An Agri-Food Supply Chain Traceability Management System based on

Hyperledger Fabric Blockchain

Angelo Marchese and Orazio Tomarchio

a

Dept. of Electrical Electronic and Computer Engineering, University of Catania, Catania, Italy

Keywords:

Blockchain, Hyperledger Fabric, Agri-Food Supply Chain.

Abstract:

Consumers are nowadays very interested in food product quality and safety. It is challenging to track the prove-

nance of data and maintain its traceability throughout the whole supply chain network without an integrated

information system. For this purpose, Agriculture and Food (Agri-Food) supply chains are becoming complex

systems which are responsible, in addition to track and store orders and deliveries, to guarantee transparency

and traceability of the food production and transformation process. However, traditional supply chains are

centralized systems, mainly depending on a third party for trading and trusting purposes. In this paper we

propose a fully distributed approach, based on blockchain technology, to define a supply chain management

system able to provide quality, integrity and traceability of the entire supply chain process. A prototype based

on Hyperledger Fabric has been designed and developed in order to show the effectiveness of the approach

and the coverage of the main use cases needed in a supply chain network.

1 INTRODUCTION

The problem of agri-food supply chain management

is gaining more and more importance given the re-

cent attention for food quality and safety (Ray et al.,

2017; Li et al., 2014). One of the main problems is

to guarantee the traceability of products, providing

a complete view of the different phases of their har-

vesting, processing and distribution (Olsen and Borit,

2018; Dabbene et al., 2014; Bosona and Gebresenbet,

2013). Current supply chain management systems al-

low to automate the monitoring and collection of in-

formation related to the various activities within the

supply chain. In this way, the set of traceability in-

formation of a product allows the future consumer to

know the provenance of that product and the events

related to its entire life cycle from harvesting to retail.

However, most of today’s supply chains are man-

aged by centralized systems: members of such supply

chains rely on a centralized authority, more specif-

ically an information supervision center, to trans-

fer and share their information. These centralized

systems are often non-transparent, monopolistic and

asymmetric information systems. This can pose a

serious threat to the security and reliability of the

traceability information and make fraud, corruption

and data falsification easier. Furthermore, such cen-

a

https://orcid.org/0000-0003-4653-0480

tralized systems have limited scalability and a single

point of failure.

To deal with such issues, the usage of blockchain

technology in this domain has recently been proposed

to support the management of supply chain traceabil-

ity (Zhao et al., 2019; Antonucci et al., 2019; Galvez

et al., 2018). Blockchain technology in particular

offers cryptographic primitives to store data within

a distributed ledger, guaranteeing their immutability

and authenticity. This eliminates the need for sup-

ply chain members to trust a single entity to manage

their traceability information. Furthermore, being a

distributed system, the blockchain can solve the prob-

lems of limited scalability and single point of failure.

In this work we propose a complete model of a

blockchain based agri-food supply chain traceabil-

ity system and provide an implementation of a sys-

tem prototype to show the applicability of blockchain

technology in this domain. The proposed system in

particular allows supply chain members to store and

manage product-related traceability information in a

distributed and immutable way. An important compo-

nent of this system is the smart contract, a blockchain

primitive that allows to automate some of the man-

agement operations related to supply chain activities.

This smart contract offers some operations that al-

low to store and update traceability information and

to reconstruct a complete history of the transactions

648

Marchese, A. and Tomarchio, O.

An Agri-Food Supply Chain Traceability Management System based on Hyperledger Fabric Blockchain.

DOI: 10.5220/0010447606480658

In Proceedings of the 23rd International Conference on Enterprise Information Systems (ICEIS 2021) - Volume 2, pages 648-658

ISBN: 978-989-758-509-8

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

related to a product during its life cycle within the

supply chain. The implemented system also makes

it possible to associate rules with supply chain prod-

ucts, allowing the expression of product specific qual-

ity control mechanisms and to verify in an automated

way the regulatory compliance of products at runtime.

This last aspect has been taken into consideration in

our work, because in the context of agri-food supply

chains the regulatory aspects are of fundamental im-

portance to ensure food safety and quality, also tack-

ing into account that these aspects vary from a case to

another one and dynamically evolve over time (Chen

et al., 2015).

Our system was implemented using the Hyper-

ledger Fabric

1

blockchain, an emerging open-source

technology widely used also in other proposed ex-

amples of supply chain management systems (Wang

et al., 2018). In addition, the components of our sys-

tem are deployed in a cloud environment within a Ku-

bernetes

2

cluster, showing that, although our system

is a prototype, it can be easily migrated to a scalable

production environment.

The rest of the paper is organized as follows. In

Section 2, we provide a background of technologies

exploited for this work and present related works.

Section 3 presents the overall architecture of our

framework and provides some implementation details

about system components and the operations offered

by the smart contract. Section 4 discusses about an

example of usage of our system in a prototype envi-

ronment. Finally, Section 5 concludes the work.

2 BACKGROUND AND RELATED

WORK

This section provides some background information

about the technologies exploited in our work, such as

the blockchain technology and in particular the Hy-

perledger Fabric system. Then, after briefly outlin-

ing the advantages that would derive from their use to

support agri-food supply chain traceability systems,

some related work in the literature are discussed.

2.1 Blockchain Technology and

Hyperledger Fabric

Blockchain technology represents a particular class

of distributed systems and as such was born with the

aim of overcoming some of the problems related to

centralized systems (Kolb et al., 2020; Gamage et al.,

1

https://www.hyperledger.org/use/fabric

2

https://kubernetes.io/

2020). The application area in which the blockchain

was initially introduced is that of transactional sys-

tems, in particular electronic payment systems. That

is the case, for example, of the Bitcoin blockchain

(Nakamoto, 2008). However, today blockchain tech-

nology is increasingly being adopted in a lot of differ-

ent application domains.

In general, operations within a blockchain are car-

ried out by nodes connected to each other through a

peer-to-peer network. In public blockchains, like Bit-

coin, every node can participate in network operations

and can decide to exit at any time. Each node partic-

ipating in the blockchain maintains a local copy of

a distributed ledger which contains a set of append-

only logs that encode the status information of the

blockchain. More specifically, an ordered sequence of

blocks is stored inside the ledger. Each block consists

of an header and a body that contains an ordered list

of transactions which are validated and executed by

the peers of the network. To guarantee the immutabil-

ity and reliability of the data in the ledger, each block

of the sequence contains a cryptographic hash of the

previous block within a header field. In this way, a

malicious attempt to change the content of a block

would require to correspondingly modify the header

of all the following blocks in the sequence, which is

a computationally expensive task thanks to the non-

invertibility property of hash functions.

Hyperledger Fabric is an open-source blockchain

platform, which falls within the category of permis-

sioned blockchains (Androulaki et al., 2018). In a per-

missioned blockchain, only authorized peers can par-

ticipate in blockchain operations. Hyperledger Fab-

ric is a distributed operating system that runs appli-

cations written in general purpose programming lan-

guages, such as Go, Java, JavaScript, and Python.

It introduces the execute-order-validate blockchain

model for transaction processing unlike other tradi-

tional blockchain systems that use the order-execute

model. Like some other blockchains, Hyperledger

Fabric offers the smart contract primitive. A smart

contract is a combination of data and code that en-

codes a set of transformations on that data. It ex-

poses a set of operations that can be invoked by the

users of the blockchain with the aim of changing the

state of the distributed ledger. The concept of smart

contract therefore makes this kind of blockchain a

distributed execution environment of general purpose

programmable logic.

Thanks to the aforementioned properties,

blockchain technology is a good candidate to address

some of the actual problems related to traditional

centralized agri-food supply chain traceability sys-

tems. In particular, it can guarantee the transparency,

An Agri-Food Supply Chain Traceability Management System based on Hyperledger Fabric Blockchain

649

verifiability and immutability of traceability data,

simplifying the information sharing between the

supply chain entities often belonging to distinct ad-

ministrative organization. In this way the traceability

of the supply chain products can be guaranteed,

allowing the consumer to reconstruct the entire

product’s life cycle within the supply chain and to

verify its origin and authenticity. Finally, smart

contracts can be used to automate the supply chain

management and product quality control operations.

2.2 Related Work

In the literature there is a variety of works that pro-

pose the use of blockchain technology to build agri-

food supply chain management systems and in some

cases implementations of such systems are also pro-

posed. Some of these works are briefly described be-

low.

In (Malik et al., 2018) a permissioned blockchain

system, called ProductChain, is proposed. The sys-

tem is administered by a consortium of entities par-

ticipating in a generic food supply chain, including

governmental and regulatory entities. It stores prod-

uct traceability information made accessible to con-

sumers. The authors propose the use of a three-

tier sharded architecture that ensures reliability and

availability of data for consumers and scalability with

respect to transaction execution throughput. They

also propose the use of a transaction vocabulary and

the implementation of access control mechanisms to

manage read and write privileges on the blockchain.

(Wang et al., 2019) propose a product traceabil-

ity system based on the Ethereum blockchain and the

smart contract primitive. The system stores informa-

tion related to the products life cycle and also pro-

vides for the implementation of event-response mech-

anisms to verify the identities of both parties of all

transactions at the time of their submission, so that

their validity is guaranteed. All the events are kept in

the system permanently, so that any disputes can be

managed and the responsible for certain actions can

be traced.

In (Caro et al., 2018) the AgriBlockIoT is pro-

posed, a totally distributed and blockchain-based sup-

ply chain management system, able to integrate mul-

tiple IoT devices that collect and produce digital data

along the supply chain. To efficiently evaluate Agri-

BlockIoT, the authors defined a use case based on

the from-farm-to-fork model. This use case was then

implemented using two different blockchain systems,

namely Ethereum and Hyperledger Sawtooth.

(Casino et al., 2019) propose a distributed func-

tional model based on blockchain to create distributed

and automated traceability mechanisms for a generic

agri-food supply chain. To evaluate the feasibility of

the proposed model, a use case is presented. The ap-

plicability of the model is also illustrated through the

development of a fully functional smart contract and

a private blockchain.

(Feng Tian, 2017) propose a food supply chain

traceability system for real-time food tracing based

on HACCP (Hazard Analysis and Critical Control

Points), blockchain and Internet of Things, which

provides a platform that ensures openness, trans-

parency, neutrality, reliability and security for trace-

ability information. The proposed system uses

BigchainDB, which combines the key benefits of dis-

tributed databases and blockchain.

(Biswas et al., 2017) propose a blockchain-based

system to achieve the traceability of the activities that

occur within the supply chain related to wine produc-

tion. The proposed traceability system uses Multi-

Chain to implement a private blockchain.

Like the aforementioned research works, in our

work we propose a complete solution of a blockchain-

based agri-food traceability system, providing in par-

ticular a description of the architectural components,

the information model and the business logic of this

system. A distinctive contribution of our work, is the

capability to allow the specification of custom regula-

tions for supply chain products at runtime and to au-

tomate the validation of these regulations. Our frame-

work has addressed this aspect considering the hetero-

geneity of product regulations among supply chains

and the fact that these regulations change over time.

3 SYSTEM ARCHITECTURE

This section first provides a high-level description

of our blockchain-based system for agri-food supply

chain traceability, the objectives that guided its design

and its general architecture. Then the business logic

of the system is described, focusing on the smart con-

tract operations. Finally some implementation details

of the developed prototype are provided.

3.1 General Architecture

The proposed system is designed to manage the trace-

ability information of products and activities related

to one or more agri-food supply chains. The main

objective is to allow to reconstruct the entire flow of

activities and transactions related to a certain product

from origin to the end consumer. The system has to

automate all those operations related to product qual-

ity control and regulatory compliance. It has to be

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

650

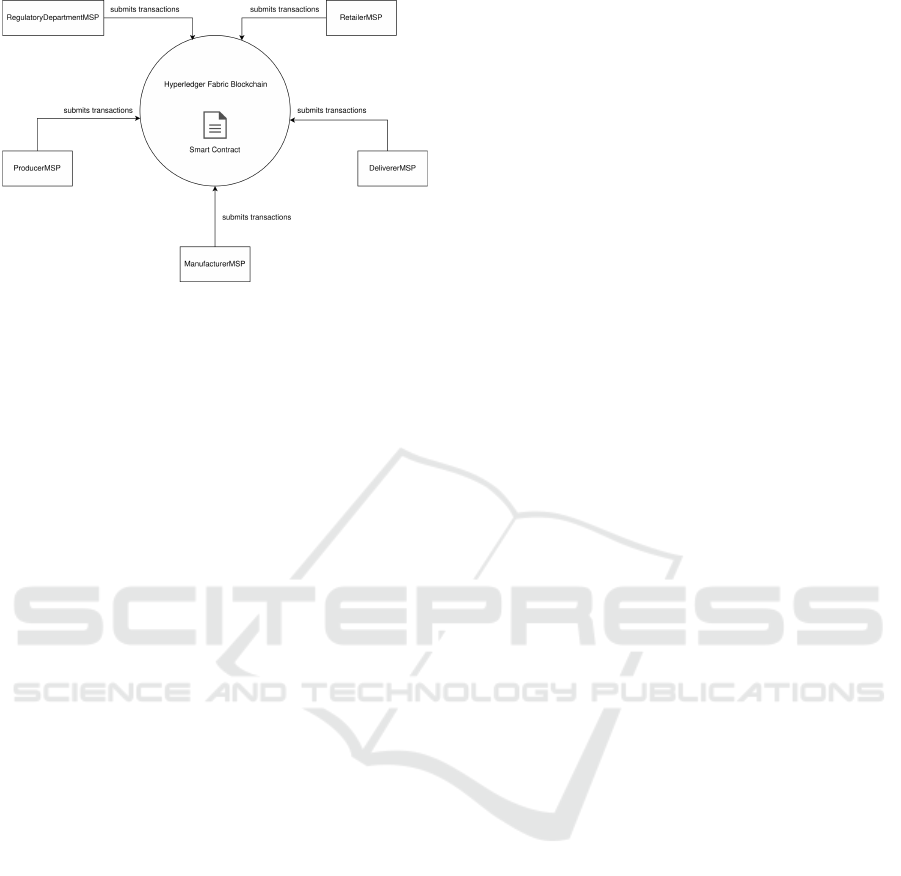

Figure 1: Typical agri-food supply chain scenario.

able to dynamically adapt to changes in laws and reg-

ulations. It should also be scalable, able to handle

an ever-increasing amount of information. Finally,

the system has to guarantee reliability and availabil-

ity, especially when dealing with environments char-

acterized by continuous flows of transactions.

The fundamental part of the framework consists of

a permissioned blockchain, implemented through the

Hyperledger Fabric framework. In this blockchain,

the core of the system’s business logic is executed in

the form of a smart contract. The smart contract of-

fers several operations that allow users of the system

to add and modify information in the blockchain in

a secure and traceable way. Users of the system are

the supply chain members and the regulatory depart-

ments. The former add and modify information re-

lated to their products, while the latter deal with the

management and regulation aspects of supply chains.

More specifically, the entities participating in the sys-

tem operations are user organizations, where each

user is identified by a certificate issued by a certifi-

cation authority associated with the organization to

which the user belongs. Since the blockchain is per-

missioned, only a well-defined set of organizations

can participate in the system operations. The inter-

action between users and the blockchain takes place

through a client application that runs within an appli-

cation server and the interaction with the latter takes

place through a frontend application that is hosted by

a web server. Each organization has its own applica-

tion server and web server.

Each organization has its own role. This role de-

fines the interactions of this organization with the sys-

tem and the operations it can perform. According to

common models of agri-food supply chain described

in literature (Wang et al., 2019; Feng Tian, 2017) we

consider the following roles:

• Producer: organization that requires the registra-

tion of one or more primary products (i.e. prod-

ucts whose batches do not derive from any other

batch). If a registration request is accepted, this

organization can register batches associated with

the registered product or products in the system.

• Manufacturer: organization that requires the reg-

istration of one or more derived products (i.e.

products whose batches derive from batches of

other primary or derived products). If a registra-

tion request is accepted this organization can reg-

ister batches associated with the registered prod-

uct or products in the system, specifying a list of

batches from which the registered batch derives.

• Deliverer: organization that buys batches from

organizations and resells them to other organiza-

tions.

• Retailer: organization that sells products to con-

sumers.

• Regulatory Department: organization that man-

ages and monitors the activities within the vari-

ous supply chains. More specifically, an organiza-

tion with the role of Regulatory Department adds

product types to the system, associating them with

rules and assigning roles to the various organiza-

tions.

In the following, while describing the behaviour

of our framework, we refer to a scenario involving five

organizations, one for each of the roles listed above,

which is depicted in Figure 1.

3.2 Information Model

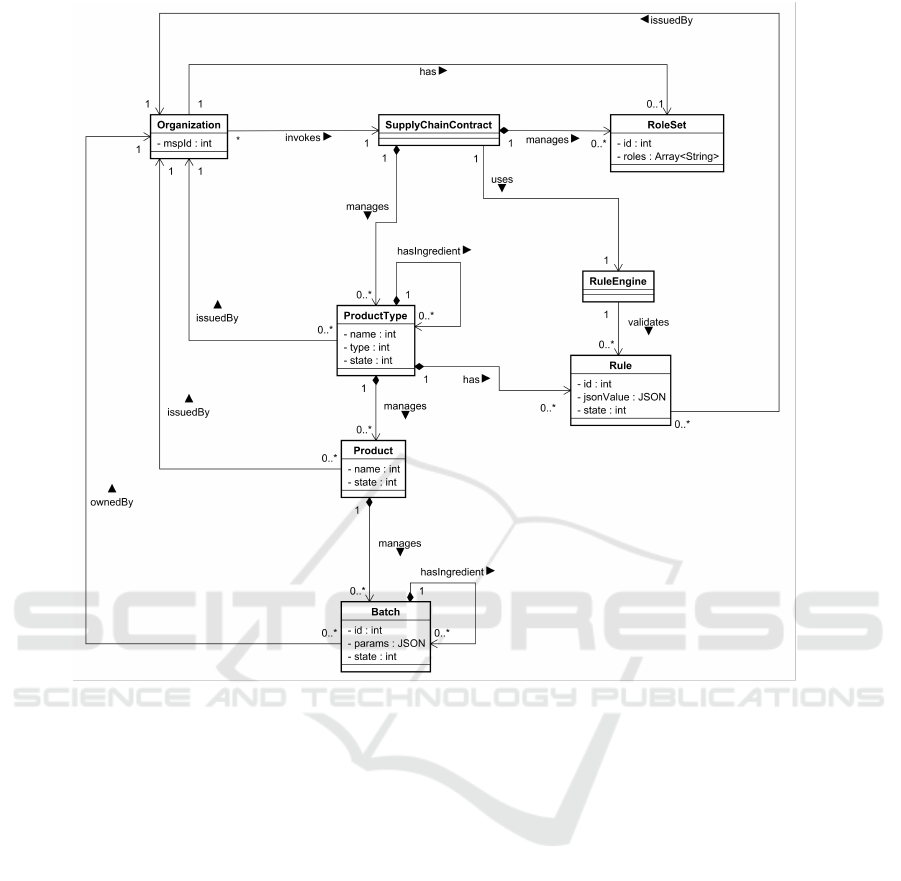

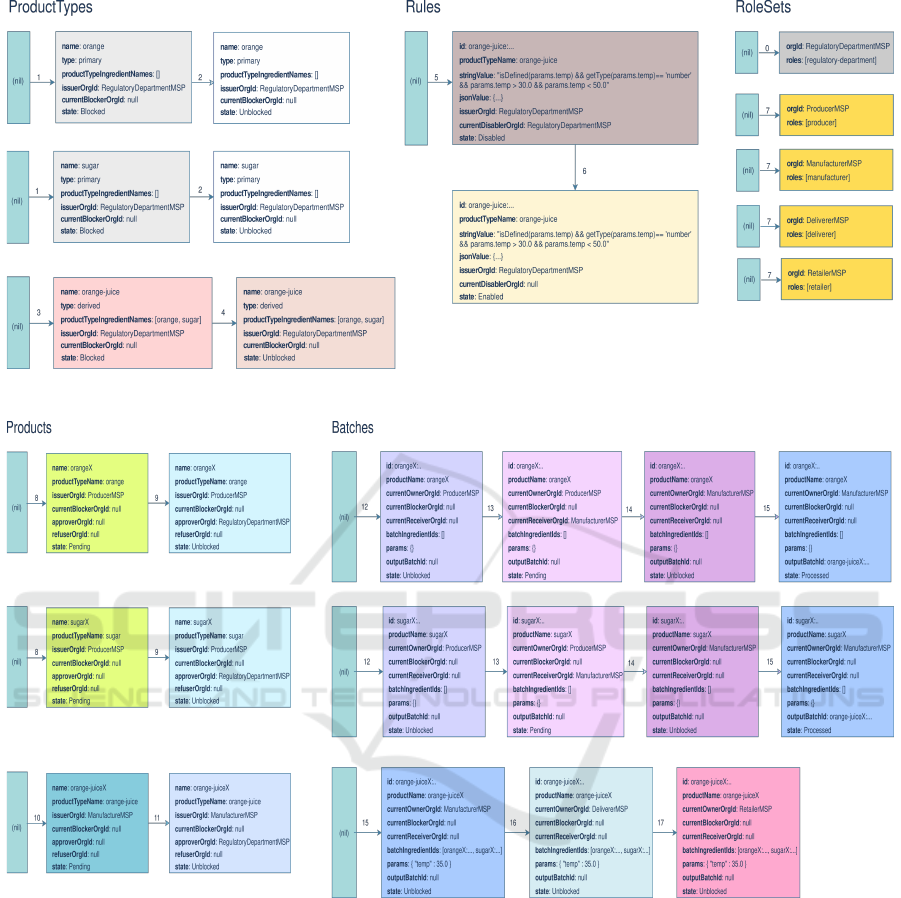

Figure 2 shows a domain model of the system’s busi-

ness logic. In this context, when we discuss about the

system’s business logic we refer to the business logic

layer performed by the smart contract that is located

within the blockchain. This business logic is exposed

to the users of the system through operations that can

be requested and executed. Client and frontend ap-

plications are nothing more than interfaces through

which users interact with the smart contract. Conse-

quently, from a functional point of view, it is possible

to represent the interaction between users and smart

contract as a direct interaction and assume that the

user directly invokes a smart contract operation.

Each Organization of the system is identified by

a unique identifier and can be associated with a Role-

Set, which represents a list of roles. A RoleSet associ-

ated with an organization defines the set of smart con-

tract operations the organization can invoke. An or-

ganization playing the role of Regulatory Department

can register one or more product types in the system.

A ProductType is uniquely identified by a name and

can be either primary or derived. In case the product

An Agri-Food Supply Chain Traceability Management System based on Hyperledger Fabric Blockchain

651

Figure 2: Domain model of the business logic.

type is derived, it has a list of product types ingredi-

ents which it is derived from. This means that any

Batch associated with this product type must have a

list of batches ingredients whose respective product

types are in the list of product types ingredients. It is

possible to associate one or more rules to a product

type, where each Rule represents a set of conditions

that have to be respected when registering batches as-

sociated with that product type. At the moment of

a batch registration these rules are validated using a

RuleEngine.

A ProductType may be associated with one or

more Products, for each of which an owner organi-

zation requires the registration in the system. A re-

quest for the registration of a product can be accepted

by an organization playing the role of Regulatory De-

partment and from that moment the organization that

owns the product can register batches of that product

in the system. A product is uniquely identified by a

name.

A Product may be associated with one or more

Batches that are registered by the organization that

owns that product. A batch is uniquely identified by

an ID and a set of parameters as specified at registra-

tion time. When registering a batch associated with a

derived product type, it is necessary to specify a list

of batches ingredients from which this batch derives.

This list must be consistent with the list of product

types ingredients associated with the product type of

the registered batch. A batch can be transferred from

one organization to another one and an organization

that owns a batch can use that batch as an ingredient

when registering a new batch. The domain model de-

picted in Figure 2 also shows that each resource in the

system has a state. It provides information on the cur-

rent conditions of that resource, determines the oper-

ations that can be performed on it and the subsequent

states in which it can transit.

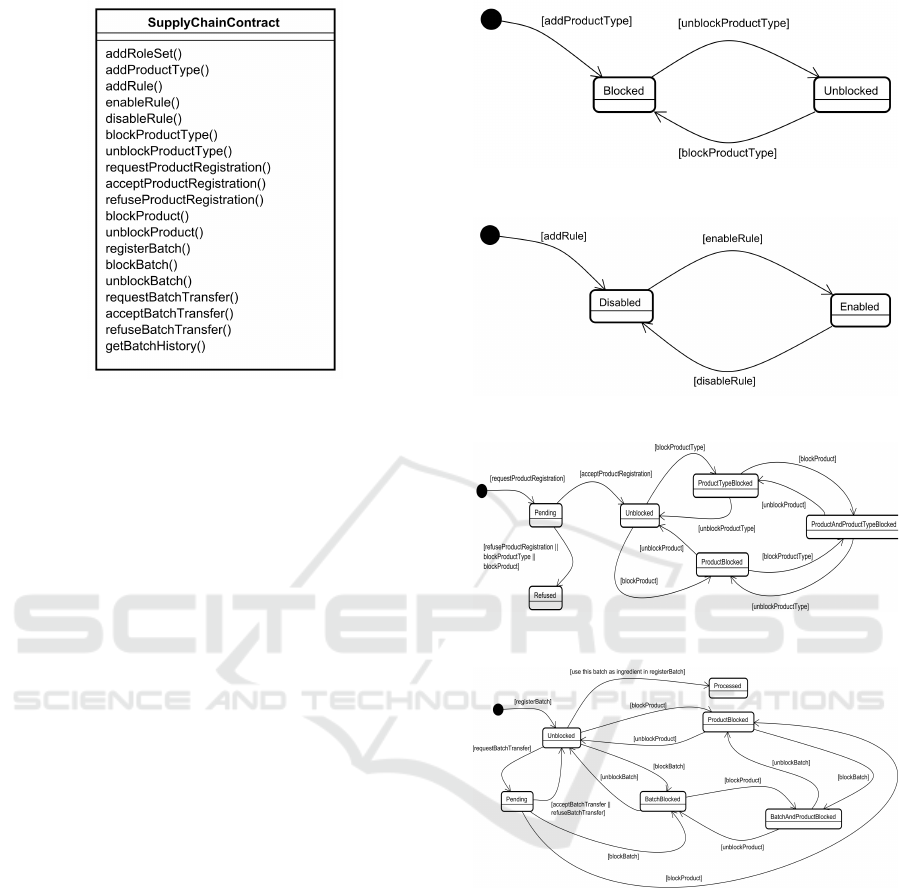

3.2.1 Smart Contract Operations

In this Section we describe more in detail the opera-

tions provided by the smart contract, which are sum-

marized in Figure 3, together with the state transitions

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

652

Figure 3: Smart contract operations.

of the different resource types caused by the execution

of these operations, shown respectively in Figures 4,

5, 6 and 7.

A new product type can be registered by an orga-

nization with role of Regulatory Department with the

operation addProductType() and initially it starts from

the state Blocked. In this state all the products related

to this product type are also blocked and no organi-

zation can request the registration of a new product

for this product type. From the state Blocked a prod-

uct type can be unblocked by an organization with

role of Regulatory Department with the operation un-

blockProductType(), causing it to pass to the state Un-

blocked.

A new rule, associated with a product type, can

be registered by an organization with role of Regu-

latory Department with the operation addRule() and

initially it starts from the state Disabled. In this state,

at the moment of registration of a new batch of the

product type with which this rule is associated, the

rule is not validated. From the state Disabled a rule

can be enabled by an organization with role of Reg-

ulatory Department with the operation enableRule(),

causing it to pass to the state Enabled. The ability

to add, enable and disable custom rules for a prod-

uct type and to do it at runtime allows to implement

product-specific quality control mechanisms that can

change over time. This aspect is of fundamental im-

portance due to the requirement of today’s agri-food

supply chains to establish products specific regula-

tions that can frequently evolve over time.

Organizations with role of Producer and those

with role of Manufacturer can request, calling the op-

eration requestProductRegistration(), the registration

of a new product associated with a primary and de-

rived product type respectively. An organization with

Figure 4: State diagram of resource type ProductType.

Figure 5: State diagram of resource type Rule.

Figure 6: State diagram of resource type Product.

Figure 7: State diagram of resource type Batch.

role of Regulatory Department can accept the regis-

tration request for a new product with the operation

acceptProductRegistration(), causing the product to

switch to the state Unblocked, or it can reject the re-

quest with the operation refuseProductRegistration(),

causing the product to switch to the state Refused. A

product can be directly blocked by the owner organi-

zation or by an organization with role of Regulatory

Department with the operation blockProduct(). While

a product is blocked all the batches related to it are

also blocked and no new batch for this product can be

registered.

The owner organization of a product can register,

An Agri-Food Supply Chain Traceability Management System based on Hyperledger Fabric Blockchain

653

with the operation registerBatch(), new batches as-

sociated with it. A new registered batch starts from

the state Unblocked. An organization that wants to

purchase a batch can submit a transfer request for

this batch with the operation requestBatchTransfer(),

causing it to pass to the state Pending. The owner or-

ganization can reject the transfer request with the op-

eration refuseBatchTransfer() or it can accept the re-

quest with the operation acceptBatchTransfer(), caus-

ing the batch to change owner. A batch can be used

as an ingredient for another batch and in this case it

passes to the state Processed. A batch can be directly

blocked by the owner organization or by an organi-

zation with role of Regulatory Department with the

operation blockBatch(). While a batch is blocked it

cannot be transferred to other organizations and can-

not be used as an ingredient for another batch.

Finally, the operation getBatchHistory() allows to

obtain a complete history of the state transitions re-

lated to a batch. In this way any organization can view

the entire batch life cycle and the chain of its owners.

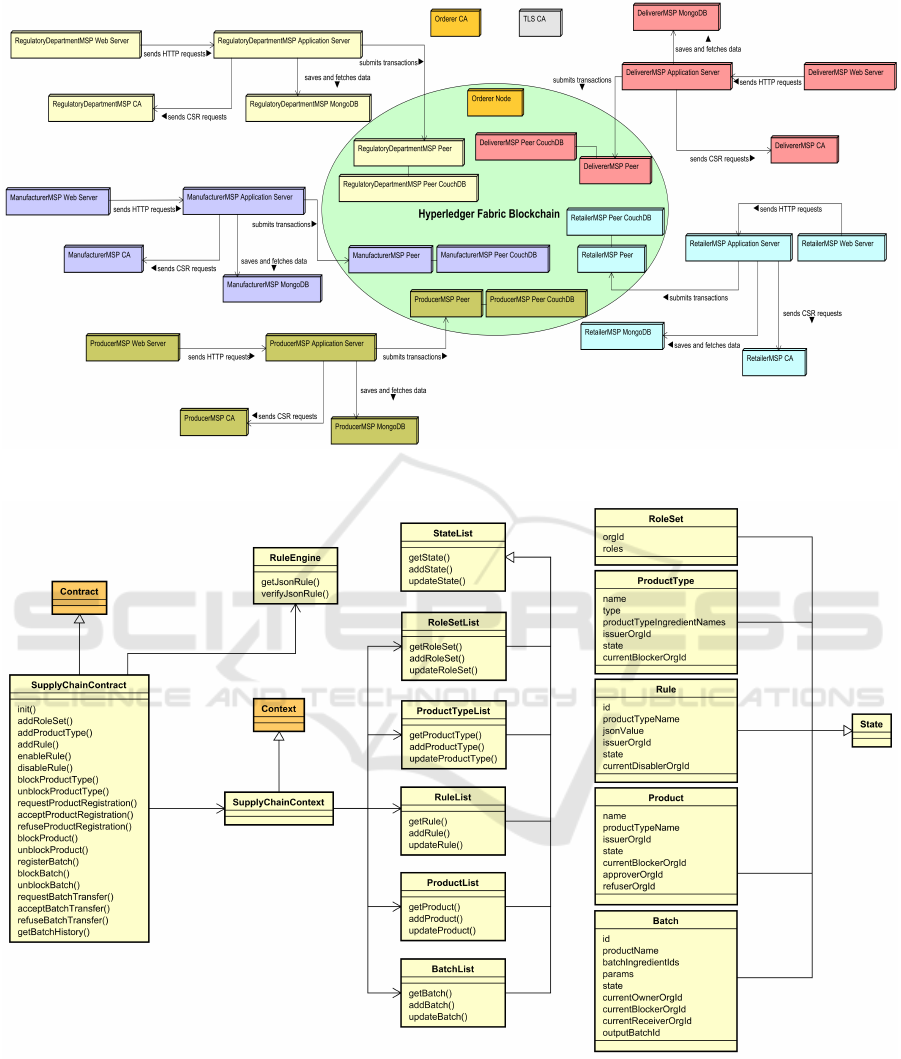

3.3 Implementation Details

The designed framework has been implemented and

a prototype has been deployed within a Kubernetes

cluster in order to emulate the distributed nature of the

whole system, and to increase its portability and in-

teroperability with existing organization IT systems.

Figure 8 shows the system architecture in terms of

the main components composing our framework: in

particular, it shows the components for each organi-

zation of the scenario presented in Section 3.1, plus a

set of components making up the Hyperledger Fabric

blockchain.

Each of the participating organizations runs a peer

node that maintains information about its local copy

of the distributed ledger in a dedicated CouchDB

database node. The management of blockchain trans-

actions ordering is handled by an Orderer node. Each

organization runs its own certificate authority that is-

sues certificates for that organization’s users and peer

nodes. In addition, each organization runs an applica-

tion server which executes the client application logic

to submit transactions to the blockchain, a MongoDB

database where the application server keeps user data

and a web server that hosts a frontend application that

allows users to interact with the application server.

The system also runs a certificate authority that issues

TLS certificates. These certificates are used by users

and system nodes to secure communications. Each

component of the system runs on a Docker container

inside a Kubernetes Pod that is managed by a Kuber-

netes Deployment. Each Pod is exposed to the re-

maining components of the cluster through a specific

Kubernetes Service.

The core of the system’s business logic is repre-

sented by a smart contract. This smart contract was

implemented using the Node.js Fabric SDK. Figure 9

shows a simplified class diagram of the smart con-

tract. The SupplyChainContract class extends the

Contract class, which is part of the SDK, and repre-

sents a controller class for the smart contract itself.

Indeed, this class implements methods that, except

for the init() method, represent the smart contract op-

erations that have been illustrated previously in Sec-

tion 3.2.1. These operations allow users to create and

modify resources in the blockchain ledger. The init()

method is the first method of this class that is invoked

as soon as the smart contract is deployed and allows

to inizialize it. The SupplyChainContract class has

a reference to an object of the SupplyChainContext

class, which extends the SDK Context class. This ob-

ject allows to read and modify the ledger state and to

retrieve information about a transaction, such as the

identity of the user who submitted that transaction.

More specifically, it has a reference to the RoleSetList,

ProductTypeList, RuleList, ProductList and BatchList

classes. These classes extend the StateList class and

represent repositories that allow to create, modify and

retrieve objects of the RoleSet, ProductType, Rule,

Product and Batch classes respectively. These latter

classes extend the State class and represent an abstrac-

tion layer to interact with the corresponding resources

in the ledger. Finally the SupplyChainContract class

has a reference to the RuleEngine class which imple-

ments the getJsonRuleFromString() and verifyJson-

Rule() methods. The first is called during the exe-

cution of the addRule() method of the SupplyChain-

Contract class and starting from the string represen-

tation of a rule, validates the rule string format and

returns the corresponding JSON object of that rule

which then is stored in the ledger. The latter is called

during the execution of the registerBatch() method of

the SupplyChainContract class and validates a rule on

the parameters of a batch at the time of its registration.

4 USE CASE

This section illustrates an example of usage of our

system in the context of the scenario presented in Sec-

tion 3.1 and depicted in Figure 1 where five differ-

ent organization (one for each of the defined role) are

present.

The use case demonstrates the system’s ability to

automate supply chain operations, maintain traceabil-

ity information and provide a complete life cycle his-

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

654

Figure 8: System components architecture.

Figure 9: Smart contract class diagram.

tory of each batch. Figures 10 and 11 summarize all

the steps of this use case and show how resources

are created and updated within the blockchain ledger.

For each resource type, different resources are shown

(each one in a different row). For each resource, rep-

resented by a box in the Figures, the main attributes

and their values are shown. Each step is associated

with a number and a colour and the boxes with that

colour represent the state of the corresponding re-

sources after the execution of that step.

First of all, when the smart contract is initialized,

the role of Regulatory Department is associated with

An Agri-Food Supply Chain Traceability Management System based on Hyperledger Fabric Blockchain

655

Figure 10: Use case steps from 0 to 7.

Figure 11: Use case steps from 8 to 17.

the organization RegulatoryDepartmentMSP (step 0).

With this role the organization RegulatoryDepart-

mentMSP can perform administrative operations.

The RegulatoryDepartmentMSP organization reg-

isters the primary product types orange and sugar

(step 1). These product types are initially in the state

Blocked. So in this state no organization can request

the registration for a product related to these product

types. Then the RegulatoryDepartmentMSP organi-

zation unblocks the two product types causing them to

pass to the state Unblocked (step 2). After registering

the product types orange and sugar the Regulatory-

DepartmentMSP organization can register the derived

product type orange-juice, specifying the two primary

product types as ingredients (step 3). Also in this case

the product type orange-juice starts from the state

Blocked and after the RegulatoryDepartmentMSP un-

blocks it, this product type passes to the state Un-

blocked (step 4).

The RegulatoryDepartmentMSP organization

then registers a new rule associated with the product

type orange-juice (step 5). This rule requires that

batches related to this product type contain, among

the parameters, a temperature parameter with a

value that must fall within a specific range. The

rule is initially in the state Disabled and in this state

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

656

the rule is not activated for batch validation. The

RegulatoryDepartmentMSP organization enables the

rule causing it to pass to the state Enabled (step 6).

The RegulatoryDepartmentMSP organization

then associates the ProducerMSP, ManufacturerMSP,

DelivererMSP and RetailerMSP organizations with

the roles of Producer, Manufacturer, Deliverer

and Retailer respectively (step 7). In this way the

ProducerMSP and ManufacturerMSP organizations

can request the registration for a primary and derived

product respectively. Moreover the DelivererMSP

organization can buy and resell batches from and to

other organizations and the RetailerMSP organization

can only buy batches.

After having gained the role of Producer, the Pro-

ducerMSP organization requests the registration of

the products orangeX and sugarX associated with the

product types orange and sugar respectively (step 8).

This products are initially in the state Pending and

after the RegulatoryDepartmentMSP organization ac-

cepts the registration requests they pass to the state

Unblocked (step 9). In the same way the Manufactur-

erMSP organization, after having gained the role of

Manufacturer, requests the registration of the product

orange-juiceX associated with the product orange-

juice (step 10). This product is initially in the state

Pending and after the RegulatoryDepartmentMSP or-

ganization accepts the registration request it pass to

the state Unblocked (step 11).

The ProducerMSP organization then registers two

batches associated with the products orangeX and

sugarX respectively (step 12). These batches are ini-

tially in the state Unblocked. The ManufacturerMSP

organization submits a transfer request for the two

batches causing them to pass to the state Pending (step

13). After the ProducerMSP organization accepts the

transfer requests, the ManufacturerMSP organization

becomes the new owner of the two batches and these

return to the state Unblocked (step 14). The Manufac-

turerMSP organization can then register a batch asso-

ciated with the product orange-juiceX, using the new

acquired batches which pass to the state Processed

(step 15). In the registration operation the Manufac-

turerMSP organization specify a value for the temper-

ature parameter compatible with the range specified in

the rule associated with the product type orange-juice.

The DelivererMSP organization then submits a

transfer request for the new registered batch and the

ManufacturerMSP organization accepts the request

causing the DelivererMSP organization to become the

new owner (step 16). Finally in the same way the

RetailerMSP organization submits a transfer request

for the same batch and the DelivererMSP organiza-

tion accepts the request causing the RetailerMSP or-

ganization to become the new owner (step 17).

The realization of the use case, demonstrates that

the proposed system supports all the basic lifecycle of

an agri-food product, from its origin to the end con-

sumer. The simple rules implemented, also show the

flexibility of the framework to add any kind of rule at

runtime in order to cope with specific quality control

strategies needed by any of the organization involved

in the supply chain.

5 CONCLUSIONS

In this work we proposed a complete model of a

blockchain-based agri-food supply chain traceability

system, also providing a prototype implementation.

The use of blockchain technology eliminates the need

for supply chain members to trust a single entity to

manage supply chain activities and store traceabil-

ity information. Furthermore, this fully distributed

approach solves the problems of limited scalability

and single point of failure. The proposed system al-

lows to automate supply chain management opera-

tions and maintain traceability information in a se-

cure and immutable way. Moreover, the possibility

to add rules at runtime allows the implementation of

product-specific quality control mechanisms in a flex-

ible way. Finally, the system provides a complete

view of the different phases of harvesting, process-

ing and distribution to which batches of product are

subject allowing to reconstruct the entire life cycle of

each batch and obtain provenance information.

REFERENCES

Androulaki, E., Barger, A., Bortnikov, V., Cachin, C.,

Christidis, K., De Caro, A., Enyeart, D., Ferris,

C., Laventman, G., Manevich, Y., Muralidharan, S.,

Murthy, C., Nguyen, B., Sethi, M., Singh, G., Smith,

K., Sorniotti, A., Stathakopoulou, C., Vukoli

´

c, M.,

Cocco, S. W., and Yellick, J. (2018). Hyperledger fab-

ric: A distributed operating system for permissioned

blockchains. In Proceedings of the Thirteenth EuroSys

Conference, EuroSys ’18.

Antonucci, F., Figorilli, S., Costa, C., Pallottino, F., Raso,

L., and Menesatti, P. (2019). A review on blockchain

applications in the agri-food sector. Journal of the Sci-

ence of Food and Agriculture, 99(14):6129–6138.

Biswas, K., Muthukkumarasamy, V., and Lum, W. (2017).

Blockchain based wine supply chain traceability sys-

tem. In Future Technologies Conference (FTC 2017),

pages 56–62.

Bosona, T. and Gebresenbet, G. (2013). Food traceability as

an integral part of logistics management in food and

An Agri-Food Supply Chain Traceability Management System based on Hyperledger Fabric Blockchain

657

agricultural supply chain. Food Control, 33(1):32 –

48.

Caro, M. P., Ali, M. S., Vecchio, M., and Giaffreda, R.

(2018). Blockchain-based traceability in agri-food

supply chain management: A practical implementa-

tion. In 2018 IoT Vertical and Topical Summit on Agri-

culture - Tuscany (IOT Tuscany), pages 1–4.

Casino, F., Kanakaris, V., Dasaklis, T., Moschuris, S., and

Rachaniotis, N. (2019). Modeling food supply chain

traceability based on blockchain technology. IFAC-

PapersOnLine, 52:2728–2733.

Chen, K., xin WANG, X., and ying SONG, H. (2015).

Food safety regulatory systems in europe and china:

A study of how co-regulation can improve regula-

tory effectiveness. Journal of Integrative Agriculture,

14(11):2203 – 2217.

Dabbene, F., Gay, P., and Tortia, C. (2014). Traceability

issues in food supply chain management: A review.

Biosystems Engineering, 120:65 – 80.

Feng Tian (2017). A supply chain traceability system for

food safety based on haccp, blockchain internet of

things. In 2017 International Conference on Service

Systems and Service Management, pages 1–6.

Galvez, J. F., Mejuto, J., and Simal-Gandara, J. (2018).

Future challenges on the use of blockchain for food

traceability analysis. TrAC Trends in Analytical

Chemistry, 107:222 – 232.

Gamage, H. T. M., Weerasinghe, H. D., and Dias, N. G. J.

(2020). A survey on blockchain technology con-

cepts, applications, and issues. SN Computer Science,

1(2):114.

Kolb, J., AbdelBaky, M., Katz, R. H., and Culler, D. E.

(2020). Core concepts, challenges, and future direc-

tions in blockchain: A centralized tutorial. ACM Com-

put. Surv., 53(1).

Li, D., Wang, X., Chan, H. K., and Manzini, R. (2014).

Sustainable food supply chain management. Interna-

tional Journal of Production Economics, 152:1 – 8.

Sustainable Food Supply Chain Management.

Malik, S., Kanhere, S. S., and Jurdak, R. (2018). Pro-

ductChain: Scalable blockchain framework to sup-

port provenance in supply chains. In NCA 2018 -

2018 IEEE 17th International Symposium on Network

Computing and Applications.

Nakamoto, S. (2008). Bitcoin: A Peer-to-Peer Electronic

Cash System.

Olsen, P. and Borit, M. (2018). The components of a food

traceability system. Trends in Food Science and Tech-

nology, 77:143 – 149.

Ray, Z., Xun, X., and Lihui, W. (2017). Food supply chain

management: systems, implementations, and future

research. Industrial Management & Data Systems,

117(9):2085–2114.

Wang, S., Li, D., Zhang, Y., and Chen, J. (2019). Smart

contract-based product traceability system in the sup-

ply chain scenario. IEEE Access, 7:115122–115133.

Wang, Y., Han, J. H., and Beynon-Davies, P. (2018). Un-

derstanding blockchain technology for future supply

chains: a systematic literature review and research

agenda. Supply Chain Management: An International

Journal, 24.

Zhao, G., Liu, S., Lopez, C., Lu, H., Elgueta, S., Chen,

H., and Boshkoska, B. M. (2019). Blockchain tech-

nology in agri-food value chain management: A syn-

thesis of applications, challenges and future research

directions. Computers in Industry, 109:83 – 99.

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

658