Energy Saving Potential in Building Envelopes through Energy

Conservation Building Code and Design Alternatives in Warm

and Humid Climate

Anuthama Mahesh

1

, Pradeep Kini

2

and Pranav Kishore

2

1

Manipal School of Architecture and Planning, Manipal Academy of Higher Education, Karnataka, India

2

Centre of Sustainable Built Environment, MSAP, Manipal Academy of Higher Education, Karnataka, India

Keywords: Energy Conservation Building Code, Building Envelope, Climate Change, Warm & Humid Climate, Thermal

Comfort, Building Energy Simulation, Sustainable Development.

Abstract: Energy usage in commercial buildings significantly adds to the total annual energy consumption of the

building sector in India which is growing at a fast pace. A large fraction of energy consumed in buildings is

attributed to space cooling systems. Heat transfer through the building envelope leads to higher demand for

space cooling and increased electricity usage for space cooling systems which further leads to higher levels

of emissions enabling climate change. In this study, the energy savings potential for commercial buildings

through the implementation of Energy Conservation Building Code (ECBC) of India has been studied for

commercial building envelope in the warm and humid climate zone of India. The existing building envelope

is analysed through documentation and a simulation model is created towards the baseline case. A second

model is then simulated with ECBC prescriptive requirements using Energy Conservation Measures (ECM)

and is evaluated based on energy consumption to analyse the relative performance of building envelope

components. The implementation of ECBC prescriptive requirements is found to reduce energy consumption

by 15.86% in the baseline case. Further implementation of Design Alternatives (DA) in the building envelope

achieved a reduction in overall annual energy consumption by 32.31%.

1 INTRODUCTION

Mass urbanization and expanding population has

brought tremendous growth in the building sector in

the warm & humid climate of India and it is poised

for greater growth in the future. It is estimated that

75% of the buildings required in the upcoming decade

is yet to be built, and a study conducted in 2010

estimates that 700-900 million square metres of

commercial and residential spaces are expected to be

built every year in India (McKinsey and Company,

2010). This large-scale development is resulting in an

increasing demand for energy. The building sector in

Warm & humid climatic zones of India contributes to

approximately one third of the total annual electrical

energy consumption in the region (McKinsey and

Company, 2010).

Commercial buildings that are being developed in

the warm and humid regions consume a significant

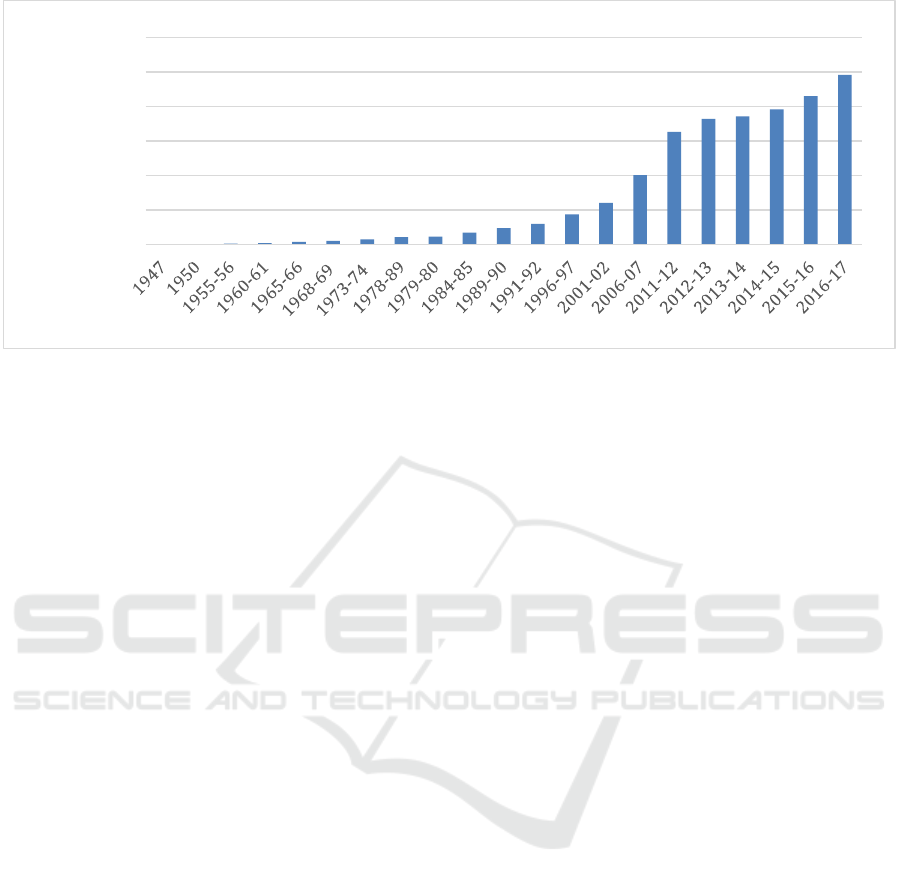

amount of energy. In the year 2016-17, the

commercial sector consumed a total of 98333 GWh

which constitutes to about 9.22% of the total energy

consumption in India (Central Electricity Authority,

2017). Figure 1 shows the growth in energy

consumption in the commercial sector in India.

A major part of the required electrical energy in

India is generated through thermal power plants

where coal is used as a major source of energy for

production. 76.08 % of total power generation in

India is based on thermal power plants using coal

(Central Electricity Authority, 2018). Generation of

power using such fossil fuels leads to emission of

GHGs and harmful particulate matter which affect the

local as well as global environment, leading to

climate change. According to a data collected in 2017

the annual growth rate of CO

2

emissions in India from

2005 to 2016 was 6% with a total emission of 2271.1

million tonnes of CO

2

(U.S. Energy Information

Administration, 2012). A study conducted in 2012

estimated that India’s net annual CO

2

emission value

would reach 2.2GT by 2035, making it the world’s

second largest emitter of GHGs (U.S. Energy

Information Administration, 2012).

Mahesh, A., Kini, P. and Kishore, P.

Energy Saving Potential in Building Envelopes through Energy Conservation Building Code and Design Alternatives in Warm and Humid Climate.

DOI: 10.5220/0010433900270034

In Proceedings of the 10th International Conference on Smart Cities and Green ICT Systems (SMARTGREENS 2021), pages 27-34

ISBN: 978-989-758-512-8

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

27

Figure 1: Electrical Energy Consumption growth in Commercial Sector in India (Source: Central Electricity Authority).

Studies have shown that the building sector, which

contributes to about 30% of the total national energy

consumption, has the potential to control the effect of

energy consumption on climate change through the

implementation of energy conservation measures. In

commercial buildings, energy consumed by HVAC

for space cooling, lighting and use of office

equipment are major contributors to the total energy

consumed. The space cooling in commercial

buildings contributes to nearly 50% of the total

commercial building energy consumption

(International Energy Agency, 2011). In India, air

conditioning systems sales has increased from 2.8

million units in 2009 to approximately 30 million

units in 2017 (TERI, 2018).

In order to mitigate the harmful effects caused by

such large-scale growth on the environment and to

promote energy efficiency in the built environment,

the energy conservation building code was

formulated by the Bureau of Energy Efficiency

(BEE). These building codes aim to conserve energy

and operation costs to the building owner over time,

relative to the building energy performance and

operation costs of a conventionally designed building.

The Energy Conservation Building Code (ECBC)

focuses on energy conservation in commercial

buildings due to their high share of energy

consumption in the nation.

Several studies have been carried out to analyse

the energy conservation potential through the

implementation of various energy conservation codes

and advanced energy efficiency measures in different

climatic zones in India. Chedwal et al. reported that

the application of ECBC strategies on the existing

hotels in Jaipur, Rajasthan could lead to an annual

savings of 27.9 GWh. Furthermore, the application of

advanced EEMs resulted in an annual energy savings

potential up to 67.04 GWh (Chedwal, Mathur,

Agarwal and Dhaka, 2015). In a study conducted for

energy conservation potential in the hot and dry

climate of Ahmedabad, Gujarat, Jayswal et al.

estimated a 31% reduction in space cooling load

through the implementation of ECBC for building

envelope design (Jayswal, 2012). Another study

conducted by Tulsyan et al. focused on six different

typologies of commercial buildings in the city of

Jaipur, Rajasthan. This study resulted in

understanding the variation of energy saving potential

with the type of building usage. Energy conservation

through ECBC implementation ranges from a

minimum of 17% in the case of an institutional

building to the highest of 42% in the case of a hospital

building in the hot and dry climate of Jaipur (Tulsyan,

Dhaka, Mathur and Yadav, 2012). A study was

conducted on the practical implementation of energy

conservation measures like cool roofs and roof

whitening for air-conditioned commercial buildings

in warm & humid climatic zone, in the city of

Hyderabad which estimated a reduction in space

cooling energy requirement by 14-26% (Xu, Sathaye,

Akbari, Garg, Tetali, 2011).

A number of studies in different climatic zones,

have proven the effectiveness of the implementation

of energy conservation codes and advanced energy

efficiency measures for energy savings in commercial

buildings. However, there are limited number of

studies related to the implementation of ECBC on

commercial buildings in warm and humid climate.

The aim of this study is to understand the factors

leading to increased electrical energy consumption in

a conventional commercial building and to estimate

the energy savings potential of an ECBC-compliant

building compared to the energy consumption in a

conventional commercial building in warm and

0

20000

40000

60000

80000

100000

120000

EnergyConsumption

GWh

Year

SMARTGREENS 2021 - 10th International Conference on Smart Cities and Green ICT Systems

28

humid climate. Energy saving potential through

ECBC recommended parameters and advanced

energy efficiency measures for the building envelope

has been studied for the demonstration building.

2 ENERGY CONSERVATION

BUILDING CODE OF INDIA

2.1 Overview

The Bureau of Energy Efficiency (BEE) is an agency

initiated by the government of India under the

ministry of power. The role of BEE is to introduce

codes and standards for the efficient use of energy in

India. One such initiative was the launch of Energy

Conservation Building Code (ECBC) in 2007 with

the objective of reducing the impacts of increasing

energy consumption and carbon emissions which

ultimately leads to a larger problem of climate

change. ECBC provides nominal guidelines and

requirements for energy efficient design of buildings

through several approaches.

A building with commercial use is classified as

per the functional requirements of its design,

construction, and use into the following categories

such as Hospitality, Healthcare, Assembly, Business,

Educational, Shopping Complex, and Mixed-use

Building. The energy efficiency criteria in

commercial buildings is achieved by implementing

certain energy efficiency measures in the design of

building systems. The code specifications are broadly

applicable to four main building systems; Building

envelope, HVAC and mechanical systems, lighting

(interior and exterior), and electrical power

generators and motors.

ECBC sets a few mandatory requirements and

provides two approaches for compliance; Prescriptive

Method and Whole Building Performance Method.

The Prescriptive Method requires a building to meet

all prescribed minimum or maximum values for all

building systems whereas in the Whole Building

Performance Method, the building is said to be

ECBC-compliant when the net annual energy

consumption value of the proposed simulation model

is lower compared to that of the standard design

model. Under this approach, it is not necessary for the

design to follow the individual ECBC prescribed

requirements.

2.2 Implementation of ECBC

Implementation of ECBC in commercial buildings in

India can be proved instrumental in energy

conservation and energy efficient design. While the

Central Government has powers under the Energy

Conservation Act, 2001 to notify standards energy

consumption in commercial buildings, the state

governments can amend the code to suit local or

regional needs and notify the same.

In the state of Karnataka, mandatory Energy

Conservation Building Code compliance was adopted

for commercial buildings in 2014 by the Karnataka

Renewable Energy Department Limited under the

Energy Department of the Government of Karnataka.

Several modifications were made to the code by The

Energy Department to suit the local requirements in

Karnataka.

2.3 ECBC for Warm and Humid

Climate Zone

All prescriptions given by the code are specific to the

climate zone in which the proposed building is

situated. All regions of the country have been

classified into the following five climatic zones:

warm-humid, composite, temperate, hot and dry, and

cold. The varying profile of each climate zone

demands different code prescriptions to facilitate the

thermal comfort requirements. ECBC prescribes

material requirements for each component of the

building envelope, specifically for ECBC compliance

in the warm and humid climate zone. For instance, the

maximum permissible U-value of a roof assembly in

the warm and humid climate zone is prescribed as

0.33 W/m

2

K and that of an opaque external wall is

0.40 W/m

2

K. The maximum allowed Energy

Performance Index (EPI) ratios for all ECBC-

compliant buildings in warm and humid climate is 1.

3 METHODOLOGY

A five-storey commercial building has been chosen

for detailed analysis and demonstration which is

located in Manipal, Karnataka. The demonstration

building envelope has extensive glazed facade and the

heat gain conditions can be well understood in such a

layout. The data of energy consumption due to each

building envelope component is studied for further

understanding of the factors that influence variation

in energy consumption. Implementation of ECBC on

commercial building envelopes has been studied and

this study aims to contribute towards the energy

Energy Saving Potential in Building Envelopes through Energy Conservation Building Code and Design Alternatives in Warm and Humid

Climate

29

saving potential especially for the warm and humid

climatic zone in India.

3.1 Climate at Study Location

Figure 2 shows the monthly temperature variation for

Manipal where the demonstration building is situated

and is a broad representative sample for this climate.

Figure 2: Monthly temperature variation in Manipal.

Manipal lies in the district of Udupi in southern

coastal Karnataka which experiences tropical warm

and humid climate. The temperature reaches a

maximum of 37°C with an average humidity of 72%

during the summer months from March to May.

Heavy rainfall of over 4000 mm is experienced in the

months of June to September with peak humidity

level up to 90%. The average annual humidity is 77%

and the and mean annual temperature is 29°C. Heavy

winds are common during the monsoon, reaching a

peak wind speed of over 12m/s.

3.2 On-site Documentation of

Demonstration Building

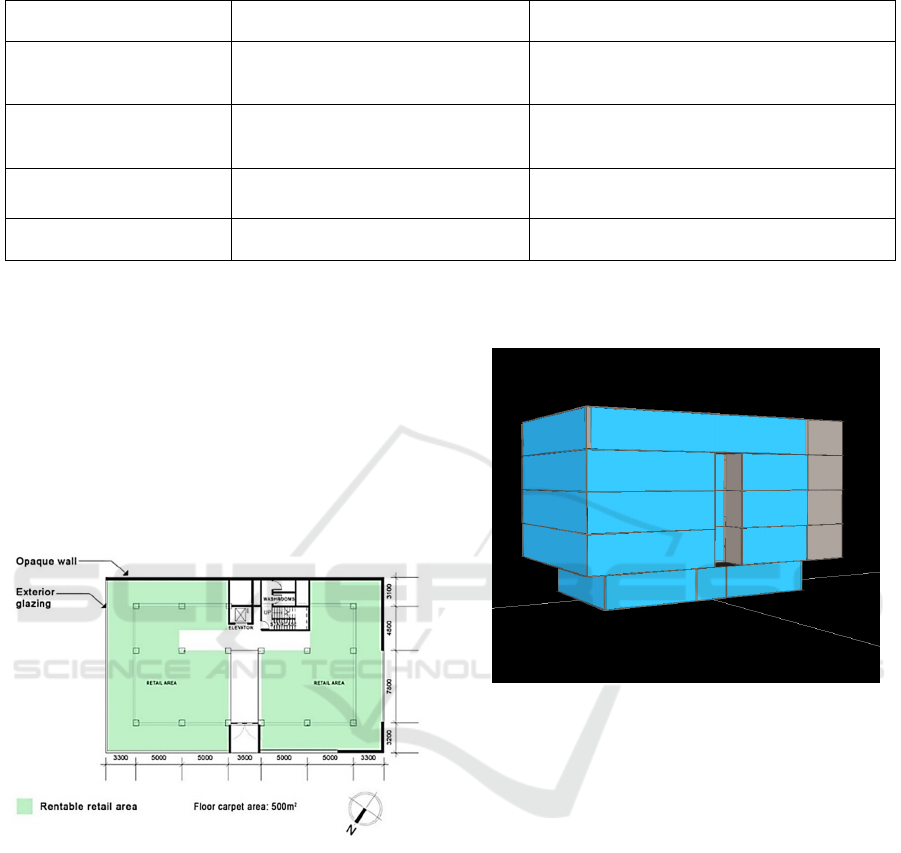

Figure 3: Exterior view of demonstration building.

On-site documentation of the building was carried out

to collect data on the building dimensions, annual

energy consumption, occupancy, building materials

etc. Figure 3 shows the exterior view of the

demonstration building.

Table 1: Lists details of the demonstration building that

have an impact on the energy consumption.

Building Information Details

Location

13°20'48.4"N

74°47'03.1"E

Site area 910 m

2

Building size G + 4

Total built-up area 2190 m

2

Ground coverage 38.5%

First floor carpet area 500 m

2

Building facing North-West

Operating schedule 9:00 AM – 9:00 PM

WWR - NW 0.85

WWR - NE 1.00

WWR - SW 0.71

WWR - SE 0.00

The demonstration building is a G+4 shopping centre

majorly occupied by departmental stores. The

building has a ground coverage of 350m

2

, total built

up area of 2190m

2

and total carpet area of 1900m

2

which is majorly occupied by departmental stores.

The stores have an operation time of 12 hours,

from 9:00AM to 9:00PM. The upper floors have a

larger floor plate area compared to the ground floor

which is achieved by a 3-meter cantilever on all sides.

The longer front façade of the building faces the

north-west direction and the structure incorporates

complete glass facades on two sides with an average

window-to-wall ratio of 0.62. A small central atrium

from the ground floor to the third-floor acts as a good

source of daylighting. Table 2 lists the material

specifications for each of the building-envelope

component.

The building envelope majorly consists of the

opaque walls, roof slab and vertical fenestrations. The

opaque walls have an overall u-value of 2.03 W/m

2

K

and are constructed with 150mm thick concrete

masonry units with interior and exterior plaster

thickness of 10mm. The building roof and floors are

150mm thick reinforced concrete slabs with a thermal

transmittance (u-value) of 2.97 W/m

2

K. Exterior

glazing curtain wall is used as vertical fenestration

with clear glass of 10mm thickness and SHGC of

0.86.

SMARTGREENS 2021 - 10th International Conference on Smart Cities and Green ICT Systems

30

Table 2: Building Material Specifications.

Building component Material(s) Detailing

Wall

Concrete masonry

U-value 2.03 W/m

2

K

200mm thick masonry (concrete block) wall +

10mm cement plaster in interior(s) and

exterior(s).

Vertical Fenestration

Exterior glazing

U-value 5.54 W/m

2

K

SHGC 0.76

Full height exterior clear glass glazing 10mm

thickness

Floor

RCC flat slab

U-value 1.8 W/m

2

K

Reinforced concrete slab 100mm thick

Roof

RCC flat slab

U-value 1.8 W/m

2

K

Reinforced concrete slab 100mm thick

The building plan follows a symmetrical layout with

a simple grid for columns placement. The building

entrance is on the north-west facade of the building.

A central atrium of 3.0m x 7.8m divides the plan into

two equal rentable areas while also serving as a good

source of daylight. The building consists of one

elevator and one staircase that reaches up to the 4th

floor. The average floor-plate area is 320m

2

on the

ground floor and 500m

2

on all above floors. Figure 4

shows the typical floor plan of the demonstration

building.

Figure 4: Typical floor plan.

3.3 Building Energy Simulation

In this study, the annual energy consumption of the

simulated model of the proposed design following

ECBC recommendations is compared to that of the

existing energy consumption value of the

demonstration building. Building energy simulation

is carried out using a BEE approved simulation

software, eQUEST, which enables detailed building

energy analysis. The software utilizes a DOE-2

simulation engine and it also includes a building

creation wizard, a graphical result display, and an

EEM wizard. The 3D simulation model of the

demonstration building made on e-QUEST is shown

in Figure 5.

Figure 5: eQUEST simulation model of demonstration

building.

As per the onsite documentation of the building

envelope and the utility bills of the building, the

baseline case with all parameters of the building

envelope and material specifications is used as input

and modeled. The simulation model is calibrated with

the onsite documentation and validated towards

ECBC compliance and ECM Design Alternatives for

building envelopes in warm & humid climatic zone.

The prescriptive requirements are achieved by

implementing design strategies such as increasing the

thickness and addition of insulating materials to the

roof(s) and opaque walls, utilising glazing with lower

SHGC in vertical fenestrations and so on. Table 3 lists

the prescriptive requirements for building envelope

components of ECBC compliant retail buildings in

warm & humid climatic zone of India.

Energy Saving Potential in Building Envelopes through Energy Conservation Building Code and Design Alternatives in Warm and Humid

Climate

31

Table 3: ECBC prescriptive requirements for building

envelope in warm and humid climate.

Building

Envelope

Component

Parameter

Prescriptive

Requirement

Opaque External

Wall

Maximum

U-Value

0.40 (W/m

2

K)

Roof

Maximum

U-Value

0.33 (W/m

2

K)

Vertical

Fenestration

Maximum

SHGC

0.27

Maximum

U-Value

3.00 (W/m

2

K)

The second model is simulated after the

implementation of ECBC prescriptive requirements

on e-QUEST to arrive at the new energy consumption

value. The difference between the energy

consumption values of the first model and the second

model gives the total energy saved through the

implementation of the energy efficiency measures

used to attain the ECBC requirements.

4 RESULTS AND DISCUSSION

On simulating the first model with existing building

parameters as a baseline, an annual electrical energy

consumption value of 547,230 kWh with EPI of 249.8

kWh/m

2

/y was obtained. Majority of the consumed

energy could be attributed to space cooling which

constitutes to 35.44% of the net building energy

consumption. Energy conservation measures for the

building envelope presents potential for reduction in

energy consumption due to space cooling.

Furthermore, it was noticed that maximum energy

consumption occurs in the months of March, April

and May which are the hottest months of the year for

this climatic region which leads to maximum

requirement for space cooling through HVAC

systems.

On obtaining these values and identifying the

major factors that cause an increased consumption of

energy during several months of the year, certain

energy conservation measures (ECMs) specific to the

building envelope were implemented as

prescribed

by ECBC in order to reduce the energy demand by

HVAC systems. The ECMs included aspects such as

change in the U-value of opaque walls, glazing and

roof which are achieved by altering the material or the

building component specifications. Once the changes

were applied to the second model, the building

performance was simulated on eQUEST. The

changes made in the second model resulted in

reduction in energy consumption compared to the

model simulated with existing parameters. The

percentage of energy conserved through the

implementation of each ECM was calculated. Table 4

lists the percentage of reduction in energy

consumption achieved through each ECBC

prescriptive requirement change in the building

envelope and the cumulative energy consumption.

Table 4: Energy savings through each ECBC prescriptive

building envelope ECM.

Parameter

Baseline

Case

ECBC

Prescriptive

ECM

Energy

Savings

(%)

Wall

thickness –

U-value

200mm

thick

concrete

masonry

wall

U-value

2.03

W/m

2

K

300mm thick

aerated concrete

block wall

U-value 0.40

W/m

2

K

7.28%

Roof slab

thickness –

U-value

100mm

thick

reinforced

concrete

slab

U-value 1.8

W/m

2

K

115mm thick

reinforced

concrete slab with

60mm thick over-

deck extruded

polystyrene

insulation

U-value 0.32

W/m

2

K

4.78%

Glazing type

– U-value

10mm

single

glazing

U-value

5.54

W/m

2

K

20mm double

glazing - 6mm

glass with 8mm

air cavity

U-value 3.0

W/m

2

K

5.84%

Glazing type

– SHGC

10mm

single

glazing

SHGC 0.76

20mm double

glazing - 6mm

glass with 8mm

air cavity

SHGC 0.27

5.84%

Cumulative

Total

Total

15.86%

It is observed that change in the properties of opaque

walls lead to maximum reduction in energy

consumption due to space cooling requirement. For

instance, reduction of U-value by using 300mm thick

aerated concrete blocks in opaque walls leads to

reduction of building energy consumption by 7.28%

SMARTGREENS 2021 - 10th International Conference on Smart Cities and Green ICT Systems

32

and addition of insulation in the roof slab to reduce

the U-value, reduced energy consumption by 4.78%.

Similarly, since nearly half of the building

incorporates a glass façade, changing the vertical

fenestration to a double-glazed unit to reduce both the

U-value and SHGC achieved a reduction in building

energy consumption by 5.84%. However, the glass

façade of the demonstration building faces the north

and north east directions and naturally receives a

lower amount of direct sunlight and hence a building

receiving direct sunlight could benefit more from

such lowering of the U-value and SHGC of glazing.

A total of 15.86% savings in energy is achieved

through the implementation of ECMs based on ECBC

prescriptive requirements leading to a reduced annual

energy consumption of 460,439 kWh compared to

547,230 kWh in the baseline case. The results

obtained can be viewed in terms of the classification

of building envelope component where opaque walls

seem to have a higher effect of heat gain compared to

the transparent glazing. This result, however, is

specific to this demonstration building and is

dependent on the type of building, orientation and

overall window to wall ratio. Figure 6 shows the

comparative effect of each ECBC prescriptive ECM

for the building envelope.

Figure 6: Comparative effect of ECBC prescriptive ECM

for building envelope.

Further implementation of Design Alternatives (DA)

for building envelops on the demonstration building

model such as the introduction of cool roof, thermal

insulation of walls and reduction of window-to-wall-

ratio yielded savings in energy in addition to the

savings through ECBC prescribed ECMs. Percentage

of energy savings through each DA and cumulative

total savings of DAs along with ECBC prescriptive

ECMs is listed in Table 5.

Table 5: Energy savings through each DA for building envelope and cumulative savings.

Parameter Baseline Case

ECBC Prescriptive

ECMs Implemented

Design Alternatives

Energy

Savings (%)

Wall thermal insulation

200mm thick concrete

masonry wall - U-

value 2.03 W/m

2

K

300mm thick aerated

concrete block wall -

U-value 0.40 W/m

2

K

– No insulation

300mm thick aerated

concrete block wall

with 60mm thick

thermal insulation

13.62%

Cool Roof

100mm thick

reinforced concrete

slab - No coating - U-

value 1.8 W/m

2

K

115mm thick

reinforced concrete

slab with 60mm thick

insulation - U-value

0.32 W/m

2

K - No

coating

115mm thick

reinforced concrete

slab with 60mm thick

insulation and

reflective coating -

Solar reflectance 0.65

8.22%

Window-to-Wall-Ratio Overall WWR of 0.62 Overall WWR of 0.62 Overall WWR of 0.40 10.47%

DA + ECBC

Prescriptive ECM

Cumulative total

32.31%

0

1

2

3

4

5

6

7

8

Energy Saving Potential in Building Envelopes through Energy Conservation Building Code and Design Alternatives in Warm and Humid

Climate

33

Addition of thermal insulation to the west and

south-west facing walls reduces internal heat gain and

consequently reduces annual energy consumption by

13.62% and the increase in roof solar reflectance to

create a cool roof resulted in 8.22% savings. To

reduce the amount of heat-gain due to direct sunlight

through vertical fenestrations, reduction in the over

WWR of the building envelope to 0.40 reduces

energy consumption by 10.47%. Simulating the

model with the combined effect of both the ECBC

prescriptive ECMs and DAs gives an overall annual

electricity consumption of 401,502 kWh with 32.31%

annual savings.

5 CONCLUSIONS

Through this study, it is evident that there is a

significant potential for energy conservation through

the implementation of ECBC in commercial

buildings. The research is carried out for a

demonstration building situated in the warm and

humid climate zone in Karnataka, India and is a broad

representative sample for this climate and a similar

methodology can be followed for any Indian city with

similar climatic conditions. Changes made to the

building envelope by following ECBC

recommendations for the building envelope achieved

a reduction in annual energy consumption by 15.86%

and additional implementation of DAs lead to an

overall annual savings of 32.31%. It is concluded that

the building envelope is a key determinant factor in

the energy consumed in commercial buildings mainly

required for space cooling. With a large part of the

building stock in India yet to be built, it is important

to implement energy conservation measures in all

upcoming buildings to achieve healthy growth and a

sustainable development of cities in the country.

REFERENCES

McKinsey and Company, 2010, India’s urban awakening:

Building inclusive cities, sustaining economic growth,

India.

U.S. Energy Information Administration, 2017,

International Energy Outlook.

Central Electricity Authority, 2017, Growth of electricity

sector in India from 1947-2017,

Ministry of Power, New Delhi, India.

Central Electricity Authority, 2018, National Electricity

Plan, Ministry of Power, New Delhi, India.

BP, Statistical Review of World Energy, 2017, 66

th

edition.

U.S. Energy Information Administration, 2012, World

Energy Outlook.

International Energy Agency, 2011, Technology Roadmap:

Energy-efficient Buildings: Heating and Cooling

Equipment.

TERI, 2018, Improving Air Conditioners in India Cooling

India with Less Warming Series – Affordable and

Efficient Room Air Conditioners.

Rajesh Chedwal, Jyotirmay Mathur, Ghanshyam Das

Agarwal, Shivraj Dhaka, 2015, Energy saving potential

through Energy Conservation Building Code and

advance energy efficiency measures in hotel buildings

of Jaipur City, India.

M. Jayswal, 2012, To examine the energy conservation

potential of passive & hybrid downdraught evaporative

cooling: a study for commercial building sector in hot

and dry climate of Ahmedabad, India.

Ankur Tulsyan, Shivraj Dhaka, Jyotirmay Mathur, Jai

Vardhan Yadav, 2012, Potential of energy savings

through implementation of Energy Conservation

Building Code in Jaipur city, India.

Tengfang Xu, Jayant Sathaye, Hashem Akbari, Vishal

Garg, Surekha Tetali, 2011, Quantifying the direct

benefits of cool roofs in an urban setting: Reduced

cooling energy use and lowered greenhouse gas

emissions.

SMARTGREENS 2021 - 10th International Conference on Smart Cities and Green ICT Systems

34