Augmented Reality Applied to Reducing Risks in Work Safety in

Electric Substations

Victor Menezes Rocha

1,2 a

and Saul Delabrida

3b

1

Programa de Pós-Graduação em Instrumentação, Controle e Automação de Processos de Mineração (PROFICAM),

Universidade Federal de Ouro Preto (UFOP) and Instituto Tecnológico Vale (ITV), Ouro Preto, Brazil

2

Vale S.A., São Luís, Brazil

3

Departamento de Computação (DECOM), Universidade Federal de Ouro Preto (UFOP), Ouro Preto, Brazil

Keywords: Electric Arc, Electric Shock, Electricity Hazards, Incident Energy, Industrial System.

Abstract: Activities that involve electric energy are among the most dangerous and most harmful to the worker they

perform. Therefore, the general objective of this work is to develop a virtual reality application that simulates

the use of augmented reality technology as a means of access guidance and safety instructions with electric

substation operators/maintainers. For this purpose, a newsletter, a simplified 3D electrical substation was

modelled for experimentation in virtual reality and, thus, to evaluate a user experience regarding the use of

the prototype and define what are the main requirements that can be used for the construction of the final

application.

1 INTRODUCTION

An industrial electrical substation is a physical

arrangement of devices and equipment which the

purpose is to modify the characteristics of electrical

energy (voltage and current) to levels suitable for use

in the machines that make up the production process

and their subsequent distribution to them (Mamede

Filho, 2005). During the performance of the

maintenance and operation activities of these

substations, the worker is exposed to several risks,

among them that of electric shock, caused by

accidental contact in energized parts, and that of the

incident energy resulting from an electric arc

(Queiroz & Senger, 2012).

In Brazil, according to the Brazilian Association for

Awareness of the Dangers of Electricity (Abracopel),

7,040 accidents were recorded in the last 5 years (2015-

2019). Its main causes are electric shock (60% or 4196

cases), short circuit fires (39% or 2764 cases) and

lightning strikes (8% or 557 cases). However, despite

the higher percentage involving domestic accidents

and people not directly related to the electricity sector,

380 fatal accidents occurred with professional

technicians or electricians (Abracopel, 2020).

a

https://orcid.org/0000-0003-3216-0159

b

https://orcid.org/0000-0002-8961-5313

In order to mitigate the risks associated with

activities involving electricity, over the years there

has been a constant evolution of safety procedures

and industrial processes. Currently, the occupational

safety management applied in electrical substations,

is mainly based on the Regulatory Standard (NR) 10.

This standard aims at safety in installations and

services in electricity and provide for individual and

collective control measures, safety in energized

electrical installations, works involving high voltage

and emergency situations (Brasil, 2019).

In turn, industrial processes are increasingly

automated. With the advent of the fourth Industrial

Revolution, a new form of more technological

production has been achieved with the aim of

increasing productivity, reducing costs and helping to

control and make quick, efficient and well-qualified

decisions.

In fact, what is sought is industrial automation

based on the perfect relationship between the worker

and Cyber-Physical Systems (CPS), embedded

systems connected in a network, capable of managing

physical processes and, through feedbacks, adapting

new conditions in real time (Lee et al., 2015). In this

way, the human being starts to assume the role of an

entity with a higher level of control, redirecting his

Rocha, V. and Delabrida, S.

Augmented Reality Applied to Reducing Risks in Work Safety in Electric Substations.

DOI: 10.5220/0010454805330540

In Proceedings of the 23rd International Conference on Enterprise Information Systems (ICEIS 2021) - Volume 2, pages 533-540

ISBN: 978-989-758-509-8

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

533

efforts to situations that require higher lines of

reasoning and more assertive decision-making.

Another point is the need for maintenance

workers to keep the machines in perfect working

order. In this scenario, Augmented Reality (AR)

enters as another technology of this revolution,

facilitating these works by providing more detailed

information on the equipment and procedures to be

performed. This technology is able to superimpose

information and virtual objects on the real

environment in which the user is. Thus, data, videos,

images, photos, animations, texts and other

computer-generated objects can be manipulated and

appear integrated into the environment through a

device, such as a smartphone, tablet or special glasses

(Figure 1).

Figure 1: Augmented Reality applied to the context of

electrical maintenance. Sources:

https://www.mtitecnologia.com.br and https://se.com,

respectively.

When associated with Virtual Reality (VR,

advanced interface technology for computational

applications, which allows the user to navigate and

interact, in real time, with a virtual three-dimensional

environment), AR has also been shown to be effective

for conducting safer virtual training for workers

(Hernández et al., 2016; Peng et al., 2018) Figure 2.

Figure 2: Representation of the visualization of objects and

scenarios in Virtual Reality, Mixed Reality and Augmented

Reality. Source: adapted from https://www.actimage.com.

The use of these last two technologies has been

documented in the literature in actions of simulation,

training and choice of more correct solutions in cases

involving electric power substations (Antonijević et

al., 2016; Torres Filho et al., 2013). However, most

of the works have as object of study open-air

substations belonging to the energy concessionaires

(Hernández et al., 2016; Peng et al., 2018).

The purpose of this work is to carry out the proof

of concept of the use of AR as support for industry

workers, for that purpose an VR application was

developed to simulate AR and the preliminary tests

with the use of AR showed a reduction of

approximately 90% in decision-making errors

regarding improper access in risk areas.

The rest of this article is structured as: Section 2

describes the main risks that workers in the electricity

sector are exposed to. Section 3 describes the work

related to AR and VR in the electricity sector. Section

4 describes the experiment developed in VR

simulating the use of AR. Section 5 the results

obtained and problems identified in the prototype.

Finally, Section 6, where we conclude this work.

2 PROBLEM STATEMENT

Electricity is an invisible risk, which does not emit

visual or audible alerts to the individual, a fact that

often lowers attention under operating conditions.

Activities related to it, present risks to people's health

and safety, and can cause everything from mild

symptoms to immediate death. In the industry, several

electrical risks can be identified, but the main ones are

electric shock, electric arc and electromagnetism, the

first two being more harmful to workers (Lourenço et

al., 2007).

Electric shock is the pathophysiological effect

resulting from the direct or indirect passage of

external electrical current through a human's body.

Depending on the exposure time, the victim's physical

resistance, the intensity and path of the circulating

electrical current, the physiological damage caused

by the shock can bring more serious complications for

the individual (Cadick et al., 2012).

The electric arc, is the passage of electric current

through a non-conductive medium, such as air or oil,

at high speeds (approximately 100 m/s). In general, it

occurs due to the dielectric rupture of this medium,

caused by the potential difference between the two

materials and the proximity between them (Mamede

Filho, 2005; Souza & Michaloski, 2017). The three

main problems that increase the danger of the electric

arc and are also capable of causing a person to die are:

a) Arc temperature - capable of reaching high

temperatures and causing incurable burns;

b) Incident energy - amount of thermal energy

(sudden fire) printed on a given surface and

released during the formation of an electric arc.

It can lead to the ignition of a worker's clothing,

further increasing the risk of burns;

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

534

c) Pressure wave - developed through the

explosive expansion of air and metals in the arc

path. It is capable of breaking eardrums,

crushing the lungs, causing head trauma, among

other things.

Thus, the electric arc is an evident danger for both

companies and workers. In companies, this

phenomenon can cause total destruction of electrical

panels and consequent loss of production, since their

high temperatures and fused and vaporized metals can

quickly reach other equipment and electrical circuits

(Floyd et al., 2005). However, the risks are even

greater for workers. People directly exposed to an

electric arc event are subject to third degree burns,

possible blindness, shock, explosion effects, hearing

loss and instant death. In order to have an idea of the

dimension of the risk of formation of an electric arc,

Cadick et al. (2012) highlight that fatal burns can

occur even at distances greater than 2.5m.

This work aims to study alternatives for workers

performing inspection and maintenance activities in

electric stations. Augmented reality and virtual reality

were defined as the core technologies for the

proposed solution. Next section describes related

works.

3 RELATED WORK

This section describes works that use Augmented

Reality (AR) or Virtual Reality (VR) in the industrial

context.

A virtual environment is the representation

through computer graphics of various elements of the

real or abstract world, such as the dimension of an

environment, lighting, size, shape and texture of an

object, among others. In turn, Virtual Reality (VR)

can be defined as the computational technique used to

create these artificial environments in a realistic way,

allowing its users to interact with it in real time

(Kirner & Siscoutto, 2007; Laviola Júnior et al.,

2017). In fact, through this human-machine interface,

the user, in addition to being able to feel immersed in

a three-dimensional environment, is also able to

navigate, interact and modify its components in a

natural and intuitive way (Cardoso et al., 2007; Lin et

al., 2002; Wiederhold & Bouchard, 2014).

In view of its benefits, VR has been used in the

most diverse areas of knowledge. In medicine, for

example, its use ranges from aid in rehabilitation

processes for patients, the simulation of complex

situations, such as surgical tests, bone marrow

collection, among other procedures, for fixing the

protocol that should be adopted from a controlled

environment (Brunner et al., 2016; Faria et al., 2016;

Souza-Junior et al., 2020). In military training, VR, in

turn, can generate a multitude of conflict simulations,

which enable the exploration of the operator's limits

and the correction of mistakes made so that there is

no compromise on the mission to be triggered

(Cuperschmid et al., 2015).

VR can be used in simulations of electrical

substations to train teachers and graduate students,

field operators and other support and maintenance

professionals. As their users are not exposed to real

equipment during the simulation, these scenarios may

represent a decrease in the risk of accidents inherent to

the learning and decision-making process. This

technology has also been considered a powerful tool as

visualization interfaces for energy system simulators

and critical systems monitoring and control operations

(Barata et al., 2015; Barcelos et al., 2013).

Still, Guangwei and Guan (2009), using a scene

graph development approach for organizing and

managing models in the realization of the Level of

Detail (LOD), present a VR system design that allows

operators to have a complete view of the process

involving simulation, training and control of a

substation's virtual environment. Finally, Silva et al.

(2013), made adjustments to the Unity3D game

engine to develop an application that would allow

better monitoring and control of substations. In this

work, Unity3D presented a good amount of resources

and a satisfactory performance in relation to

supporting scenes with large amounts of polygons;

the LOD resource; the flexibility to choose

programming languages (C #, JavaScript and Boo);

the creation and use of packages with sufficiently

generic functionalities that enable the reuse of

functions; and the possibility of creating components

to automate the scene editor.

If, on the one hand, virtual reality (VR) uses virtual

objects and environments, on the other, augmented

reality (AR) allows the visualization in an integrated

way of a virtual element in the real world in which the

user is; a real “augmented world” (Azuma, 1997;

Mullen, 2011). Simplistically, Drascic and Milgram

(1996) define AR as a technology capable of

generating a real environment with graphic

improvements. In other words, AR brings with it a new

concept of visualization of information and images

generated by computer, as it complements real

environments instead of replacing them as in VR

applications. Several AR technologies are available on

the market, ranging from a simple smartphone camera,

to more expensive options, such as AR glasses, which

have semitransparent displays, coupled with a 3D

camera for the projection of the virtual image.

Augmented Reality Applied to Reducing Risks in Work Safety in Electric Substations

535

By being able to generate a sense of dominance in

the user, combining the presentation process and the

possibility of interaction and manipulation of virtual

objects, AR has become an increasingly immersive

experience (Cardoso et al., 2014). In the last decade,

several sectors have benefited from the development

of its applications, such as educational, tourism,

medical, design, geospatial, among others

(Carmigniani et al., 2011; Engelke et al., 2015;

Fiorentino et al., 2014; Gheisari et al., 2016; Mekni

& Lemieux, 2014; Nee et al., 2012).

AR-based systems, for example, can support a

variety of services, such as sending repair instructions

via mobile devices or selecting parts in a warehouse,

reducing travel costs and preventing maintenance

rework from having to be misinterpreted (Bahrin et

al., 2016). Still, new human-machine interfaces can

be created from AR in the manufacture of

applications and IT assets, displaying KPIs (Key

Performance Indicator) and feedbacks about

manufacturing processes in real time, in order to

improve decision making (Gorecky et al., 2014).

Peres et al. (2018), for example, propose the

application of AR for access to accumulated data and

information in hydroelectric dams to be analyzed for

cracks in the concrete, thus reducing the demand for

mental workload in the employee. However, despite

this new area of technology that has been discussing

for some time in academic papers, Martinez et al.

(2016) reviewing the literature on Industry 4.0, found

no reference to augmented reality in the 531 abstracts

of the analyzed publications, which indicates that this

subject seems to be in an early stage of development.

In the context of electrical power substations,

Barcelos et al. (2013), identifying the difficulty of

graduates from Electrical Engineering courses in

differentiating and classifying the elements of a

substation, present a proposal for the use of AR in the

visualization of these components as a way of

complementing learning. For this, a protocol for

creating an interactive catalog was suggested.

Initially, virtual objects were created in 3D Studio

Max® and, after the generation of their respective

markers, the Unity 3D® game building engine and

the NyARToolKit library enabled the

synchronization between reading the catalog and

viewing these objects in three dimensions. Also, the

availability of AR glasses for students provided a

greater experience of usability of the generated

system and better immersion of the user. Finally, as

suggested by Antonijević et al. (2016), AR can also

be used as a support tool to increase the information

visible to the user and contribute to the automation of

electrical substations, using a simple smartphone.

These authors developed an application based on QR

markers and a combination of IEC61850

communication with AR, so that engineers received

in real time the information necessary for

maintenance and inspection of equipment from the

process data recorded in the SCADA system.

4 PROPOSED SOLUTION

Based on the technologies and concepts presented in

sections 2 and 3, a proof of concept of the use of AR

is presented in this work. To this end, the aim was to

develop a use case to be applied to the electrical

maintenance team that involved the development of a

prototype using Unity 3D, for a virtual environment

(VR) similar to a physical arrangement of an

industrial electrical substation in the context of

simulation of maintenance activities on equipment

contained in this room with (and without) the use of

AR to read information from the equipment (RV

simulating an AR environment); and evaluate the use

and perceptions (user experience) by the maintenance

execution teams, identifying advantages and

problems arising from such a solution and verifying

the team's propensity regarding the need to use (or

not) the proposed solution for knowledge of details

and information in real time of electrical installations.

Therefore, the prototype to be developed should be

able to:

1) Run on Android phones and simulated with the

support of Virtual Reality Glass (VR Box) and

Bluetooth Remote Controllers;

2) Represent as accurately as possible the physical

arrangement of an electrical substation;

3) Allow the user to move everywhere within the

scene and have a first-person camera

perspective;

4) Establish virtual barriers to enable the correct

positioning of the user in relation to the area of

risk of electric arc and, if this exceeds the

delimitation, show an alert indication on the

screen;

5) Provide information about each electrical panel

(data of current, voltage, active power and

category of the panel) at the moment the user

positioned himself in front of him;

6) Record the number of infractions committed

during the execution of the pre-established task.

After application development, the use case was

elaborated a 9 members the electrical maintenance

teams (engineers and technicians) in Vale's operating

areas in the ports of Tubarão (Vitória/ES) and Ponta

da Madeira (São Luís/MA; Figures 3-4). The texts

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

536

contained in figures 4 are in the official language of

the developing country (Portuguese). Therefore, the

experiment took place as follows:

1) Users were allowed to browse the virtual

environment momentarily, through computers,

before starting the test itself, in order to become

familiar with the environment and with the

movement controls.

2) Participants were asked to perform a field survey

task of short-circuit current information on all

panels contained in the fictitious substation and

write it down on a clipboard. Assumptions were

passed on to the participants and should be

considered when performing the task:

i. The information to be obtained (short circuit

current) would be available on labels affixed

to the front of each panel;

ii. Electricians would be wearing flameproof

clothing (Nomex), category 2, that is,

minimum protection of 8 cal/cm2 (incident

energy, according to ATPV index) as PPE;

iii. The substation would not have an adjustment

group, that is, there would be no mechanisms

to reduce the incident energy of the panels, by

changing /adjusting the operating times of the

protection relays and/or using internal arc

relays.

3) The experiment was carried out for the first time

with the virtual Scenario 1 without the

indication of the information on a virtual panel

located to the left of the vision in the glasses,

simulating the current method (without the use

of AR). The expected behavior for this scenario

would be for the electrician to refuse to do the

activity. As he does not have prior knowledge of

this information, he should adopt his right of

refusal when considering the possibility of the

panels presenting an incident energy higher than

the category of his PPE (in this example,

category 2). However, once he made the wrong

decision to read the data, accessing the risk

zone, an improper access counter was increased.

4) The experiment was repeated in a second virtual

Scenario 2, with indication of the information,

simulating the augmented reality method,

informing the electrician about the data in

advance, and allowing a safe decision not to

violate the safe and adequate distance to your

PPE (flameproof clothing, with a category

appropriate to the incident energy of the panel).

A video with the view of the substation modeled

in 3D can be accessed behind the address:

https://youtu.be/ZXw46D-LZYM. In the video we

are running the application on the second scenario

Figure 3: (A) Overview of the modeled substation; (B)

Practical Reproduction of the Experiment in São Luís; (C)

VR Box and Bluethooth Remote Controler glasses used for

the experiment.

Figure 4: (A) Front view of a panel and tag with their

respective information (with AR); (B) Front view of a panel

and tag with their respective information. Image with the

entry warning tag in the risk area and panel indication.

Highlighted within the red square without filling is the

accounting of errors made by the user when applying the

tests.

(with RA). Therefore, it is not necessary for the user

to access the unsafe area to view the main information

on the panel. At the end of the video, it is shown that

to read the label attached to the panel, it is necessary

Augmented Reality Applied to Reducing Risks in Work Safety in Electric Substations

537

to get closer, consequently exposing the work to risk.

It is also possible to view the error/unsafe actions

counter in the lower left corner of the screen.

5 RESULTS

After performing the tests, with the help of NASA

TLX methodology, users were asked to evaluate the

workload in both scenarios in terms of mental

demand, physical demand, temporal demand,

performance, effort and frustration. Thus, after

compiling the results, it was found that the scenario

without AR had a final score of 54,81, while the

scenario with AR had a final score of 48,59. For this

methodology, the lower the grade, the better the

performance of the technology, since it requires less

work demands, indicating a propensity of the team

regarding the need to use the proposed solution. An

analysis by arithmetic mean of the grades was also

performed, confirming the data obtained previously

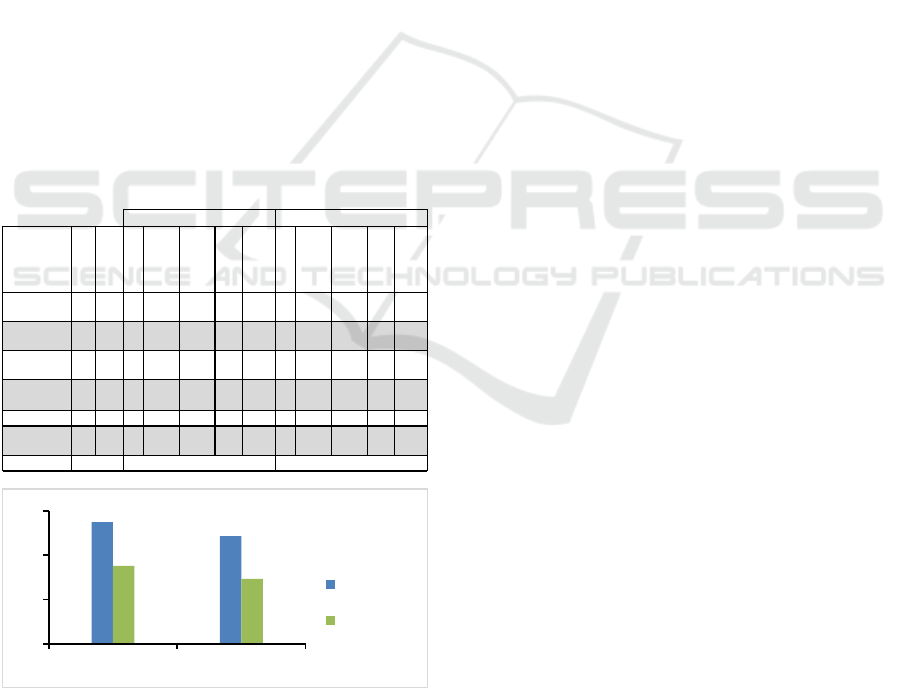

(Table 1; Figure 5).

Table 1: Notes from Scenario 1 (without AR) and 2 (with

AR), according to NASA TLX methodology and

Arithmetic Average. Legend: WN - weighted note; SD -

standard deviation.

Figure 5: Comparison of the user's final grades (NASA

TLX and arithmetic mean) in relation to the demands

demanded during the execution of the experiment without

and with the use of augmented reality.

Finally, the scenario with augmented reality

showed an approximate reduction of 90% in errors of

decision making regarding the improper access in risk

areas (39 errors made in the scenario without AR and

four with AR). This may indicate that the developed

system has been successfully tested, confirming that,

from its improvement, its application in real

environments of electric power substations would be

an effective solution to mitigate the risks associated

with the activities carried out in it. However, two

limitations were identified, which should be

addressed in future projects: the low resolution of the

video, which made it difficult to read the information

with the use of cell phones; and the difficulty in

recognizing by the user the model used to represent

the electrical panels, being recommended the

adoption of market design standards and/or the

substation to be implemented the technology, so that

users feel familiar with the interfaces.

6 CONCLUSIONS

This work evaluated augmented reality as a feature to

support the workers in the industry field. Our focus is

to provide a friendly user interface in hazardous

environments. In this case, we evaluated the human

operation of electric panels.

We also have used a virtual reality environment

for stakeholders' experience. This strategy allowed us

to understand the real application's best requirements

and reduced the time spent developing the real

application. Our methodology also reduces the need

to access the hazardous environment.

The developed prototype was experimented by

application stakeholders. Our findings demonstrate

that the system is a feasible alternative to reduce and

emit alert to workers in the field. Finally, as indirect

advantages of using this technology, we can highlight

the increase in the productivity of the teams, through

a quick return of information and performance in the

maintenance process, increase in the perception of

information reliability, elimination of human errors in

the collection / reading of data and reducing the level

of stress of workers in making decisions that involve

their safety. Then, with the lessons learned in this

experiment, a real augmented reality system (not VR)

is being developed for future user evaluation.

Item

Score

Weight

Sum (score)

WN

Average

SD

Variance

Sum (score)

WN

Average

SD

Variance

Mental

Demand

27 20% 63 12,60 7,00 1,12 1,25 44 8,80 4,89 2,71 7,36

Physical

Demand

13 10% 48 4,62 5,33 2,50 6,25 26 2,50 2,89 1,69 2,86

Temporal

Demand

27 20% 57 11,40 6,33 2,65 7,00 34 6,80 3,78 2,49 6,19

Overall

Performance

33 24% 58 14,18 6,44 3,57 12,78 82 20,04 9,11 0,93 0,86

Effort

19 14% 55 7,74 6,11 3,26 10,61 54 7,60 6,00 3,50 12,25

Frustration

Level

16 12% 36 4,27 4,00 3,28 10,75 24 2,84 2,67 1,66 2,75

135 54,81 35,21 48,58 29,34

Scenario 1 Scenario 2

54,81

48,58

35,21

29,34

0

20

40

60

Without RA With RA

NasaTLX

Mean

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

538

ACKNOWLEDGEMENTS

This study was financed in part by the Coordenação

de Aperfeiçoamento de Pessoal de Nível Superior -

Brasil (CAPES) – Finance Code 001, the Conselho

Nacional de Desenvolvimento Científico e

Tecnológico (CNPQ), the Fundação De Amparo a

Pesquisa Do Estado De Minas Gerais -

FAPEMIG grant code APQ-01331-18, the Instituto

Tecnológico Vale (ITV), the Universidade Federal de

Ouro Preto (UFOP) and Vale S.A.

REFERENCES

Abracopel. (2020). Anuário estatístico de acidentes de

origem elétrica 2020 – ano base 2019. Retrieved

15/05/2020 from http://mkt.abracopel.org.br/w/jereX

jpe7Bymp6sjCShe94-3-125e!uid?egu=o0n9udpuxa0w

8pau

Antonijević, M., Sučić, S., & Keserica, H. (2016).

Augmented reality for substation automation by

utilizing IEC 61850 communication. 39th International

Convention on Information and Communication

Technology, Electronics and Microelectronics

(MIPRO), Opatija, Croatia.

Azuma, R. T. (1997). A survey of augmented reality.

Presence: Teleoperators and Virtual Environments,

6(4), 355-385. https://doi.org/10.1162/pres.1997.

6.4.355

Bahrin, M. A. K., Othman, M. F., Azli, N. H. N., & Talib,

M. F. (2016). Industry 4.0: A review on industrial

automation and robotic. Jurnal Teknologi, 78(6-13).

Barata, P. N. A., Ribeiro Filho, M., & Nunes, M. V. A.

(2015). Consolidating learning in power systems:

Virtual reality applied to the study of the operation of

electric power transformers. IEEE Transactions on

Education, 58(4), 255-261. https://doi.org/10.1109/

TE.2015.2393842

Barcelos, M. A., dos Santos Peres, I. C., Mattioli, L. R.,

Júnior, E. L., & Cardoso, A. (2013). Uso de realidade

aumentada na visualização de componentes de

subestações de energia elétrica. XI Conferência de

Estudos em Engenharia Elétrica, Minas Gerais, Brasil.

Brasil, M. d. T. (2019). NR-10 - Segurança em instalações

e serviços em eletricidade. https://enit.trabalho.gov.br/

portal/images/Arquivos_SST/SST_NR/NR-10.pdf

Brunner, I., Skouen, J. S., Hofstad, H., Aßmuss, J., Becker,

F., Pallesen, H., Thijs, L., & Verheyden, G. (2016). Is

upper limb virtual reality training more intensive than

conventional training for patients in the subacute phase

after stroke? An analysis of treatment intensity and

content. BMC neurology, 16(1), 219. https://doi.org/

10.1186/s12883-016-0740-y

Cadick, J., Neitzel, D. K., & Capelli-Schellpfeffer, M.

(2012). Electrical safety handbook (4 ed.). McGraw-

Hill.

Cardoso, A., Júnior, E. A. L., & A Barcelos, M. (2014).

Ferramentas de apoio ao ensino de componentes de

subestações de energia elétrica com uso de realidade

virtual e aumentada. Iniciação-Revista de Iniciação

Científica, Tecnológica e Artística, 4(3).

Cardoso, A., Kirner, C., Júnior, E. L., & Kelner, J. (2007).

Tecnologias e ferramentas para o desenvolvimento de

sistemas de realidade virtual e aumentada. Editora

Universitária UFPE, 1-19.

Carmigniani, J., Furht, B., Anisetti, M., Ceravolo, P.,

Damiani, E., & Ivkovic, M. (2011). Augmented reality

technologies, systems and applications. 51(1), 341-377.

https://doi.org/10.1007/s11042-010-0660-6

Cuperschmid, A. R. M., Amorim, J. A., Matos, C. E. A., &

Einstein, A. (2015). Uso de Realidade Aumentada para

o Treinamento Militar. Revista Militar de Ciência e

Tecnologia

, 3, 5 - 17.

Drascic, D., & Milgram, P. (1996). Perceptual issues in

augmented reality. Stereoscopic displays and virtual

reality systems III, San Jose, CA, United States.

Engelke, T., Keil, J., Rojtberg, P., Wientapper, F., Schmitt,

M., & Bockholt, U. (2015). Content first: a concept for

industrial augmented reality maintenance applications

using mobile devices. 6th ACM Multimedia Systems

Conference, Portland, EUA.

Faria, A. L., Andrade, A., Soares, L., & i Badia, S. B.

(2016). Benefits of virtual reality based cognitive

rehabilitation through simulated activities of daily

living: a randomized controlled trial with stroke

patients. Journal of Neuroengineering and

Rehabilitation, 13(1), 96. https://doi.org/10.1186/

s12984-016-0204-z

Fiorentino, M., Uva, A. E., Gattullo, M., Debernardis, S., &

Monno, G. (2014). Augmented reality on large screen

for interactive maintenance instructions. Computers in

Industry, 65(2), 270-278.

Floyd, H. L., Doan, D., Wu, C., & Lovasic, S. (2005). Arc

flash hazards and electrical safety program

implementation. Fourtieth IAS Annual Meeting.

Conference Record of the 2005 Industry Applications

Conference, 2005., Kowloon, Hong Kong, China.

Gheisari, M., Sabzevar, M. F., Chen, P., & Irizarry, J.

(2016). An augmented panoramic environment to

access building information on a construction site. 52nd

ASC Annual International Conference Proceedings,

Provo, Utah, EUA.

Gorecky, D., Schmitt, M., Loskyll, M., & Zühlke, D.

(2014). Human-machine-interaction in the industry 4.0

era. 2014 12th IEEE international conference on

industrial informatics (INDIN), Porto Alegre, RS,

Brazil.

Guangwei, Y., & Guan, Z. (2009). Scene graph

organization and rendering in 3D substation simulation

system. 2009 Asia-Pacific Power and Energy

Engineering Conference, Wuhan, China.

Hernández, Y., Pérez-Ramírez, M., Ramírez, W. I., Ayala,

E. N., & Ontiveros-Hernández, N. (2016). Architecture

of an Intelligent Training System based on Virtual

Environments for Electricity Distribution Substations.

Augmented Reality Applied to Reducing Risks in Work Safety in Electric Substations

539

Res. Comput. Sci., 129, 63-70. https://doi.org/

10.13053/rcs-129-1-7

Kirner, C., & Siscoutto, R. (2007). Realidade virtual e

aumentada: conceitos, projeto e aplicações. IX

Symposium on Virtual and Augmented Reality,

Petrópolis, RJ, Brasil.

Laviola Júnior, J. J., Kruijff, E., McMahan, R. P., Bowman,

D., & Poupyrev, I. P. (2017). 3D user interfaces: theory

and practice. Addison-Wesley.

Lee, J., Bagheri, B., & Kao, H.-A. (2015). A cyber-physical

systems architecture for industry 4.0-based

manufacturing systems. 3, 18-23. https://doi.org/

10.1016/j.mfglet.2014.12.001

Lin, F., Ye, L., Duffy, V. G., & Su, C.-J. (2002).

Developing virtual environments for industrial training.

Information Sciences, 140(1-2), 153-170.

https://doi.org/10.1016/S0020-0255(01)00185-2

Lourenço, S. R., Silva, T. A. F., & da Silva Filho, S. C.

(2007). Um estudo sobre os efeitos da eletricidade no

corpo humano sob a égide da saúde e segurança do

trabalho. 5(1), 135-143. https://doi.org/10.5585/

exacta.v5i1.1043

Mamede Filho, J. (2005). Manual de Equipamentos

Elétricos (3 ed.). Grupo Gen-LTC.

Martinez, F., Jirsak, P., & Lorenc, M. (2016). Industry 4.0.

The end lean management? 10th International Days of

Statistics Economics, Prague, Czech Republic.

Mekni, M., & Lemieux, A. (2014). Augmented reality:

Applications, challenges and future trends. Applied

Computational Science, 20, 205-214.

Mullen, T. (2011). Prototyping augmented reality. John

Wiley & Sons.

Nee, A. Y., Ong, S., Chryssolouris, G., & Mourtzis, D.

(2012). Augmented reality applications in design and

manufacturing. 61(2), 657-679.

Peng, Y., Yu, G., Ni, W., Lv, Z., Jiang, Y., & Chen, J.

(2018). Design and development of intelligent

operation and maintenance training system for

substation based on augmented reality. 2017 Chinese

Automation Congress (CAC), Jinan, China.

Peres, F. F., Scheer, S., & de Faria, É. F. (2018). A

taxonomy of tasks in dam cracks surveillance for

augmented reality application. International Journal of

Advanced Engineering Research Science, 5(10).

https://doi.org/10.22161/ijaers.5.10.24

Queiroz, A. R. S., & Senger, E. C. (2012). A natureza e os

riscos do arco elétrico, EPIs e proteção contra arco

elétrico. Retrieved 10/01/2020 from https://www.o

setoreletrico.com.br/capitulo-i-a-natureza-e-os-riscos-

do-arco-eletrico/

Silva, A. C., Mattioli, L. R., Peres, I. C. S., Cardoso, A., do

Prado, P. R. M., & Newton, J. (2013). Uso da Engine

de Jogos Unity3D para Sistemas de Realidade Virtual

Aplicado a Monitoramento e Controle de Subestações

de Energia Elétrica. https://doi.org/10.13140/

2.1.1696.0807

Souza-Junior, V. D. D., Mendes, I. A. C., Tori, R., Marques,

L. P., Mashuda, F. K. K., Hirano, L. A. F., & Godoy, S.

D. (2020). VIDA-Enfermagem v1. 0: realidade virtual

imersiva na coleta de sangue a vácuo em adulto. Revista

Latino-Americana de Enfermagem, 28. https://doi.org/

10.1590/1518-8345.3685.3263

Souza, S., & Michaloski, A. O. (2017). A Norma

Regulamentadora Nº10 e a aplicação em instalações

elétricas e seus entornos. Revista Técnico-Científica,

5(6), 145-152.

Torres Filho, F., Vieira, M. d. F. Q., & Soares, W. L. F.

(2013). Processo para o desenvolvimento de cenários

de treinamento para ambientes Virtuais 3D. Simpósio

Brasileiro de Automação Inteligente.

Wiederhold, B. K., & Bouchard, S. (2014). Advances in

virtual reality and anxiety disorders. Springer.

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

540