Using Resource-saving Wastewater Treatment Technology in an

Industrial City

Natalia V. Barabash

a

and Valeria N. Orobinskaya

b

Institute of Service, Tourism and Design (Affiliate), North-Caucasus Federal University, Pyatigorsk, Russia

Keywords: Waste Water, Treatment Methods, Coagulation, Coagulant "Bopak-E", Resource Saving.

Abstract: Rapid demographic growth of the population has led to the fact, that the renewable water resources are not

renewable over time. Already, today there is a shortage of fresh water. Methods for purification and resource

saving technology of water is the only alternative directions in coming decades. Therefore, there is a great

need for the development of suitable, inexpensive and fast wastewater treatment and reuse or conservation

methods in this century. Various types of water treatment and recycling methods were discussed in terms of

their fundamentals, applications, costs, maintenance and suitability. In addition, a systematic approach to

water purification and recycling was presented, including their understanding, assessment and selection of

parameters. A quick guide on the selection of appropriate technologies for specific applications was evaluated.

The article discusses not only global issues related to solutions to the problem of water shortage, but also the

results of experimental studies showing the feasibility of using a purification method using coagulants.

1 INTRODUCTION

One of the most important international political

agendas is the conservation of resources, today

conditionally renewable fresh water resources – so in

July 28, 2010 The UN General Assembly has

included the right to water in the list of basic human

rights. The aggravation of global and regional

problems related to freshwater water resources has

led, according to the UN, to the fact that in the 21st

century water is a strategically valuable resource,

gradually displacing oil and gas from the market.

According to the research of Petukhova E.O.

(Petukhova, 2018) “… In many countries of the

world, programs are being developed to ensure water

security, since a ton of clean water in an arid climate

is already more expensive than oil. Today this

problem is relevant in various areas and industries.

Conservation, efficient using (recycling) and

securing of clean freshwater render focus of

sustainable development policies and economic

growth in the countries including the Russian

Federation, as Russian input in Top 5 largest

a

https://orcid.org/0000-0001-5361-1081

b

https://orcid.org/0000-0002-6484-3109

countries in the world by fresh water reserves (Fig.

1).

In terms of fresh water reserves, the Russian

Federation ranks second after Brazil, more than 2.5

million rivers and 2.7 million lakes and freshwater

depots are glaciers (Gupta et al, 2012, Danilov-

Danilyan, 2009, Sazhin et al, 2012).

In order to preserve water resources in the main

drainage areas, it is necessary to solve the following

problems, considered on the example of the North

Caucasian Federal District, the solution of which will

stabilize the economic situation associated with this

region (Gupta et al, 2012, Danilov-Danilyan, 2009,

Sazhin et al, 2012).

Barabash, N. and Orobinskaya, V.

Using Resource-saving Wastewater Treatment Technology in an Industrial City.

DOI: 10.5220/0010586500810088

In Proceedings of the International Scientific and Practical Conference on Sustainable Development of Regional Infrastructure (ISSDRI 2021), pages 81-88

ISBN: 978-989-758-519-7

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

81

Figure 1: Countries of the world rich in fresh water

reserves.

Pollution Pool and Don River sewage led to

shortages of freshwater sources, depletion and

degradation of small rivers.

Kuban River basin - one the of the strategic

objects of water resources in the region, has led to

water use restrictions for the needs of the population,

agricultural organizations and industry.

This situation is a consequence of the presence of

a fairly large number of problems related to water use

in Russia and the North Caucasian Federal District in

particular.

One of the main problems of water use in Russia

is excessive pollution of water bodies. On average,

per year in the Russian Federation, wastewater

discharge into surface water bodies is 54,712 million

m3, of which polluted wastewater is 36%, including

21% without any treatment (Gupta et al, 2012,

Danilov-Danilyan, 2009, Sazhin et al, 2012).

The demand for water is enormous and increases

every year. But, even realizing the importance of the

role of water, a person still continues to toughly

exploit water bodies, irrevocably changing their

natural regime with discharges and waste.

At present, the problem of water pollution is

perhaps the most urgent. And one of the most

important aspects of environmental protection is the

protection from pollution of water resources and

ensuring the needs of the population and the national

economy with clean water.

“… .According to Rosstat, economic growth in

Russia is accompanied by a disproportionate

deterioration in the environmental situation, Fig. 1 . ,

it is noted that in third place, as a pollutant, is energy,

more precisely, “production and distribution of

electricity, gas and water” (21.2%) ... ” (Sazhin et al,

2012).

To reduce the negative impact on the

environment, it is necessary to implement the

necessary environmental protection measures, such

as the treatment of waste, industrial and storm water.

This is possible at sewage treatment plants, where

wastewater used in the process of life is cleaned and

neutralized to such an extent that it does not have a

harmful effect on the environment. But despite all the

measures taken to protect water bodies, treatment of

waste water, which are formed as a result of

household and industrial activities, not always is so

effective event and requires continuous improvement.

Disposal of waste water and neutralization is a

one second of the most important ecological

problems of the present time and in this direction

continuously carried out a wide variety of research,

which are based on physico-chemical or biochemical

degradation processes harmful components of waste

water.

2 MATERIALS AND METHODS

What do we mean by the concept of "waste water"? It

is the water, the former in the domestic, industrial or

agricultural use, as well as passing through any

contaminated areas. Depending on the conditions of

formation, wastewater is divided into domestic or

household fecal, atmospheric (storm) and industrial.

Domestic water formed from Stock s showers,

baths, kitchens, toilets, washing floors and from

others. They contain impurities, of which

approximately contains 58% organic matter and a

42% mineral (Gupta et al, 2012).

Atmospheric waters are formed as a result of

atmospheric precipitation and flowing down from the

territories of enterprises. They are contaminated with

organic and mineral substances. Industrial

wastewaters are liquid wastes which arise during

extraction and processing organic and inorganic

materials. The quantity and quality composition of

industrial wastewater depends on the type of

production.

The WHO committee recommended the

following classification of chemical water pollutants:

1) biologically unstable organic compounds;

2) low toxic e inorganic salts;

3) petroleum products;

4) biogenic compounds;

5) substances with specific toxic properties,

including heavy metals.

There are several ways to reduce the amount of

contaminated wastewater, including such as:

development and implementation of anhydrous

technological processes; improvement of existing

processes; development and implemented equipment;

introduction of air coolers; reuse of treated

wastewater in recirculating and closed systems.

ISSDRI 2021 - International Scientific and Practical Conference on Sustainable Development of Regional Infrastructure

82

The lack of clean natural waters and the high

demand of the industry for water determine the need

to continue work on the further improvement of

treatment systems.

Under these conditions, the development of new

technological solutions that ensure high and stable

quality of wastewater treatment is relevant and in

demand.

The choice of one or another treatment method is

carried out taking into account the sanitary and

technological requirements for treated wastewater for

the purpose of their further discharge into a water

body and use, as well as taking into account the

volume of wastewater and the concentration of

pollution in them, the necessary material and energy

resources, and economic efficiency. process.

The use of physicochemical methods for

wastewater treatment has a number of advantages

over biochemical ones:

1) the ability to remove toxic biochemically non-

oxidizable organic pollutants from wastewater;

2) achieving a deeper and more stable degree of

cleaning;

3) smaller structures;

4) less sensitivity to load changes;

5) the possibility of full automation;

6) a deeper study of the kinetics of some

processes, as well as issues of modeling,

mathematical description and optimization, which is

important for the correct choice and calculation of

equipment;

7) methods are not related to control over the

activity of living organisms;

8) the possibility of recovering various

substances.

Of the most common methods of physicochemical

purification, it is necessary to single out, first of all,

the use of various reagents that cause coagulation of

contaminants, which are indispensable in cases where

it is necessary to remove finely dispersed suspended

substances from wastewater.

What is coagulation? Coagulation is the process

of conglomeration of suspended particles through

interaction and aggregation. Used in clearing

(recycling) of waste water with the aim of

accelerating the precipitation of fine impurities and

emulsified substances under the influence of special

compounds – coagulants, forming flakes of metal

hydroxides, precipitate. Aggregation occurs due to

the difference in charges of colloidal and suspended

particles (weak negative charge) and coagulating

agents (weak positive charge), which leads to

aggregation (Joss et al, 2006).

The process of hydrolysis of coagulants and the

formation of flocs occurs in the following stages:

Me

3+

+ HOH → Me (OH)

2+

+ H

+

Me (OH)

2+

+ HOH → Me (OH)

2

+

+ H

+

Me (OH)

2

+

+ HOH → Me (OH)

3

+ H

+

Me

3+

+ 3 HOH → Me (OH)

3

+ 3 H

+

In reality, the hydrolysis process is much more

complicated. The metal ion forms a number of

intermediates through reactions with hydroxide ions

and polymerization. The formed compounds have a

positive charge and are easily adsorbed by negatively

charged colloidal particles (Bernet et al, 2000,

Rodionov et al, 2000).

As coagulants, salts of aluminum, iron or their

mixtures are usually used. The choice of coagulant

depends on its composition, physicochemical

properties and cost, the concentration of impurities in

the water, on the pH and salt composition of the

water.

As coagulants used aluminum sulfate Al

2

(SO

4

)

3

×18 H

2

O; sodium aluminate NaA1O

2

;

oxyaluminum chloride Al

2

(OH)

5

Cl ; tetraoxo c

ulphates of aluminum-potassium and aluminum-

ammonium [alum - potassium alum KAl (SO

4

)

2

×

12 H

2

O and ammonia NH

4

Al ( SO

4

)

2

× 12 H

2

O ].

Of these, the most widespread is aluminum sulfate,

which is effective in the range of pH = 5-7.5. It is

highly soluble in water and has a relatively low cost.

It is used in dry form or as 50% - of the solution.

Of iron salts, iron sulfates Fe

2

(SO

4

)

3

× 2 H

2

O,

Fe (SO

4

)

3

× 3 H

2

O and FeSO

4

× 7 H

2

O, as well as

ferric chloride FeCl

3,

are used as coagulants . The

greatest clarification occurs when using ferric salts.

Ferric chloride is used in dry form or in the form of

10 - 15% solutions. Sulfates are used in the form of

powders.

The coagulant dose depends on the pH of the

wastewater. Fe

3+

the рН is 6-9, and for Fe

2+

the рН

is 9, pH is 9.5 and higher. For alkalinization of

wastewater, NaOH and Са(ОН)

2

. Water treatment

with coagulants is the most common method for

purifying large volumes of water from coarsely

dispersed and colloidal contaminants. The use of

the coagulation method has increased in recent

years, and this trend continues. In this regard, the

assortment of coagulants and related reagents,

offered for the purification of natural waters in

order to improve the quality of treated water, is

rapidly growing. In currently increasingly

widespread coagulants are highly BASIC spine-oxy

chlorides of aluminum, which until recently only

been used in water purification obtained for

drinking purposes.

Using Resource-saving Wastewater Treatment Technology in an Industrial City

83

Recently, the variety of impurities in wastewater

has increased significantly with significant

fluctuations in their composition and color. This

requires a lot of effort in wastewater treatment, for

which aluminum sulphate is traditionally used, which

no longer always meets the requirements.

To provide a comprehensive solution to these

problems, we propose to use a coagulant - aluminum

oxy chloride (polyaluminium- hydrochloride) of the

highest quality category with a basicity index of

"5/6", which received 1st place in the international

competition for coagulants.

Development of production and application of

technology oxy chloride and aluminum "BOPAK" to

purify water in the cities of Russia took place in the

framework of inter-regional environmental programs.

Production hydroxy chloride and aluminum for

organizations - water channels carried in Azov,

Rostov region and Ekaterinburg on TU 216350-002-

39928758-02.

Coagulant " Bopak-E " is a low-hazard compound

of the 3rd hazard class, the limiting hazard indicator

is sanitary-toxicological, maximum concentration

limit is 0.5 mg / l (for aluminum).

Guaranteed quality indicators water treatment

technical and economic advantages of using oxy

chloride Aluminum:

ꞏ Causes highly effective coagulation of colloidal-

dispersed particles and organic substances from

water, as a result of which a rapidly precipitating and

well-filtered flock is formed;

Decrease in the content of organochlorine

compounds;

Ensuring the content of residual aluminum is less

than 0.2 mg / l;

Consumption of the reagent in the range of 0.3 -

3.0 mg Al / liter of water;

Stability of the coagulation process, including at

low water temperatures;

When introduced into water, it practically does

not reduce the alkalinity and pH of the treated water,

as in comparison with traditionally used coagulants,

which contributes to: a decrease in the rate of

corrosion of metals in water supply and heat supply

systems, by eliminating the formation of aggressive

carbon dioxide and the possibility of refusing to use

alkaline agents;

In comparison with traditional coagulants, it

reduces the amount of anions introduced into the

water by 10 times;

Easy-to-use and stored solution, which is easily

diluted to the required degree before dosing;

Transition to a new reagent in the conditions of

operating stations, as a rule, does not require

reconstruction of the existing reagent facilities,

greatly facilitates the work of the service personnel;

Approved for use in drinking and hot water supply

systems.

Application hydroxy chloride and aluminum has

many advantages, directly affecting the economics of

its use (including and in comparison with a

conventional aluminum sulphate):

being a partially hydrolyzed salt, aluminum

oxy chloride has a greater ability to polymerize,

which accelerates flocculation and

precipitation of coagulated suspension;

work confirmed hydroxyl chloride and

aluminum in a wider pH range as compared

with aluminum sulfate, which leads to a

complete hydrolysis and, consequently, reduce

the concentration of residual aluminum in the

drinking water;

reducing alkalinity when coagulating oxy

chloride ohm aluminum is substantially smaller

that, along with the absence of the addition of

sulphate results in a reduction of corrosion of

water activity, exclusion stabilization

treatment, to improve water pipelines status

urban distribution network and preserve

consumer properties of water during

transportation and also allows to completely

abandon from the use of alkaline agents and

leads to savings of those at the middle station

up to 20 tons per month;

low residual aluminum content at high doses

administered;

reduction of the working dose of the coagulant

by 1.5 - 2.0 times in comparison with

aluminum sulfate;

delivery in a ready-made working solution,

which makes it possible to abandon the process

of dissolving the coagulant, leading to energy

savings for stirring at the middle station up to

100 thousand kW / h annually;

during the transition to oxy chloride, aluminum

does not require changes in the technology of

the station with the drinking water;

reduction of labor intensity and operating costs

for storage, preparation and dosing of the

reagent, improvement of sanitary and hygienic

working conditions.

Inorganic cationic polymer coagulant " Bopak-E

" has the ability to form complex compounds with a

wide range of organic and inorganic substances in

water.

It fundamentally differs from ordinary aluminum

salts in that it has a so-called surface acidic shell,

ISSDRI 2021 - International Scientific and Practical Conference on Sustainable Development of Regional Infrastructure

84

which ensures the highest possible efficiency of water

purification from suspended solids and metals.

According to sanitary characteristics, it

corresponds to the quality required for food products

and is made from pure hydrochloric acid and metallic

aluminum.

The technical characteristics of the coagulant are

shown in Table 1.

Table 1: Specifications hydroxy chloride and aluminum.

Formula is the

product

Al

2

( OH )

5

CI , aqueous

solution

basicity

5/6

mass fraction of

aluminu

m

(10 ± 1)%

mass fraction of

Al

2

O

3

(17.0 - 20.8)%

mass fraction of

chlorides

(6.2 ± 0.5)%

specific gravity (1.27 ± 0.03) kg / dm

3

pH

4.5 ± 0.5

viscosity 30 ± 10 cps

freezing point

minus 18

о

С , after defrosting

does not lose coagulation

p

ro

p

erties

Application area:

in drinking water treatment systems;

treatment of municipal, industrial waste water;

preparation of water for technical needs, for

heat power engineering.

in perfumery, pulp and paper, leather industry

(Chong et al, 2010, Zapolsky, Baran, 1987).

Oxychloride, aluminum " Bopak -E" can deliver

any chemically resistant containers: cans, barrels,

containers, tanks and other containers.

The coagulation rate depends on the concentration

of the electrolyte. At low electrolyte concentrations,

the efficiency of particle collisions, that is, the ratio

of the number of collisions that ended in adhesion to

the total number of collisions, is close to zero. As the

concentration increases, the rate of coagulation

increases, but not all collisions are effective; such

coagulation is called slow. Further, rapid coagulation

occurs, in which all collisions of particles end in the

formation of aggregates.

In polydisperse systems, coagulation occurs faster

than in monodisperse systems, since coarse particles,

when settling, entrain smaller ones. Particle shape

also affects the rate of coagulation. For example,

elongated particles coagulate faster than spherical

ones.

The size of the flakes (in the range of 0.5-3 mm)

is determined by the ratio between the molecular

forces holding the particles together and the

hydrodynamic forces of detachment, which tend to

destroy the aggregates.

The strength of the flakes depends on the particle

size distribution of the resulting particles and

plasticity. Agglomerates of particles that are

inhomogeneous in size are stronger than

homogeneous ones. Due to the release of gases from

the water, as well as a result of aeration and flotation,

gas saturation of the flocs occurs, which is

accompanied by a decrease in the density of the flocs

and a decrease in the sedimentation rate.

The process of wastewater treatment by

coagulation consists of the following stages: dosing

and mixing of reagents with wastewater; flocculation

and sedimentation.

Various mixers are used to mix coagulants with

water. In hydraulic mixers, mixing occurs due to

changes in the direction of movement and the speed

of water flow. In mechanical mixers - devices with a

stirrer, the stirring process should be uniform and

slow so that the particles, when approaching, form

flakes that would not collapse when the mixer rotates.

After mixing the waste water with the reagents,

the water is sent to the flocculation chambers.

Cloisonne, vortex, and mechanical-agitated chambers

are used. The formation of flakes in the chambers

proceeds slowly - within 10-30 minutes. They are

reservoirs, divided by partitions into a series of

corridors, in succession, passable by water, in which

the coagulant is mixed with waste water. The speed

of the water in the corridors is 0.2-0.3 m / s.

The settling of flakes occurs in sedimentation

tanks and clarifiers. Hour then mixing step of

coagulation and precipitation carried out in a single

apparatus. Coagulant flakes are formed in the annular

zone. Suspended particles with flakes settle to the

bottom and are removed from the apparatus. Clarified

water through the hole enters the tray, from where it

is sent for further purification (Babenkov, 1983.

Danilov-Danilyan, Bolgov, 2009, Sazhin et al, 2012)

The optimal dose of the mouth of the reagent - the

time here to probe based coagulation laboratory

Company, successively changing the dose of

coagulant. At the same time, the properties of its

macromolecules and the nature of dispersed particles

are considered.

Using Resource-saving Wastewater Treatment Technology in an Industrial City

85

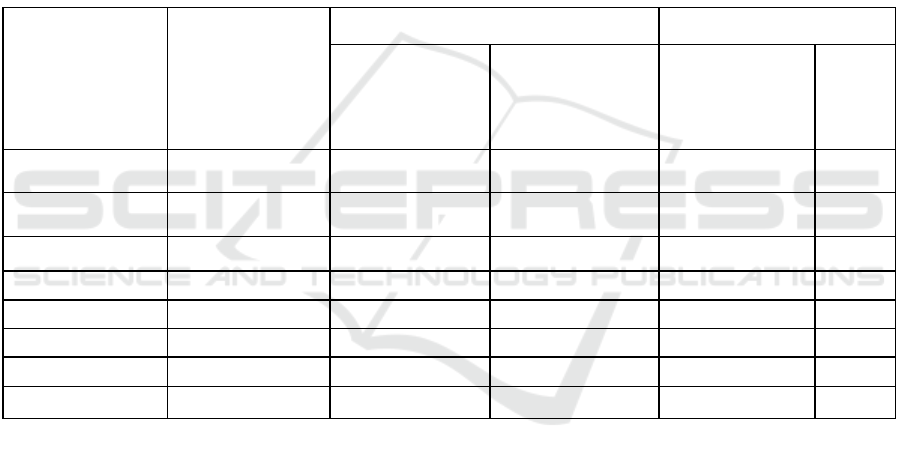

3 RESULTS AND DISCUSSSIONS

Taking into account the composition and properties

of wastewater entering the Lermontov wastewater

treatment plant, we proposed to use as a trial

coagulant aluminum oxychloride with a

concentration of 2 mg / l instead of aluminum sulfate

determined by the technological regulations with an

optimal dose of 20 mg / l. The results of water analyze

before and after vertical sedimentation tanks using

aluminum oxychloride are shown in Table 2.

The complex of treatment facilities in the city of

Lermontov consists of two technological lines with a

capacity of 25 thousand m3 / day.

Wastewater from the municipal and industrial

sewage system is pumped from the sewage pumping

station to the receiving chamber of the treatment

plant. The receiving chamber with the help of surface

shield gates directs part to the first stage of treatment

facilities, and the remaining part to physical and

chemical treatment facilities.

The first technological line is designed for

wastewater treatment in the amount of 10 thousand m

3 / day. The operation of this line is based on the

method of biological wastewater treatment. The

second technological line is designed to receive and

purify 15 thousand m 3 / day of waste water. The

operation of this line is based on the method of

physical and chemical cleaning. It is on this

technological line that the coagulation process is

used.

Table 2: The results of analyzes of the use of coagulant about aluminium oxychloride in vertical settling tanks.

The substance to be

determined

Incoming for

cleaning, mg / l

After settling tank, mg / l Cleaning effect

Using Al

2

(OH)

5

CI

Without using Al

2

(OH)

5

CI

Using Al

2

(OH)

5

CI

Without

using

Al

2

(OH)

5

CI

Suspended

substances

158.6 3.97 14.9 97.5 90.6

Ammonia nitrogen 30.4 21.1 24.7 30.7 18.75

Nitrite 0.57 0.34 0.36 40.4 36.8

Phosphates 8.2 3.5 7.8 56.7 4.9

Aluminum 0.022 0.0134 0.0154 39.0 30.0

BOD

5

178.89 60.3 75.7 66.2 57.6

Copper 0.052 0.019 0.021 64.0 59.6

Fluoride 0.45 0.31 0.36 31.1 20.0

It can be seen from the results obtained that the

use of aluminum oxychloride as a coagulant makes it

possible to obtain a higher cleaning effect in terms of

such indicators as suspended solids, ammonium

nitrogen, nitrites, phosphates, aluminum, BOD 5 ,

copper and fluorides.

Wastewater, after being cleaned on two

technological lines, goes to the post-treatment

section, where it is additionally processed on sand

filters and disinfected in tanks by chlorination.

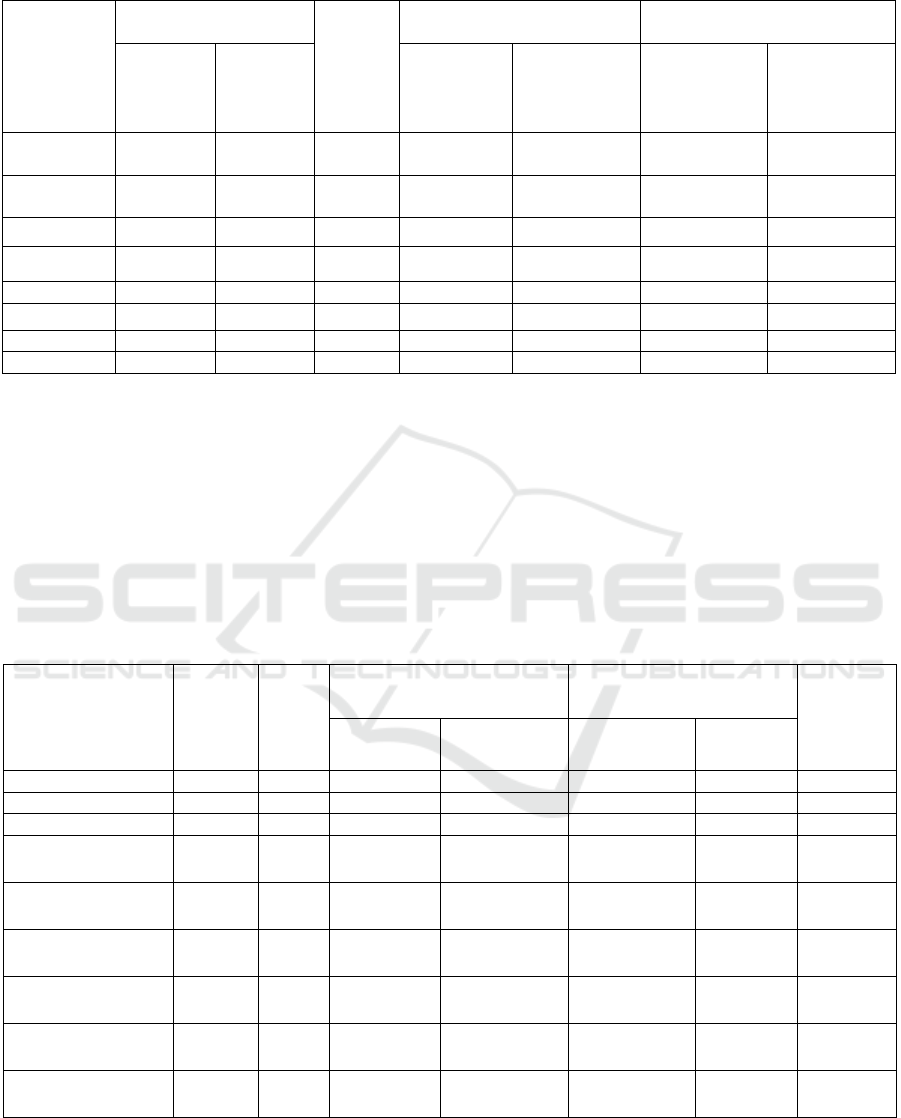

Comparative results of complete wastewater

treatment at the wastewater treatment plant in the city

of Lermontov are shown in Table 3.

ISSDRI 2021 - International Scientific and Practical Conference on Sustainable Development of Regional Infrastructure

86

Table 3: Wastewater analysis results.

Substance to

be

determined

After PCH, mg / l

After

biologic

al

treatme

nt, mg /

l

After cleaning, mg / l Cleaning effect,%

Using

Al

2

( OH

)

5

CI

Without

using

Al

2

( OH

)

5

CI

Using

Al

2

( OH )

5

CI

Without

using

Al

2

( OH )

5

CI

Using

Al

2

( OH )

5

CI

Without

using

Al

2

( OH )

5

CI

Suspended

substances

3.97 14.9 53.53 2.7 4.2 92.1 87.71

Ammonia

nitrogen

21.1 24.7 6.4 1.58 2.5 89.87 83.97

Nitrite 0.34 0.36 0.279 0.11 0.13 65.62 59.37

Phosphates 3.5 7.8 2.37 0.061 0.27 98.91 95.17

Aluminu

m

0.0134 0.0154 0.0176 0.003 0.005 75.75 69.69

BOD

5

60.3 75.7 24.5 1.25 3.28 97.5 93.45

Co

pp

e

r

0.019 0.021 0.0312 0.003 0.004 88.46 84.61

Fluoride 0.31 0.36 0.44 0.19 0.22 52.5 45.0

4 CONCLUSION

The use of a new technological solution will

significantly reduce the content of pollutants in the

discharged wastewater into the receiving water within

the limits of the MPD, which will significantly reduce

the amount of payments for pollution of the Gorkaya

River and, thereby, improve the financial

performance of the enterprise. An approximate

calculation of the prevented annual economic damage

is shown in Table 4.

Table 4: Ecological characteristics of discharges before and after the implementation of environmental protection measures

and the prevented annual economic damage.

Pollutant name

MPC

i

p/x,

mg/l

А

i

Reduced discharge mass

(М

i

), t/year

Specific annual damage

(D

i

)

Averted

economic

annual

damage

(D)

Before events After the events Before events

After the

events

Sus

p

ende

d

substances 3,20 0,31 4,657 2,9938 268062,26 172326,55 95735,71

Ammonia nitro

g

en 0,500 2,0 18,384 11,303 1058204,27 650613,72 407590,55

Nitrite 0,080 12,5 5,8123 4,9181 334562,71 283091,51 51471,2

Phosphates 0,020 5 4,82868 1,145824 277944,40 65954,94

211989,4

6

Aluminum 0,005 200 3,5768 2,14608 205884,74

123530,8

2

82353,92

BOD

5

3,00 0,33 3,8715 1,4754 261885,46 84925,71

176959,7

5

Copper 0,001 1000 14,3072 10,7304 1386270,94

617654,1

9

768616,7

5

Fluoride 0,180 5,55 4,36727 3,77173 251385,10

217105,1

1

34279,99

Total output - - 59,80475 38,484334 4044199,88

2215202,

55

1828997,

33

Thus, the use of coagulant aluminium oxychloride

in urban wastewater treatment plants instead of

traditional aluminum sulfate will allow achieving a

higher degree of wastewater treatment and reducing

the negative impact on the environment.

Using Resource-saving Wastewater Treatment Technology in an Industrial City

87

REFERENCES

Gupta, V.K., Ali, I., Saleh, T.A., Nayak, A. and Agarwal,

S. (2012). Chemical treatment technologies for waste-

water recycling - an overview. RSCAdv, 2: 6380-6388.

Petukhova, E.O. (2018). Causes of shortage of fresh water.

Innovative methods and projects for obtaining drinking

water. Bulletin of PNRPU. Construction and

architecture, 9(3): 141-151

Joss, A., Zabczynski, S., Göbel, A., Hoffmann, B., Löffler,

D., McArdell, C.S., Ternes, T.A. and Siegrist, H.

(2006). Water Res. 40: 1686-1696.

Talarposhti, A.M., Donnelly T., Anderson, G.K. (2001).

Water Res., 35: 425-432.

Bernet, N., Delgenes, N., Akunna, J.C., Delgenes, J.P.,

Moletta, R. (2000). Water Res., 34: 611-619.

Rodionov, A.I., Klushin, V.N., Sister, V.G. (2000).

Technological processes of ecological safety.

Publishing house "N. Bochkarevoy", Kaluga, 792 p.

Chong, M.N., Jin, B., Chow, C.W.K., Saint, C. (2010).

Water Res., 44: 2997–3027.

Zapolsky, A.K. and Baran, A.A. (1987). Coagulants and

flocculants in water purification processes. Properties.

Receiving. Application.-L.: Chemistry. 208 p.

Babenkov, E.D. (1983). Water is purified by coagulants.

Moscow: Znanie, 64 p.

Danilov-Danilyan V.I. (2009). Water resources of the

world and prospects of the water management complex

of Russia. OOO "Typography LEVKO", Institute for

Sustainable Development, Center for Environmental

Policy of Russia.

Danilov-Danilyan V.I. and Bolgov M.V. (2009). On the

water strategy of the Russian Federation for the period

up to 2020. Water problems of large river basins and

ways to solve them. Collection of scientific papers.

Barnaul: LLC "Agency of advertising technologies",

pages 59-81.

Sazhin, V.B., Seldinas, I., Kochetov, O.S., Kochetov, L.M.,

Belousov, A.S., Sazhina, M.B. and Dmitrieva, L.B.

(2008). Problems of rational use of water resources in

Russia. Advances in chemistry and chemical

technology. XXII 11 (91): 56-70.

ISSDRI 2021 - International Scientific and Practical Conference on Sustainable Development of Regional Infrastructure

88