A SEMI-AUTOMATED QUALITY ASSURANCE TOOLBOX FOR

DIAGNOSTIC RADIOLOGICAL IMAGING

Christodoulos Constantinou

1

, Andreas Grondoudis

2

, Andreas Christoforou

2

Christakis Constantinides

1,3

, Andreas Lanitis

2

1

CNC Medical Physics Limited, 14 E. Loizidou, Strovolos, Nicosia, Cyprus

2

School of Computer Science and Engineering, Cyprus College,P.O. Box 22006, Nicosia, Cyprus.

3

Department of Mechanical and Manufacturing Engineering, , University of Cyprus, 75 Kalipoleos, Nicosia, Cyprus,

Keywords: Automated Quality Assurance, Diagnostic Radiology, Image Processing, Data Management System.

Abstract: Magnetic Resonance (MRI), Computed Tomography (CT) and Ultrasound (US) are three of the most

commonly used clinical imaging modalities. The aim of this study was to establish a Quality Assurance

program for MRI, CT and US scanners. A well-designed quality assurance program is of utmost importance

in the clinical setting, because it indicates whether diagnostic imaging modalities meet the minimum criteria

of acceptable performance and because it helps determine those scanner parameters that need adjustment in

order to ensure optimum performance. Quality assurance programs that rely on manual data collection and

analysis are tedious and time consuming and are often abandoned due to the significant workload required

for their implementation. In this paper we describe an integrated software system for automating the process

of data collection and management in Quality Assurance for diagnostic radiological imaging. The developed

system is comprised of two main units: The Image Processing Unit (IPU) and the Data Management Unit

(DMU). The IPU is used for analysing images from different diagnostic modalities in order to extract

measurements. The IPU is dynamically linked to the DMU so that measurements are transferred directly to

the DMU. This process allows the generation of quality assurance reports for all such modalities.

1 INTRODUCTION

Quality assurance (QA) programs are essential for

diagnostic radiological modalities. Apart from their

intended purposes to detect changes in the

equipment’s performance, they allow early

identifications of deviations from pre-determined

accuracy limits, and reduce unnecessary radiation or

radiofrequency exposure to patients. Early on, Task

Groups (Och1992) were formed for safety and QA

for various diagnostic modalities, both in the USA

and Europe. Price et. al. (Price1990) developed basic

algorithms and procedures for Magnetic Resonance

Imaging (MRI), but Bourel et. al. (Bourel1999) was

the first to present automatic quality assessment

software. A more elaborate effort was the recent

work of McRobbie et. al. (McRobbie2002) that

summarized results over a period of 8 years, for 17

MRI scanners, and recommended standards for

corrective action.

In this work we take advantage of prior efforts

for developing QA programs and protocols for

diagnostic radiological equipment using

methodology and guidelines proposed by the

American College of Radiology (Radiology1996),

the American Association of Physicists in Medicine

(AAPM) and the Eurospin tests (Lerski1993), to

develop algorithms and semi-automated procedures

to perform QA in MRI, Computed Tomography

(CT), and Ultrasound (US). No prior work has been

reported that involves a generalised and

comprehensive approach for QA for all these

modalities, that uses fast, semi-automated

procedures, employing basic and advanced image

processing for data analysis and generation of

results, as proposed in this work. Such effort is

realised by developing an Image Processing Unit

(IPU) that provides all the necessary functionalities

required for assessing the quality of medical images.

The IPU is integrated with a Data Management Unit

216

Constantinou C., Grondoudis A., Christoforou A., Constantinides C. and Lanitis A. (2006).

A SEMI-AUTOMATED QUALITY ASSURANCE TOOLBOX FOR DIAGNOSTIC RADIOLOGICAL IMAGING.

In Proceedings of the Eighth International Conference on Enterprise Information Systems - AIDSS, pages 216-221

DOI: 10.5220/0002445802160221

Copyright

c

SciTePress

(DMU) in order to allow data transfer and provide a

data repository for longitudinal serial measurements

and results from diagnostic equipment.

The main focus and value of this work relates to

the development of an integrated software system

that deals effectively with the application of

systematic quality control and quality assurance

control programs for diagnostic radiological imaging

equipment. The development of such a system will

contribute towards the enforcement of systematic

quality control in diagnostic centres in order to

ensure optimum performance of imaging equipment.

The QA methodology adopted in our work

involves phantom tests and measurements on an

MRI, a CT, and an ultrasound scanner. A typical

phantom used for MRI quality control is shown in

figure1. The general procedure of the QA process is

as follows:

a. The parameters of the scanner unit are determined.

Recorded parameters include demographic details

and data acquisition parameters.

b. Once the scanner is in operation a number of

measurements using electronic instruments are

performed. In the case of MRI scanners for

example, the intensity and uniformity of the

magnetic field is measured.

c. Images of dedicated phantoms are generated.

d. Measurements related to the appearance of

phantoms in the images obtained in step (c) are

extracted. This process usually involves manual

inspection of the images and/or the use of image-

processing packages.

e. All parameters derived from the previous steps are

used to calculate various quantities required for

assessing the diagnostic quality of the images.

Such quantities assess discrepancies between the

expected and actual features.

f. Based on the results obtained from step (e), a QA

report is generated.

Significant workload is required for carrying out

the method outlined above which justifies our effort

for automating this process. Considering that

effective quality control procedures involve periodic

inspection for each scanner unit, automation of the

QA process becomes an essential and integral part of

a QA program. With this work, we aim to automate

processes in steps d, e and f, and to provide an

effective system for managing the application of

periodic QA control to a large number of MRI, CT

and US scanners.

Figure 1: ACR phantom used for MRI QA (left), and a

typical sagital MRI image (right).

2 SYSTEM DESCRIPTION

The system is divided into two main components –

the Data Management Unit (DMU) and the Image

Processing Unit (IPU). The IPU is used to allow the

user to perform QA related measurements on

medical images. Such measurements can then be

transferred to the DMU for further processing and

storage.

2.1 Data Management Unit

The data engine of the project is a relational

database. It relates clients that own specific imaging

units (modalities) with their modalities, and links

modalities with periodic QA tests and their results.

QA test results are determined based on user-defined

parameters and image measurements from analysed

images generated from the scanner unit under

inspection. The DMU also allows generation of

basic reports summarising the QA results based on

the information that is stored in the database tables.

The Database Model: The model relates three

primary entities as part of the system: the clients, the

modalities (that each client owns), and the QA tests

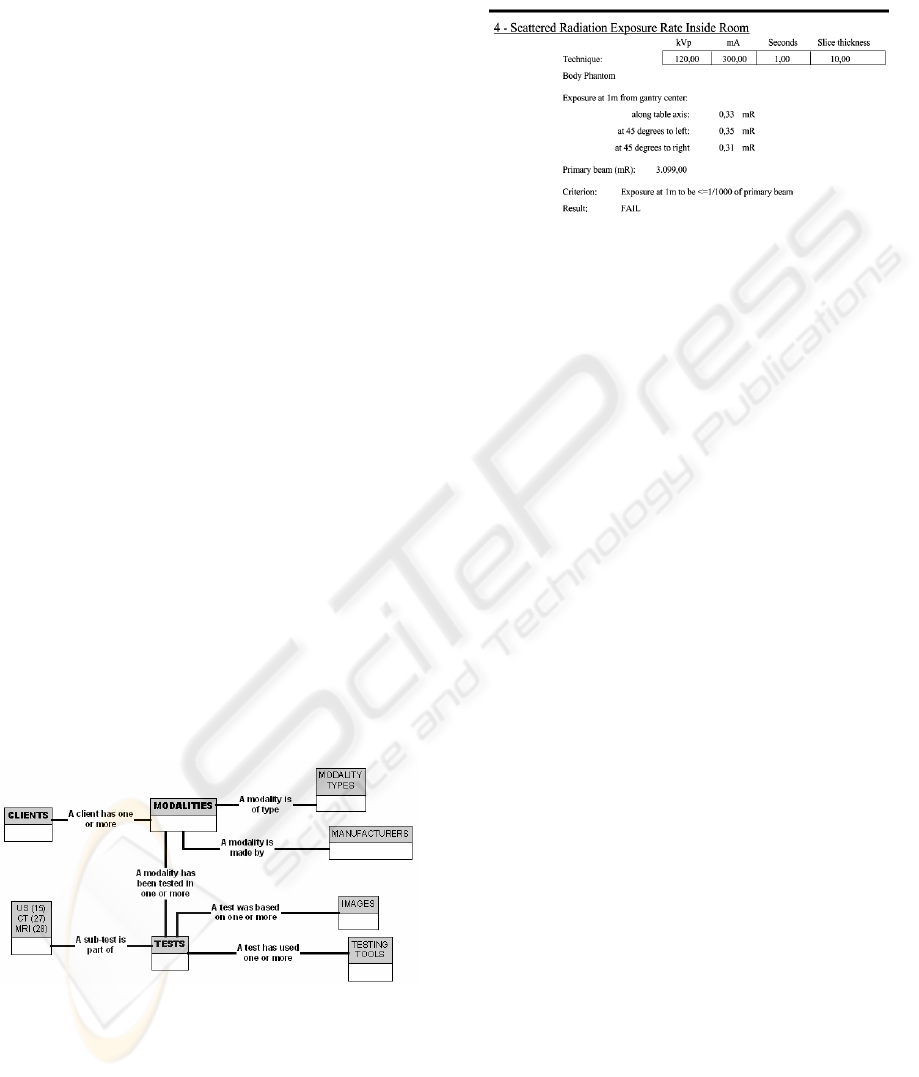

that are performed on these modalities. Figure 2

depicts these entities together with their

interrelations and some of the secondary tables and

entities of the model.

The information stored for every client includes

the primary demographic information, such as the

owner name and basic contact details. The data

collected for each modality is more elaborate. The

unit is documented with respect to its name,

modality type, client, manufacturer, model, and

serial number. Included in the modality are also

details on the purchased date and the date the

equipment was last-serviced, with related comments.

We refer to a test as a collection of smaller, more

specific, individual tests that can be run for the unit.

These tests (collectively referred to as sub-tests for

clarity) focus on specific areas/aspects of the

A SEMI-AUTOMATED QUALITY ASSURANCE TOOLBOX FOR DIAGNOSTIC RADIOLOGICAL IMAGING

217

modality under inspection and vary depending on

the modality type.

Secondary entities that are part of the database

model include users and user types, acceptance

criteria, forms of the interface, images and imaging

fields, lookups (for standard lookup values) and

lookup types, manufacturers, modality types, units

and testing tools.

Database Functionality: The database itself and the

interface are custom-built software components.

Their functionality is unique, defined by the

interdependence of the database and the imaging

engine. The results from measurements and

calculations must conform and comply with required

standards but their representation, manipulation and

eventual reporting will be unique. The

functionalities of database and interface software are

outlined in the following:

a. Generation of quality assurance results: Each of

the subtests conducted has been programmed to

produce a pass/fail result. The outcome of the

criterion depends on either one or more (or a

combination of) pre-determined factors. These

factors include measurements on images, values

depending on the imaging unit, standard lookup

values, parameters entered by the user etc.

b. Inter-operability with the imaging engine: The

database’s interface can, on demand start the IPU (if

it is not already running), and communicate certain

sub-tests to be performed by the imaging engine. On

returning from completing those tests, the database

interface is able to import the resulting

measurements and update the relevant tables with

the recently acquired/calculated values.

Figure 2: Database Model entities.

c. Report generation capabilities: The interface can

generate reports that will output the information in

the database. There are standard printout reports, for

clients, modalities etc., and there are test and sub-

test reports that can be customised to include certain

parts of a test. An example of a typical excerpt from

a report is shown in Figure 3.

Figure 3: Excerpt from a QA CT report.

d. Database maintenance and interface

customisation: The database’s interface is an integral

part of the developed software. All details of most

primary and all secondary tables and entities can be

edited and manipulated by the users if the system.

e. Dynamic features of the interface. The database-

interface setup is dynamic. The database or the

server can be changed from within the interface with

no service disruption. The location of the imaging

engine software and the location of the report files

are also set dynamically.

2.2 Image Processing Unit

We have developed a dedicated image-processing

tool that provides the required functionality for a QA

program in diagnostic radiology. In summary, the

developed image-processing tool includes the

following (region specific or image specific)

features:

• Loads and saves images of any format including

the DICOM format.

• Allows image data visualisation in different ways

(i.e Histogram Viewer, Profile Viewer, 3D viewer,

contour plots viewer) and provides tools for

windowing and levelling options.

• Includes basic algorithms for image operations,

such as thresholding, linear and non-linear

filtering, morphological operations, Fourier

transformations, histogram equalization and

others.

• Includes basic image segmentation techniques

such as border extraction methods.

• Allows the user to define regions of interest in an

image of any shape or size.

ICEIS 2006 - ARTIFICIAL INTELLIGENCE AND DECISION SUPPORT SYSTEMS

218

• Performs customised measurements on images, in

order to support the determination of the quality of

MRI, CT and US images.

• Allows data transfer to and from the DMU, so that

the results of the measurements are stored in the

database.

The quality of images can be assessed based on

dedicated measurements/tests carried out on images

of specially designed phantoms. In total, 26 different

image tests are supported by the IPU, 13 of which

refer to MRI images, eight refer to CT images and

the remaining five refer to US images. In all cases

the test results are transferred to the DMU, so that

appropriate calculations are performed in order to

assess compliance with preset standards.

In the following sections we describe typical

techniques used as the basis for implementing

complete test measurement procedures for each of

the 26 tests.

2.2.1 Texture Measurements

In several occasions we wish to obtain

measurements that relate to the mean signal

intensity, the standard deviation and the signal-to-

noise ratio (SNR) in a region of interest (ROI). For

this purpose, we have implemented algorithms for

obtaining first order texture measurements in an

image region. Texture measurements are carried out

in a semi-automatic way, since the user is required

to specify and/or modify the ROI. Texture

measurements are usually used for assessing the

homogeneity of image regions, calculating

differences in signal strength in image areas

corresponding to different materials in phantoms and

assessing the contrast between bright and dark tissue

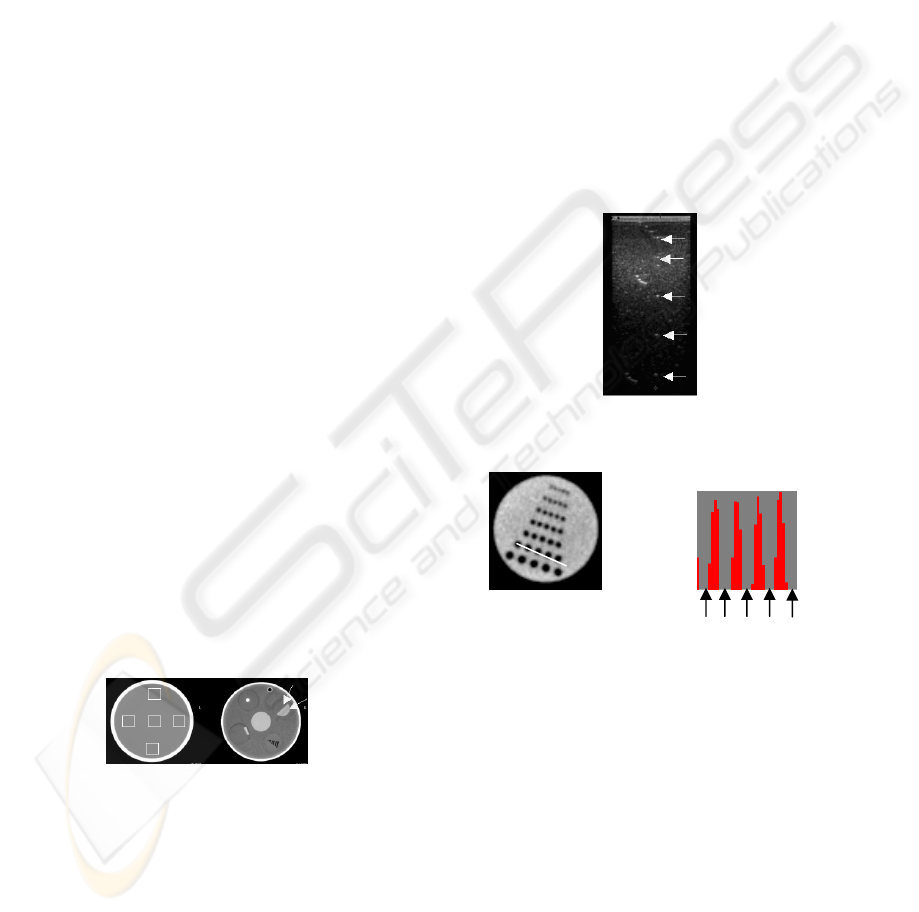

regions. Figure 4 shows typical image examples

where texture measurements are performed.

Figure 4: Typical Regions-of-Interest (ROI’s) on CT

images where texture measurements are performed.

(ROI’s are indicated by the squares and arrows overlaid on

the images).

2.2.2 Locating Points of Reference

On various occasions, phantoms contain objects

used as reference points for a number of

measurements. Examples of such reference points

are shown in Figure 5. To automate the process of

analysing test images, the user must be able to locate

reference points in images. To achieve this in the

developed system we employed either a

convolution-based approach or a profile-based

approach.

The convolution-based approach is used in noisy

datasets (a preferred approach for US images).

Based on this approach profiles are extracted in the

ROI that contains the points of reference; the

extracted profiles are then convolved with a one-

dimensional Gaussian function. The resulting vector

indicates the positions of the points of reference.

Figure 5 shows an example of reflectors in a US

image, which are automatically located using the

convolution-based approach.

The profile-based approach is used in low noise

images. Using this approach the locations of the

reference points are determined by detecting the

minima loci in the profile data (Figure 6).

Figure 5: A typical ultrasound (US) phantom image with

point-reflector sources, indicated by the arrows.

Figure 6: Locating reference points on a CT image of a

resolution phantom, using the profile-based method. (a)

Axial image of a resolution CT phantom (b) One-

dimensional profile from the second row of air holes

drilled in an epoxy resin-based insert of the CT phantom;

the arrows point to locations of minima.

2.2.3 High Contrast Spatial Resolution

High contrast spatial resolution is the ability of an

image device, to produce images where adjacent

high contrast objects are distinguishable. In order to

assess the ability of imaging equipment to produce

acceptable high contrast spatial resolution, a series

of high contrast circular objects of varying size and

separation is studied. The aim in such cases is to

define whether the circular objects are

distinguishable at a particular size and separation

(a)

(b)

A SEMI-AUTOMATED QUALITY ASSURANCE TOOLBOX FOR DIAGNOSTIC RADIOLOGICAL IMAGING

219

level. Examples of high contrast circular objects

considered for this test are shown in figure 7.

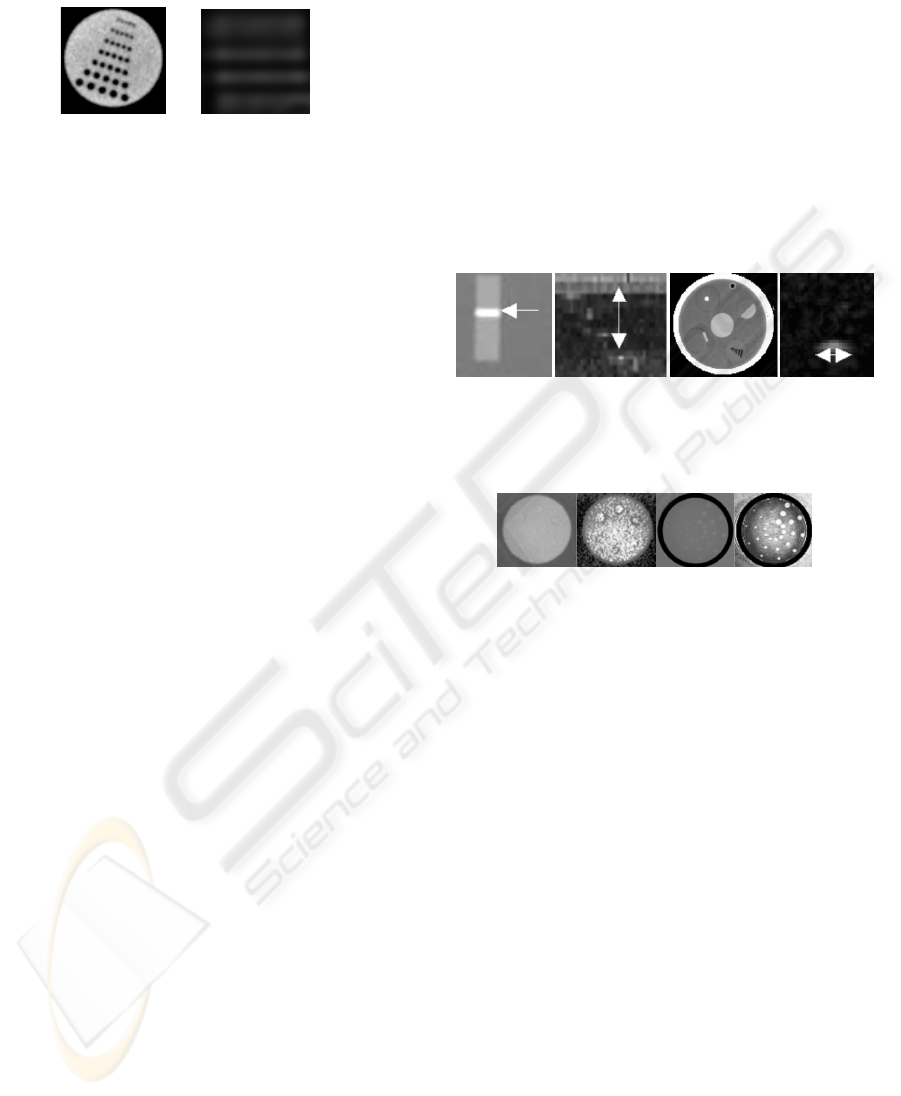

Figure 7: Details of a CT (left) and zoomed MRI image

(right) showing the spots used for computing the high

contrast spatial resolution. In the case of the MRI image

the spots are not distinguishable.

Techniques developed for detecting points of

reference in images (see section 2.2.2) were

employed in this case, to count the number of

objects detected in each region of interest.

2.2.4 Distance Measurements

In several occasions it is necessary to measure

distances between structures and/or the dimensions

of image objects. To perform distance

measurements, the user defines the ROI containing

the structure of interest and the required

measurements are performed automatically. Typical

cases where distance measurements involved

include:

• Measuring the width of image structures. The user

draws a profile across the image structure and

based on the extracted profile data, the width of

the structure is calculated (Figure 8a).

• Measuring the distance between reflectors.

Reflectors in an image region are automatically

located (see figure 5 and figure 8b) and the

distances between them are calculated.

• The calculation of the distances and dimensions of

circular structures (see figure 8c). In this case we

extract the boundaries of a circle and then

establish the attributes of the circle (i.e height,

width, center).

• Measuring the width of reflectors in noisy images

(see figure 8d). The reflector is first located and

then a profile is extracted across the center of the

reflector. Gaussian functions of different standard

deviations are convolved with the extracted profile

– the standard deviation value that produces the

best fit is used for estimating the width of the

reflector.

2.2.5 Low Contrast Detectability

In order to assess the ability of diagnostic equipment

to produce images where low contrast objects are

visible, procedures have been developed to detect

the presence of low contrast image objects in image

regions. For this purpose, an automated and a

manual method were implemented. In the automated

method a convolution-based approach is used for

detecting the presence of low-contract objects. In

several occasions, however, low contrast image

objects are dominated by noise, causing failures to

the automatic object detection algorithms. As an

alternative, a manual method was implemented for

low contrast object detection; in that case, the

system performs histogram equalization in the

region of interest and the user indicates the presence

of low contrast objects in the enhanced image

regions (Figure 9).

(a) (b) (c) (d)

Figure 8: Typical examples of distance measurements in

CT (a and c) and US (b and d) images.

Figure 9: Examples of image regions containing low

contrast objects (a and c) and the corresponding

histogram-equalized image regions (b and d).

3 SYSTEM IMPLEMENTATION

The database back-end has been implemented using

the Microsoft Database Engine, Desktop Edition of

SQL Server 200 including Service Pack 3. The

database front-end has been implemented using

Microsoft Visual Basic .NET 2003 on the .NET

Framework v1.1. The front-end is a stand-alone

application utilising the Windows Application

Programming Interface (API) and connecting to the

locally installed and running SQL server. The

database has been created and maintained by using

the ‘server explorer’ interface of the Microsoft

Development Environment. Reports generated

utilise Crystal Reports capabilities provided by the

Microsoft Development Environment.

The image processing tool has been implemented

using the Microsoft Visual C# .NET 2003 on the

.NET Framework v1.1. Dedicated image processing

routines have been implemented using the

MATLAB R13 programming environment and the

(

a

)

(

b

)

(

c

)

(

d

)

ICEIS 2006 - ARTIFICIAL INTELLIGENCE AND DECISION SUPPORT SYSTEMS

220

MATLAB Image Processing Tool Box. We have

exploited the MATLAB Com Builder to convert

MATLAB applications (routines and functions) to

Component Object Model (COM) objects. These

objects can be immediately integrated with any

COM-based application, such as Visual C#

applications.

4 CONCLUSIONS

We have presented a custom-made system for

managing quality control measurements and quality

assurance program for diagnostic radiological

imaging equipment. The proposed system uses an

Image Processing Unit for image analysis, and a

Database Management Unit to deposit all the data

that relates to the Quality assurance process. Reports

describing the performance of specific imaging units

are generated based on the Data Management Unit.

The main value of this paper is the design of a

system that supports the automation of the

application of systematic quality assurance programs

for diagnostic radiological imaging equipment in

compliance with International Regulatory

Committees and standards. Our study presents

original work in the particular application domain

since:

• There is support for the three main imaging

modalities (MRI, CT, US)

• Measurements on images are carried out using

dedicated image analysis algorithms rather than

relying on manual measurements

• Measurements derived from images and user

defined analyses are stored in a database so that

quality assurance reports are automatically

generated.

An important issue in the development of quality

assurance programs is the reliability in reported

measurements. In the case of the IPU, additional

user visual checks served as an independent method

of correctness of the software measurements.

Additionally, for measurements that may fail in the

case of using low image quality datasets, we have

incorporated secondary methods that depend on

human intervention.

The end result of this work is being used for re-

enforcing the efforts of staging proper and effective

Quality Assurance programs for medical imaging

equipment, both at national and international level.

The system has been tested extensively on real

images produced by MRI, CT and US scanners and

the system performance has proved to be

satisfactory. Since the system developed is unique it

is not possible to compare it directly with other

systems in this category. Initial feedback received by

potential users of the system, proves the value of our

approach for dealing effectively with QA control of

medical images in real applications.

ACKNOWLEDGEMENTS

The work presented was supported by the Cyprus

Research Promotion Foundation (project NEPRO-

0204).

REFERENCES

Bourel P, Gibon D, Coste E, Daanen V, Rousseau J. 1999.

Automatic quality assessment protocol for MRI

Equipment. Med. Phys. 26(12):2693-700.

Lerski RA, de Certaines JD. 1993. Performance

assessment and quality control in MRI by Eurospin

test objects and protocols. Magn. Reson. Imaging

11(6):817-33

McRobbie DW, Quest RA. 2002. Effectiveness and

relevance of MR acceptance testing: results of an 8-

year audit. Br. J. Radiology 75(894):523-31.

Och JG, Clarke GD, Sobol WT, et. Al , 1992 Acceptance

testing of Magnetic Resonance Imaging systems:

report of AAPM Nuclear Magnetic Resonance Task

Group No. 6. Med. Phys. 18:217-229.

Price RR, Axel L, Morgan T, et. al. 1990. Quality

assurance methods and phantoms for magnetic

resonance imaging:report of the AAPM Nuclear

Magnetic ResonanceTask Group No. 1. Med. Phys. 17

(Mar/Apr):2.

Radiology Centennial Inc., 1996, “A HISTORY OF THE

RADIOLOGICAL SCIENCES 1996 3 Volumes,

(American College of Radiology group)

A SEMI-AUTOMATED QUALITY ASSURANCE TOOLBOX FOR DIAGNOSTIC RADIOLOGICAL IMAGING

221