GLOBAL CONDITION MONITORING SYSTEM

Implementing MATLAB®-Based Analysis Services

Henri Helanterä, Mikko Salmenperä, Hannu Koivisto

Institute of Automation and Control, Tampere University of Technology, P.O. Box 692,FIN-33101 Tampere, Finland

Keywords: Proactive maintenance, condition monitoring, fault diagnostics, distributed automation, Java, MATLAB®

Abstract: Proactive maintenance is a solution to increase the availability

of the production equipment in the process

industry. It involves online condition monitoring of field devices and reliably diagnosing the reason behind

any abnormal behaviour, thus helping to rationalise maintenance operations. Making the information of

different industrial sites available for analysis, significant improvements could be made to the predicting

capabilities of condition monitoring and to the accuracy of fault diagnostics. The global condition

monitoring system described in this paper is based on distributed agent-architecture and employs data

communication networks to connect the industrial sites to one or more service centres. Many successful

methods used in condition monitoring and fault diagnostics often require advanced tools. MATLAB®

software is the de facto standard in numerical computing but integrating MATLAB® as a computing server

to the J2EE-based condition monitoring system is a laborious task as no all-purpose and easy-to-use

methods exist. However, this paper introduces some strategies to overcome the integration problem. The

most important solution presented here is so called inverted calling scheme. Also two other approaches are

discussed: using MATLAB® engine functions via C-language native methods and deployment of stand-

alone MATLAB® COM components. All the above strategies have their strengths and weaknesses.

Implementing the inverted call requires more effort from the programmer but is standard-compliant.

Exploiting engine functions or COM components is easier as some ready-made software can be employed

but the emerging solutions are not pure-Java.

1 INTRODUCTION

The role of proactive maintenance in process

industry is growing in importance, since there is an

ever-increasing demand for improvement of

productivity and reliability of the plants. At the same

time there are requirements for reducing the overall

maintenance costs and carrying out the maintenance

operations during the planned stoppages. Meeting

these requirements—conventionally seen as opposite

alternatives—means that any device failures have to

be predicted reliably and the diagnosis of faulty

devices has to be performed quickly and efficiently.

This is not possible without highly automated

condition monitoring and diagnostic systems.

Individual factories, however, don’t have sufficient

resources to meet the demanding goals set to the

maintenance. Thus, outsourcing is a potential option

here.

If the huge amount of information available at the

diffe

rent industrial sites were available for analysis,

significant improvements could be made to the

predicting capabilities of condition monitoring and

the accuracy of fault diagnostics. This paper first

introduces the overall structure of the global

condition monitoring system designed to answer the

needs of predictive maintenance. Then we examine

how this system can be used in data-analysis.

Finally, techniques to integrate MATLAB®

software as a computing server to the J2EE-based

condition monitoring system are presented,

including a nouvelle approach that—unlike the

others—is pure-Java.

2 STRUCTURE OF THE GLOBAL

CONDITION MONITORING

SYSTEM

The overall structure of the global condition

monitoring system is studied in (Salmenperä, 2000),

(Nikunen, J. et al., 2001) and (Salmenperä, M.,

Koivisto, H., 2001). The system consists of devices,

300

Helanterä H., Salmenperä M. and Koivisto H. (2004).

GLOBAL CONDITION MONITORING SYSTEM - Implementing MATLAB

R

-Based Analysis Services.

In Proceedings of the First International Conference on Informatics in Control, Automation and Robotics, pages 300-305

DOI: 10.5220/0001134303000305

Copyright

c

SciTePress

databases, software components and

communications links that connect all the above

together. Factory-specific subsystems, sites, are

connected to one or more central systems, service

centres.

The system works at two levels. Automated agent-

based level is meant to be the framework of the

system. All continuous data acquisition, generation

of regular reports and alerts takes place at this level.

More specific operations are carried out by human

operators. The agents provide interfaces, through

which users and other agents can access system

resources without having to be aware of their

implementation. (Salmenperä, 2000)

Agent is a somewhat vague term. According to

Franklin & Graesser (1996), the most significant

characteristics of software agents are independence

and goal-orientation. These also necessitate that the

agents are capable of communicating with each

other. In the global condition monitoring system

analysis agents are used to act on behalf of human

experts in routine data-analysis and fault reasoning.

Administration of the scattered large-scale system

requires that all the essential information is stored in

one place, in the service centre, where it can be

easily accessed (Salmenperä, 2000). Employing the

agent-architecture makes it possible to distribute the

routine analyses to factory-level thus preventing

unnecessary transfer of raw data. As a result only the

most important information ends up to the service

centre for further scrutiny and refinement. Extracting

the raw data into interesting and valid information is

one of the key tasks of the condition monitoring

system.

The information within the system is of great

importance for the companies and thus to be held

confidential. Yet, making use of existing

communication networks, mainly Internet, is

essential when implementing a global system.

Consequently, network security is a key issue.

Possible threats include external factors but also

other parts of the system, such as other industrial

sites, can be seen as potential risks, since the

maintenance service provider might well cooperate

with rival companies. (Nikunen, 2001)

Network speed and the amount of transferred data

have to be considered when designing the system in

order to make it robust to possible delays and breaks

in the communication. The sites are independent

units that have to be able to perform basic

maintenance operations without intervention of the

service centre. The system has to work even if the

connection to the service centre broke.

3 GLOBAL ANALYSIS SCHEME

Analysis services in the global condition monitoring

system are routine analysis automatically run by the

analysis agents, or more specific—but still

predefined—operations put into effect by a user. The

analysis services need three different kinds of

databases: namely device, knowledge and analysis

databases. The device database consists of

measurements and diagnostic information. The

knowledge base contains expert knowledge of the

devices accumulated in the long run. The analysis

database includes the results of analyses for later use

and scrutiny.

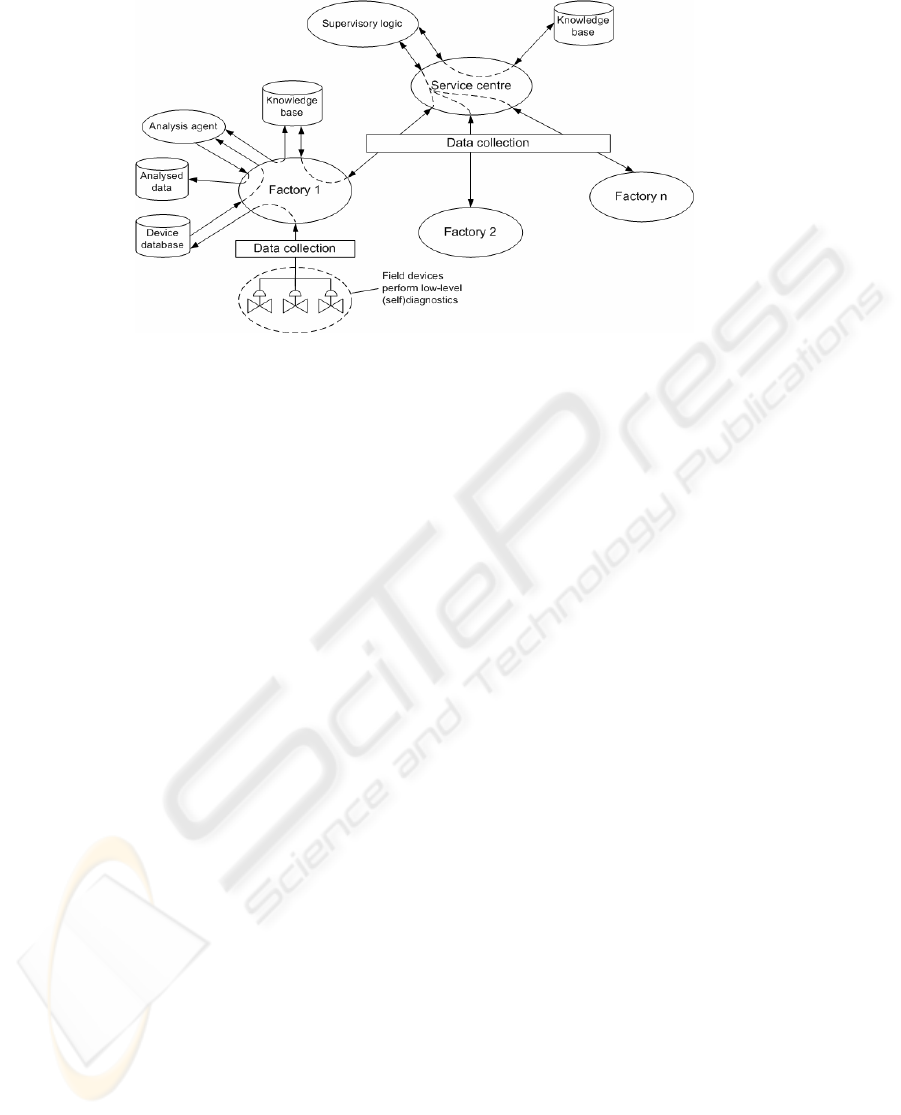

The analysis components of the global condition

monitoring system are shown in figure 1. The field

devices perform low-level self-diagnostics by

monitoring their own state and condition. The

analysis agent responsible for the site’s automated

condition monitoring integrates the device

Fi

g

ure 1: The anal

y

sis com

p

onents of the

g

lobal condition monitorin

g

s

y

stem.

GLOBAL CONDITION MONITORING SYSTEM - Implementing MATLAB® - Based Analysis Services

301

diagnostic information with the information in the

site databases to carry out more thorough analyses.

The information gathered at the sites is further

processed and analysed by the high-level analysis

services (supervisory logic) in the service centre.

The analysis operations are mainly carried out

automatically by the site subsystems. However, if

the site’s analysis agent cannot identify the reason

for the abnormal behaviour of a device—i.e., it

discovers a situation that does not match to its

existing deduction rules—it sends a warning to the

system. Experts of the service centre then examine

the device and, if the cause can be worked out, the

new deduction rule is updated to the knowledge

base. The experts can use, in addition to their own

knowledge, the data from all the other sites, and

therefore have a better chance to clear up the

problem than the local staff at the site. (Helanterä,

2004)

The global condition monitoring system has to work

in a diverse environment of different field devices,

automation systems, database systems etc. Thus, the

architecture of the system has to be flexible to

accommodate the variety of industrial sites

(Nikunen, J. et al, 2001). Modularity is one of the

reasons behind choosing agent-architecture as the

general framework of the system and modularity

requirements have to be taken into account in the

design of the analysis services as well. The

advantage of the modular structure is that the

implementation of the computational module can be

changed without having to modify the analysis

agent.

The computation can be transferred to a separate

computing server or distributed among various

machines. The information about the computing

server(s) can be included in system configuration

files. Using a separate computing server or various

distributed servers should be considered when the

amount of data to be processed increases and thus

the load caused to the agent server becomes

intolerable. Separating the computation from the

agent server is relevant when considering the overall

system stability.

4 COMPUTATIONAL

IMPLEMENTATION OF THE

ANALYSES

The computational implementation of the analyses

means in this context the tools and mathematical

libraries that are needed to perform the analyses. The

way of implementation is affected by the general

architecture of the system, the systems integration

issues and the analysis methods to be used.

Two alternative technologies have been studied as a

framework of the global condition monitoring

system—namely Sun’s J2EE (Kero, 2004) and

Microsoft’s .Net (Haavisto, 2001) and (Salmenperä,

M. et al., 2003). In this paper we concentrate on the

J2EE architecture and thus, the analysis components

have to be compatible with Java in some way. The

main driving force behind choosing the Java

technology is its platform independence, which is

one of the central requirements of the global

condition monitoring system and has to be taken into

account with the analysis services as well. On the

other hand, the condition monitoring system also has

to deal with legacy systems, thus making systems

integration necessary. Therefore we may well ask if

it is possible to use something else than a Java-based

solution, provided that it is otherwise more

convenient.

It is a great advantage if the analysis components

could be developed and implemented with the same

tool. In practise, there are two different alternatives:

using Java tools both in development and

implementation, or using non-Java tools in

development and then integrating the emerged

components to the system. In the field of numerical

computing MATLAB® is the de facto standard and

the development of analyses would most probably

be carried out with it. Then again, the J2EE

framework of the condition monitoring system

makes using pure-Java applications desirable.

Basically MATLAB® consists of the computational

engine, its own programming language and a variety

of toolboxes that contain a combination of functions

for special tasks. In the context of analysis services

e.g. the Statistical, Neural Network, Fuzzy Logic

and Database toolboxes provide a solid base for both

developing and implementing the analyses. In the

Java world there are tools for these tasks as well but

they are not as advanced as those of MATLAB®

and also the experience of using them is not as

extensive.

5 JAVA-MATLAB® INTEGRATION

MATLAB® is a competent tool for analysis

development but in terms of systems integration it is

problematic. Especially the integration with Java-

based systems is difficult, even though the more

recent versions of the software (since version 5.3

R11) include the Java virtual machine, which makes

it possible to call Java classes from MATLAB®

code but the contrary is not possible. However, we

present here some ways to use MATLAB® from a

ICINCO 2004 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

302

Java application. The first method makes use of

MATLAB®’s Java virtual machine. The latter two

use MATLAB®’s external C-language interface and

the ability to compile MATLAB® programs into

stand-alone COM components.

5.1 Inverted call

Java Runtime class enables executing commands in

the command line of the operating system. Thus,

starting the MATLAB® process from a Java

application is possible. As a command line option

the name of an m-file—a program written in

MATLAB®’s own programming language—that

MATLAB® executes upon start-up can be given.

Then, within the m-file we can call a Java class that

listens to analysis requests from the analysis agent.

The analysis request can consist of e.g. the name of

an m-file to be used to perform the analysis, and the

data to be analysed, or the parameters with which

the data can be fetched. In the inverted calling

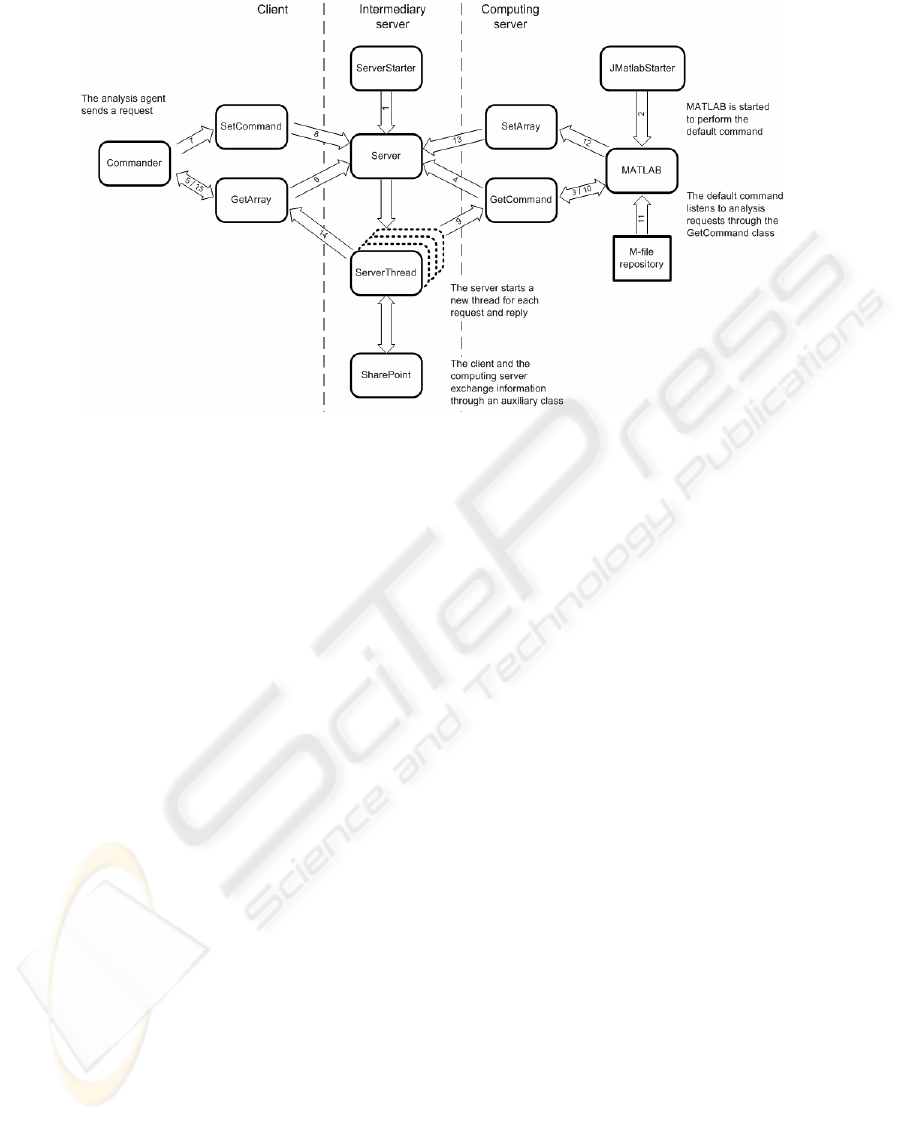

method, which is illustrated in figure 2, the Java

application that listens to the analysis requests is run

in the MATLAB®’s Java virtual machine. The

analysis agent, on the other hand, is run in another

virtual machine. The virtual machines can reside on

different physical machines. Thus, a method for

these two applications to communicate over the

network is needed. The simplest solution is to use

Java sockets. With the help of sockets it is possible

to read from and write to a defined network

connection that is described by an IP address and a

port number. Here, the client and the computing

server exchange information through an auxiliary

class called SharePoint.

The inverted call was presented by Helanterä (2004)

and it works as follows (have a look at the numbers

in figure 2):

The ServerStarter class starts the intermediary server

Server.

The JMatlabStarter class starts the MATLAB®

process from the operating system command line

and gives the name of the m-file (located in the m-

file repository) to be run upon the start-up.

MATLAB® calls the GetCommand class to get

analysis requests from Server.

GetCommand uses a socket connection to poll

Server for any analysis requests.

The analysis agent (referred as Commander in the

figure 2) calls the GetArray class to get analysis

result from Server.

GetArray uses a socket connection to poll Server for

available results.

The analysis agent uses the SetCommand class to

send a request for an analysis to be performed in the

computing server.

SetCommand sends the request to Server using a

socket connection.

ServerThread sends the analysis request to listening

GetCommand through the established socket

connection.

GetCommand returns the analysis request to

MATLAB®.

MATLAB® gets the appropriate m-file from the m-

file repository and performs the analysis.

MATLAB® calls the SetArray class to return the

results.

SetArray sends the result to Server through a socket

connection.

ServerThread sends the result to listening GetArray

through the established socket connection.

GetArray returns the result to the analysis agent.

The socket-based solution is simple but probably not

suitable to be used in the real-world global condition

monitoring system. The analysis requests are likely

to occur simultaneously and the problem with the

socket-based approach is how to bind the right

answer to the right request. A more elegant solution

is to replace the socket server with JMS-based (Java

Message Service) message queue that handles the

ties between the client and the server, the request

and the answer. Using JMS to implement messaging

in the global condition monitoring system is studied

by Kero (2004). Other alternatives, in addition to

Java sockets and JMS, are e.g. making use of Java

RMI (Remote Method Invocation) or CORBA

(Common Object Request Broker Architecture) to

do the interoperation needed.

The main advantage of the inverted call is its

conformity to standards. No additional software is

needed but the solution relies solely on J2EE

standard libraries. The Runtime class is partly

platform dependent because command syntax is

system specific. Considering the minor role of the

use of system commands—they are only used to

start the MATLAB® process—this cannot be

viewed as a stumbling block as choosing the correct

syntax for each system is programmatically easy to

implement.

5.2 MATLAB® engine functions

MATLAB® provides engine functions with which it

is possible to use MATLAB® as a computing engine

from other software. The engine functions enable

executing MATLAB® commands and transferring

data and variables between MATLAB® and the

calling application. Engine functions are C or

FORTRAN programs that communicate with the

MATLAB® process via COM interface in MS

Windows and named pipes in UNIX/LINUX

environment. (The Mathworks, 2003)

GLOBAL CONDITION MONITORING SYSTEM - Implementing MATLAB® - Based Analysis Services

303

Engine functions do not support Java (The

Mathworks, 2003) but it is possible to use so called

native methods in Java via JNI (Java Native

Interface) (Sun Microsystems, 2003). Native

methods are functions programmed in another

language, e.g. in C, that are embedded in the Java

program. JNI acts as a bridge between Java and the

native program code. It is worth noting that by using

JNI we lose the platform independence of Java,

since native methods are operating system specific.

MATLAB® engine functions can be used from a

Java program by implementing engine function calls

in C language native methods. There is an existing

implementation called JMatLink (Müller, 2002) that

uses engine functions with C native methods in Java.

5.3 MATLAB® COM Builder

COM (Component Object Model) is Microsoft’s

component model that makes it possible for

programs to use each others’ resources. The latest

version of MATLAB® (version 6.5 R13) comes

with the COM Builder tool that can be used to

convert m-files to stand-alone COM components. A

stand-alone COM component does not need

MATLAB® to function, since all the required

libraries are packed within the installation program

of the component. The analysis modules (m-files)

developed with MATLAB® can be made stand-

alone COM components with the help of COM

Builder. (The Mathworks, 2002)

COM components cannot be used directly from a

Java program and therefore some kind of

intermediation is needed. Fortunately such Java-

COM bridges do exist. One useful implementation is

JIntegra that uses proxy classes to enable two-way

communication between Java programs and COM

components. The proxy classes are pure Java

applications that cast COM data types as Java data

types, thus avoiding the need to use any platform-

dependent code. The JIntegra software generates the

proxy classes automatically for each COM

component. (Intrinsyc Software International ,2004)

MATLAB® licence allows the free use of COM

components and consequently the low-cost is one of

the most important aspects in favouring them. On

the other hand COM technology binds the

implementation strictly to MS Windows

environment whereas the other integration

techniques presented here are also suitable to all the

other operating systems supported by MATLAB®.

6 CONCLUSIONS

This paper first described the general structure and

requirements set for the global condition monitoring

system that is designed to achieve predictive

maintenance in process industry. We also outlined

the way in which the information management and

analysis in the system should be done. Then three

methods to integrate MATLAB® software to

perform computations required by condition

monitoring and fault diagnostics were introduced.

It was proposed that distributed agent-architecture is

needed to guarantee modularity as well as automated

operation—essential requirements for such a large-

scale system. Distribution applies also to the

Figure 2: Calling MATLAB from Java using inverted call

ICINCO 2004 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

304

analysis services that are scattered to the site

subsystems. On top of that, data pre-processing and

device self-diagnostics are done at the field level to

further decrease the system workload and to avoid

unnecessary data transfer.

Systems integration has grown in importance

especially in medium and large-scale industries

where it is difficult to launch unified, comprehensive

information solutions. The global condition

monitoring system has to deal with legacy systems

and some basic tools, like MATLAB®, may need to

be integrated to the system as well. Modularity and

generality requirements have to be considered when

making the decision about the integration solution to

allow for future changes to the system.

Combining MATLAB® and a Java-based system is

not a straightforward task. Choosing the integration

solution is a matter of deciding between ease-of-use

against generality and portability of the solution. Out

of the three approaches introduced in this paper only

the inverted call can guarantee platform

independence. The disadvantage, however, is the

more complicated integration process and the more

extensive programming effort compared to the other

two solutions. Moreover, the simple socket-based

implementation detailed in section 5.1 is not

applicable to a full-scale production system.

However, by employing more sophisticated inter-

process communication methods, like JMS, Java

RMI or CORBA, to implement the analysis request

broking, the inverted call can be improved and can

be seen as the most promising alternative to

integrate MATLAB® software with a Java-based

system.

REFERENCES

Franklin, S. & Graesser, A., 1996. Is it an agent or just a

program?: A Taxonomy of autonomous Agents. In

Proceedings of the Third International Workshop on

Agent Theories, Architectures, and Languages.

Springer-Verlag, Berlin.

Haavisto, H., 2001. Kunnonvalvontajärjestelmän

viestinvälityksen toteutusmahdollisuudet .NET

tekniikoin. MSc Thesis, Tampereen teknillinen

korkeakoulu.

Helanterä, H., 2004. Analyysipalvelut globaalissa

kunnonvalvontajärjestelmässä. M.Sc. Thesis,

Tampereen teknillinen yliopisto.

Java Native Interface, 2003. [Internet]. Sun Microsystems,

Inc. Available from: <http://java.sun.com/j2se/1.4.2/

docs/guide/jni/>. [Accessed 24 February, 2004].

J-Integra Documentation, 2004. [Internet]. Intrinsyc

Software International, Inc. Available from:

<http://j-integra.intrinsyc.com/j-integra/doc/>.

[Accessed 24 February, 2004].

Kero, J., 2004. Advanced Messaging in Enterprise Scale

Maintenance System. MSc Thesis, Tampereen

teknillinen korkeakoulu.

MATLAB® COM Builder User’s Guide, 2002. [Internet].

Version 1. Natick, MA. The Mathworks, Inc.

Available from: <http://www.mathworks.com/access/

helpdesk/help/pdf_doc/combuilder/combuilder.pdf>.

[Accessed 24 February, 2004].

MATLAB® External Interfaces/API, 2003. [Internet].

Version 6. Natick, MA. The Mathworks, Inc.

Available from: <http://www.mathworks.com/access/

helpdesk/help/pdf_doc/matlab/apiext.pdf>. [Accessed

24 February, 2004].

Müller, S., 2002. JMatLink – MATLAB® Java Classes.

[Internet]. Available from: <http://www.held-

mueller.de/JMatLink/>. [Accessed 24 February,

2004].

Nikunen, J., 2001. Security Considerations on Wide Area

Networking Industrial Solutions. M.Sc. Thesis,

Tampereen teknillinen korkeakoulu.

Nikunen, J. et al., 2001. Global Condition Monitoring

Network. In Automaatio2001, Helsinki, September 2-

9. Suomen Automaatioseura ry.

Salmenperä, M., 2000. E-speak in Enterprise Scale

Condition Monitoring Network. MSc Thesis,

Tampereen teknillinen korkeakoulu.

Salmenperä, M. & Koivisto, H., 2001. Using E-speak in

Condition Monitoring Network. In Automaatio2001,

Helsinki, 2-9 September. Suomen Automaatioseura ry.

Salmenperä, M. et al., 2003. Applying .NET Framework

to Conditioning Monitoring in Globally Distributed

Environment. In Automaatio2003, Helsinki, 9-11

September. Suomen Automaatioseura ry.

GLOBAL CONDITION MONITORING SYSTEM - Implementing MATLAB® - Based Analysis Services

305