Evaluating the Use of the Open Trip Model for Process Mining:

An Informal Conceptual Mapping Study in Logistics

Jean Paul Sebastian Piest

a

, Jennifer Alice Cutinha

b

, Rob Henk Bemthuis

c

and Faiza Allah Bukhsh

d

University of Twente, Drienerlolaan 5, 7522 NB, Enschede, The Netherlands

Keywords:

Open Trip Model, Process Mining, Logistics, Event Data.

Abstract:

When aggregating logistic event data from different supply chain actors and information systems for process

mining, interoperability, data loss, and data quality are common challenges. This position paper proposes and

evaluates the use of the Open Trip Model (OTM) for process mining. Inspired by the current industrial use

of the OTM for reporting and business intelligence, we believe that the data model of OTM can be utilized

for unified storage, integration, interoperability, and querying of logistic event data. Therefore, the OTM data

model is mapped to a generic event log structure to satisfy the minimum requirements for process mining.

A demonstrative scenario is used to show how event data can be extracted from the OTM’s default scenario

dataset to create an event log as the starting point for process mining. Thus, this approach provides a foundation

for future research about interoperability challenges and unifying process mining models based on industry

standards, and a starting point for developing process mining applications in the logistics industry.

1 INTRODUCTION

The logistics sector can be referred to as a network

where multiple organizations come together for the

planning, organization, coordination, and execution

of transportation of goods and logistics services. Typ-

ically, a logistic process involves multiple parties

(e.g., shippers, logistics service providers, transport

operators, or carriers), different entities within an or-

ganization, and is spread across different countries.

As a result, logistic processes are exceedingly com-

plex and dynamic, and data usually comes from het-

erogeneous data sources in various (un)structured for-

mats (Intayoad and Becker, 2018).

Shipment data are commonly administered in

multiple information systems (e.g., ERP, WMS, TMS,

and FMS) (Evofenedex, TLN, and Beurtvaartadres,

2019). As a result of business transactions, the status

of shipments and whereabouts of goods are tracked

and traced during the physical handling processes.

Data are exchanged in different formats (e.g., e-mail

and EDI) and supported by industry standards and in-

a

https://orcid.org/0000-0002-0995-6813

b

https://orcid.org/0000-0003-4706-2228

c

https://orcid.org/0000-0003-2791-6070

d

https://orcid.org/0000-0001-5978-2754

teroperability models (Evofenedex, TLN, and Beurt-

vaartadres, 2019).

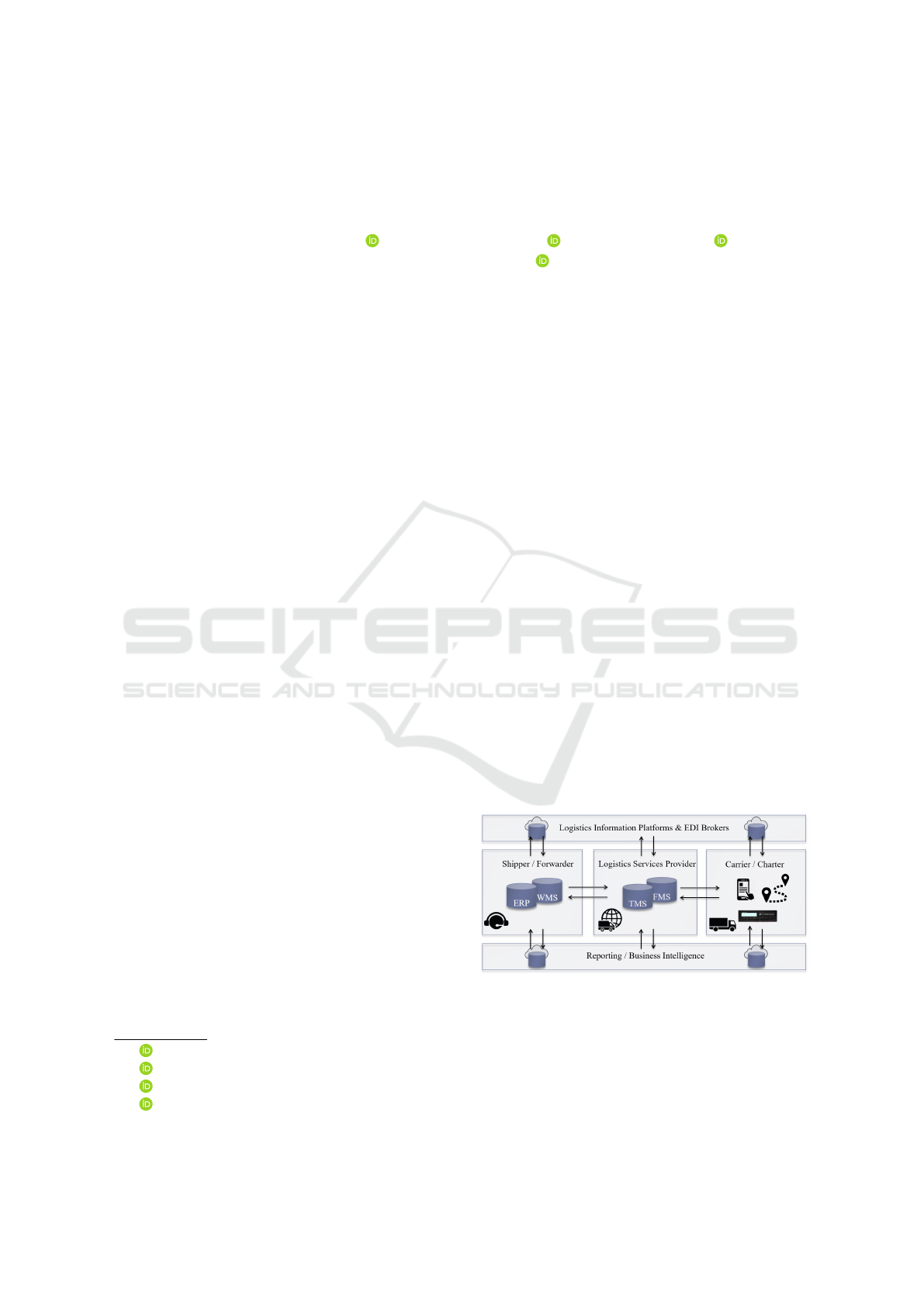

The Open Trip Model (OTM) is such a data ex-

change standard and adopted by the Dutch logistics

industry as part of a federated data sharing infras-

tructure (Bastiaansen et al., 2020). Figure 1 depicts

the default OTM scenario for data exchange and data

sharing between involved stakeholders and their in-

formation systems.

Figure 1: Interaction of multiple logistic parties (adapted

from OTM presentation).

In the industry, the OTM data model is also used for

reporting and business intelligence, as illustrated in

Figure 1, however, to our best knowledge, not for

process mining. Process mining focuses on extract-

ing knowledge from data generated and stored in the

290

Piest, J., Cutinha, J., Bemthuis, R. and Bukhsh, F.

Evaluating the Use of the Open Trip Model for Process Mining: An Informal Conceptual Mapping Study in Logistics.

DOI: 10.5220/0010477702900296

In Proceedings of the 23rd International Conference on Enterprise Information Systems (ICEIS 2021) - Volume 1, pages 290-296

ISBN: 978-989-758-509-8

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

databases of information systems in the form of event

logs (Van der Aalst et al., 2012). Logistic processes

generate large amounts of event data. Event data are

expected to be a rich source for behavior analysis as

it comprises data concerning the dynamic behavior of

people, objects, and systems at a detailed level. Pro-

cess mining techniques can be helpful to produce in-

sightful information based on logistic event data.

When event data are aggregated from different

systems for process mining, interoperability, data

loss, and data quality issues are common challenges.

Existing approaches aim to increase the accuracy of

process mining techniques despite noisy data. Con-

sequently, various tools and algorithms have been

built in process mining tools to eliminate the effect

of noisy data and determine the actual control-flow

of a process. However, as logistic event data are typi-

cally complex, dynamic, and heterogenous, it remains

challenging to generalize their results (Intayoad and

Becker, 2018). More precisely, much of the current

literature pays little attention to unified standards of

logistic process definitions. The OTM provides such a

standard for sharing logistic data. We believe that the

usage of the OTM, in addition to addressing (some)

interoperability issues, can provide a promising foun-

dation for a more unified implementation of process

mining practices in the logistics domain and its het-

erogeneous environment.

This paper aims to evaluate the use of the OTM

for process mining. An informal conceptual mapping

study is conducted to determine whether the basic re-

quirements for process mining can be fulfilled. More

specifically, the data model of the OTM is mapped

to a generic event log structure. Based on a step-by-

step walkthrough, we demonstrate how the OTM data

model can be used to extract event data and create an

event log. The event data are imported in the pro-

cess mining tool Disco to generate a process model.

This way, we provide researchers a common ground

for solving interoperability issues related to process

mining in heterogeneous environments using industry

standards, including OTM, and practitioners a ded-

icated, potentially generalizable, process model and

approach to develop process mining applications.

The remainder of this paper proceeds as follows.

Section 2 discusses related work. Section 3 positions

the use OTM for process mining. Section 4 discusses

preliminary results. Section 5 concludes and provides

an outlook for future research.

2 RELATED WORK

The practice of process mining has gained attention in

many domains, such as healthcare (Mans et al., 2012;

Erdogan and Tarhan, 2018), education (Bogarín et al.,

2018), finance (De Weerdt et al., 2013), logistic, and

supply chain processes.

2.1 Process Mining in Logistics

There are several studies available on process mining

in the logistics domain.

A systematic mapping study (dos Santos Garcia

et al., 2019) illustrates that less than 5% of their pa-

per sample is about the logistics domain. This map-

ping study identified 27 studies with a focus on lo-

gistic processes, including transportation, storage of

goods, and stock management. Most of the studies

focus on process discovery in the logistical context.

Specific studies study process mining in regard to net-

work analysis, resource configuration, prediction of

event times, and remodeling of business processes.

These studies indicate a rich spectrum of use cases.

Additional studies examined logistic processes

through process mining, mainly focusing on the inter-

nal logistics of case-specific scenarios (Knoll et al.,

2019a; Knoll et al., 2019b). Others developed a pro-

cess mining system for determining the root causes

of quality problems in a supply chain (Lau et al.,

2009). Based on daily captured logistic data, the au-

thors fine-tuned configuration parameters to improve

operational performance.

2.2 Interoperability Challenges

There are relevant studies in the logistics domain that

address the interoperability challenges using process

mining techniques and the need for standardization.

On a high abstraction level, the interoperability is-

sues are addressed in the four levels of big data in-

teroperability (Singh and van Sinderen, 2016). More

specifically, the study of (Lont et al., 2018) shows

how different systems and devices can be linked to

the data model of OTM, eliminating certain interop-

erability issues.

Some studies emphasize the complexity of mon-

itoring logistic processes (Cabanillas et al., 2013;

Wang et al., 2014). The authors pinpoint the im-

portance of new research, novel contributions on dis-

cretizing, aggregating, and correlating events in a way

that the overall business process can be better traced.

This work indicates that further research should be

done on improving the quality of the event log data

by including a reconciliation of the data.

Evaluating the Use of the Open Trip Model for Process Mining: An Informal Conceptual Mapping Study in Logistics

291

3 INFORMAL CONCEPTUAL

MAPPING OF OTM FOR

PROCESS MINING

3.1 Aim and Data Model of OTM

The OTM is an open-source, flexible data sharing

model that contributes to uniform and consistent ex-

change of information across various information sys-

tems. This model is managed by the Stichting Uni-

forme Transport Code (SUTC) and its goal is to help

logistics companies in the Netherlands share real-time

logistic data efficiently (Stichting Uniforme Transport

Code (SUTC), 2019).

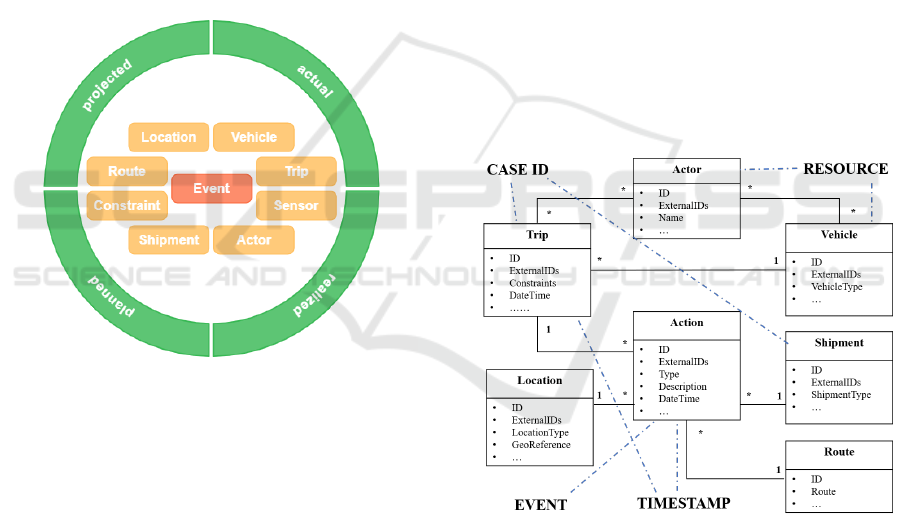

The constructed data model of the OTM, as shown

in Figure 2, is centered around event data and consid-

ers eight entities and four lifecycles.

Figure 2: OTM data model (Open Trip Model, 2020).

Entities are used to represent various objects within a

logistic process, e.g., vehicles. All dynamic behavior

of actors is modeled as (a series of) event(s) and are

related to shipments, trips, and routes. The order of

these events indicates the workflow over time, and this

is depicted by the lifecycle. This way, a trail of event

data is created. The lifecycle expresses the different

phases in the transport process and enables different

views on the operation (e.g., look ahead at events that

have been planned, what is taking place right now

or look back at what has been realized). Event data,

together with related entities and the lifecycles, pro-

vide the foundation to develop process mining appli-

cations, behavioral analysis, and performance man-

agement.

3.2 Using OTM for Process Mining

In addition to data exchange, the data model of the

OTM can be used for storage, integration, and query-

ing of logistic event data originating from multiple in-

formation systems as the foundation for process min-

ing use cases relevant to various stakeholders in the

logistics industry. The event log should contain four

data elements to fulfill the minimal requirements for

process mining, namely, the case id, which represents

the process instance, the names of the events or activ-

ities in the process, the timestamps of the events, and

the resource that conducted the activity (Van der Aalst

et al., 2012).

3.3 Evaluating and Demonstrating the

Use of OTM for Process Mining

The OTM walkthrough scenario and example data de-

scribed on the website (Open Trip Model, 2020) are

used to evaluate the use of the OTM for process min-

ing. Figure 3 shows how version 4.2 of the data model

of the OTM can be mapped to satisfy the minimum

process mining requirements.

Figure 3: Adapted OTM data model version 4.2 linked to

the minimum process mining requirements.

In the following part, we will walk through an op-

erational logistics scenario and discuss how this sce-

nario can be expressed in OTM entities and events,

and eventually used for process mining.

3.3.1 Describe the Scenario

The example scenario is related to the logistics oper-

ation of a supermarket chain that contracts transport

companies to transport goods from their warehouse

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

292

to the stores. Only a limited part of the operations is

discussed here, as that will be enough to highlight the

most important concepts of OTM.

The OTM scenario (Open Trip Model, 2020) starts

with the planning department of the supermarket

chain, sending the following instructions to a con-

tracted transport company:

“I have a transportation request, requiring a

diesel-powered boxtruck to transport refrigerated

goods from “warehouse A”, dock 14 (start loading

at 6:15 AM, 30 minutes loading time) to two stores:

“store B”, where there is 30 minutes unloading time

and “store C”. From store C some goods must be re-

turned to “terminal D" at the warehouse location. At

store C there’s also 30 minutes for loading and un-

loading. According to our route planner, you should

be able to go from A to B, B to C and C to D in a

given time and by driving no more than the given dis-

tance. The set access routes to the stores are taken

into account.”

3.3.2 Identify and Map Entities

We can identify the following OTM entities in this

text: vehicle, shipment, location, route, and trip. The

scenario contains a refrigerated boxtruck, which can

be mapped to the vehicle entity as follows:

Vehicle:

id: 1

type: refrigerated boxtruck

fueltype: diesel

The scenario informally describes three types of

goods that need to be transported and can be mapped

to the shipment entity as follows:

Shipment:

id: 1

contents: refrigerated goods

from: location A

to: location B

Shipment:

id: 2

contents: refrigerated goods

from: location A

to: location C

Shipment:

id: 3

contents: returned goods

from: location C

to: location D

The shipments are transported to four locations and

can be mapped to the location entity as follows:

Location:

id: A

name: warehouse A, dock 14

Location:

id: B

name: store B, loading bay

Location:

id: C

name: store C, loading bay

Location:

id: D

name: returned goods, terminal D

The route and trip are informally formulated and con-

sidered identical in this scenario. Event data typically

originates from multiple actors and systems.

3.3.3 Identification of Events

Based on the identification and mapping of entities

from the text, the following events can be identified:

Planned event on Trip 1:

start loading 6:15 AM

Planned event on Vehicle 1:

load Shipment 2

Planned event on Vehicle 1:

load Shipment 1

Planned event on Trip 1:

stop loading 6:45 AM

Planned event on Trip 1:

start driving from A 6:45 AM

Planned event on Trip 1:

stop driving at B 7:45 AM

Planned event on Trip 2:

start loading/unloading 7:45 AM

Planned event on Vehicle 1:

unload Shipment 1

Planned event on Trip 2:

stop loading/unloading 8:15 AM

Planned event on Trip 2:

start driving from B 8:15 AM

Planned event on Trip 2:

stop driving at C 9:15 AM

Planned event on Trip 3:

start loading/unloading 9:15 AM

Planned event on Vehicle 1:

unload Shipment 2

Planned event on Vehicle 1:

load Shipment 3

Planned event on Trip 3:

stop loading/unloading 9:45 AM

Planned event on Trip 3:

start driving from C 9:45 AM

Planned event on Trip 3:

stop driving at D 10:45 AM

Planned event on Trip 3:

start loading/unloading 10:45 AM

Planned event on Vehicle 1:

unload Shipment 3

Planned event on Trip 3:

stop loading/unloading 11:05 AM

3.3.4 Extract the Event Data

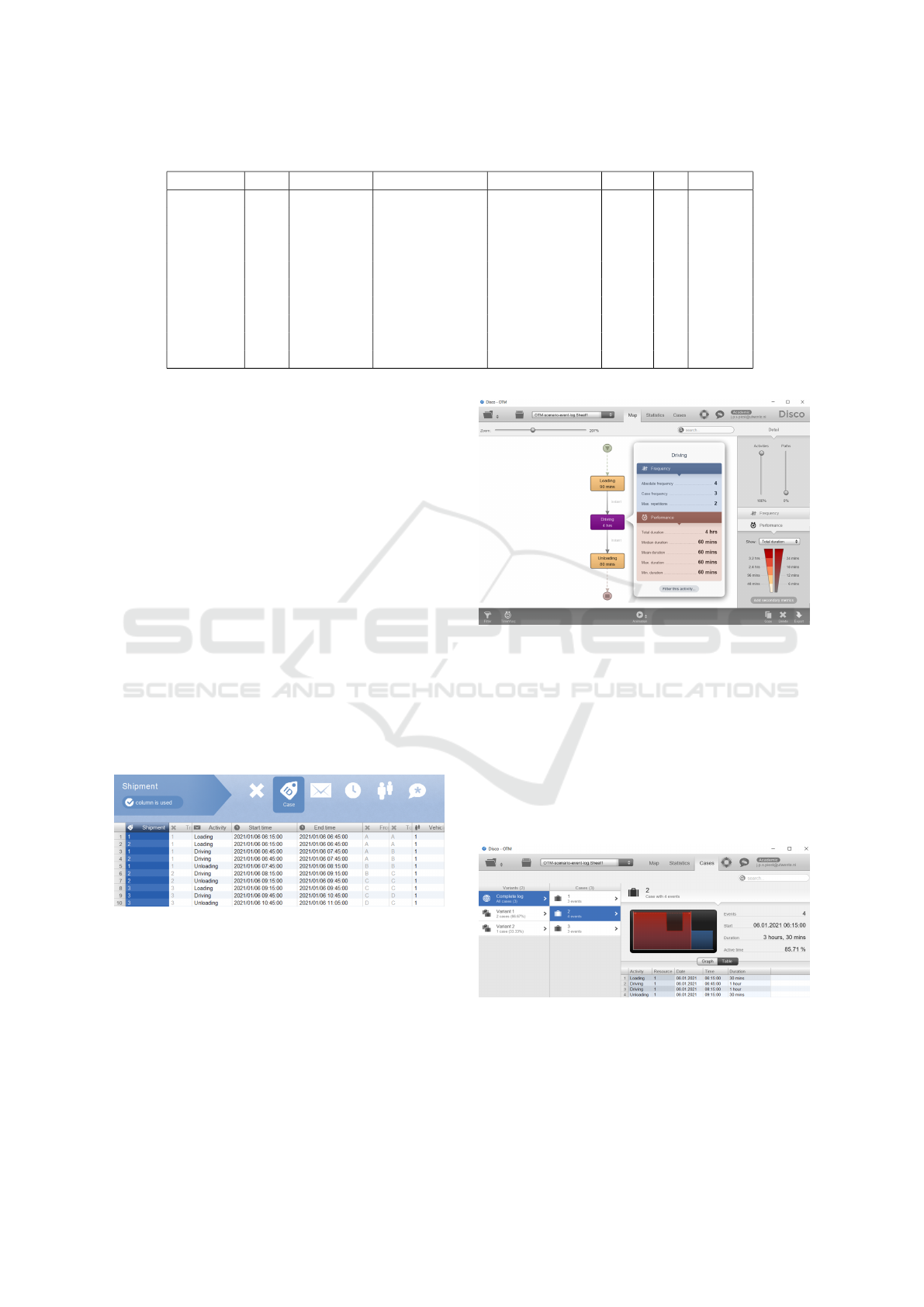

Based on the identified entities and events, event data

are created based on the scenario. Table 1 presents

Evaluating the Use of the Open Trip Model for Process Mining: An Informal Conceptual Mapping Study in Logistics

293

Table 1: Event Log Created based on the OTM Walkthrough and Example Data.

Shipment Trip Activity Start time End time From To Vehicle

1 1 Loading 6-1-2021 06:15 6-1-2021 06:45 A A 1

2 1 Loading 6-1-2021 06:15 6-1-2021 06:45 A A 1

1 1 Driving 6-1-2021 06:45 6-1-2021 07:45 A B 1

2 1 Driving 6-1-2021 06:45 6-1-2021 07:45 A B 1

1 1 Unloading 6-1-2021 07:45 6-1-2021 08:15 B B 1

2 2 Driving 6-1-2021 08:15 6-1-2021 09:15 B C 1

2 2 Unloading 6-1-2021 09:15 6-1-2021 09:45 C C 1

3 3 Loading 6-1-2021 09:15 6-1-2021 09:45 C C 1

3 3 Driving 6-1-2021 09:45 6-1-2021 10:45 C D 1

3 3 Unloading 6-1-2021 10:45 6-1-2021 11:05 D C 1

the test dataset. The dataset contains three shipments,

three trips to visit three locations, three types of activ-

ities, planned start and end times, three locations, and

an assigned vehicle.

3.3.5 Create the Event Log

We used the process mining tool Disco (developed by

Fluxicon) to import the event data using the following

script:

Import column mapping:

‘Shipment’ → Case ID

‘Activity’ → Activity

‘Start time’ → Timestamp

(Pattern: ‘yyyy/MM/dd HH:mm:ss’)

‘End time’ → Timestamp

(Pattern: ‘yyyy/MM/dd HH:mm:ss’)

‘Vehicle’ → Resource

Based on the import script, the event log can be cre-

ated in Disco. Figure 4 shows how the minimal re-

quirements for process mining are fulfilled.

Figure 4: Screenshot of the event log created in Disco.

3.3.6 Generate the Process Model

Based on the event log, the process model can be gen-

erated. Figure 5 depicts the generated process model,

including some basic model statistics (e.g., frequen-

cies, repetitions) and performance indicators (e.g., du-

ration).

Using process mining techniques, the event data

are split up into three cases and two variants, as shown

in Figure 6, which can be analyzed for patterns. When

Figure 5: Screenshot of the process model, statistics, and

performance in Disco.

the actual process is executed, the planned lead times

could be used as a norm for performance monitoring

based on the OTM data model. The lifecycles might

be used to detect deviations and compliance check-

ing (e.g., using rules and regulations regarding driving

and rest times). In addition, the lifecycles could po-

tentially be used for simulations, optimizations, pre-

dictions, and model enhancements.

Figure 6: Screenshot of the detailed view with cases and

variants in Disco.

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

294

4 DISCUSSION

Current literature indicates a rich spectrum of process

mining use cases in logistics. The absence of unified

process definitions or standardized process models

makes it hard to generalize their results. Furthermore,

the aggregation of event data in logistics has proven

difficult due to the complex and heterogeneous nature

of logistics. Interoperability issues are addressed in

several studies. However, established approaches and

tools focus on working with noisy data.

The ideas put forward in this position paper are

based on a different approach, and propose the use

of OTM for process mining, addressing the interoper-

ability challenges and develop applications based on a

dedicated but generalizable process model. Although

this position paper contains promising preliminary re-

sults and demonstrates how the basic requirements for

process mining can be fulfilled, the support is limited.

The conducted informal conceptual mapping study in

logistics requires further experimental research and

comparative studies.

This position paper describes and traces the use of

OTM for process mining through an example, map-

ping OTM to the requirements for process mining and

demonstrating its use. Nevertheless, it is likely that

even if OTM is widely adopted that handling data in-

tegration and extraction challenges for other systems

would still need to be addressed.

Besides that, the work is still in an initial stage and

the approach should be tested in industry to determine

how it helps decision-makers in the process of con-

ducting process mining analysis. Additional exam-

ples and more complex use of the proposed approach

should be explored, considering the relevant concerns

and issues of the decision-makers in the logistic pro-

cesses. More precisely, to verify whether OTM has

the potential to be considered.

5 CONCLUSIONS

Inspired by the current industrial use of the OTM for

reporting and business intelligence, its use for process

mining is evaluated and demonstrated in this paper.

5.1 Preliminary Results and Findings

Based on an informal conceptual mapping study in

logistics, it is shown how the minimum process min-

ing requirements can be satisfied based on the OTM

data model. Based on the default OTM scenario and

example data, the step-by-step walkthrough discusses

and demonstrates how event data can be extracted to

create an event log. The process mining tool Disco is

employed to generate a process model.

5.2 Implications and Limitations

This demonstration provides initial support that the

OTM can fulfill the minimum requirements for pro-

cess mining. However, this paper’s demonstration

only covers one implementation of the OTM and is

based on synthetic data. Therefore, further experi-

mental research and development is required, involv-

ing decision-makers from the logistics industry.

The approach proposed in this paper requires the

adoption of the OTM by all involved actors and their

supporting information systems. The OTM is cur-

rently mainly used in the Netherlands. However,

given its prominent position within the federated data

sharing infrastructure for the Dutch logistics industry,

it is considered to be a promising direction for future

research and development. To increase the applica-

bility and potential generalization of the proposed ap-

proach, similar global industry standards should be

evaluated and compared.

5.3 Future Research Directions

Future research could focus on systematically map-

ping the process mining spectrum to the OTM based

on formal methods and techniques.

To extend the preliminary research, a full im-

plementation of OTM is required and this approach

should be tested for robustness with real-life datasets

in multiple use cases. The identified use cases provide

a starting point to conduct case study research. Future

work should aim to determine if implementations of

OTM and real-world data are also as straightforward

to map for process mining.

Further research directions could also include ap-

plying process mining techniques to these explored

use cases in organizations that implement the OTM.

A comparison-based study, in this regard involving

organizations that implement and do not implement

the OTM, would be an interesting next step.

Furthermore, a comparison study on solution al-

ternatives (e.g., the GS1 EPICS) and alternative ap-

proaches (e.g., data mining, machine learning) should

be conducted to evaluate the use of industry standards

in a broader sense.

ACKNOWLEDGEMENTS

This research is financially supported by TKI DINA-

LOG (grant nr. 2018-2-169TKI) as part of the IC-

Evaluating the Use of the Open Trip Model for Process Mining: An Informal Conceptual Mapping Study in Logistics

295

COS Project. The authors thank the involved consor-

tium partners for their support and contribution to this

research. The authors also thank the anonymous re-

viewers for their constructive feedback.

REFERENCES

Bastiaansen, H., Nieuwenhuis, C., Zomer, G., Piest, J., van

Sinderen, M., Dalmolen, S., and Hofman, W. (2020).

The logistics data sharing infrastructure: whitepaper

august 2020. Technical report. Available online:

https://www.dinalog.nl/wp-content/uploads/2020/08/

Dinalog_Whitepaper-Data-Infrastructure_DEF.pdf

(accessed on 8 March 2021).

Bogarín, A., Cerezo, R., and Romero, C. (2018). A survey

on educational process mining. WIREs Data Mining

and Knowledge Discovery, 8(1):e1230.

Cabanillas, C., Baumgrass, A., Mendling, J., Rogetzer, P.,

and Bellovoda, B. (2013). Towards the enhancement

of business process monitoring for complex logistics

chains. In International Conference on Business Pro-

cess Management, pages 305–317. Springer.

De Weerdt, J., Schupp, A., Vanderloock, A., and Baesens,

B. (2013). Process mining for the multi-faceted anal-

ysis of business processes—a case study in a finan-

cial services organization. Computers in Industry,

64(1):57–67.

dos Santos Garcia, C., Meincheim, A., Junior, E. R. F., Dal-

lagassa, M. R., Sato, D. M. V., Carvalho, D. R., San-

tos, E. A. P., and Scalabrin, E. E. (2019). Process min-

ing techniques and applications–a systematic mapping

study. Expert Systems with Applications, 133:260–

295.

Erdogan, T. G. and Tarhan, A. (2018). Systematic mapping

of process mining studies in healthcare. IEEE Access,

6:24543–24567.

Evofenedex, TLN, and Beurtvaartadres (2019). Nationaal

onderzoek data en digitalisering in de logistiek. Avail-

able online: https://www.tln.nl/app/uploads/2019/11/

Rapport-data-en-digitalisering.pdf (accessed on 8

March 2021).

Intayoad, W. and Becker, T. (2018). Applying process min-

ing in manufacturing and logistic for large transac-

tion data. In International Conference on Dynamics in

Logistics, pages 378–388. Springer International Pub-

lishing.

Knoll, D., Reinhart, G., and Prüglmeier, M. (2019a). En-

abling value stream mapping for internal logistics us-

ing multidimensional process mining. Expert Systems

with Applications, 124:130–142.

Knoll, D., Waldmann, J., and Reinhart, G. (2019b). Devel-

oping an internal logistics ontology for process min-

ing. Procedia CIRP, 79:427–432.

Lau, H., Ho, G., Zhao, Y., and Chung, N. (2009). De-

velopment of a process mining system for support-

ing knowledge discovery in a supply chain net-

work. International Journal of Production Eco-

nomics, 122(1):176–187. Transport Logistics and

Physical Distribution Interlocking of Information Sys-

tems for International Supply and Demand Chains

Management ICPR19.

Lont, Y., van Duin, R., Jens, D.-P., and van Lier, B.

(2018). Demasking the black hole of transportation?

A blocking road naar de ontwikkeling van een CO2

Blockchain-georienteerde (product) app. Bijdragen

vervoerslogistieke werkdagen 2018, pages 1–12.

Mans, R. S., van der Aalst, W. M., Vanwersch, R. J., and

Moleman, A. J. (2012). Process mining in healthcare:

Data challenges when answering frequently posed

questions. In Process Support and Knowledge Repre-

sentation in Health Care, Lecture Notes in Computer

Science, pages 140–153. Springer, Berlin, Heidelberg.

Open Trip Model (2020). The OTM5 model. Available on-

line: https://www.opentripmodel.org/docs (accessed

on 8 March 2021).

Singh, P. and van Sinderen, M. (2016). Big data interoper-

ability challenges for logistics. In Enterprise interop-

erability in the digitized and networked factory of the

future, pages 325–335. ISTE Press.

Stichting Uniforme Transport Code (SUTC) (2019).

Algemene Presentatie SUTC. Available online:

https://dutchmobilityinnovations.com/spaces/

1168/connected-transport-corridors/files/27520/

algemene-presentatie-sutc-pptx?version=1 (accessed

on 1 September 2020).

Van der Aalst, W. et al. (2012). Process mining manifesto.

In Business Process Management Workshops, Lecture

Notes in Business Information Processing, pages 169–

194. Springer, Berlin, Heidelberg.

Wang, Y., Caron, F., Vanthienen, J., Huang, L., and Guo,

Y. (2014). Acquiring logistics process intelligence:

Methodology and an application for a chinese bulk

port. Expert Systems with Applications, 41(1):195–

209.

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

296