ADAPTING ERP SYSTEMS FOR SUPPORTING DEFENSE

MAINTENANCE PROCESSES

Case study of a repair and overhaul organization

Robert Pellerin

Department of Automated Manufacturing Engineering, École de Technologie Supérieure,

1100 Notre-Dame Ouest, Montreal, Canada

Keywords: ERP, Defense, Public sector, Maintenance, R&O, Remanufacturing.

Abstract: The defense sector represents one of the largest potential areas for new ERP sales. Many defense

organizations h

ave already implemented ERP solutions to manage and integrate the acquisition,

maintenance, and support processes. This paper addresses specifically the defense maintenance

management functions that need to be integrated into an ERP solution by adopting the view of a defense

repair and overhaul facility. We first discuss the specific nature of the defense maintenance activities, and

then we present the difficulties of integrating a maintenance strategy into an ERP solution. We finally

conclude by proposing a coherent and integrated ERP structure model for the management of the defense

repair and overhaul processes. The model has been partly applied in a Canadian repair and overhaul facility

and adapted into the SAP R/3 software.

1 INTRODUCTION

Many organizations have undergone significant

process changes in recent years to adapt to their new

market reality. Process improvements were obtained

mainly by a combination of business process

reengineering (BPR) efforts, organizational

restructuring, and the adoption of Enterprise

Resource Planning (ERP) systems. While BPR and

organization restructuring aim at eliminating non

added-value activities and administration barriers, an

ERP solution seeks to streamline the operation

processes of an organization, which typically

involve various functional units, and by integrating

the information flow into one single system.

Despite the complexity of such implementation,

th

e rate of adoption of ERP systems in the private

sector have been significant in the last decade with

almost 80% of the Fortune 500 firms having

implemented some form of ERP system and with the

growing number of small and medium sized

companies now adopting the same strategy (Wagner

and Antonucci, 2004). More recently, public sector

organizations are following their private

counterparts by adopting a business process-oriented

management model (Gulledge and Sommer, 2002).

Driven largely by budget reduction and efficiency

concerns, public sector organizations are shifting

from a purely hierarchical organizational structure to

a process oriented structure which accommodates

horizontal workflows (Gulledge and Sommer, 2003).

In that context, it is not surprising to note that

pu

blic sector organizations are also increasingly

implementing ERP systems to replace existing

operational systems (Shang et al., 2000). Small and

large-scale ERP implementations have been

attempted in various governmental agencies in

Australia, Canada, Germany, and the US (Blick et

al., 2000, Boyer, 2001, Chang et al., 2001, Menard

and Bernier, 2004, Wagner and Antonucci, 2004).

As a result the public sector has emerged as a key

initiative for the top ERP vendors which are

primarily targeting at federal, state and municipal

agencies (Makulowich, 1999).

Among the public sector, defense organizations

have al

ways been recognized as early adopters.

Various defense organizations, such as the US Naval

Air Systems Command (Blick et al., 2000), the

Danish Defense Command, the Canadian

Department of National Defense, the New Zealand

Defense Command, and the Royal Norwegian Air

Force have implemented an ERP solution and a

293

Pellerin R. (2005).

ADAPTING ERP SYSTEMS FOR SUPPORTING DEFENSE MAINTENANCE PROCESSES - Case study of a repair and overhaul organization.

In Proceedings of the Seventh International Conference on Enterprise Information Systems, pages 293-299

DOI: 10.5220/0002533702930299

Copyright

c

SciTePress

large number of NATO countries are looking to do

the same in the near future. In fact, the defense

sector represents one of the largest potential areas

for new ERP sales. For example, it is projected that

the US Navy will soon spend $3B on its ERP

implementation (Wagner and Antonucci, 2004).

So far, ERP projects in defense organizations are

primarily concerned with the acquisition,

maintenance, and support processes. This paper

focuses only on the defense maintenance

management functions that need to be integrated into

an ERP solution. We will first discuss the specific

nature of the defense maintenance activities, and

then we present the difficulties of integrating a

maintenance strategy into an ERP solution. We

finally conclude by proposing a coherent and

integrated ERP structure model for the management

of the defense repair and overhaul processes. The

proposed model relies heavily on the author personal

experience working for a Canadian defense repair

and overhaul facility.

2 ADOPTION OF ERP IN

DEFENSE ORGANIZATIONS

Defense organizations are facing increasingly

complex challenges as governments force them to be

more flexible and efficient within existing budgets

and as new technology are introduced (Gulledge and

Sommer, 2003). After years of under-finding,

commanders are left with only few alternatives:

Make significant cuts in capabilities and

infrastructures;

Re-assign resources to higher priority

activities;

Realize efficiency and productivity gains.

Mission preparation and deployed operations

being the core business of the defense, it is not

surprising to note that commanders initially focused

their reduction efforts on non strategic logistics

resources such as their repair and overhaul (R&O)

facilities. After successive cuts, it now seems that

further R&O capability reductions may jeopardize

the required support for the actual war-fighting

operations and peace mission level. Therefore,

further productivity gain will be realized mainly

through process improvements.

At the same time, defense organizations adopted

the concept of integrated supply chain which aims at

providing commanders the ability to plan and

control the flow of logistics resources to equip,

deploy, sustain, and reconstitute forces in support of

military operations. To do so, the military logistics

adopted and adapted best commercial practices.

Consequently, their former functional information

systems became obsolete.

In that context of continuous pressure to achieve

productivity gains and the adoption of commercial

processes, ERP implementation represents an

information management strategy pillar for defense

logistic organizations.

3 R&O ORGANZATIONS

Defense maintenance management covers the whole

process of equipment configuration management,

lifecycle analysis, maintenance program planning,

condition recording, procurement of indirect goods

and services, repair and remanufacturing execution,

project closing, and settlement. For most armed

forces, a central organization ensures the

maintenance program coordination and determines

the overall equipment support strategy. On the other

hand, the maintenance activities are executed by a

multitude of local maintenance groups organized in

three lines of maintenance.

1

st

line organizations are relatively small and

give immediate support to deployed units. Their

tasks include only minor repairs on equipments.

2

nd

line organizations can be deployed or

remained static. They possess more capabilities and

perform various tasks that range from minor repairs

to planned preventive inspections. Their role is to

support 1

st

line organizations and military bases.

The 3

rd

maintenance line is essentially composed

of R&O facilities. They are large industrial

organizations and therefore are exclusively static.

They perform long and complex repairs. Most R&O

organizations also conduct modification and

remanufacturing projects as specified by their

customers, the fleet managers (Pellerin, 1997).

3.1 R&O planning process

Defense R&O organizations must respond to

multiple demands. They first need to support long

term equipment fleet plan by preparing large and

complex life extension programs. These programs

are planned in accordance with the long term user

operation plan and necessitate a detailed knowledge

of the commander’s equipment requirements and

ICEIS 2005 - DATABASES AND INFORMATION SYSTEMS INTEGRATION

294

capabilities. They also have to respond to unplanned

breakdowns as part of their support mission.

The R&O planning process starts with the

equipment fleet manager supplying the R&O facility

with a list of equipments to be overhauled in the

future. Requirement’s horizon can range from

months to 10 years depending on the nature of the

projects. As part of their business and budgeting

plan, each R&O facility defines the maintenance

content to be performed and then it uses them to

determine the sequence of all activities in a project.

Based on its current capacity, the facility establishes

a maintenance program that specifies the estimated

starting and ending dates of every project and a

detailed budget.

When all the maintenance program budgets are

approved at the fleet manager level, a detailed

production plan is built by allocating the limited

pool of resources to each project. Different

production plans using different resource and

equipment levels are simulated and tested in order to

obtain a feasible plan that results in good utilization

of resources and also meets the customer’s

expectations. When the proposed plan is approved

by the customers, it is used as the master production

schedule for the next fiscal year.

3.2 R&O execution process

The R&O execution process includes the realization

of both unplanned repairs and planned

remanufacturing projects. For a typical overhaul

project, work starts with a disassembly activity. The

project content is defined as the main equipment is

inspected (Gharbi et al., 1998). The next step, the

most important in terms of workload, includes the

replacement and repair of a large number of parts

and components. At the same time, the main

structure of the equipment can be overhauled and

modified to accept the new components and the

repaired ones. The remanufacturing process then

ends with the assembly and a final inspection. Such

projects may also include paint stripping and

painting operations.

The network or routing topology of a

remanufacturing project is therefore divergent at its

start, followed by many parallel paths representing

the repair of systems or components, and converges

at the end (Gharbi et al., 1999). It is important to

note that not all MRPII or ERP systems can support

that type of work sequence and its related bill of

material (Pellerin, 1997).

The other element of complexity when executing

and controlling a repair and overhaul project resides

in the nature of each maintenance operation. The

amount of work depends on the specific condition of

the component being repaired or rebuilt. Therefore,

the exact duration of any repair is never known

before its end. The highly stochastic behavior of a

repair operation is also responsible for a high

variability in material consumption. Inventory

management for spares parts is extremely difficult in

that context. Parts usage must be planned according

to the maintenance program and based on historical

consumption data.

3.3 Integrating R&O management

process into ERP

Maintenance has always been considered as a supp:

ort function and rarely as a core enterprise process.

Consequently, most software development

companies have spent relatively little time and

efforts at integrating the maintenance processes into

their MRPII (Ip et al., 2000) or ERP applications

(Nikolopoulos et al., 2003).

Although the role of maintenance has become

more important in the last few years, most ERP

providers still position their maintenance

management system or module as an execution

system. This may be acceptable for traditional

manufacturing companies but it comes short to

satisfy all the needs of purely maintenance

organization such as a remanufacturing or an R&O

plant. These organizations need to integrate all

levels of their planning activities, from the strategic

business plan to the actual detailed maintenance

plan. This process requires planning, negotiating,

sourcing, inventory controlling, scheduling,

monitoring, quality assurance, and dispatching of the

necessary resources (Nikolopoulos et al., 2003).

They also need to be able to translate a customer

requirement into a firm order with an expected

delivery date. This is not an easy task because of

the stochastic nature of any major maintenance

request, as described earlier.

In the case of a defense R&O organization, the

management complexity increases with the length of

the planning horizon. Remanufacturing and overhaul

projects are planned at the fleet level and with

relatively few information at the equipment level.

The generic sequence of work is known with

certainty but this is not the case with the material

consumption and the work duration. In practice,

ERP applications are usually good at composing

with the changing nature of a maintenance order but

ADAPTING ERP SYSTEMS FOR SUPPORTING DEFENSE MAINTENANCE PROCESSES

295

offer very limited functionality to do effective

stochastic planning and forecasting.

Maintenance program also required an increasing

number of competencies as the equipment

technology evolves. Manpower level and training

decisions must be planned well in advance. Most

ERP maintenance modules do not permit such

evaluation which is normally restricted to a

production management module. In addition, the

long term plan must accommodate for the unplanned

breakdowns that will occur in the future. Those

maintenance activities are often mission critical

tasks and need to be carried out in a short time

frame. Those high priority orders usually need the

same pool of resources as the planned maintenance

projects.

Finally, some ERP applications have difficulty in

tracking the parts during the repair process. When

technically feasible, spare parts and repaired

components may be interchanged between orders to

ensure a quick completion of a high priority order

while not compromising the overall maintenance

program. Parts usage and tracking must be done at

the equipment and order level while the impact of

parts interchanges must be evaluated at the

maintenance program level.

4 PROPOSED MODEL

The proposed model considers two types of

maintenance management approaches:

Proactive planning: includes the project

management and the planning activities

required to determine the long term

requirements in terms of budget, resources, and

inventory levels.

Reactive planning and controlling: includes all

the planning and scheduling activities required

for the execution of a maintenance order. This

includes activities such as repair content

evaluation and changes, parts interchanges,

expediting, sourcing, procurement, and testing.

The integration of both planning approaches is

realized by combining a traditional MRPII structure

with the one normally used by a maintenance

management information system as described in the

next section. Program management functionalities

are also included to facilitate remanufacturing

project planning and budgeting.

4.1 The ERP model

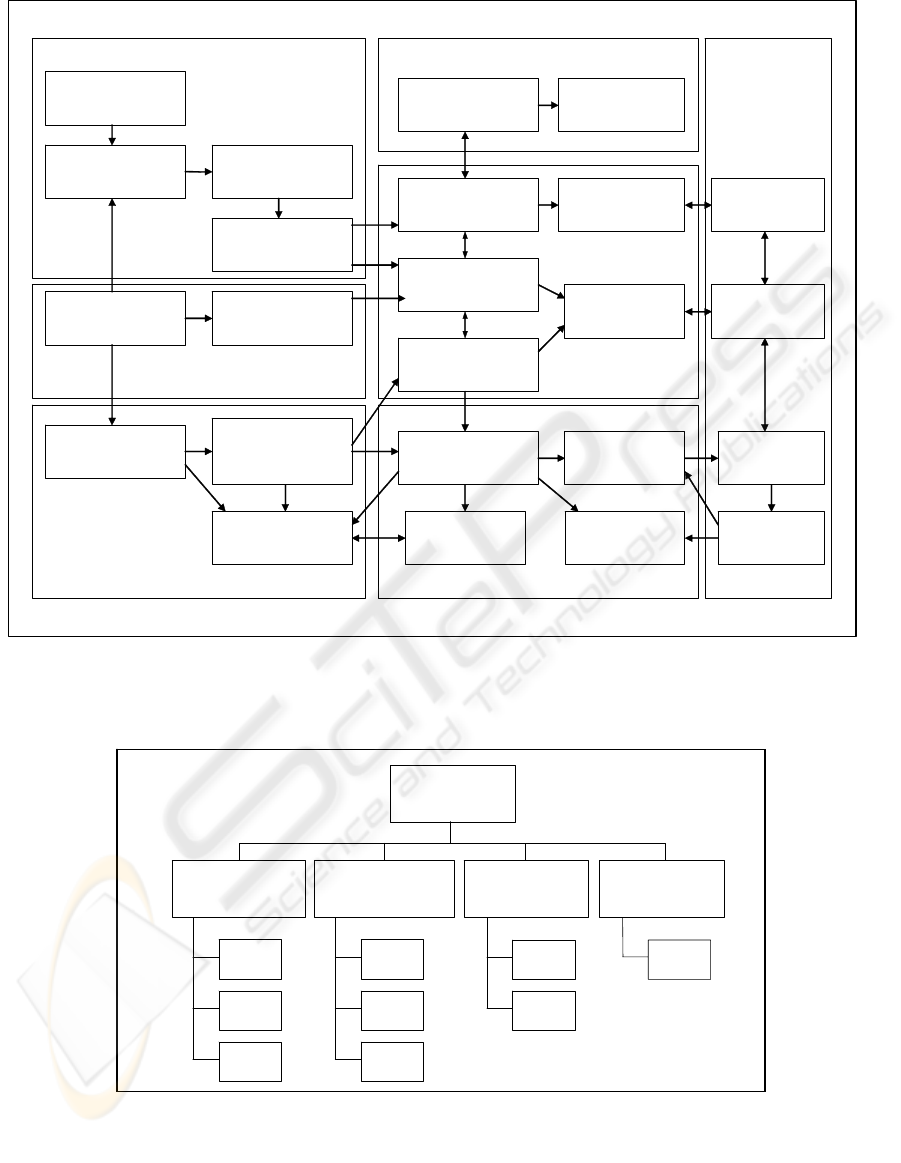

The proposed ERP structure, as shown in Figure 1,

is able to compose with the nature of the R&O

workload which is partly deterministic (planned

programs) and also stochastic (unplanned

maintenance requests).

The implementation of both maintenance

management approaches is realized by integrating

the following functions in our ERP model:

Strategic planning;

Maintenance program planning;

Corrective maintenance management;

Manufacturing requirement planning;

Maintenance execution and control;

Workforce management; and

Material management.

The proposed structure divides the planning

processes into three subsystems. The top layer, the

Strategic planning subsystem, addresses all long

term business issues. It supports the strategic

planning function by defining the global priority of

the R&O organization and its corresponding budget

plan.

The second level of planning is supported by the

Manufacturing Requirement Planning subsystem.

Important outputs of the MRP subsystem include the

Master Production Schedule and the Material

Requirement Plan. Load and capacity analysis can

be performed for all MRP plans.

The final planning layer of this top-down

approach is done by the Maintenance Execution &

Control subsystem which controls the actual

execution, scheduling, testing, and costing of all

maintenance orders.

The Maintenance Program Management and the

Corrective Maintenance subsystems capture

customer demands which become the input of all

planning subsystems. The Maintenance Program

Management subsystem includes all required

functionalities to effectively prepare a planned

maintenance project. On the other hand, the

Corrective Maintenance subsystem manages the

unplanned requests. Both inputs are required to

establish a complete master production schedule.

The Material Management subsystem support the

critical tasks of establishing and procuring the

appropriate level of spare part inventory and of

ICEIS 2005 - DATABASES AND INFORMATION SYSTEMS INTEGRATION

296

managing outsourced work in accordance with the

detailed production schedule.

The last subsystem, Workforce management, is

used to ensure that the R&O organization personnel

are skilled and available to accomplish the

production plan. Competency planning includes fit-

gap analysis to determine the required skills and

competencies for a maintenance project. This task

is usually performed after each maintenance

program approval in order to give sufficient time to

proceed with training or recruiting activities as

required. The Workforce management subsystem

also performs operations dispatching and time

recording transactions in support of the maintenance

execution process.

4.2 Implementation issues

The proposed model aim at effectively integrating

all aspects of the R&O defense requirements. With

that objective in mind, we built the model by

separating the main processes into subsystems.

Each subsystem contains functions or transactions

that are mostly included in commercial ERP

solutions. Nevertheless, the adaptation of an ERP

system, which goes beyond the normal configuration

of the software, is still required since the proposed

model do not use the traditional integration points

that normally prevail in such system. Workflow

modifications, user-exit or function programming,

and report developments are therefore required.

The proposed model has been successfully

applied by a Canadian repair and overhaul facility.

This facility repairs and remanufactures several

types of army vehicles and components for the

Canadian Armed Forces. The model was used to

adapt a well known commercial ERP system, SAP

R/3. Selected modules for this ERP implementation

project are presented in figure 2. The ERP structure

makes use of the Human Resources (HR), the

Controlling (CO) modules, and most of the SAP R/3

logistic modules (Project System (PS), Plant

Maintenance (PM), Production Planning (PP),

Material Management (MM), and Quality

Management (QM)).

Initial work was conducted to integrate the

manufacturing requirement planning processes with

the maintenance transactions that support the

execution of maintenance orders. As of today,

demand planning and forecasting of remanufacturing

programs is used to build an aggregate production

plan. Multiple versions exist to allow load

simulation and rough-cut capacity planning analysis.

The active version of the plan is used to generate

planned orders into a detailed master production

schedule (MPS). Unplanned requests, recorded by

the maintenance order subsystem, are also included

in the MPS.

Material Requirement Planning (MRP) is

performed based on this global master production

schedule. The execution process then follows the

typical maintenance execution process and is tightly

integrated to the Material Management (MM),

Quality Assurance (QM), Cost Controlling (CO),

and Human Resources (HR) modules.

This approach has contributed to achieve

significant productivity gains and inventory

reductions while allowing the organization to better

plan its workload.

5 CONCLUSION

This paper recognizes the difficulty to integrate

defense maintenance strategy and planning

processes into

existing ERP applications. The defense needs in

terms of integrated logistics requires that R&O

organizations be

ADAPTING ERP SYSTEMS FOR SUPPORTING DEFENSE MAINTENANCE PROCESSES

297

SAP R/3

Planning

(fleet/program level)

Execution

(equipment level)

Controlling &

reporting

PS

PP

MM

PM

QM

MM

CO

LIS

Workforce

management

HR

Production

Planning

Master Production

Schedule (MPS)

Material Reqmt

Planning (MRP)

Resource reqmt

planning

Capacity

planning (CRP)

MRP

Maintenance Program Management

Corrective Maintenance Management

Material Management Maintenance Execution & Control

Business

Planning

Operations &

budget planning

Strategic Planning

Eqpt lifecycle

planning

Defense

planning

Project

management

Demand

management

Maintenance order

management

Order

costing

Operations

scheduling

Service & order

request

Eqpt Condition

monitoring

Procurement &

sourcing mgmt

Spares parts &

consumables

inventory mgmt

Configuration

management

Workforce

management

Competency

planning

Time

recording

Workforce

planning

Operations

dispatching

Quality

control

Figure 1: A proposed ERP structure for defense R&O

Figure 2: SAP R/3 selected modules for defense R&O management

ICEIS 2005 - DATABASES AND INFORMATION SYSTEMS INTEGRATION

298

able to plan maintenance activity at the fleet or

program level while monitoring and controlling the

specific condition of any equipment. The proposed

model contributes to provide a modular and generic

structure for adapting an ERP system in that context.

The model covered all practical aspects of the

defense R&O planning process and has been

implemented successfully in a real defense R&O

environment. Our further research will focus on

adapting the actual model for commercial R&O

organizations. As an example, integration between

the sales and the production planning processes need

to be resolved. Management of returnable items is

also an important issue to address in the future.

REFERENCES

Blick, G., Gulledge, T, & Sommer, R., 2000. Defining

Business Process Requirements for Large-Scale Public

Sector ERP Implementations: A Case Study, In

Proceedings of the European Conference on

Information Systems, Wirtschafts Universitat, Wien.

Boyer, D., 2001. ERP Implementations: Managing the

Final Preparation and Go-Live Stages, In Government

Finance Review, December, 41-44.

Chang, S., Gable, G., Smythe, E., & Timbrell, G., 2000, J.,

1998. A Delphi examination of public sector ERP

implementation issues, In Proceedings of the twenty

first International Conference on Information Systems,

494-500.

Gharbi, A., Girad, J., Pellerin, R., & Villeneuve, L. 1998.

Bombardier turned to simulation to validate the CF-18

maintenance program, In Interfaces, Vol. 27 No. 6, 22-

34.

Gharbi, A., Pellerin, R., & Villeneuve, L. 1999. A New

Constraint Based Approach for Overhaul Project

Scheduling with work Space Constraints, In

International Journal of Industrial Engineering,

Special Issue on Project Management, Vol. 6 No. 2,

494-500.

Gulledge, T.R. & Sommer, R.A., 2002. Business Process

management: public sector implications. In Business

Process Management Journal, Vol. 8 No. 4, 364-376.

Gulledge, T.R. & Sommer, R.A., 2003. Public sector

enterprise resource planning. In Industrial

Management & Data Systems, Vol. 103 No. 7, 471-

483.

Ip, W., Kwong, C., & Fung, R., 2000. Design of

maintenance system in MRPII, In Journal of Quality in

Maintenance Engineering, Vol. 6 No. 3, 177-191.

Makulowich, J., 1999. Enterprise resource planning: It’s in

the Morphing. In Washington Technology, April 26.

Menard, C., Bernier, C., 2004. Le cas d'une mise en

oeuvre ERP réussie aux centres hospitaliers de LaSalle

et de Verdun : comprendre la démarche par laquelle

s'installent les nouvelles façons de faire. In Gestion,

Vol. 28 No. 4, 61-68.

Nikolopoulos, K., Metaxiotis, K, Lekatis, N, &

Assimakopoulos, V., 2003. Integrating industrial

maintenance strategy into ERP. In Industrial

Management & Data Systems, Vol. 103 No. 3, 184-

191.

Pellerin, R., 1997. Conception d’un systeme integré de

gestion de la production dans un environnement de

refection d’équipements, In Actes du 2ème Congrès

Franco-Québécois de Génie Industriel, Albi, France.

Wagner, W. & Antonucci, Y., 2004. An Analysis of the

Imagine PA Public Sector ERP Project, In Proceedings

of the 37

th

Hawaii International Conference on System

Sciences.

ADAPTING ERP SYSTEMS FOR SUPPORTING DEFENSE MAINTENANCE PROCESSES

299