURATE, AND TIMELY DATA IN LEAN PRODUCTION ENVIRONMENTS - RFID in Supply Chain Management.

In Proceedings of the Eighth International Conference on Enterprise Information Systems - DISI, pages 221-225

DOI: 10.5220/0002466402210225

Copyright

c

SciTePress

1.7% of sales (Dabney, et al, 2004). Although stock

loss, and especially loss due to theft, varies among

product categories and the types of business, the

inventory inaccuracies due to the causes mentioned

above remains high for most companies. Inventory

inaccuracies may have ripple effects in the entire

organization. Lee, et al, 2004, cite research

estimating the indirect loss due to inventory

shrinkage can be more than 30 times that of direct

loss. What are the probable causes of these high

indirect costs? Inventories are important assets that

affect many decisions of an organization. Inventory

levels form a basis for decisions pertaining to when

to produce, how much to produce, where and how

much to transport, and many other operating

decisions. The inaccuracies in inventory records will

propagate through out the organization setting-off a

chain of suboptimal decisions. The situation cause

by inventory errors can be much worse than

“garbage in garbage out,” contaminating the entire

processes that connect inputs and outputs of a

system. If not corrected, inventory inaccuracies can

lead to incorrect shelf replenishment policies, stock

outs, and loss of sales.

2 RFID

The consequences of inventory record inaccuracies

extend beyond cost of reconciling inventory system

counts and physical counts. Raman, et al, (2001)

report that in two stores they studied, inventory

inaccuracies reduced profits by 10% and 25%.

Substantial inventory errors were present despite the

use of modern information systems for inventory

management.

Technology provides a solution to mitigate the

problems due to inventory inaccuracies. RFID

provides solutions to track and manage inventory

items in the entire transformation process from raw

materials to finished products. It enables wireless

exchange between tagged items and a reader. Unlike

barcodes, RFID tracking does not require line-of-

sight, and accommodates greater distances between

reader and the tag. The array of RFID applications

within businesses include manufacturing, asset

management, production tracking, inventory control

and logistics. RFID enables improvements of

internal efficiencies of many business processes. For

example, the “group select” feature of RFID utilizes

information contained in the RFID tags for locating

containers with a particular product in a large

shipment consisting of many different types of

products..

2.1 RFID and Inventory Accuracy

RFID may not be able to eliminate all stock losses,

but it can identify discrepancies in system and

physical inventories and recalibrate these accounts

much more efficiently than periodic inventory

audits. By establishing connectivity with the

products real-time inventory information can be

obtained. The accuracy of the data extends beyond

physical presence of the inventory item within the

premises. By embedding expiration data of

perishable products and other information in the

RFID tags other causes of inventory inaccuracies

such as obsolescence, damage, and expiry can be

detected and inventory records can be updated in

real-time. Incidence of data entry errors mentioned

above are much less prevalent in RFID data entry.

The DoD study reports that the use of transponders

(RFID tags), on the average, results in one error in

entering 30 million characters. The RFID technology

has advanced since the DoD study and the error rates

are expected to be even less – resulting in virtual

elimination of inventory record inaccuracies.

3 RFID IN SUPPLY CHAIN

MANAGEMENT

Due to their ability to preserve information in their

tags across organizational boundaries, RFID can be

useful in tracking and managing inventories over the

entire supply chain. Retailers can achieve lower

stockouts, cost savings and increased

responsiveness. Distribution centres and warehouses

can improve accuracy and reduce costs due to

automated routing, and cross-docking.

Manufacturers in the supply chain can also benefit

from the RFID tags by using them in their receiving,

shipping and inventory management. Suppliers can

set the automated identification in motion by

sending their shipments with tags. These tags can

also be useful for suppliers in their own shipping

operations and inventory management. That is,

every echelon in the supply chain can achieve better

planning, control, and coordination with automated

identification. The RFID technology can nearly

eliminate inventory record inaccuracies and improve

visibility of inventory data across the entire supply

chain. In addition sharing of information each

member of the supply chain can get timely, accurate

information at a low cost.

ICEIS 2006 - DATABASES AND INFORMATION SYSTEMS INTEGRATION

222

3.1 Prior Research

Two streams of prior research is relevant for this

study. The first deals with inventory errors and their

effect on inventory management. Iglehart and Morey

(1972) consider the combined effect of inventory

errors, safety stock and frequency of inventory

counts, service levels and inventory costs. They

derive the level of safety stock and frequency of

inventory count to minimise total costs of holding

and inventory count while maintaining a desired

service level. The present paper and the others

studies dealing with RFID in supply chains attempt

to answer what happens in the limit if inventory

errors tend to zero, or cost of inventory count tends

to zero and frequency of inventory count tends to

infinity. However, these are very difficult issues to

tackle analytically and simulations are used to

answer the above questions. Ganeshan, et al, 2001

deals with forecasting error (similar to inventory

errors) on supply chain performance. Their

simulation results confirm that forecasting errors

have a significant impact on service levels and cycle

time of a supply chain.

Three other recent papers have a direct

connection to this study. All of them deal with

inventory errors on the supply chain and how RFID

technology by nearly eliminating inventory affects

different supply chain performance measures. Kang

and Gershwin, 2005 compare different methods to

cope with inventory inaccuracies. They compare

stockout percentage and average inventory using 1)

additional safety stock, 2) manual inventory

verification, 3) manual reset of the inventory count,

4) periodic write-down to reflect stock loss, and 5)

automatic inventory identification. Not surprisingly,

the last choice achieves the best trade-off between

low stockout and low levels of inventory cost.

Lee, et al, 2004 study a supply chain consisting of a

retailer, distribution centre, and a manufacturer.

They mainly study the impact of inventory accuracy

and inventory replenishment policies on inventory

levels at each echelon. They find that inventory

levels are more stable and lower with RFID

inventory tracking.

Fleisch and Tellkamp, 2005 use simulations to

study the impact of inventory inaccuracy on a retail

supply chain. They disaggregate the sources of

inventory inaccuracy into its component factors

(theft, unsaleables, and misplaced item and incorrect

deliveries) and study their impact on probability of

out-of-stock and cost of inventory inaccuracies.

Their results indicate that theft is the most important

factor impacting supply chain performance and the

level of unsaleable items do not affect supply chain

performance significantly.

Two additional studies are also relevant for this

research as they study the performance of supply

chains with imperfect information. Chen, et al, 2000

study the effect of sharing of customer demand

information at every stage of the supply chain and

conclude that information sharing will mitigate the

so called bullwhip effect (amplification of demand

variability along the supply chain away from the

customers). Their analytical model and simulation

results show that sharing of customer demand

forecasts reduces forecasting errors resulting in

softening of bullwhip effect; however, reduced

forecasting error will not completely eliminate the

bullwhip effect.

Joshi, 2000 in his masters’ thesis develops a

comprehensive framework to improve visibility of

information in supply chains by reducing the delays

in information flows.

4 MOTIVATION AND RESEARCH

QUESITONS

The recent surge in RFID implementations raises the

questions regarding supply chain performance and

RFID. Supply chains are complex dynamic systems

with complex flows of products and information.

With uncertainties at, and complex interactions

between, various levels it is nearly impossible to

analytically solve research questions. Simulation

models facilitate tight control of research

environment and ability to manipulate extraneous

factors resulting in excellent internal validity.

However, genralizability, or external validity of

simulation studies are low. Most of the simulation

studies reviewed above do not model “pull”

production environments where customer demand

sets the production process in motion. Lean

production systems and just-in-time inventory

management are characterized by “pull-type”

production processes. Lee, et al, 2004 consider a

production system operating under “push” system

and the retailer using a “pull” system.

In this study will concentrate on “pull” system

where the inventory movement is triggered by

customer demand. In these systems stockout rate,

service level or fill rate is not an appropriate

performance measure since the customer generates

an order and waits for the fulfilment of the order.

Appropriate performance measure is these supply

chains is the cycle time for inventory. The cycle

time in the supply chain refers to the time it takes to

fill an order.

The research question of interest in this study is:

What is the effect of RFID deployment in a supply

chain characterized by pull type production

THE BENEFITS OF ACCURATE, AND TIMELY DATA IN LEAN PRODUCTION ENVIRONMENTS - RFID in

Supply Chain Management

223

environments on the customer order cycle time?

This question is relevant since the predominant trend

is to implement pull type production environments

with just-in-time inventory management. In these

environments inventory errors are expected to be

critical since level of inventories are kept to a

minimum. A typical strategy of carrying extra safety

stock to cope with inventory errors is contrary to the

motives for implementing lean environments.

5 SIMULATION

METHODOLOGY

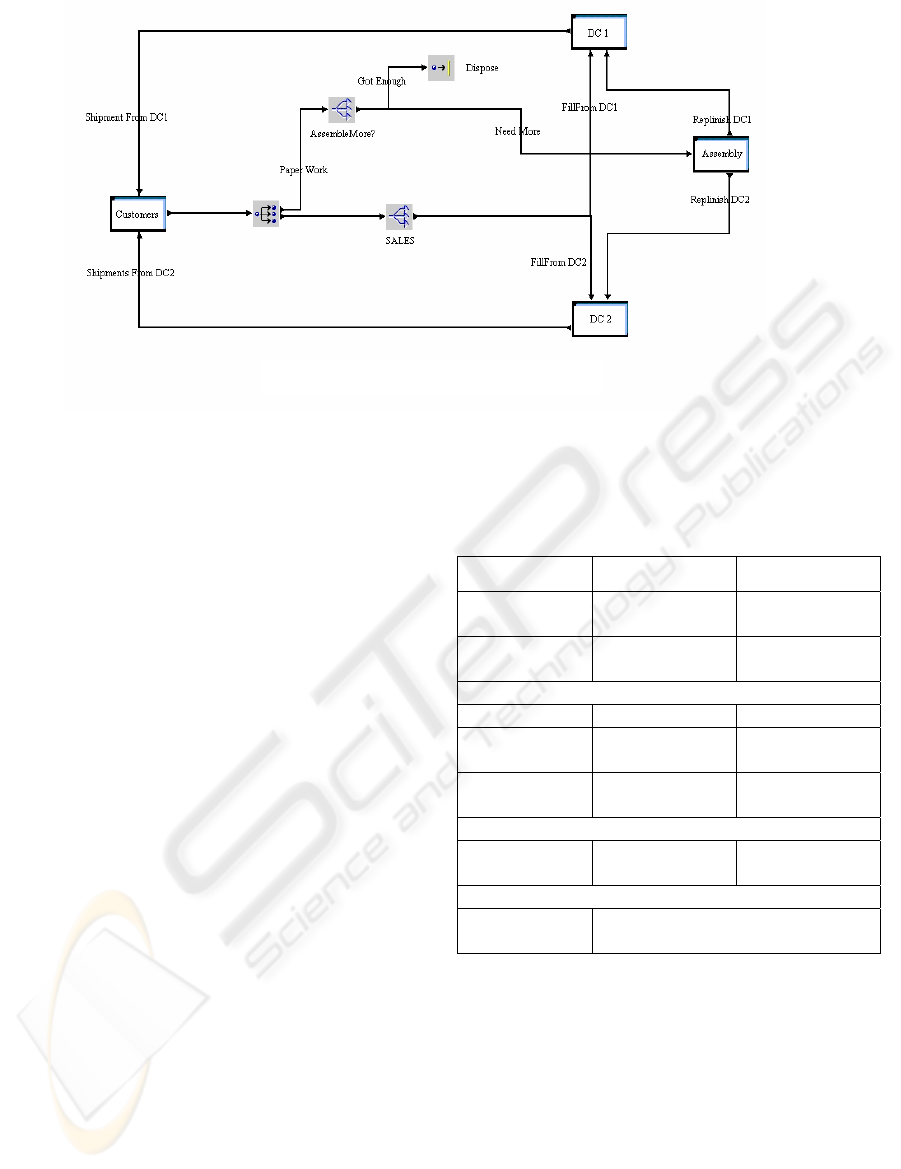

The supply chain we model consists of two

customers calling at random for varying amounts of

goods. The marketing department receives the calls

and sends the orders to nearest distribution centre

(DC): DC1 for customer 1, and DC2 for customer 2.

If enough units are not available at the closest DC,

the sales order is sent to the other DC.

Replenishment at the DCs are based on (s, S) policy,

if the inventory level drops below s units, an order is

sent to bring the inventory level to S units. The

timing of a purchase order is triggered by incoming

purchase orders. The products are manufactured in

the Assembly department. Figure 1 shows overall

flow of goods and information and the location of

the decisions made. Each of the rectangles

represents a business process within the supply chain

and includes subprocesses. Due to space limitations,

the details contained within these subprocesses are

not shown, but implements the description of the

supply chain above.

We used SimProcess 4.2 program to conduct the

simulations. This modelling environment enabled us

to easily construct hierarchical business processes,

activity based costing for allocating overhead costs

and optimisation routines to determine optimal

strategies within the simulation environment.

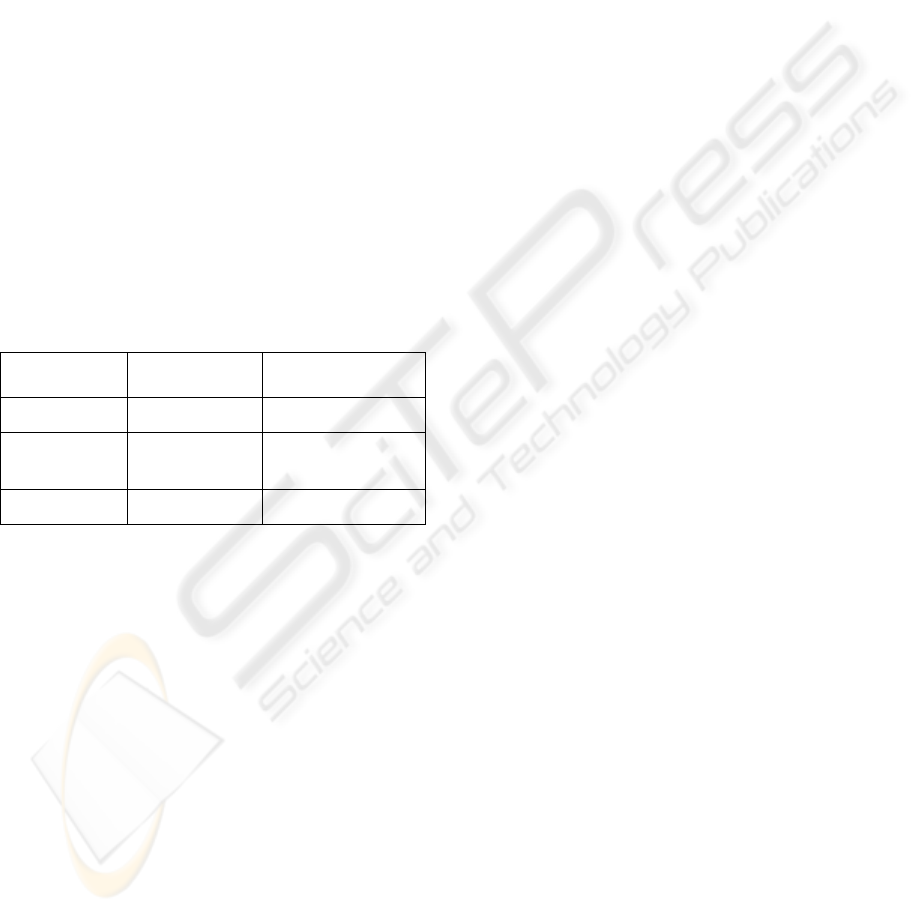

Table 1 shows the model parameters and their

distributions.

Table 1: Model Parameters.

Customer 1 Customer 2

Order

Generation

Normal (5,

1) Hours

Normal

(2.5, 1) Hours

Order Size

Uniform

(25, 100)

Uniform

(50, 200)

s S

Replinishmen

t at DC1

200 500

Reprinishmen

t at DC2

500 2,000

Distance to

DC1

Distance to

DC2

Production

Time

1 minute per unit

In order to answer the research question,

simulations are run under two different assumptions.

Under the first assumption, inventory shrinkage

takes place but the RFID system will detect the

shrinkage immediately and the inventory

replenishment decisions are made based on the

correct level of inventory in stock. This scenario is

compared with cycle times attained when the system

is not aware of the inventory loss.

Many use Retail Security Survey (Dabney, et al,

2004) estimate of 1.7% of gross annual sales as the

annual loss due to inventory shrinkage. However,

mistakenly, they apply this percentage to inventory

Figure 1: Top Level Supply Chain Model.

ICEIS 2006 - DATABASES AND INFORMATION SYSTEMS INTEGRATION

224

levels (Lee et al, 2004, and Fleisch and Tellkamp,

2005). Based on average turnover ratio of about 5

and gross profit ratio of 70%, inventory shrinkage is

closer to 12% of inventory levels. Inventory

shrinkage cannot go undetected forever. We assume

that once every quarter (at the time of preparation of

quarterly financial statements) the shrinkage will be

detected and the information system is corrected to

reflect actual count. Many use quarterly reset of the

system inventory for the detection of inventory

shrinkage. We simplify this situation by running

simulation for a quarter at a time. To mitigate the

effect of initial conditions, and to obtain steady state

results, we use a warmup period of 10 days (run

length is 120 days). To obtain robust results we

repeated the simulation for 25 quarters.

6 RESULTS

Table 2 compares cycle times with incorrect

inventory records and perfect inventory counts

obtained by deploying RFID technologies.

Table 2: Comparison of Supply Chain Performance.

Accurate

Inventories

Inaccurate

Inventories

Mean 2.002 Hours 2.646 Hours

Standard

Deviation

1.125 Hours 1.165 Hours

Sample Size 25 25

Hypothesis test resulted in a t-value of 1.988 and

a p-value of .026. Based on these statistics we

conclude that accurate inventories result in lower

cycle time and faster fulfilment of purchase orders.

The analysis of the simulation results is not yet

completed. Sensitivity of cycle times to

manufacturing times, capacities and other important

parameters are being established. Other important

supply chain performance criteria are being

examined. The framework and the model we have

established so far will enable us to extend the

analysis of supply chain performance measures with

accurate inventory counts now possible with RFID

tags.

7 CONCLUSIONS

Our research addresses important issues related to

the role of RFID in supply chain management.

Accurate inventory data is especially important in

lean manufacturing environments as large inventory

buffers and excess safety stock are not available to

forgive inventory inaccuracies. Our simulation

model consisting of a pull production environment

concludes that the cycle time (time it takes to fill a

purchase order) is reduced by accurate inventory

counts. The performance of a supply chains using

alternative performance criteria and the sensitivity of

performance to parameters of the production

environment are currently developed.

REFERENCES

Chen, F., Drezner, Z., Ryan, J.K., and Simchi-Levi, D.,

2000. Quantifying the Bullwhip Effect in a Simple

Supply Chain: The Impact of Forecasting Lead Times,

and Information. Management Science, 46, 436-443.

Dabney, D., Hollinger, R., and Dugan, L., 2004. Who

Actually Steals? A Study Of Covertly Observed

Shoplifters, Justice Quarterly, 21, 693-728.

Fleisch, E., and Tellkamp, C., 2005)\. Inventory

Inaccuracy and Supply Chain Performance: A

Simulation Study of Retail Supply Chain. International

Journal of Production Economics, 95, 373-385.

Ganeshan, R., Boone, T., and Stenger, A., 2001. The

Impact of Inventory and Flow Planning Parameters on

Supply Chain Performance: An Exploratory Study.

International Journal of Production Economics, 71,

111-118.

Iglehart, D.L., and Morey, R.C., 1972. Inventory Systems

with Imperfect Asset Information. Management

Science, 18, B388-B394.

Joshi, Y., 2000. Information Visibility and Its Effect on

Supply Chain Dynamics. Masters Degree Thesis, MIT.

Kang, Y., and Gershwin, S.B., 2005. Information

Inaccuracy in Inventory Systems: Stock Loss and

Stockout. IEEE Transactions, 37, 843-859.

Kohn, L., Corrigan, J. and Donaldson, M., (Eds.), 2000.

To Err Is Human: Building a Safer Health System,

National Academies Press, Washington, D.C.

Lee, Y.M., Cheng, F., and Leung, Y.T., 2004. Exploring

the Impact of RFID on Supply Chain Dynamics.

Proceedings of the 2004 Winter Simulation

Conference. December 5-8, 2004. Washington, D.C.

Raman, A., DeHoratius, N. and Ton, Z., 2001. Execution:

The Missing Link in Retail Operations. California

Management Review, 43, 136-152.

Taylor, D., 2004. Supply Chains: A Manager’s Guide,

Addison Wesley, Boston, MA.

Wendel S., 2000. Medical errors: Institute of Medicine

report raises questions about technology. Healthcare

Informatics, 17, 37-38.

THE BENEFITS OF ACCURATE, AND TIMELY DATA IN LEAN PRODUCTION ENVIRONMENTS - RFID in

Supply Chain Management

225