Lead Time Forecasting with Machine Learning Techniques for a

Pharmaceutical Supply Chain

Maiza Biazon de Oliveira

1 a

, Giorgio Zucchi

2,3 b

, Marco Lippi

4 c

, Douglas Farias Cordeiro

5 d

,

N

´

ubia Rosa da Silva

1,6 e

and Manuel Iori

4 f

1

Special Academic Engineering Unit, Department of Production Engineering, Federal University of Goi

´

as,

St. Dr. Lamartine Pinto de Avelar, 1120, 75704020, Catal

˜

ao, Goi

´

as, Brazil

2

Fondazione Marco Biagi, University of Modena and Reggio Emilia, Largo Marco Biagi 10, 41121 Modena, Italy

3

R&D Department, Coopservice S.Coop.p.A, Via Rochdale 5, 42122 Reggio Emilia, Italy

4

Dipartimento di Scienze e Metodi dell’Ingegneria, University of Modena and Reggio Emilia,

Via Amendola 2, Pad. Morselli, 42122 Reggio Emilia, Italy

5

Faculty of Information and Communication, Federal University of Goi

´

as, Campus Samambaia,

74690900, Goi

ˆ

ania, Goi

´

as, Brazil

6

Institute of Biotechnology, Federal University of Goi

´

as, St. Dr. Lamartine Pinto de Avelar,

1120, 75704020, Catal

˜

ao, Goi

´

as, Brazil

Keywords:

Lead Time Forecasting, Machine Learning, Pharmaceutical Supply Chain.

Abstract:

Purchasing lead time is the time elapsed between the moment in which an order for a good is sent to a supplier

and the moment in which the order is delivered to the company that requested it. Forecasting of purchasing

lead time is an essential task in the planning, management and control of industrial processes. It is of particular

importance in the context of pharmaceutical supply chain, where avoiding long waiting times is essential to

provide efficient healthcare services. The forecasting of lead times is, however, a very difficult task, due to

the complexity of the production processes and the significant heterogeneity in the data. In this paper, we use

machine learning regression algorithms to forecast purchasing lead times in a pharmaceutical supply chain,

using a real-world industrial database. We compare five algorithms, namely k-nearest neighbors, support

vector machines, random forests, linear regression and multilayer perceptrons. The support vector machines

approach obtained the best performance overall, with an average error lower than two days. The dataset used

in our experiments is made publicly available for future research.

1 INTRODUCTION

Long waiting times for service interventions are a

recurring feature in the health sector, especially for

public services. Clearly, timely treatments and drug

administrations are crucial factors for improving the

quality of healthcare services, and often also for

saving the lives of patients, mainly in emergen-

cies (Brown et al., 2016; Tetteh, 2019). The delay

for medical interventions, whether through medica-

tion, diagnosis or surgical procedures, can indeed ag-

a

https://orcid.org/0000-0002-8981-1314

b

https://orcid.org/0000-0002-5459-7290

c

https://orcid.org/0000-0002-9663-1071

d

https://orcid.org/0000-0002-5187-0036

e

https://orcid.org/0000-0003-1982-5144

f

https://orcid.org/0000-0003-2097-6572

gravate pathologies, given the possibility of deterio-

ration of health conditions over time. Longer wait-

ing times for medical intervention can increase read-

mission rates as well (Moscelli et al., 2016). Nowa-

days, this is even more crucial because of the recent

COVID-19 pandemic, which is causing an increase

in the number of pharmaceutical products urgently

required by the many patients affected by the dis-

ease (Harapan et al., 2020).

Among other factors, long waiting times for re-

ceiving medicines can be associated with delay in

the administrative packaging, logistic problems with

tracking and delivery (Haugh, 2014) and several other

factors that could be outside the control of patients

or healthcare professionals. Within this scenario, the

analysis and proposition of measures to reduce wait-

ing times for all possible related factors is important

in healthcare policy guidelines (Moscelli et al., 2016).

634

Biazon de Oliveira, M., Zucchi, G., Lippi, M., Cordeiro, D., Rosa da Silva, N. and Iori, M.

Lead Time Forecasting with Machine Learning Techniques for a Pharmaceutical Supply Chain.

DOI: 10.5220/0010434406340641

In Proceedings of the 23rd International Conference on Enterprise Information Systems (ICEIS 2021) - Volume 1, pages 634-641

ISBN: 978-989-758-509-8

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

The availability of medicines in healthcare service

networks, pharmacies and hospitals is directly related

to the lead time of the supply chain (Tetteh, 2019).

Our work is motivated by the activity of a logistic

company, Coopservice group, that receives the phar-

maceutical products from the suppliers and then or-

ganizes the shipping, when needed, to the healthcare

facilities. To organize the service in the best possi-

ble way, it is crucial for the company to correctly

estimate the purchasing lead time, that is, the time

that is elapsed between the moment in which an or-

der for a good is sent to a supplier and the moment

in which the good is delivered to the company. Cor-

rectly forecasting this purchasing lead time (lead time

for short, in the following) in the supply chain of the

pharmaceutical sector is a crucial task, as it largely

affects the whole industrial process of the healthcare

services. In addition, proper estimation of lead time

is a critical parameter in the relationship between the

management process and the customer (Noori-Daryan

et al., 2019), being lead time one of the most impor-

tant performance indicators for the management of

manufacturing and service production processes (Kim

et al., 2014). Furthermore, accurate forecasting of

lead times can assist in optimizing the production pro-

cesses, by more accurately selecting the needed quan-

tities and thus shortening the overall production times

(Gyulai et al., 2018).

Besides, lead time prediction is a crucial aspect

to keep under control in the pharmaceutical supply

chain, because sometimes having the medicine avail-

able at the right time can save lives. Lead time fore-

casting could allow the pharmaceutical companies to

predict and to avoid possible out of stock, caused by

a supplier. Besides, based on the lead time, it is pos-

sible to evaluate the different suppliers and select the

best ones. In addition, with a good prediction it is

possible for the pharmaceutical companies to define

different level of security stock of the goods for each

month, making the procurement process leaner and

more cost effective.

However, lead time forecasting is an extremely

challenging task. In general, the estimation of lead

times from historical data has been a recurrent issue in

the literature since the 1960s, and even in recent years

some traditional systems simply obtain lead time by

computing average values based on historical data,

with the result of deficiencies in production planning

and control (Lingitz et al., 2018). The proposed ap-

proaches in this research field can be divided into con-

ventional methods and intelligent methods, with the

former not using artificial intelligence and the latter

exploiting data mining and machine learning. In both

cases, data used for experimental evaluation can be

real and/or simulated. In this research, we exploit in-

telligent methods, leaving conventional methods to an

analysis of the literature.

Recently, there have been significant advances in

this research field using artificial intelligence (Ioan-

nou and Dimitriou, 2012; Gyulai et al., 2018). This

process is mainly due to the growing availability of

large data collections in different fields of manufac-

turing, that can enable data-driven technologies such

as machine learning, data mining, knowledge discov-

ery in databases, and big data analytical tools (Fayyad

et al., 1996; Tsai et al., 2016; Frank et al., 2019;

Kabugo et al., 2020)). Nevertheless, most of the in-

telligent techniques used in recent research do not

make use of real data (

¨

Ozt

¨

urk et al., 2006), while us-

ing computer simulations to generate data and consid-

ering many simplifying assumptions for the internal

manufacturing process.

Given the limitations of the methods mentioned

so far, in this paper we aim to use intelligent meth-

ods to predict the delivery times of suppliers who

have to deliver the goods to a company that man-

ages the pharmaceutical supply-chain of hospitals. To

this aim, we compared five different machine learn-

ing regression approaches, namely: k-nearest neigh-

bors (KNN), support vector machines (SVM), ran-

dom forests (RF), linear regression (LR) and multi-

layer perceptrons (MLP).

The use of accurate lead time forecast can be

highly beneficial in the planning of both production

and logistic services in the pharmaceutical field. We

mention, to this regard, the work by (Gatica et al.,

2001), who studied stochastic aspects related to prod-

uct development and capacity planning in the phar-

maceutical sector, by proposing a multistage stochas-

tic programming approach, and that of (Kramer et al.,

2019), who proposed a metaheuristic algorithm for

the delivery of pharmaceutical products in the region

of Tuscany (operated by the Coopservice group). In

the former work, accurate prediction of the lead time

for purchasing the products could be used within the

what-if analysis, while in the latter work, accurate

predictions could be used to define the starting points

of the deliveries, as multiple depots are available, and

the possible use of temporary depots at the hospitals,

so as to reduce transportation costs and times.

The reminder of the paper is organized as follows.

In Section 2 we present the related works and com-

pare our work with the literature. In Section 3 we

briefly present the classic techniques that we used to

predict the lead time. In Section 4 we describe the

dataset used in the experiments, which are illustrated

in Section 5. Finally, Section 6 concludes.

Lead Time Forecasting with Machine Learning Techniques for a Pharmaceutical Supply Chain

635

2 RELATED WORKS

In an Industry 4.0 scenario, big data analytics can be

divided into five different categories: predictive, de-

scriptive, inquisitive, preventive and prescriptive an-

alytics. Predictive analytics aims to anticipate what

will happen in the future: descriptive analytics in-

stead provides information and explanations about

what has happened; inquisitive analytics tries to an-

swer why it has happened, and preventive analytics

provides insight to understand what is necessary to be

done. Finally, prescriptive analytics provides infor-

mation for decision-making (Sivarajah et al., 2017;

Cabrera-S

´

anchez and Villarejo-Ramos, 2020). Big

data analytics is very often associated with artificial

intelligence, data mining, and machine learning in-

struments (Dean, 2014), with the aim to develop sys-

tems that can automatically extract information and

discovery patterns in large data collections (Lu et al.,

2015; Kuo et al., 2018), so as to provide beneficial

insights to decision makers (Chamikara et al., 2020).

By mid-1980s, many studies on operating and lead

time estimation through mathematical formulations,

as well as statistical methods with analysis of variance

(ANOVA) were proposed (Chang, 1997; Tatsiopou-

los and Kingsman, 1983). Forecasting through math-

ematical modeling approaches has also been recently

proposed for a custom system disregarding the current

system workload (Vandaele et al., 2002). In a more

complex product development scenario, a heuristic

approach was proposed, by explicitly modeling net-

works of operating system activities (Jun et al., 2006).

Other research has proposed the use of queuing net-

works for lead time analysis and prediction (Ioannou

and Dimitriou, 2012; Berling and Farvid, 2014) with

the use of discrete event simulation through mathe-

matical expressions, assuming a continuous demand

and studying the variance of the lead time. Con-

versely, a case-based reasoning approach was pro-

posed in (Mourtzis et al., 2014) to predict the lead

time of complex engineered-to-order products. (Pfeif-

fer et al., 2016) made use of multivariate regression

statistical methods using simulated data to obtain the

production lead time of a flow-shop system.

Mathematical and statistical formulas were refor-

mulated and proposed for production lead time esti-

mates in chemical sector modular production plants

(Sievers et al., 2017). However, the main disadvan-

tage of all the methods cited so far is that they con-

sider that past trends could possibly be repeated in the

future (

¨

Ozt

¨

urk et al., 2006; Ioannou and Dimitriou,

2012). Moreover, there are few researches evaluating

the interactions of supply chain elements such as lead

times and forecasting procedures (Sievers et al., 2017;

Hosoda and Disney, 2018; Lingitz et al., 2018; Golt-

sos et al., 2019). Additionally, databases generated

by simulation often consider a perfect production sys-

tem, without introducing machine breakdowns, main-

tenance downtime and raw material delays (Lingitz

et al., 2018). When performing lead time analysis

and forecasting, it is important to consider external

factors too, such as relationships and interactions be-

tween different supply chains (Hosoda and Disney,

2018; Ponte et al., 2018; Goltsos et al., 2019; Noori-

Daryan et al., 2019). (Chung et al., 2018) showed

that lead time prediction is a key factor because the

lead time uncertainties can affect service level and or-

der lead time performance. Understanding these dy-

namics allows companies to reduce their exposure to

different types of delivery risk and to better manage

their supply chain.

Despite the large amount of works in this area,

we could not find comprehensive studies on machine

learning algorithms for lead time forecasting in the

field of pharmaceutical distributions. Related works

are limited to the use of Monte Carlo simulation to

predict the production lead time (Eberle et al., 2014),

and to the proposal of cyclic production plans com-

bined with outsourcing in the packaging of medicines

in the Netherlands (Strijbosch et al., 2002). With this

paper we aim at filling this research gap.

3 METHODOLOGY

As already stated in Section 1, we employ a machine

learning approach for purchasing lead time forecast-

ing of pharmaceutical services. We formulate the task

as a regression problem, where the aim is to predict

a single real number y ∈ R as a function of a set of

features x ∈ R

d

. Supervised machine learning ap-

proaches are able to learn a function f that computes

a value ˆy from a given input vector ˆx. Such a function

is learned from a dataset D, which consists of a col-

lection of N pairs (x

i

, y

i

) where each input example

x

i

is associated with the corresponding target y

i

, that

is the target of the forecasting system. In this work,

we compare several simple, classic regression algo-

rithms, largely used in statistics and machine learn-

ing applications, with the aim of finding the one that

performs the best on our real-world data set, without

resorting to more sophisticated approaches. We com-

pare two efficient linear methods, namely linear re-

gression and linear support vector machines, against

three simple non-linear ones, namely random forests,

k-nearest neighbors, and multi-layer perceptron. We

leave the use of more advanced machine learning ap-

proaches for future research.

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

636

3.1 Linear Regression

Linear regression (LR) is a widely employed paramet-

ric regression technique (Montgomery et al., 2012),

where function f is computed as a linear combination

of input features: f (x) = β

T

x + β

0

. The vector of pa-

rameters β is typically learned by minimizing the sum

of squared errors on the training set. Clearly, this ap-

proach achieves good results when a linear function

results to be a reasonable approximation of the de-

pendency relation holding between input and output

variables, while suffering when such dependency is

strongly non-linear.

3.2 Linear Support Vector Machines

Support vector machines (SVM) are a classic machine

learning approach that can be used both for classifica-

tion and for regression. In the regression setting, the

goal is to find a function f for which the forecasting

error with respect to target y is at most equal to a pre-

defined tolerance threshold ε for the elements in the

training set (Drucker et al., 1997). In its linear formu-

lation, which is the one we employ in this paper, the

function to be learned is still a linear combination of

the features. The optimal (or close to optimal) param-

eters are found by heuristically solving a constrained

quadratic optimization problem (Albers et al., 2011).

3.3 Random Forests

A random forest (RF) is an ensemble classifier that

consists in a collection of n different decision trees

(Breiman et al., 1984). A decision tree is an inter-

pretable classifier that inductively learns classification

rules by testing the informativeness of the attributes

(features) with respect to the category (in case of clas-

sification) or the target value (in case of regression) to

be predicted. Several different decision trees can be

obtained either considering different sets of features,

or by subsampling different sets of training examples.

In the regression setting, the output prediction of the

RF is computed as the average of the predictions of

individual trees.

3.4 k-Nearest Neighbors

Based on the concept of distance (or similarity) be-

tween examples, k-nearest neighbors (KNN) is not

properly a learning algorithm. Given a test exam-

ple x, the KNN algorithm looks for the k examples

in the training set that are the most similar to x, i.e.,

the nearest ones according to a given metric, such as

the Euclidean distance, which we use in our experi-

mental evaluation. Once the k nearest neighbors are

found, the algorithm computes the prediction as an

average, or voting procedure, among them. In a re-

gression setting, the predicted target value ˆy is simply

computed as the weighted average of the targets y

j

of

all k neighbors.

3.5 Multi-Layer Perceptron

A multi-layer perceptron (MLP) is a very simple ar-

tificial neural network that can learn non-linear func-

tions between input and output variables (Rumelhart

and McClelland, 1987). An MLP consists in a stack

of layers, each consisting of a certain number m of

neurons. The first layer consists of input variables.

In the second layer, named hidden layer, the output

of each neuron is computed as a non-linear combina-

tion of input variables, whose weights are learned dur-

ing a training phase. Finally, the last layer computes

the output of the network as a non-linear combina-

tion of the output of the hidden neurons, again with

adjustable, learnable weights.

4 DATASET

A crucial ingredient of any machine learning applica-

tion is the preparation of the dataset used for training

and evaluation (Ristoski and Paulheim, 2016). The

database used in this research was made available

by an integrated service company, the Coopservice

Group. Founded in 1992, the Coopservice Group pro-

vides specialised services to private companies and

public entities. The Group operates worldwide, with

its headquarters in Italy, and counts around 20,000

employees. It offers a variety of facility services, es-

pecially the ones that are not part of the core busi-

nesses of the clients, including: industrial, commer-

cial and healthcare cleaning; management and main-

tenance of buildings and systems; management of en-

ergy supplies; security and surveillance; transport and

handling of goods; industrial and commercial mov-

ing; collection and transport of special waste. With

18 logistic warehouses and a storage area of over

150,000 squared meters, Coopservice Group is the

leader in healthcare and pharmaceutical logistics in

Italy, and a key provider of management and distri-

bution services for pharmaceuticals, medical-surgical

devices and non-medical consumables. The key as-

pects for the services are relying on a large workforce,

working at client-sites, maintaining consistent quality

and monitoring performance.

Forecasting lead times is a crucial task for

Lead Time Forecasting with Machine Learning Techniques for a Pharmaceutical Supply Chain

637

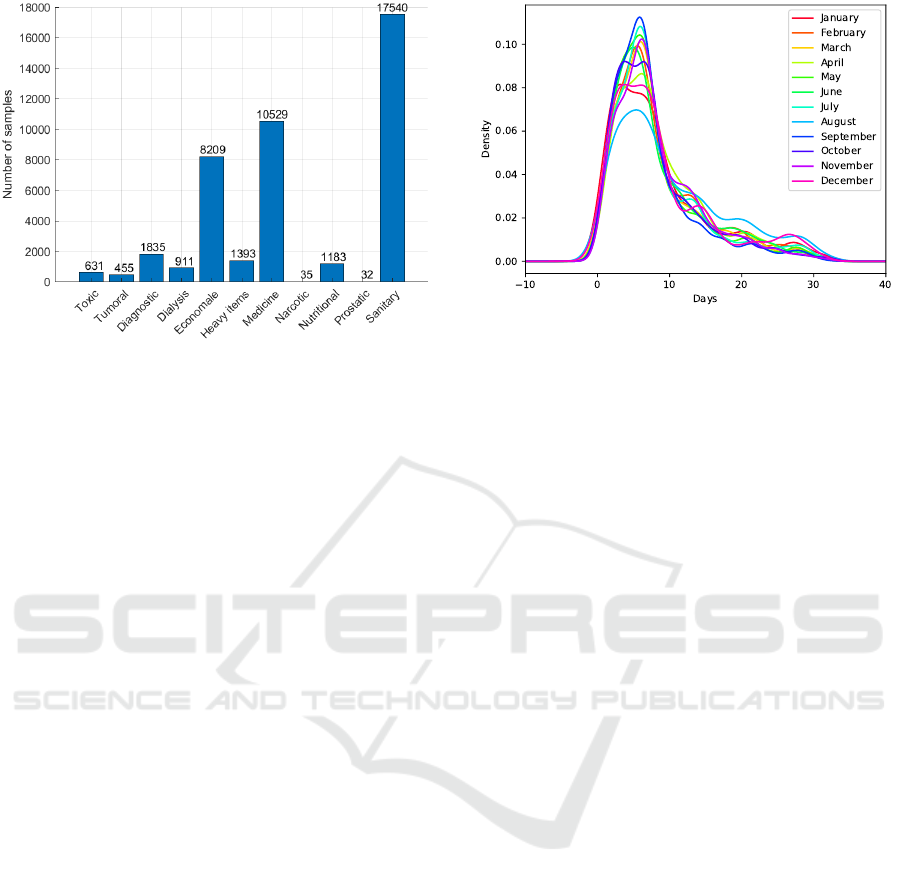

Figure 1: Distribution of the number of samples in the

dataset, for each different category.

Coopservice, because with an accurate prediction it is

possible to optimize and manage the scheduling of the

truck deliveries, as well as predict the unloading pro-

cess schedule for the inbound area. Thanks to this, it

is possible to better organize the shifts of the employ-

ees in the warehouse. In addition, lead time prediction

allows the company to have a better knowledge of the

supplier and to evaluate its performance. In order to

do this, a supplier rating system can be created, con-

sidering the historical data and the prediction. Finally,

with an accurate forecasting of lead times, the man-

agement of safety stock in the warehouse can be safer,

avoiding negative events like overstock and stockout.

In the pharmaceutical database provided by

Coopservice, the total number of samples was 42,753

collected during 2018.

All pharmaceutical products in the database are

associated with some specific categories, namely: tu-

moral, diagnostic, medicine, nutritional, prostatic,

sanitary, dialysis, heavy items, toxic, narcotic, and

economale (that are all the non-medical items like

pens, papers...). All these categories were used in our

study, although most of the data belong to economale,

medicine, or sanitary categories, as shown in Figure 1.

For each sample in the database, eight indepen-

dent variables were considered as the input vector x

for our machine learning systems used to forecast lead

times:

• day of the month of the customer order (1 to 31);

• weekday of the customer order (1 to 5, from Mon-

day to Friday);

• month (1 to 12) of the customer order;

• supplier code identifier;

• product name identifier;

• pharmaceutical product type category;

Figure 2: Lead time distribution, as a function of the month.

• ordered quantity (pills);

• distance between supplier and the pharmacy ware-

house (km).

A standard pre-processing phase was applied to the

database, including explorative data visualization,

cleaning and removal of duplicates and corrupted

data, outlier detection, manipulation of missing val-

ues (Ristoski and Paulheim, 2016). In particular, we

used boxplots to identify outliers and extreme values

(Hu et al., 2018; Sagaert et al., 2019) to remove cor-

rupted data. Figure 2 shows the distribution of the

lead time for each month. It can be noticed that the

trend is quite similar for all the months, with a peak

between 3 and 7 days, and very few values exceed-

ing 32 days. After a detailed analysis of the cases

with such a large lead time, we noticed they were

due to insertion errors in the original database, and

hence we discarded them. Overall, around 5% of data

were removed following the whole pre-processing

and cleaning procedure. The resulting dataset is avail-

able for research at https://github.com/regor-unimore/

Pharmaceutical-Lead-Time-Forecasting.git.

5 EXPERIMENTAL RESULTS

To compare the machine learning systems employed

in our analysis, we performed two different experi-

ments, splitting the whole corpus by category, as well

as by month.

Initially, in order to select the best hyper-

parameters of each algorithm, we employed a stan-

dard 10-fold cross-validation procedure, where the

whole dataset is partitioned into 10 different groups,

named folds. In turn, each fold is considered as test

set, whereas the remaining folds were split into 2/3

for the training set, and 1/3 for the validation set.

The training set is the set of examples used during

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

638

the learning phase to find the optimal model parame-

ters, whereas the validation set is the set of examples

that is employed to evaluate the performance of the

learned model. In this way, we selected the following

hyper-parameters for our machine learning systems:

100 estimators (i.e., number of trees) for the RF, lin-

ear kernel and a regularization term C = 1 for SVM,

a value of k=13 for the number of neighbors in KNN,

and a single hidden layer with 3 neurons for MLP.

Then, we performed two distinct experiments. As

a first experiment, we partitioned the dataset by cat-

egory, and we split each portion into 2/3 to be used

for training, and 1/3 to be used for test. As a sec-

ond experiment, we partitioned the dataset by month,

and again we split the data of each month into 2/3 for

training, and 1/3 for test. In both experiments, as a

standard performance metric, we considered the mean

squared error (MSE) as the average of the squared dif-

ference between true and predicted lead time: MSE =

∑

n

i=1

(y

i

− ˆy

i

)

2

where y

i

is the true lead time, and ˆy

i

is

the forecast value.

The two experiments have different goals. In the

first case, one full year of data for each category is

used both for training and for test, thus we can eval-

uate the performance of a forecasting approach when

a long period of data is available, for each single cat-

egory. Conversely, in the second experiment, we take

into account all the categories, by partitioning the data

by month: in this way, we can evaluate whether data

from different categories can help in forecasting the

lead times of each product.

As for the first experiment, in Table 1 we report

the performance achieved by all the competitors on

each distinct category. The results show that LR is

the best performing method. A very similar perfor-

mance is also obtained by the SVM approach, that

achieves the lowest error in two categories (Tumors

and Medicine). Narcotics results to be the most diffi-

cult category to forecast, which is not surprising, as it

contains very few examples. For that category, KNN

is the best-performing algorithm.

In our second setting, the samples of all the cate-

gories are used within the training and test set of each

month. As shown in Table 2, in this case SVM is

clearly the best performing algorithm, achieving the

lowest MSE in every month, with an average error

equal to 1.89 days, which is largely better than the

second best approach, which is RF, that achieves an

MSE equal to 3.07 days only. Overall, the results

of both settings suggest that the use of non-linear ap-

proaches does not significantly lower the forecasting

error.

Table 1: Mean squared error obtained per each different cat-

egory (best results in bold).

KNN LR RF MLP SVM

Tumors 3.37 2.23 2.39 3.87 1.94

Diagnosis 4.98 2.37 3.40 7.41 2.51

General 4.59 2.22 3.48 8.12 2.30

Medicine 4.10 2.22 2.71 5.51 2.02

Nutritional 2.90 2.21 2.28 4.60 2.28

Prostatic 3.11 1.75 3.07 3.15 3.38

Sanitary 3.11 2.22 2.49 6.98 2.30

Dialysis 3.23 1.50 2.49 2.34 1.83

Heavy Goods 2.66 1.79 2.40 5.40 1.86

Toxic 3.73 1.70 2.68 2.03 1.73

Narcotics 3.72 5.16 5.44 4.29 4.81

Average 3.59 2.31 2.99 4.88 2.45

Table 2: Mean squared error obtained per each different

month (best results in bold).

KNN LR RF MLP SVM

January 3.43 5.13 2.62 5.60 1.86

February 2.77 4.20 2.05 5.46 1.58

March 3.88 2.83 6.14 6.94 1.80

April 3.96 9.51 2.94 8.03 1.87

May 3.57 5.74 2.54 7.69 1.55

June 3.79 5.91 2.71 7.01 1.58

July 3.84 2.69 3.00 8.75 2.09

August 4.01 2.43 3.15 13.47 2.02

September 3.49 5.47 2.55 6.44 1.55

October 3.87 2.36 2.95 7.36 1.76

November 3.91 2.72 2.95 6.95 2.21

December 4.09 7.01 3.25 10.33 2.86

Average 3.72 4.67 3.07 7.84 1.89

6 CONCLUSIONS

This paper presented a methodology for lead time

forecasting in the pharmaceutical supply chain with

machine learning techniques. In particular, we com-

pared support vector machines, random forests, multi-

layer perceptron, linear regression, and k-nearest

neighbors on a very large collection of examples pro-

vided by a large company with headquarters in Italy.

Our experimental results are very encouraging, show-

ing how the purchasing lead time can be forecast with

high accuracy, especially for linear support vector re-

gression. In particular, the use of simple non-linear

approaches does not seem to yield significant im-

provements in the forecasting.

The research described in this paper aims to fill

a gap in the scientific literature regarding lead time

forecasting for the purchase of pharmaceutical prod-

ucts. An accurate forecast of such lead time can

be crucial for decision making, optimization, and

planning in the overall pharmaceutical supply chain.

Waiting times for drugs and medicines could in fact be

reduced, and hospitals and pharmacies could choose

Lead Time Forecasting with Machine Learning Techniques for a Pharmaceutical Supply Chain

639

the most convenient supplier at every moment on the

basis of accurate predictions. This can be very rele-

vant when treating patients with urgent needs, as well

is fast-changing medical conditions, as the ones we

are currently facing in the COVID-19 pandemic.

Future research will incorporate forecasting of in-

ternal supply chain lead times of real service pro-

cesses. In this way, the forecast of lead time for pur-

chasing products will be coupled with the forecast of

the entire supply chain lead time, providing decision

makers with a larger instrument of analysis. In addi-

tion, more sophisticated approaches to lead time fore-

casting could be exploited, with simulation of non-

linear systems to investigate how machine faults and

maintenance procedures can influence lead time.

ACKNOWLEDGMENT

The research described in this paper was carried

out with funding from the Brazilian State Funding

Agency of Goi

´

as (FAPEG), Brazilian National Coun-

cil of State Funding Agencies (CONFAP-ITALY) and

Higher Education Personnel Improvement Coordina-

tion (CAPES).

REFERENCES

Albers, C. J., Critchley, F., and Gower, J. C. (2011).

Quadratic minimisation problems in statistics. Jour-

nal of Multivariate Analysis, 102(3):698–713.

Berling, P. and Farvid, M. (2014). Lead-time investiga-

tion and estimation in divergent supply chains. Inter-

national Journal of Production Economics, 157:177–

189.

Breiman, L., Friedman, J., Stone, C. J., and Olshen, R. A.

(1984). Classification and regression trees. CRC

press.

Brown, M. T., Bussell, J., Dutta, S., Davis, K., Strong, S.,

and Mathew, S. (2016). Medication adherence: truth

and consequences. The American journal of the med-

ical sciences, 351(4):387–399.

Cabrera-S

´

anchez, J.-P. and Villarejo-Ramos,

´

A. F. (2020).

Acceptance and use of big data techniques in services

companies. Journal of Retailing and Consumer Ser-

vices, 52(C):101888.

Chamikara, M., Bertok, P., Liu, D., Camtepe, S., and Khalil,

I. (2020). Efficient privacy preservation of big data for

accurate data mining. Information Sciences, 527:420–

443.

Chang, F.-C. (1997). Heuristics for dynamic job shop

scheduling with real-time updated queueing time esti-

mates. International Journal of Production Research,

35(3):651–665.

Chung, W., Talluri, S., and Kov

´

acs, G. (2018). Investigat-

ing the effects of lead-time uncertainties and safety

stocks on logistical performance in a border-crossing

jit supply chain. Computers & Industrial Engineering,

118:440–450.

Dean, J. (2014). Big data, data mining, and machine learn-

ing: value creation for business leaders and practi-

tioners. John Wiley & Sons.

Drucker, H., Burges, C. J., Kaufman, L., Smola, A. J.,

and Vapnik, V. (1997). Support vector regression ma-

chines. In Mozer, M. C., Jordan, M. I., and Petsche,

T., editors, Advances in neural information processing

systems 9, pages 155–161. MIT Press.

Eberle, L. G., Sugiyama, H., and Schmidt, R. (2014). Im-

proving lead time of pharmaceutical production pro-

cesses using monte carlo simulation. Computers &

Chemical Engineering, 68:255–263.

Fayyad, U., Piatetsky-Shapiro, G., and Smyth, P.

(1996). From data mining to knowledge discovery in

databases. AI magazine, 17(3):37.

Frank, A. G., Dalenogare, L. S., and Ayala, N. F. (2019).

Industry 4.0 technologies: Implementation patterns in

manufacturing companies. International Journal of

Production Economics, 210:15–26.

Gatica, G., Shah, N., and Papageorgiou, L. G. (2001). Ca-

pacity planning under clinical trials uncertainty for the

pharmaceutical industry. In Gani, R. and Jørgensen,

S. B., editors, European Symposium on Computer

Aided Process Engineering - 11, volume 9 of Com-

puter Aided Chemical Engineering, pages 865 – 870.

Elsevier.

Goltsos, T. E., Ponte, B., Wang, S., Liu, Y., Naim, M. M.,

and Syntetos, A. A. (2019). The boomerang returns?

accounting for the impact of uncertainties on the dy-

namics of remanufacturing systems. International

Journal of Production Research, 57(23):7361–7394.

Gyulai, D., Pfeiffer, A., Nick, G., Gallina, V., Sihn, W., and

Monostori, L. (2018). Lead time prediction in a flow-

shop environment with analytical and machine learn-

ing approaches. IFAC-PapersOnLine, 51(11):1029–

1034.

Harapan, H., Itoh, N., Yufika, A., Winardi, W., Keam, S.,

Te, H., Megawati, D., Hayati, Z., Wagner, A. L.,

and Mudatsir, M. (2020). Coronavirus disease 2019

(covid-19): A literature review. Journal of Infection

and Public Health, 13(5):667 – 673.

Haugh, K. H. (2014). Medication adherence in older adults:

The pillbox half full. Nursing Clinics of North Amer-

ica, 49(2):183–199.

Hosoda, T. and Disney, S. M. (2018). A unified theory of

the dynamics of closed-loop supply chains. European

Journal of Operational Research, 269(1):313–326.

Hu, X., Pedrycz, W., and Wang, X. (2018). Fuzzy classifiers

with information granules in feature space and logic-

based computing. Pattern Recognition, 80:156–167.

Ioannou, G. and Dimitriou, S. (2012). Lead time estima-

tion in mrp/erp for make-to-order manufacturing sys-

tems. International Journal of Production Economics,

139(2):551–563.

Jun, H.-B., Park, J.-Y., and Suh, H.-W. (2006). Lead time

estimation method for complex product development

process. Concurrent Engineering, 14(4):313–328.

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

640

Kabugo, J. C., J

¨

ams

¨

a-Jounela, S.-L., Schiemann, R., and

Binder, C. (2020). Industry 4.0 based process data an-

alytics platform: A waste-to-energy plant case study.

International Journal of Electrical Power & Energy

Systems, 115:105508.

Kim, S. H., Kim, J. W., and Lee, Y. H. (2014). Simulation-

based optimal production planning model using dy-

namic lead time estimation. The International Jour-

nal of Advanced Manufacturing Technology, 75(9-

12):1381–1391.

Kramer, R., Cordeau, J.-F., and Iori, M. (2019). Rich vehi-

cle routing with auxiliary depots and anticipated deliv-

eries: An application to pharmaceutical distribution.

Transportation Research Part E: Logistics and Trans-

portation Review, 129:162–174.

Kuo, C.-F. J., Lin, C.-H., and Lee, M.-H. (2018). Ana-

lyze the energy consumption characteristics and af-

fecting factors of taiwan’s convenience stores-using

the big data mining approach. Energy and Buildings,

168:120–136.

Lingitz, L., Gallina, V., Ansari, F., Gyulai, D., Pfeiffer, A.,

and Monostori, L. (2018). Lead time prediction using

machine learning algorithms: A case study by a semi-

conductor manufacturer. Procedia CIRP, 72:1051–

1056.

Lu, W., Chen, X., Peng, Y., and Shen, L. (2015). Bench-

marking construction waste management performance

using big data. Resources, Conservation and Recy-

cling, 105(Part A):49–58.

Montgomery, D. C., Peck, E. A., and Vining, G. G. (2012).

Introduction to linear regression analysis, volume 821

of Wiley Series in Probability and Statistics. John Wi-

ley & Sons.

Moscelli, G., Siciliani, L., and Tonei, V. (2016). Do waiting

times affect health outcomes? evidence from coronary

bypass. Social Science & Medicine, 161:151–159.

Mourtzis, D., Doukas, M., Fragou, K., Efthymiou, K., and

Matzorou, V. (2014). Knowledge-based estimation of

manufacturing lead time for complex engineered-to-

order products. Procedia CIRP, 17:499–504.

Noori-Daryan, M., Taleizadeh, A. A., and Jolai, F.

(2019). Analyzing pricing, promised delivery lead

time, supplier-selection, and ordering decisions of a

multi-national supply chain under uncertain environ-

ment. International Journal of Production Economics,

209:236–248.

¨

Ozt

¨

urk, A., Kayalıgil, S., and

¨

Ozdemirel, N. E. (2006).

Manufacturing lead time estimation using data min-

ing. European Journal of Operational Research,

173(2):683–700.

Pfeiffer, A., Gyulai, D., K

´

ad

´

ar, B., and Monostori, L.

(2016). Manufacturing lead time estimation with

the combination of simulation and statistical learning

methods. Procedia CIRP, 41:75–80.

Ponte, B., Costas, J., Puche, J., Pino, R., and de la

Fuente, D. (2018). The value of lead time reduction

and stabilization: A comparison between traditional

and collaborative supply chains. Transportation Re-

search Part E: Logistics and Transportation Review,

111:165–185.

Ristoski, P. and Paulheim, H. (2016). Semantic web in data

mining and knowledge discovery: A comprehensive

survey. Journal of Web Semantics, 36:1–22.

Rumelhart, D. E. and McClelland, J. L. (1987). Learning

Internal Representations by Error Propagation, pages

318–362. MIT Press.

Sagaert, Y. R., Kourentzes, N., De Vuyst, S., Aghezzaf, E.-

H., and Desmet, B. (2019). Incorporating macroe-

conomic leading indicators in tactical capacity plan-

ning. International Journal of Production Economics,

209:12–19.

Sievers, S., Seifert, T., Franzen, M., Schembecker, G., and

Bramsiepe, C. (2017). Lead time estimation for modu-

lar production plants. Chemical Engineering Research

and Design, 128:96–106.

Sivarajah, U., Kamal, M. M., Irani, Z., and Weerakkody, V.

(2017). Critical analysis of big data challenges and

analytical methods. Journal of Business Research,

70:263–286.

Strijbosch, L., Heuts, R., and Luijten, M. (2002). Cyclical

packaging planning at a pharmaceutical company. In-

ternational Journal of Operations & Production Man-

agement, 22(5):549–564.

Tatsiopoulos, I. and Kingsman, B. (1983). Lead time man-

agement. European Journal of Operational Research,

14(4):351–358.

Tetteh, E. K. (2019). Reducing avoidable medication-

related harm: What will it take? Research in Social

and Administrative Pharmacy, 15(7):827–840.

Tsai, C.-F., Lin, W.-C., and Ke, S.-W. (2016). Big data

mining with parallel computing: A comparison of dis-

tributed and mapreduce methodologies. Journal of

Systems and Software, 122:83–92.

Vandaele, N., Boeck, L. D., and Callewier, D. (2002). An

open queueing network for lead time analysis. IIE

transactions, 34(1):1–9.

Lead Time Forecasting with Machine Learning Techniques for a Pharmaceutical Supply Chain

641