Model-based Systems Design for Green IoT Systems

Kristin Majetta

a

, Jan Bräunig

b

, Christoph Sohrmann

c

, Roland Jancke

d

and Dirk Mayer

e

Fraunhofer Institute for Integrated Circuits IIS, Division Engineering of Adaptive Systems EAS,

Zeunerstrasse 38, Dresden, Germany

Keywords: Green IoT, Low-power IoT, Model-based Systems Development, MBSE Methods.

Abstract: The energy consumption of the Internet of Things is predicted to be about a quarter of the total world-wide

energy consumption by 2030. There are already numerous approaches and operating strategies to reduce the

energy consumption of wireless sensors. Nevertheless, it is essential to implement a formalized model-based

development process that enables the designer of IoT nodes, platforms and systems to balance between the

function and non-functional requirements with respect to energy consumption. Therefore we promote a

model-based systems design methodology that employs multi-physical co-simulation in a virtual simulation

environment in order to optimize the overall energy consumption.

1 INTRODUCTION

The term Internet of Things (IoT) was coined in 1999

by K. Ashton from the Massachusetts Institute of

Technology. Although there is no exact definition

(Prockl 2012), IoT describes linking identifiable

physical objects with each other and users via an

internet-like structure (Kaufmann 2020). The objects

collaborate via information- and communication

technologies (ICT). The term IoT is widely used

nowadays and vastly popular. A study concerning IoT

(Mauerer 2020) shows that companies that

established IoT projects benefit from higher

profitability, reduced costs and increased sales. They

also record lower downtime and achive higher

utilization. IoT applications can be found in nearly

every application area such as productions and

logistics, mobility, living and health. In the building

sector multisensor systems are often used to monitor

the status of technical equipment such as photovoltaic

systems (Hussain 2019). Also in energy and grid

management, especially in smart grids, monitoring

via distributed sensors is an essential requirement

(Laß 2019). In the area of smart farming IoT is used

to connect hundreds of small swarm robots to sow,

a

https://orcid.org/0000-0003-0823-0225

b

https://orcid.org/0000-0002-7282-723X

c

https://orcid.org/0000-0003-1981-7216

d

https://orcid.org/0000-0001-8857-6132

e

https://orcid.org/0000-0002-4972-6529

weed and harvest instead of using one single tractor.

This allows the work to be carried out faster and more

precisely. Additionally, underground wireless sensors

provide information about how many nutrients have

to be applied to the soil. Although (Aulbur 2019)

predicts that long term “in-ground sensors will be

replaced by in-vehicle sensors as the technology

improves”. Also in the field of productions and

logistics so called smart factories are on the rise.

Intelligent machines that exchange their status, filling

level or maintenance cycles with each other enable

production facilities to react dynamically to changes

in production processes and hence become highly

adaptive.

(Koomey 2011) investigated the evolvement of

efficiency of computation over several decades.

There are strong indications that energy consumption

per computational operation will decrease with the

miniaturization on transistor level. According to

Koomey’s law, this will drive mobile embedded

computing applications. However, Koomey also

states that power consumption of memory,

communication and other hardware might not

necessarily follow that trend, i.e. Koomey’s law

might not apply to IoT applications that heavily

utilize networking.

204

Majetta, K., Bräunig, J., Sohrmann, C., Jancke, R. and Mayer, D.

Model-based Systems Design for Green IoT Systems.

DOI: 10.5220/0010474602040211

In Proceedings of the 10th International Conference on Smart Cities and Green ICT Systems (SMARTGREENS 2021), pages 204-211

ISBN: 978-989-758-512-8

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

According to (Frost and Sullivan 2020), about 26

billion devices will be connected in the IoT by 2030

particularly in the fields of collaborative robots, cloud

manufacturing, virtual reality, remote maintenance of

machines, digital twin technology, and autonomous

driving. This rapid development will be significantly

accelerated by the introduction of the 5G standard for

communication, that has been designed with respect

to the demands of the IoT.

However, the expected growth is expected to raise

new challenges, especially regarding energy

consumption:

While the efficiency of data transmission over the

internet is expected to improve over time (Aslan

2018), there are indications that the overall energy

consumption by data transmission is predicted to

grow due to the steep increase in the number of

networked devices enabled by the new technologies

(Andrae 2015), even when accounting for the

improved efficiency of 5G. (Jones 2018) estimated

that the overall energy consumption of

communication networks will increase due to the

growing traffic, i.e. improvements in transmission

efficiency would be compensated. This would be in

blatant contradiction to the global goal of the

international community to reduce energy

consumption in order to limit the global warming to

2 K. Besides the, admittedly uncertain, energy

prognoses on a global scale, energy comsumption

also matters on a small scale: In case of mobile

wireless IoT devices, increased energy consumption

on the device level causes problems especially in

mobile applications, e.g. wireless sensor networks,

where data exchange is not permanent and local

energy storage devices are used, that are subject to

environmental conditions. The resulting demand for

regular battery replacement raises challenges of

maintenance of IoT devices and the question of

resource efficiency of such applications in general.

This aspect has been investigated by (Bonvoisin

2012) at the example of a sensor network, integrating

environmental costs of production and replacement of

components over the lifetime of the whole

application. Besides resource awareness during the

production, which is beyond the scope of this paper,

the optimization of energy consumption by system

design and operation will be considered here.

A number of actions to reduce the energy

consumption of the IoT are already established. These

include for instance (Nandyala 2016):

▪ Turning off inactive nodes (sleep mode)

▪ Sending required data only

▪ Using radio optimization techniques

▪ Using data reduction mechanisms

▪ Using energy-efficient routing techniques

▪ Using renewable green power sources such as

energy harvesting

Still an open question is how to orchestrate these

measures dynamically at run-time, especially in case

of time-varying environments. This will require the

IoT system to become an adaptive system.

Considering the metamodel presented by (Sabatucci

2018), the adaptation integrates functional as well as

non-functional aspects related to the energy level on

the device. The result is a complex system that can

adapt it’s operation schedule following a

multicriterial decision making process.

We therefore propose a paradigm shift towards

the introduction of intelligent energy-awareness for

any kind of IoT hardware nodes. While energy-

analysis functionality is already featured by many

nodes, there is still a great deal of unused potential for

optimizing energy consumption by leveraging

intelligent and adaptive operation. However, this

requires new design principles such as model-based

systems design. In the following, we will sketch some

of the changes that are needed in the system design

process to enable a more intelligent use of ressources.

From this, a corresponding hardware structure

including intelligent software control is derived,

which is described in more detail below.

2 ENERGY AS A KEY DESIGN

PARAMETER IN IoT SYSTEMS

The energy consumption of an IoT device strongly

depends to the actual application scenario, i.e. the

attached sensors, utilized communication technology,

and many other parameters, for instance sampling

rates, required on-board signal processing or quality

of the radio connection. While a wireless sensor in the

agricultural sector or in a smart city application might

not require maintenance for years, a self-powered

vibration sensor for continuous condition monitoring

can still be regarded a complex task including several

compromises in the design .

Therefore, there are major uncertainties regarding

battery lifetime and availability, which is why many

industrial applications and technologies still remain

in a prototypical or even a research stage.

2.1 Main Drivers of Energy

Consumption

The common smart wireless sensor can be regarded

Model-based Systems Design for Green IoT Systems

205

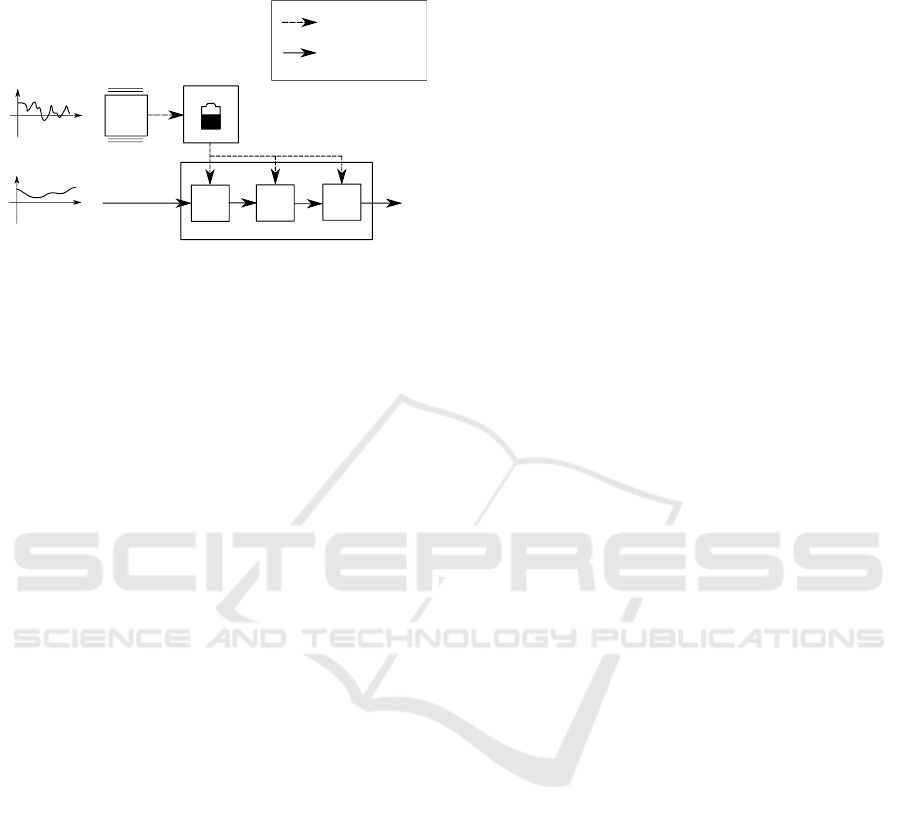

as a local energy system, optionally powered by

environmental sources (see Figure 1).

Figure 1: Energy model of a wireless sensor (according to:

Martinez 2015).

Generally, the power consumption has to be balanced

with the energy supply, either from an energy

harvesting (EH) system or by renewing, i.e. filling up,

the energy buffer e.g. by changing a battery. Thus,

with respect to the energy, the general condition

(1)

has to be satisfied at any time , where

is the

power on the supply side, and

is the power

consumed by the sensor’s subsystems.

2.2 Approaches for Low-power IoT

Wireless IoT devices promise the largest benefit

when they are operating fully autonomously. It is

attractive to replace power supply from conventional

batteries by conversion of environmental energy into

electrical energy directly at the IoT device. Sources

for this kind of energy harvesting are for instance

solar, vibration, or thermal energy (Hadas 2010).

The main challenge in application of these

renewable power sources is that the supply is often

uncontrollable and even unpredictable (Kansal 2007).

In turn, a system design considering uncertainties and

a sufficiently sized energy buffer has to be

implemented. Furthermore, adaptive energy

management to schedule energy consumption

according to the available energy supply is necessary

as shown in (Tahiliani 2018).

A main area of research and development

regarding energy reduction of wireless IoT devices is

the selection of a suitable radio transmission protocol.

The decision also needs to take into account the

required radio transmission range. Several standards

are available with different power consumptions and

operating ranges: from power intensive WiFi for

home networking, over Bluetooth or Bluetooth Low

Energy (BLE) for nearby peripherals down to ZigBee

and Z-Wave for e.g. metering and industrial

applications. Other protocols like EnOcean, Long

Range (LoRa), Narrow Band IoT (NB-IoT) have been

added with significantly lower power budget and

longer ranges for home and building automation

(Krödel 2020). And even 5G with its massive

Machine Type Communication (mMTC) usage

scenario aims at very large numbers of connected

low-power IoT devices (Lei 2020).

Another important aspect is the intelligent

organization of larger networks of such nodes in order

to minimize the number of active nodes for power

saving purposes. This is the aim of protocols like

Bluetooth Mesh, Dust Network, IQRF, and

NeoCortec (Halkier 2020) as well as the model-

checking approaches, as shown in (Demigha 2019).

Reducing the amount of transmitted data saves

energy at the IoT device. A possible approach is the

implementation of data analytics and machine

learning on the smart sensor platform, which should

extract the relevant information from the input data

stream, e.g. acquired by sensors. An example

comprises anomaly detection with an autoencoder

algorithm for condition monitoring of bearings (Bose

et al., 2019).

The previous example shows that there are often

trade-offs that developers of such systems have to

deal with: weighing computing intensive algorithms

for feature extraction or data compression against

power demanding data transmission. Similarly, the

number of sensing events may have to be balanced

against the achievable measurement accuracy. On top

of that, data security and privacy requirements are

demanding additional data encryption. The safer the

transmission the more compute resources are required

in the IoT node. In order to support the developers in

taking informed decisions on such questions, model-

based systems design principles and tools have to be

employed.

3 MODEL-BASED SYSTEMS

DESIGN AND ENGINEERING

3.1 Model-based Systems Development

Systematic development processes of complex

technical systems save time and money, while

maintaining high standards of quality, reliability and

safety.

SMARTGREENS 2021 - 10th International Conference on Smart Cities and Green ICT Systems

206

Originating from the "scientific method" (Roger

Bacon), methods like "Plan-Do-Study-Act" to

iterative and incremental development (IID) have

emerged, aiming at a continuous and iterative

workflow with alternating stages of system

implementation and system design (Larman 2003).

Modern systems integrate mechanical functions,

actuators, sensors and information processing, which

calls for development methods tailored for

mechatronic systems. Validation of the system design

requires complex, potentially multi-physical

simulations before actually implementing the

hardware. For even more complex systems that

feature advanced control loops, also hybrid strategies

such as hardware-in-the-loop simulation, that couple

real-time simulation and hardware components, have

been established (Isermann 1996). This mechatronic

system design (V-model) is widely used in aerospace

and automotive engineering, has also been

successfully applied to autonomous systems powered

by energy harvesting (Hadas 2010, Koch 2012).

Efforts have been made to transfer methods from

agile software development to hardware projects. One

basic idea of agile methods is the early and iterative

validation and testing of product increments,

including technical functions, but also acceptance by

potential customers and users; in case of hardware,

also a rapid implementation of prototypes is required

(Schuh 2016).

The increasing complexity of cyber-physical

systems, the more general case of an IoT system,

raised demands for model-based design methods that

allow for automation of virtual system validation.

Particularly for distributed, learning (adaptive)

systems-of-systems, the interactions between their

subsystems sometimes cause an unpredictable system

behaviour. This complicates the detection of design

faults (both hardware design and software). As a

potential solution, platform and contract based design

methods have been proposed (Sangiovanni-

Vincentelli 2012).

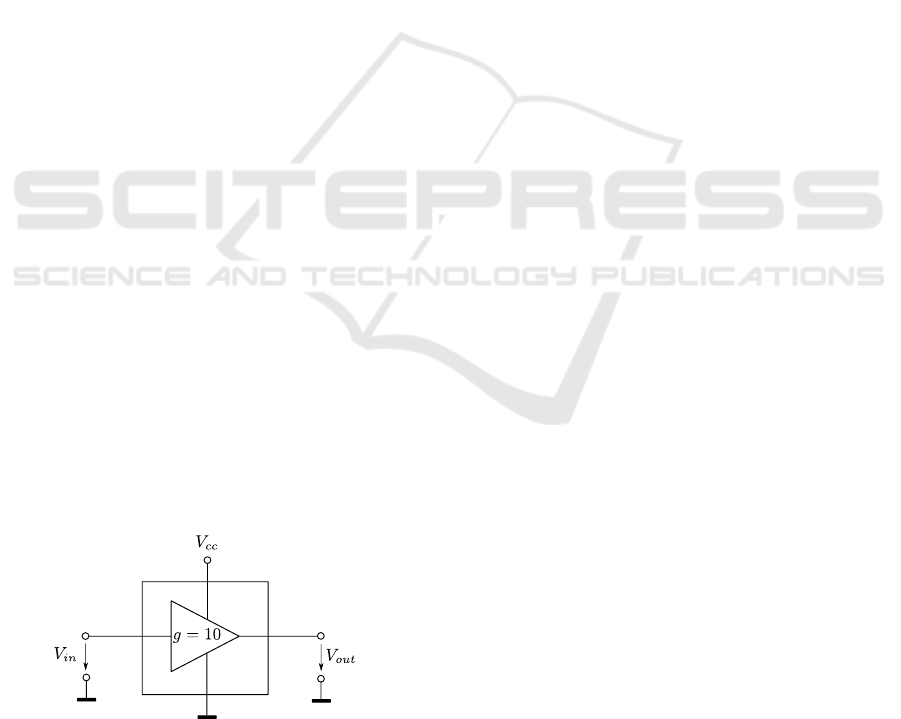

Figure 2: Example for a Very Simple Component in a

Contract based Design Scenario.

These methods are using collections of component

models on different abstraction levels. The interaction

of the components, defined by the system topology,

is analysed by applying assume-guarantee contracts,

i.e. a component is guaranteed to function properly,

under the assumption that other components provide

specified working conditions.

The concept shall be demonstrated by a very

simple example as shown in Figure 2. An amplifying

circuit will guarantee that it interacts with its

environment variables, i.e. the input voltage V

in

and

output voltage V

out

, according to the equation

under the assumptions that the conditions

are satisfied.

Contract-based design for optimization of a

complex distributed control system in the IoT has

been used for collaborating robots. A system

simulation has been set up using ROS (Robot

Operating System), a platform for the implementation

and simulation of robotic systems (Spellini et al.,

2019). Another application is design automation of

complex building automation and energy systems (Jia

2018): Components with standardized interfaces are

drawn from a library to build a complex automation

system by a design automation algorithm that aims at

fulfilling several functional and non-functional

requirements. These approaches could be transferred

to the design of networked, energy-aware smart

sensors. However, this requires component models

for the building blocks of a wireless sensor node that

describe the function and its effect on the energy

balance. Since modelling energy consumption from

circuit models can be very time consuming, Martinez

presented an approach to use measured power

consumption data on subsystem level and estimated

the energy consumption on the system level from the

composition of the measured profiles (Martinez

2015).

3.2 Simulation-based Virtual System

Validation

Formalized systems development and validation

requires proper metrics for the evaluation of system

concepts. In the field of cellular wireless

communication, several metrics as Quality of Service

have been established.

For the integration of energy consumption at the

device level, the metrics can be enhanced by energy

related KPI (Martinez‐Caro 2020):

Model-based Systems Design for Green IoT Systems

207

(2)

Where QC is the Quality Cost metric, nodes is the

number of nodes, states is the number of operational

states of the nodes,

is the power consumption

in each state, and

the period of each state being

active.

The dynamic behaviour of wireless networks can

be simulated with event driven simulators such as

OMNeT++. These include also the physical

characteristics of the transmission paths (e.g. dense

urban or rural environments etc.). An existing system

simulation for a LoRa network extends the OMNeT

framework by the "Quality cost" metric that considers

the energy needed for the operation of the nodes

(Martinez-Caro 2020). However, the behaviour of the

IoT edge devices such as data acquisition and data

analysis was not included in the simulation.

The interaction of adaptive (or self-learning) systems

can be simulated by applying agent-based simulation

frameworks. In an agent based system-of-systems,

each IoT device is assumed as self-learning and

autonomous, with the capability to interact with its

environment including other agents. Jung et al.

studied modelling networked IoT systems in a

production environment (Jung 2020). The developed

framework offers scalability and also the option for

hybrid virtual-experimental system validation (HiL).

One remaining open point is the integration of

energy-awareness in modelling the agents.

Jha et al. present a simulation that extends the

CloudSim framework by the energy consumption of

IoT devices (Jha 2020). However, the considered IoT

devices are representing rather wireless sensors

without considering the option to reduce transmitted

data directly on the sensor platform. In this approach,

the analysis is implemented in an intermediate edge

device, which can be considered to be less energy-

sensitive.

Simulation of large systems can take high

computation effort, slowing down the virtual testing

and validation. D'Angelo et al. developed a scalable

discrete event simulation framework, that distributes

the simulation of the networked IoT devices in a

computing cluster. Furthermore, the simulation can

switch between models of different abstraction levels

during runtime, so that efficient computation is

combined with detailed insights whenever necessary

(D’Angelo 2016).

An autonomous, potentially self-powered

wireless sensor is a multi-physical, cyberphysical

system, comprising mechanical, electromechanical,

electronic components as well as software-

implemented functions. For each domain, specific

simulation tools are available and well established,

which include Modelica for multi-physical systems or

SystemC for microelectronic systems. In modern

development processes, system simulations usually

interface with sub-models from multiple other

domains, e.g. by using the Functional Mockup

Interface (FMI) standard, that has been widely

adopted (Blochwitz 2011).

4 PROPOSED SYSTEMS

ENGINEERING METHOD FOR

GREEN IoT

The design of wirelessly connected, low-power IoT

devices is a highly complex task that requires a

holistic view on multiple domains and abstraction

levels as well as HW/SW interaction. Functional

requirements from data acquisition to data analyses

have to be balanced with non-functional requirements

derived from the energy consumption, storage and

harvesting technologies. In the widely popular V-

model development process, a requirements

specification is broken down into tasks than can be

implemented independently. However, especially for

the analysis of energy-consumption, a more agile co-

design approach is required instead. Technological

details are strongly affecting the choices on

architecture- as well as implementation-level.

Therefore, a model-based systems engineering

(MBSE) approach needs to be applied that establishes

technological dependencies and constraints across the

various stages of the design process. But whereas the

usual model-driven development is based on static

data models, we propose to go beyond that by

employing of multi-domain system-simulation as the

key technology for solving this multi-criterial design

optimization problem. This should enable the

engineers to balance the different functional and non-

functional aspects (Zulkipli 2017) and help to retrieve

an optimal solution in terms of energy consumption.

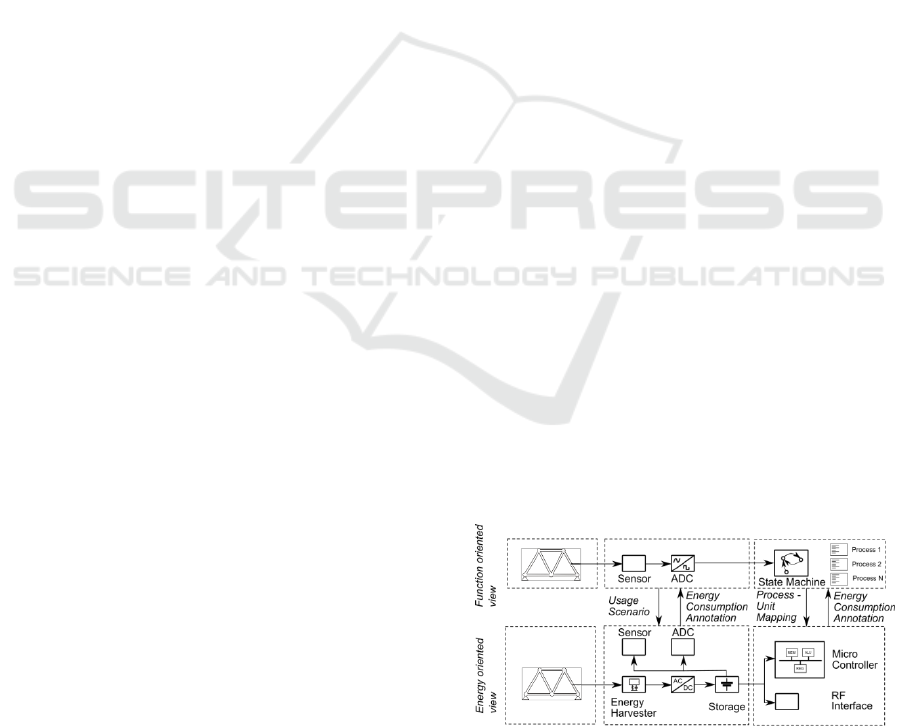

In Figure 3 we have shown a concept for an energy-

aware multi-domain simulation approach.

Figure 3: Energy-aware HW/SW co-simulation: physical

input (left) is fed into an analog frontend model (center)

which is coupled to a digital backend model (right).

SMARTGREENS 2021 - 10th International Conference on Smart Cities and Green ICT Systems

208

The physical input is fed into a power-aware model

of the analog system frontend. This frontend model

includes a model of the sensor data pre-processing

unit as well as the (possibly) electro-mechanical

model of the energy harvester. Therefore the system

is constantly aware of its internal power state. In

addition, a co-simulation with a model of the digital

backend (e.g. processor model) is running, which is

aware of the state and duration of the currently

executed processes as well as the power-consumption

of the analog parts. Using this information, a power-

state-machine is able to map the current state/power

information into the time-dependent energy

consumption. Our proposed simulation approach has

to support the following set of features:

• Multi-physical simulation for realistic dynamic

modelling of energy harvesting and other

interactions of the IoT device with the physical

world. This should be implemented using an

established format standard such as FMI.

• The system simulation should be scalable, since a

network might be composed from a large number

of wireless IoT devices.

• The modelling environment should support

parallel execution, e.g. on a high performance

compute cluster.

• Each IoT device should be represented as an

energy-aware agent. The device should

potentially interact with its physical environment,

e.g. for data acquisition at a machine or energy

harvesting; also communication with other

devices and the possibility to adapt to changing

requirements, particularly w.r.t. energy supply,

should be supported.

The sketched approach requires a robust model

coupling interface in the analog and digital domains.

For the physical models, we suggest to use the

Functional Mock-up Interface (FMI) technology. As

of today, FMI is supported by more than 100

modelling tools, such as Matlab and many of the

Modelica simulators. On the digital side, we suggest

to use SystemC TLM technology, which has the

required flexibility and performance to model entire

processors including the software.

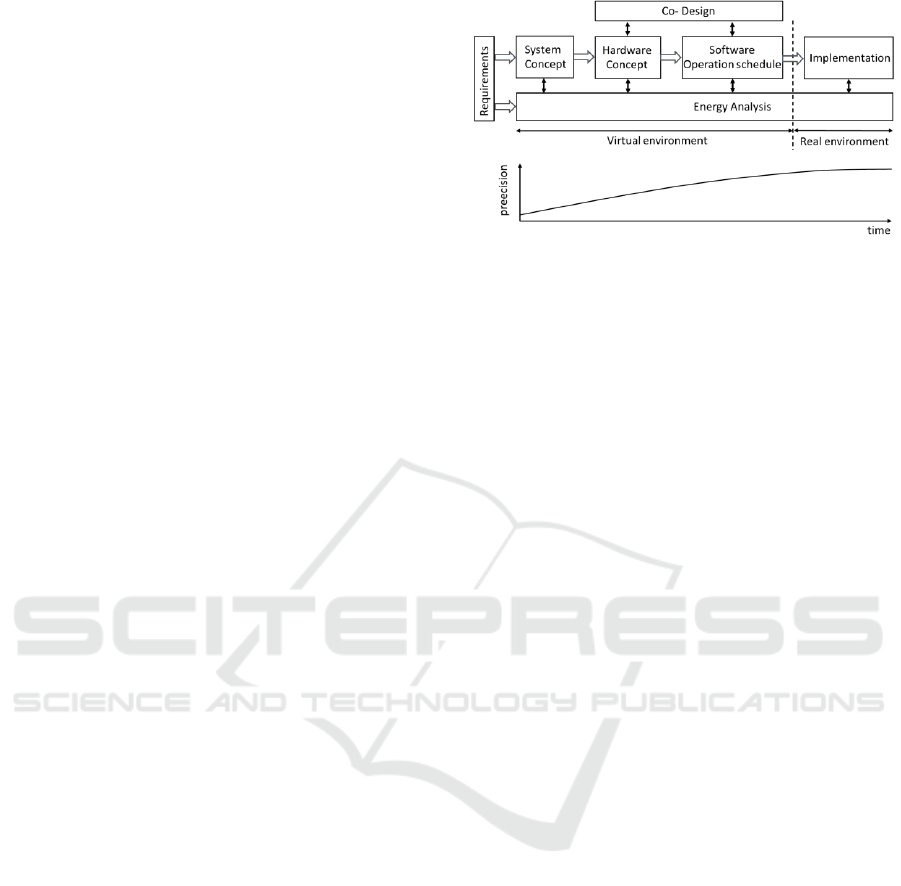

From the above system-simulation approach, a

continuous and seamless energy-aware design flow

can be created. The feasibility of the IoT application

considering the given functional and energy-related

requirements is assessed from the early beginning to

the final implementation. Model based validation

should start with coarse estimations of feasibility and

should be refined during the design process. This

includes a step-wise integration of hard- and software

in terms of co-design and in-the-loop (XiL) methods,

as shown in Figure 4.

Figure 4: Integration of energy awareness into MBSE.

5 CONCLUSIONS

Innovations in microelectronics and communication

technology enable a rapidly growing number of

applications for wireless and smart IoT devices.

However, considering energy consumption in the

design process is essential to ensure an autonomous

long-term operation of wireless sensor platforms as

well as to reduce the overall power consumption of

large IoT networks.

As discussed in this paper, the system design

process of IoT applications is a complex task that has

to consider functional aspects in parallel to the energy

sensitivity on device and system level and adaptive,

time-varying characteristics of the IoT devices.

The most promising way to cope with this

challenge seems the adoption of design methods and

tools for mechatronic systems and integrate them with

tools from the design of communication systems and

agent based systems-of-systems. Only with such a

model-based systems design approach, the full

potential for lower-power design of green IoT

systems can be leveraged.

REFERENCES

Prockl G., Pflaum A., 2012. Mehr Transparenz in der

Versorgungskette durch das „Internet der Dinge“. In

Business Innovation in der Logistik. Business

Innovation Universität St. Gallen (Profilbereich

Business Innovation). Springer Gabler, Wiesbaden.

https://doi.org/10.1007/978-3-658-00644-0_5

Kaufmann, T., Servatius, H.-G., 2020. Das Internet der

Dinge und Künstliche Intelligenz als Game Changer.

Springer Vieweg, Wiesbaden. https://doi.org/10.

1007/978-3-658-28400-8

Mauerer, J., 2020. Studie Internet of Things 2019/2020.

IDG Business Media GmbH (Ed.). https://www.tuv

sud.com/de-de/-/media/de/cyber-security/pdf/allgemein/

marketing/studie_internet-ofthings_2019_2020.pdf?la=

de-e&hash=A7B2170BE5F8474914E1458F94D9EF76

Model-based Systems Design for Green IoT Systems

209

Hussain, S. S., Khurram, S. K., Khan, A., et al., 2019. Cyber

Physical System for Solar Energy Monitoring. In 2019

International Conference on Frontiers of Information

Technology (FIT), 185–1855, 2019. https://doi.org

/10.1109/FIT47737.2019.00043.

Laß, D., Brockmann, C. Stube, B., et al., 2019. Autarke

Mikrosysteme – Anwendungen in der Energiewirtschaft,

Wireless Sensor Networks (WSN) – Applications for

Utilities. https://www.forschungsfabrik-mikroelektronik.

de/content/dam/ipms/forschungsfabrik-mikroelektronik/

de/Unser-Angebot/Anwendungsangebot/Energy/Doku

mente/Paper%20Autarke%20Mikrosysteme%20in%20d

er%20Energiewirtschaft.pdf

Aulbur, W., Henske, R., Uffelmann, W., et. al. 2019.

Farming 4.0: How precision agriculture might save the

world. Berger, R. (Ed.) https://www.rolandberger.com/

de/Publications/Landwirtschaft-4.0-Digitalisierung-als

-Chance.html

Koomey, J., Berard, S., Sanchez, M., & Wong, H. 2011.

Implications of Historical Trends in the Electrical

Efficiency of Computing. IEEE Annals of the History of

Computing, 33(3), 46–54. https://doi.org/10.1109/

MAHC.2010.28

Frost and Sullivan, 2020. Role of 5G Communication

Revolutionizing Industrial Internet of Things.

Landscape and Opportunities Assessment In Industrial

Operations.

Aslan, J., Mayers, K., Koomey, J. G., & France, C. 2018.

Electricity Intensity of Internet Data Transmission:

Untangling the Estimates. Journal of Industrial Ecology,

22(4), 785–798. https://doi.org/10.1111/jiec.12630

Andrae, A., Edler, T., 2015. On Global Electricity Usage

of Communication Technology: Trends to 2030.

Challenges, 6, 117--157. https://doi.org/10.3390/challe

6010117

Jones, N., 2018. How to Stop Data Centres from Gobbling

up the World’s Electricity. In Nature 561, Nr. 7722 (12.

September 2018): pp. 163–66. https://doi.org/10.

1038/d41586-018-06610-y.

Bonvoisin, J., Lelah, A., Mathieux, F., & Brissaud, D. 2012.

An environmental assessment method for wireless

sensor networks. Journal of Cleaner Production, 33,

145–154. https://doi.org/10.1016/j.jclepro.2012.04.016

Nandyala, C. S., Haeng-Kon K., 2016. Green IoT

Agriculture and Healthcare Application (GAHA). In

International Journal of Smart Home 10, Nr. 4 (30.

April 2016): pp. 289–300. https://doi.org/10.14257/ijs

h.2016.10.4.26.

Sabatucci, L., Seidita, V., Cossentino, M., 2018. The Four

Types of Self-adaptive Systems: A Metamodel. In

Intelligent Interactive Multimedia Systems and Services

2017 (S. 440–450). Springer International Publishing.

https://doi.org/10.1007/978-3-319-59480-4_44

Tang, X., Wang, X., Cattley, R., Gu, F., & Ball, A. D., 2018.

Energy Harvesting Technologies for Achieving Self-

Powered Wireless Sensor Networks in Machine

Condition Monitoring: A Review. Sensors, 18(12),

4113. https://doi.org/10.3390/s18124113

Martinez, B., Montón, M., Vilajosana, I., & Prades, J. D.,

2015. The Power of Models: Modeling Power Consum-

ption for IoT Devices. IEEE Sensors Journal, 15(10),

5777–5789.https://doi.org/10.1109/JSEN.2015.2445094

Hadas, Z., Singule, V., Vechet, S., Ondrusek, C., 2010.

Development of energy harvesting sources for remote

applications as mechatronic systems. In Proceedings of

14th International Power Electronics and Motion

Control Conf. EPE-PEMC, https://doi.org/10.1109/E

PEPEMC.2010.5606867

Koch, M., Kurch, M., Mayer, D., 2012. On a Methodical

Design Approach for Train Self-Powered Hot Box

Detectors. Proceedings of the First International

Conference on Railway Technology: Research,

Development and Maintenance. In: Proc. First

International Conf. on Railway Technology: Research,

Development and Maintenance. https://doi.org/10.42

03/ccp.98.90

Kansal, A., Hsu, J., Zahedi, S., & Srivastava, M. B., 2007.

Power management in energy harvesting sensor

networks. ACM Trans. on Embedded Computing Sys.,

6, pp. 32

Krödel, M., 2020. Trends im Umfeld von ‚Smart Buildings‘

sowie Eignungsvergleich funkbasierter Übertragungs-

protokolle. White Paper. https://www.enocean-

alliance.org/wp-ontent/uploads/2020/06/Funkbasierte-

SB-U%CC%88bertragungsprotokolle.v2.pdf

Lei, W., Soong, A.C.K., Jianghua, L. et al., 2020. 5G

System Design. An End to End Perspective. Springer,

Cham, 1

st

edition. ISBN 978-3-030-22238-3

Halkier, T.S., 2020. Funksensornetzwerke – Protokoll für

sich dynamisch verändernde Netzwerke. Elektronik

Business & Märkte 2020, H. 5-6, S. 8-13

Bose, S. K., Kar, B., Roy, M., Gopalakrishnan, P. K., &

Basu, A., 2019. ADEPOS: anomaly detection based

power saving for predictive maintenance using edge

computing. In Proceedings of the 24th Asia and South

Pacific Design Automation Conference (pp. 597--602).

ACM. https://doi.org/10.1145/3287624.3287716

Larman, C., Basili, V. R., 2003. Iterative and incremental

developments. a brief history. Computer, 36, 47--56.

https://doi.org/10.1109/MC.2003.1204375

Isermann, R., 1996. Modeling and design methodology for

mechatronic systems. IEEE/ASME Transactions on

Mechatronics, 1, 16--28. https://doi.org/10.1109/3516.

491406

Schuh, G., Schröder, S., Lau, F., Wetterney, T., 2016. Next

generation hardware development: Requirements and

configuration options for the organization of

procurement activities in the context of Agile new

Product Development. In 2016 Portland International

Conference on Management of Engineering and

Technology (PICMET) (pp. 2583--2591). https://

doi.org/10.1109/PICMET.2016.7806809

Jia, R., Jin, B., Jin, M., Zhou, Y., Konstantakopoulos, I. C.,

Zou, H., Kim, J., Li, D., Gu, W., Arghandeh, R.,

Nuzzo, P., Schiavon, S., Sangiovanni-Vincentelli, A. L.,

& Spanos, C. J., 2018. Design Automation for Smart

Building Systems. Proceedings of the IEEE, 106(9),

1680–1699. https://doi.org/10.1109/JPROC.2018.28569

32

SMARTGREENS 2021 - 10th International Conference on Smart Cities and Green ICT Systems

210

Martinez‐Caro, J.-M., & Cano, M.-D., 2020. A novel

holistic approach for performance evaluation in Internet

of Things. International Journal of Communication

Systems, 2020, e4454. https://doi.org/10.1002/dac.4454

Jung, T., Jazdi, N., Krauß, S., Köllner, C., & Weyrich, M.,

2020. Hardware-in-the-Loop Simulation for a Dynamic

Co-Simulation of Internet-of-Things-Components.

Procedia CIRP, 93, 1334--1339. https://doi.org/10.10

16/j.procir.2020.03.073

Sangiovanni-Vincentelli, A., Damm, W., & Passerone, R.,

2012. Taming Dr. Frankenstein: Contract-Based

Design for Cyber-Physical Systems, European Journal

of Control, 18(3), 217–238. https://doi.org/10.3166/ej

c.18.217-238

Spellini, S., Lora, M., Fummi, F., & Chattopadhyay, S.,

2019. Compositional Design of Multi-Robot Systems

Control Software on ROS. ACM Transactions on

Embedded Computing Systems, 18(5s), 1–24. https://

doi.org/10.1145/3358197

Jha, D. N., Alwasel, K., Alshoshan, A., Huang, X., Naha,

R. K., Battula, S. K., Garg, S., Puthal, D., James, P.,

Zomaya, A., Dustdar, S., & Ranjan, R., 2020. IoTSim-

Edge: A simulation framework for modeling the

behavior of Internet of Things and edge computing

environments. Software: Practice and Experience, 50,

844--867. https://doi.org/10.1002/spe.2787

D’Angelo, G., Ferretti, S., & Ghini, V., 2016. Simulation of

the Internet of Things. In 2016 International Conf. on

High Performance Computing Simulation (HPCS) (pp.

1--8). https://doi.org/10.1109/HPCSim.2016.7568309

Blochwitz, T., Otter, M., et al., 2011. The Functional

Mockup Interface for Tool independent Exchange of

Simulation Models. In: Proceedings of the 8th

International Modelica Conference, Seiten 105-114.

Linköping University Press. 8th International Modelica

Conference, 20.-22 März 2011, Dresden. ISBN 978-91-

7393-096-3 ISSN 1650-3740

Zulkipli, N., Alenezi, A. and Wills, G., 2017, IoT Forensic:

Bridging the Challenges in Digital Forensic and the

Internet of Things. DOI: 10.5220/0006308703150324

In Proceedings of the 2nd International Conference on

Internet of Things, Big Data and Security (IoTBDS

2017), pages 315-324, ISBN: 978-989-758-245-5

Tahiliani, V., Digalwar, M., 2018, Green IoT Systems: An

Energy Efficient Perspective. In Proceedings of 2018

Eleventh International Conference on Contemporary

Computing (IC3), 2-4 August, 2018, Noida, India.

Demigha, O., Khalfi, C., 2019, Formal Analysis of Energy

Consumption in IoT’S. In Proceedings of the 4th

International Conference on Internet of Things, Big

Data and Security (IoTBDS 2019), pages 103-114,

ISBN: 978-989-758-369-8

Model-based Systems Design for Green IoT Systems

211