A Decision Support System to Evaluate Suppliers in the Context of

Global Service Providers

Bruno P. Bruck

1 a

, Dario Vezzali

2 b

, Manuel Iori

3 c

, Carlo Alberto Magni

4 d

and Daniele Pretolani

3

1

Centro de Inform

´

atica, Universidade Federal da Para

´

ıba, 58058-600 Jo

˜

ao Pessoa, Brazil

2

“Marco Biagi” Foundation, University of Modena and Reggio Emilia, 41121 Modena, Italy

3

Department of Sciences and Methods for Engineering, University of Modena and Reggio Emilia,

42122 Reggio Emilia, Italy

4

Department of Economics “Marco Biagi”, University of Modena and Reggio Emilia, 41121 Modena, Italy

Keywords:

Supplier Selection, Global Service Providers, Multi-criteria Decision Analysis, Analytic Hierarchy Process,

Decision Support System.

Abstract:

In this paper, we present a decision support system (DSS) developed for a global service provider (GSP),

which solves a real-world supplier selection problem. The GSP operates in the Italian market of facility

management, supplying customers with a variety of services. These services are subcontracted to external

qualified suppliers spread all over Italy and chosen on the basis of several criteria, such as service quality,

availability and proximity. Selecting the best supplier is a complex task due to the large number of suppliers

and the great variety of facility management services offered by the GSP. In the proposed DSS, the choice of

the best supplier for a certain service is made according to a thorough multi-criteria analysis. The weights for

the criteria were generated by implementing both a simplified analytic hierarchy process and a revised Simos’

procedure, later validated by the decision makers at the GSP. The DSS provides quick access to historical

performance data, visual tools to aid decisions, and a suggested ranked list of suppliers for each given contract.

The effectiveness of the proposed system was assessed by means of extensive simulations on a seven-year

period of real-data and several rounds of validation with the company.

1 INTRODUCTION

Supplier selection is a well known strategical prob-

lem in supply chain management. Many authors agree

on the idea that a careful selection of suppliers leads

to long-term competitive advantages (Goffin et al.,

1997). To perform this careful selection, it might

be convenient to adopt a multi-criteria evaluation that

takes into account different characteristics of suppli-

ers. According to (Ho et al., 2010), quality, deliv-

ery and cost are the most popular criteria, but several

other aspects might be as important depending on the

context. Grouping and weighting these multiple cri-

teria is not an easy task though, and a careful analysis

is usually required to obtain the best results.

a

https://orcid.org/0000-0003-4361-7476

b

https://orcid.org/0000-0002-3842-6678

c

https://orcid.org/0000-0003-2097-6572

d

https://orcid.org/0000-0003-3066-8426

Such a careful selection is particularly critical

in the facility management industry, where the term

Global Service Provider (GSP) is used to identify gen-

eral players which compete to supply their customers

(e.g., banks, hotels, offices or shop chains) with fa-

cility management services, by subcontracting their

execution to external qualified suppliers. Indeed, the

definition of a comprehensive multi-criteria evalua-

tion might be crucial to support GSPs in the selection

of the most adequate partners in their business.

Multi-criteria decision analysis (MCDA) is a well-

established research field which deals with deci-

sion problems, such as ranking and sorting, where

the decision process must consider multiple criteria

(Ishizaka and Nemery, 2013). In this sense, applying

MCDA to the problem of selecting the best supplier

for a requested service is of particular interest. As

reported by (Ghodsypour and O’Brien, 2001), (C¸ ebi

and Bayraktar, 2003) and (Ho et al., 2010), integrated

approaches that combine MCDA and other methods,

420

Bruck, B., Vezzali, D., Iori, M., Magni, C. and Pretolani, D.

A Decision Support System to Evaluate Suppliers in the Context of Global Service Providers.

DOI: 10.5220/0010412304200430

In Proceedings of the 23rd International Conference on Enterprise Information Systems (ICEIS 2021) - Volume 1, pages 420-430

ISBN: 978-989-758-509-8

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

like optimization and simulation, are to some extent

diffused in the literature of supplier selection.

This paper presents a real case study on the imple-

mentation of a DSS for a multi-criteria supplier eval-

uation problem in the facility management industry.

In particular, the DSS was developed to support H2H

Facility Solutions S.p.A., an Italian GSP based in Zola

Predosa (Bologna), in the process of supplier selec-

tion. H2H Facility Solutions S.p.A., as a GSP, supplies

its customers with a series of facility management

services, which can be classified as planned preven-

tive maintenance, corrective maintenance or extraor-

dinary maintenance. The category of services pro-

vided might vary from air-conditioning and heating

systems maintenance to water supply, electrical sys-

tems, elevators, fire protection systems maintenance,

cleaning, surveillance, and so forth. The DSS was de-

veloped in partnership with the company by carefully

defining a comprehensive hierarchical tree of criteria

on which supplier evaluation is performed and im-

plementing a simplified Analytic Hierarchy Process

(AHP) to compute the weights of identified criteria.

In order to formally describe the decision problem

that H2H Facility Solutions S.p.A. solves each time

a facility management service, or long-term main-

tenance contract, has to be subcontracted, a multi-

objective integer programming (IP) model was for-

mulated. The proposed methodology was imple-

mented and integrated in a prototype (i.e., a web ap-

plication), which was tested with potential users on a

real data set obtained both from historical data pro-

vided by the company and by collecting additional

data from an online survey sent to a sample of suppli-

ers. Following an accurate data preparation process,

a ranking of suppliers for each specific service cat-

egory has been derived by evaluating an aggregated

score. Finally, a simulation of supplier selection over

a seven-year horizon was performed by combining the

implemented multi-criteria evaluation method with a

heuristic algorithm derived from the multi-objective

IP model. The problem was solved using a weighted

sum scalarization method in order to create and com-

pare different scenarios, with the objective of maxi-

mizing the average aggregated score of selected sup-

pliers and minimizing the average distance between

the facilities of customers and the appointed branches

of suppliers to whom the maintenance contract is sub-

contracted.

The remainder of this paper is structured as fol-

lows. Section 2 presents a brief literature review on

supplier selection. In Section 3, the supplier selec-

tion problem in the context of GSPs is formally de-

fined. The proposed multiple criteria evaluation, the

computation of weights using the AHP and the re-

vised Simos’ procedure and the detailed comparison

of results are provided in Section 4. Section 5 de-

scribes the DSS prototype implementation, while the

computational experiments are reported in Section 6.

Finally, in Section 7, we draw conclusions and formu-

late possible future research directions.

2 LITERATURE REVIEW

Integrated approaches, optimization and evaluation

methods based on multiple criteria for supplier se-

lection have been widely studied since the early

1990s. For relevant seminal works we refer to (We-

ber et al., 1991), (Goffin et al., 1997), (Ghodsypour

and O’Brien, 1998) and (Ghodsypour and O’Brien,

2001). Instead, for a more in-depth overview on this

field of research, we refer the interested reader to the

recent surveys of (Ho et al., 2010), (Ware et al., 2012)

and (Chai et al., 2013). Then, in the latest years, the

topic of sustainability is drawing increasing attention

even in supply management due to its high applicabil-

ity. For an overview on the problem of green supplier

selection we refer to the survey of (Govindan et al.,

2015).

The AHP is a multi-criteria decision method de-

veloped in the early 1970s by Thomas Saaty, whose

purpose is to break down a decision (e.g., a selection

or ranking problem) into factors, arranged in a hier-

archic structure from an overall goal to criteria, sub-

criteria and alternatives in successive levels (Saaty,

1990). The AHP can be applied as an individual

method or integrated with other techniques, due to its

simplicity, ease of use, and flexibility. Among the

multi-criteria decision making approaches for sup-

plier evaluation and selection surveyed by (Ho et al.,

2010), integrated AHP approaches were proved to be

the most commonly used. In addition, from the very

recent survey of (Ho and Ma, 2018) it also emerges

that integrations of the AHP were widely applied in

manufacturing and logistics areas, whereas the most

commonly studied problem is supplier evaluation and

selection. The integrated approach that most concern

our work is indeed AHP-mathematical programming.

In the following, a more detailed review of a

few relevant articles is reported concerning integrated

AHP-mathematical programming approaches. The

first two papers are taken from a stream of literature

between 1997 and 2006, as surveyed by (Ho, 2008);

the next two come from a stream of literature between

2007 and 2016, as surveyed by (Ho and Ma, 2018).

In (C¸ ebi and Bayraktar, 2003), an integrated ap-

proach which combines AHP and Lexicographic Goal

Programming was proposed and applied for a particu-

A Decision Support System to Evaluate Suppliers in the Context of Global Service Providers

421

lar supplier selection problem of a Turkish food com-

pany. In this case, quality, delivery and cost factors

were selected as the objective functions of a math-

ematical model, while a utility function, expressing

supplier scores, was added to the model and derived

through an AHP. The AHP considers further crite-

ria not related to quality, delivery and cost, such as

logistics, technological capability, business (in terms

of reputation, market position, financial strength, and

management skills), and relationship (in terms of abil-

ity to communicate, past experiences, and compe-

tences of sales representatives).

In (Wang et al., 2004), an integrated multi-criteria

decision making methodology for supplier selection

was developed, which combines AHP and Preemptive

Goal Programming (PGP). In particular, the selection

of criteria and their arrangement in a hierarchic struc-

ture is based on the Supply Chain Operations Ref-

erence framework. The PGP model is then used to

address some problem constraints, such as the capac-

ity of suppliers, the number of suppliers required, and

so on. In this case, the priorities computed using the

AHP are inserted in the objective function as coeffi-

cients.

In (Kull and Talluri, 2008), an integrated approach

for risk reduction in supplier selection, resulting in

a combination of AHP and Goal Programming (GP),

has been proposed. In particular, the AHP is used to

derive risk scores for suppliers, while taking into ac-

count product life cycle phases. The so-obtained risk

scores are then incorporated in an objective function

of a GP model, which considers other constraints, re-

lated to lead time, quality, capacity of suppliers, min-

imum order quantities, and demand satisfaction. The

proposed integrated approach was tested at a mid-size

second-tier automotive supplier.

In (Mafakheri et al., 2011), an integrated approach

for supplier selection and optimal order allocation,

combining AHP and Dynamic Programming (DP),

was proposed. Firstly, a ranking of suppliers based on

four criteria (price performance, quality, delivery per-

formance, and environmental performance), which

are further divided into 21 total sub-criteria, is created

using the AHP. Then, the information obtained by ap-

plying the AHP is passed to a bi-objective DP model,

whose goal is to maximize the Total Value of Purchas-

ing, while minimizing the Total Cost of Purchase. The

two objective functions are subjected to a series of

constraints, related to capacity of suppliers, maximum

level of inventory allowed, and demand satisfaction.

Recently, several authors have successfully devel-

oped DSSs based on MCDA to help decision makers

in selecting the best suppliers. An interesting work

that resembles ours is the one by (Dweiri et al., 2016),

in which an integrated AHP-based DSS for supplier

selection in automotive industry was developed. In

this implementation, AHP is applied to rank automo-

tive suppliers in Pakistan, identifying four main crite-

ria (price, quality, delivery and service) from a litera-

ture review, and further dividing them into sub-criteria

(e.g., lead time, error, and on-time delivery in order

to assess delivery; order update, warranty, and geo-

graphical location in order to evaluate service). The

relative weights of criteria and sub-criteria were com-

puted using an AHP-based on the opinions of sourc-

ing experts, collected through a survey. The DSS was

tested on a simplified case study consisting of three

suppliers and a sensitivity analysis was performed in

order to verify the robustness of the proposed method.

In contrast, our DSS was implemented in the con-

text of GSPs and tested on a broader database consist-

ing of 158 suppliers. The identification of the main

criteria, and their relative sub-criteria, was performed

in partnership with the company in an early stage of

our work. The computation of the weights was per-

formed using AHP and data from a survey performed

with experts from the company.

Remarkably, our work provides a series of valu-

able contributions, as compared to the reviewed liter-

ature:

• The choice of criteria and their relative sub-

criteria, performed jointly with an extended work-

ing group from the company, is consistent with the

most popular evaluating criteria found in the liter-

ature on supplier selection.

• We use the AHP to compute the weights of a com-

plex and multilevel tree of criteria and, addition-

ally, the obtained results are compared and vali-

dated by a revised Simos’ procedure (Figueira and

Roy, 2002). Our pairwise comparisons are based

on a simplified 1-5 scale instead of the fundamen-

tal 1-9 scale for AHP preference originally pro-

posed by Saaty, in order to simplify the surveying

process that precedes the definition of comparison

matrices. Nevertheless, the proposed methodol-

ogy is highly repeatable and can be reiterated at

regular intervals in accordance with the desider-

ata of the company.

• The specific supplier evaluation and selection

problem of H2H Facility Solutions S.p.A. was for-

mally defined by a multi-objective IP model, in

order to consider a set of constraints.

• Our case study is built on a broad database of 158

suppliers, which it makes particularly relevant in

terms of problem dimension.

• Extensive simulations on a seven-year period of

real-data were performed, in order to recreate and

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

422

repeat the choices made by the company, while

applying the multi-criteria evaluation.

• Finally, the proposed methodology was imple-

mented and integrated in a DSS prototype (i.e., a

web application) which was delivered to the com-

pany.

To the best of our knowledge, no analogous strategic

and operational tool exists in supplier selection liter-

ature. Furthermore, because of the emerging role of

GSPs in many different markets, our study constitutes

a valuable real-world application of AHP, MCDA and

optimization.

3 PROBLEM DEFINITION

In our case study, a facility management contract is

related to a service and concerns a particular facil-

ity. Every time the GSP formalizes a contract with

a customer, the contract is subcontracted to an ex-

ternal qualified supplier that is capable of providing

the required service, in accordance with a predefined

service-level agreement (SLA). Both the contract and

the subcontract demand a negotiation phase, respec-

tively, between the GSP and the customer, and be-

tween the GSP and the supplier.

Formally, given a set C of contracts and a set F

of suppliers, the supplier selection problem in the

context of GSPs is to subcontract a series of facil-

ity management contracts to the best suppliers with

the dual objective of (i) maximizing the total score

of the selected suppliers and (ii) minimizing the total

distance. In particular, we define d

c f

as the geograph-

ical distance between the facility to whom contract c

is related and the branch of supplier f that is respon-

sible for supplying the facility management service.

For each supplier, a score s

f

∈ [0,100] is obtained by

means of the MCDA that is described in the follow-

ing section. Basically, s

f

represents an aggregated

adimensional score derived from the tree of criteria.

This tree was developed in partnership with the com-

pany to serve as the basis for the supplier evaluation

procedure. Furthermore, let us define q

f

as the ca-

pacity in terms of the maximum number of contracts

that can be assigned to supplier f . Possible prefer-

ences of customers are expressed through a binary

parameter p

c f

, which takes value 1 if supplier f is

explicitly required for contract c and 0 otherwise. On

the other hand, the potential refusal of a supplier by a

customer is expressed through another binary param-

eter r

c f

, taking value 1 if contract c cannot be sub-

contracted to supplier f and 0 otherwise. In addition,

we set a maximum acceptable distance α, between the

nearest branch of supplier f and the particular facility

of customer associated with contract c.

Let x

c f

be a binary variable that takes value 1 if

contract c is subcontracted to supplier f and 0 other-

wise, and y

f

be a binary variable that takes value 1 if

at least one contract is subcontracted to supplier f and

0 otherwise.

The supplier selection problem (SSP) is a particu-

lar bi-objective version of the generalized assignment

problem, which consists of determining the assign-

ment of each contract to a supplier, by satisfying the

aforementioned constraints, while maximizing the to-

tal score and minimizing the total distance. Indeed,

proximity between customers and suppliers is desir-

able because it should guarantee a better compliance

with SLAs and, consequently, a greater customer sat-

isfaction. The SSP can be then modeled as in the fol-

lowing.

z(SSP) = min

−

∑

c∈C

∑

f ∈F

s

f

x

c f

;

∑

c∈C

∑

f ∈F

d

c f

x

c f

!

(1)

subject to

∑

f ∈F

x

c f

= 1 ∀ c ∈ C (2)

∑

c∈C

x

c f

≤ q

f

∀ f ∈ F (3)

x

c f

= 1 ∀ c ∈ C, f ∈ F : p

c f

= 1 (4)

x

c f

= 0 ∀ c ∈ C, f ∈ F : d

c f

> α,r

c f

= 1 (5)

x

c f

∈ {0,1} ∀ c ∈ C, f ∈ F. (6)

The objective function (1) maximizes the score of the

selected suppliers and minimizes the total distance.

Constraints (2) impose that each contract c has to be

assigned to exactly one supplier, whereas constraints

(3) express the capacity of suppliers. According to

constraints (4), contract c is assigned to supplier f if

the customer expresses its preference for it. On the

other hand, according to constraints (5), contract c

cannot be assigned to supplier f if the customer ex-

presses its refusal for it or if supplier f is more distant

than α. Finally, constraints (6) define the domain of

the variables.

The purpose of this formulation is mainly descrip-

tive. However, note that the greedy heuristic algo-

rithm proposed in Section 5 is more advanced because

it considers a dynamical aspect of the problem, such

as the daily update of score s

f

due to the assignment

of new contracts to suppliers. Such a dynamical eval-

uation should avoid the issue of saturating a few sup-

pliers with most of the contracts, which has the po-

tential of gradually deteriorating their performance in

the long-term.

A Decision Support System to Evaluate Suppliers in the Context of Global Service Providers

423

4 MULTIPLE CRITERIA

EVALUATION

In the previous section, we introduced the score s

f

as an aggregated value for each supplier f ∈ F. Re-

call that the evaluation of this score is a result from

an MCDA performed in partnership with the com-

pany. This analysis has been conducted through sev-

eral rounds of interviews, which have led to the defini-

tion of a multi-level tree of criteria, on which supplier

evaluation is based.

In particular, three levels of criteria were identi-

fied. The macro criteria directly contribute to define

the score s

f

for each supplier f . This first level is bro-

ken down into a second level of micro criteria, which,

in a few cases, are further split into a third level of

nano criteria.

Economic indicators (ECI), technical and profes-

sional capability (TPC), additional saturation capac-

ity (ASC), service level performance (SLP), and ref-

erences (REF) were carefully selected as the macro

criteria that fully describe the principal dimensions of

supplier evaluation in the context of GSPs.

For the sake of conciseness, we only report a deep-

ened explanation of the five macro criteria. In detail,

ECI aim to give an evaluation of suppliers in terms

of dimension and economic soundness, regarding the

last year financial statements. TPC evaluates the orga-

nizational structure, the competencies and the exten-

siveness of suppliers over the territory. ASC gives the

residual capacity of suppliers in terms of possibility to

accept new contracts. SLP aims to deeply evaluate the

suppliers on the basis of several dimensions of perfor-

mance and on their historical data. Finally, REF are

particularly important to qualify suppliers, given that

they specify the references of customers with whom

they have already worked.

In the following, we report the detailed list of mi-

cro criteria for each of the aforementioned macro cri-

teria:

• ECI: revenue (REV) and leverage (LEV);

• TPC: workers per service (WPS), qualifications

per worker (QPW), office workers per employee

(OPE), revenue per employee (RPE), and number

of provinces per branch (PPB);

• ASC: facilities per worker (FPW), square meters

per worker (SMW), and revenue produced with

H2H Facility Solutions S.p.A. per total revenue

(RPR);

• SLP: operational punctuality (OPT), administra-

tive punctuality (APT), flexibility (FLX), quality

(QLT), internal feedback (IFB), and external feed-

back (EFB);

• REF: number of references (NRF) and average

reference segment (ARS).

These micro criteria are very context-specific and,

among them, the micro criteria regarding SLP are fur-

ther broken down into a series of nano criteria, which

are listed in the following:

• OPT: percentage of planned preventive mainte-

nance services performed out of SLA (PPO), per-

centage of corrective maintenance services per-

formed out of SLA (PCO), percentage of quotes

presented late (PQP), and percentage of quotes ex-

ecuted late (PQE);

• APT: percentage of requested documents pre-

sented late (PDL), and percentage of maintenance

reports erroneously filled out (PRE);

• FLX: ratio of extraordinary maintenance to

planned preventive maintenance (REP), percent-

age of rejected corrective maintenance services

(PRS), and assigned but not performed services

(NPS);

• QLT: ratio of quoted extraordinary maintenance

to extraordinary maintenance (RQE), percentage

of accepted quotes (PAQ), percentage of noti-

fications from customers (PNC), percentage of

incomplete maintenance services (PIS), percent-

age of additional information sent by means of

the maintenance app (PAI), and percentage of

planned preventive maintenance services not per-

formed (PPN);

• IFB: average internal score (AIS), and affordabil-

ity index (AFI);

• EFB: this micro criterion is not further defined.

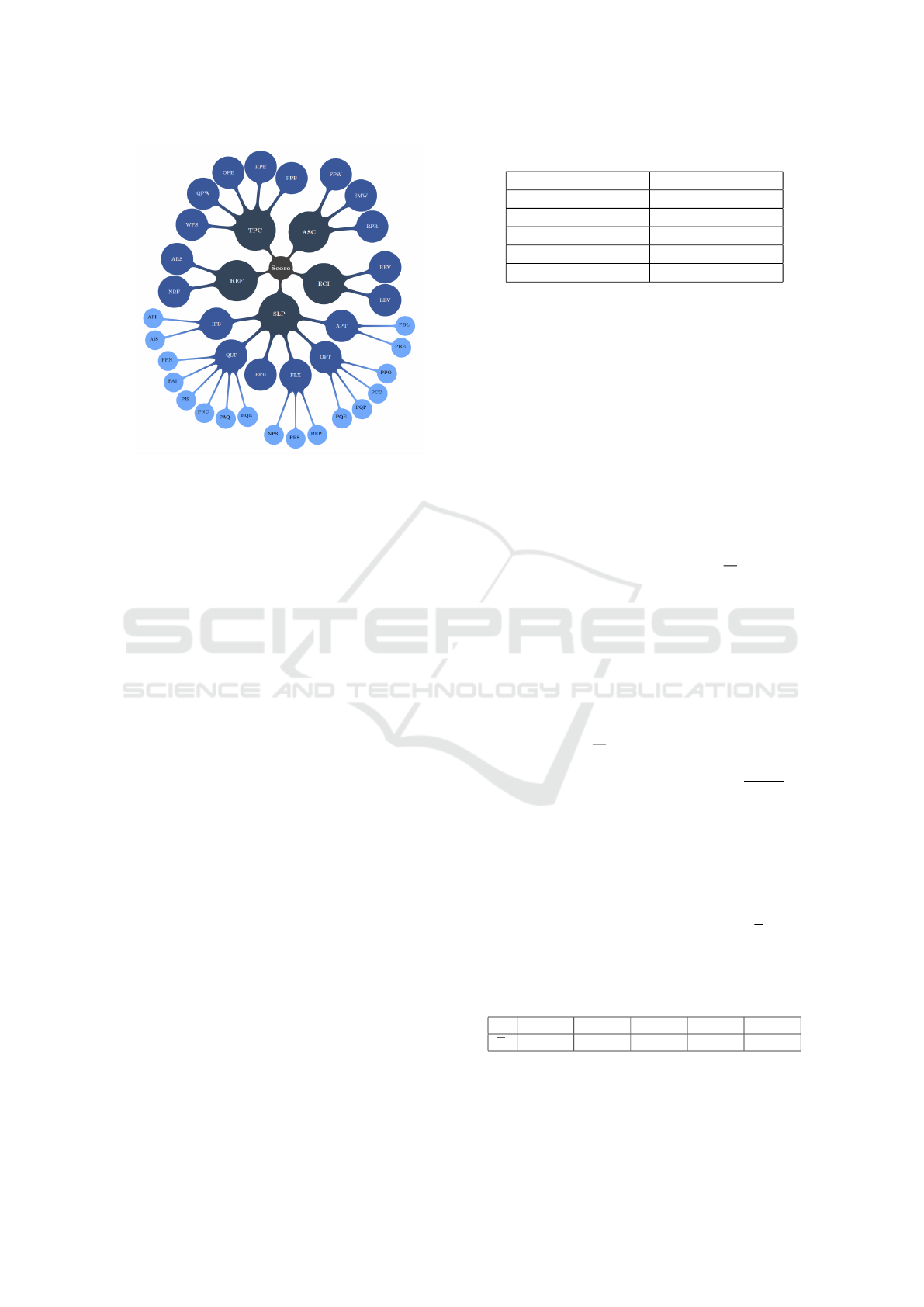

Figure 1 illustrates the three-level tree of criteria, on

which supplier evaluation is based.

Starting from the aforementioned tree of criteria,

the score s

f

is derived as the sum of the products of

weights of criteria and their evaluations, which are

first of all normalized in [0,1] and then scaled in the

interval [0,100] for better understanding. We provide

further details about the normalization process in Sec-

tion 5.

In particular, by using the simplified AHP and the

revised Simos’ procedure described in Sections 4.1

and 4.2, the weights of criteria are computed as fol-

lows:

1. At the first level, the weights of macro criteria are

determined.

2. At the second level, for each macro criterion, the

weights of micro criteria are determined.

3. At the third level, for each micro criterion, the

weights of nano criteria, if they exist, are deter-

mined.

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

424

Figure 1: Tree of criteria.

Note that, at each sub-level (i.e., a sub-level might be

related to the score s

f

or a particular macro or micro

criterion) the sum of the weights should be equal to 1.

The score s

f

is then obtained by an iterative

bottom-up sum of the products of weights and nor-

malized evaluations, where the partial score of each

micro criterion is determined based on weights and

evaluations of its nano criteria, if they exist, and the

partial score of each macro criterion is determined

based on weights and evaluations of its micro crite-

ria.

At the end of this iterative process, the score s

f

is

computed as follows:

s

f

= (p

IEC

s

IEC

) + (p

T PC

s

T PC

) + (p

ASC

s

ASC

)

+ (p

SLP

s

SLP

) + (p

REF

s

REF

) (7)

where p

IEC

, p

T PC

, p

ASC

, p

SLP

, and p

REF

are the

weights of macro criteria, while s

IEC

, s

T PC

, s

ASC

, s

SLP

,

and s

REF

correspond to their normalized evaluations.

4.1 Weights Computation using the

Simplified AHP

After defining the multi-level tree of criteria, the com-

putation of weights was performed. We accomplished

this task by applying a simplified AHP, based on pair-

wise comparisons and the reduced scale reported in

Table 1. For each pairwise comparison, the respon-

dents were asked to answer the following standard

question: “What is the relative importance of crite-

ria A compared to criteria B?”. The answers from 20

decision makers at the GSP were collected through an

online survey.

Given the practical implication of our work, the

rationale behind using a reduced scale, instead of the

Table 1: The reduced scale.

Relative Importance Comparison Value

Strongly less 1/5

Moderately less 1/3

Equal 1

Moderately more 3

Strongly more 5

fundamental scale originally proposed by Saaty, is to

simplify the collection of pairwise judgments, possi-

bly minimizing inconsistencies.

For each respondent and for each level of criteria,

judgments were converted into comparison values and

were recorded in comparison matrices such as the fol-

lowing one:

A =

a

11

a

12

... a

1n

a

21

a

22

... ...

... ... ... ...

... ... a

i j

...

a

n1

a

n2

... a

nn

(8)

where a

i j

corresponds to the comparison value of cri-

teria i compared to criteria j, a

i j

=

1

a

ji

and a

i j

=

1 ∀ i, j : i = j.

Given a comparison matrix, the relative weights of

criteria were derived by applying the so-called “mean

of row” method described by (Ishizaka and Labib,

2011), which is based on the following three steps:

1. Sum the elements of each column j: S

j

=

∑

n

i=1

a

i j

∀ j

2. Divide each element a

i j

by the relative column

sum S

j

: a

0

i j

=

a

i j

S

j

∀ i, j

3. Compute the mean of each row i: p

i

=

∑

n

j=1

a

0

i j

n

∀ i.

In group decision making contexts like ours, when

several decision makers express their judgments,

weights are combined by applying the geometric

mean method (GMM) in order to obtain synthetic val-

ues for the entire group, as suggested by (Acz

´

el and

Saaty, 1983).

The aggregated weights obtained for the macro

criteria are reported in Table 2. We define p

i

as the

aggregated weight for macro criteria i.

Table 2: Aggregated weights for macro criteria using the

AHP.

i IEC TPC ASC SLP REF

p

i

0.1527 0.2672 0.1794 0.2394 0.1614

A Decision Support System to Evaluate Suppliers in the Context of Global Service Providers

425

4.2 Weights Computation using the

Revised Simos’ Procedure

In order to verify the results obtained using the simpli-

fied AHP, we applied a second multi-criteria decision

method (MCDM): the revised Simos’ procedure pro-

posed by (Figueira and Roy, 2002), which is particu-

larly suitable to assess group decision processes with

several sets of criteria. In this case, the experiment

was restricted to a group of 8 decision makers at the

GSP, whose answers were collected during individual

interviews.

The experiment followed a four-step procedure

which was repeated for each level of criteria, with the

aim of collecting the necessary information to deter-

mine the weights of the criteria. The first three steps

correspond to the original Simos’ procedure, while

the fourth step was introduced in the revised method-

ology proposed by (Figueira and Roy, 2002) in order

to improve a few drawbacks of the original work. The

whole procedure is described in the following:

1. Given a set of n criteria that have to be weighted,

give the respondent a first set of n cards with the

name of each criterion written on them. Then give

the respondent a second set of white cards, having

the same size. The number of white cards is not

fixed, but it depends on the needs of the respon-

dent.

2. Ask the respondent to rank the criteria in ascend-

ing order, from the least important to the most

important. If some criteria have the same impor-

tance, they should be grouped together.

3. Ask the respondent to insert white cards between

successive criteria (or subsets of ex aequo criteria)

if a difference in terms of importance has to be

highlighted. The principle of white cards insertion

is simple: the greater the difference, the greater

the number of white cards.

4. Finally, ask the respondent to estimate the rela-

tive importance of the last criterion (or subset of

ex aequo criteria) compared to the first. This in-

formation is stored into the parameter z.

The computation of weights was performed by im-

plementing the nontrivial algorithm proposed by

(Figueira and Roy, 2002), where specific attention is

paid to the rounding technique while determining the

normalized weights of criteria.

Again, the aggregation of weights was obtained

by means of the GMM. The so-derived aggregated

weights for the macro criteria are reported in Table

3.

The results are consistent with those obtained us-

ing the simplified AHP and, except for REF macro

Table 3: Aggregated weights for macro criteria using the

revised Simos’ procedure.

i IEC TPC ASC SLP REF

p

i

0.1571 0.2608 0.1971 0.2676 0.1175

criterion, they show an acceptable variation.

5 DSS IMPLEMENTATION

The DSS is composed by two main modules. The first

one is a database that stores data regarding all suppli-

ers available to the company and all the necessary in-

formation about contracts. The second module is then

responsible for evaluating the score of each supplier

according to the tree of criteria presented in Section

4.

As previously mentioned, when evaluating a given

supplier, the score s

f

is derived by means of an iter-

ative bottom-up sum of the products of weights and

normalized evaluations of nano, micro and macro cri-

teria, in this order. The normalization process occurs

in this second module and it is performed as follows:

1. For each criterion i ∈ I and for each supplier f ∈ F

we are given an evaluation e

i f

.

2. For each set of evaluations e

i f

related to a particu-

lar criterion i ∈ I we identify potential outliers by

means of box plots.

3. In case of direct normalization (i.e., the greater

the evaluation, the greater the normalized value

we want to obtain), we compute the evaluation

E

i f

= e

i f

/e

max

∀ i, f , where e

max

is the maximum

evaluation. The outliers take value 1, if they fall

outside the external upper edge value of our box

plot, and 0, if they fall outside the external lower

edge value.

4. In case of reverse normalization (i.e., the greater

the evaluation, the fewer the normalized value we

want to obtain), we compute the evaluation E

i f

=

1 − e

i f

/e

max

∀ i, f , where e

max

is the maximum

evaluation. The outliers take value 0, if they fall

outside the external upper edge value of our box

plot, and 1, if they fall outside the external lower

edge value.

5. The normalized evaluations E

i f

are then scaled in

the interval [0,100].

Because the evaluation of suppliers depends on the

information stored in the database (past and present),

the score of a certain supplier may well change over

time. For instance, as more contracts are assigned to

the same supplier, it might become saturated, poten-

tially reducing its score for future contracts.

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

426

In general, the proposed DSS is designed to re-

trieve updated information from the database of the

company on a daily basis and recompute the score of

each supplier. Then, every time a new contract is for-

malized, the decision makers can query the system,

filter the returned ranking of suppliers, and use their

experience to select the most appropriate from a re-

duced list of candidates. Note that, at this stage, it

is important not only to consider the score of suppli-

ers but also their distance from the facilities of cus-

tomers. In this sense, to build the reduced list of can-

didates, we sort the suppliers according to the follow-

ing weighted function:

δ S

f

+ (1 − δ) D

c f

, (9)

where f ∈ F and c ∈ C are, respectively, the sup-

plier being evaluated and the contract that we want

to assign. S

f

= (s

f

/s

max

) ∗ 100 expresses the score

of supplier f , given the previously defined score s

f

and the maximum score s

max

, whereas D

c f

= (1 −

(d

c f

/d

max

)) ∗ 100 defines the distance score, given

the geographical distance d

c f

between the nearest

branch of supplier f and the facility of customer as-

sociated with contract c, and the maximum distance

d

max

. Both the score S

f

and the distance score D

c f

are normalized and scaled so that the result of (9) lies

in the interval [0, 100]. Finally, δ is a multiplier be-

tween [0.1,0.9] that controls the relative importance

of each term of the aforementioned weighted func-

tion, and can be customized by the decision maker.

To simplify, we refer to the aggregated value com-

puted by this function as assignment score, given that

it is associated with a specific assignment of a contract

c to a supplier f .

In order to validate and assess the quality of the

recommendations proposed by the system, we imple-

mented a third module into the DSS. This module

takes as input a list of contracts that were handled by

the company on a certain day, and tries to select an

appropriate supplier by means of a greedy heuristic

algorithm. For each contract, the algorithm computes

the assignment score for all available suppliers and

assigns it to the one with the highest score. We report

in the following page the pseudo-code of the proposed

greedy heuristic algorithm, where t ∈ T is a day in the

simulation horizon T .

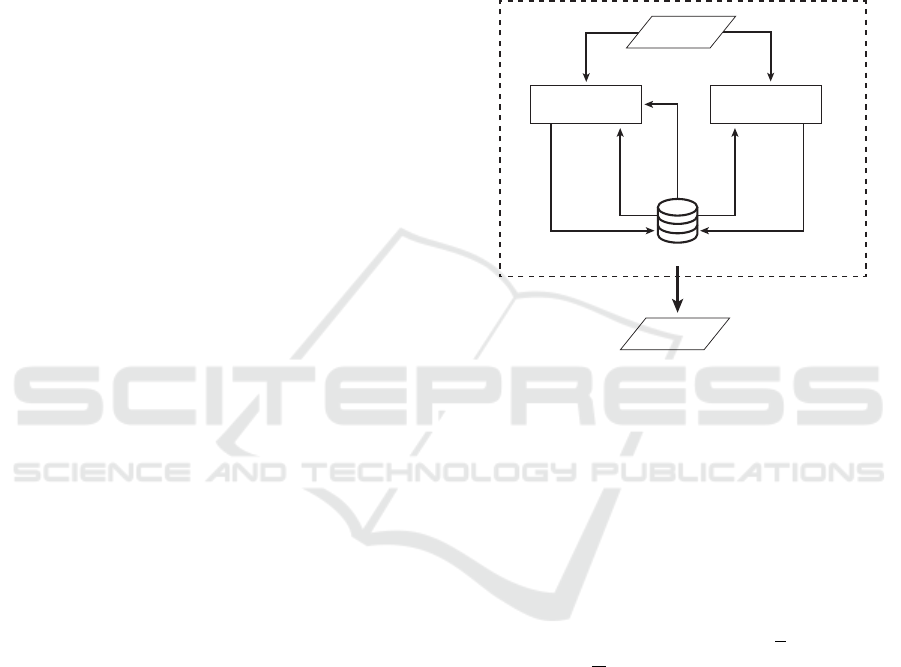

The results of the aforementioned simulation are

stored in the database, so that when new contracts

have to be assigned, the scores are recomputed and

updated accordingly. The DSS architecture with all

the three modules is depicted in Figure 2. Note that,

with this structure, we are able to run simulations for

any period of time based on past data from the com-

pany. However, it is worth mentioning that these sim-

ulations are intended to fine-tune the system and vali-

date the recommended assignments together with the

company. In practice, the DSS is designed to provide

decision makers with the necessary tools to make an

informed decision based on an ordered ranking of the

best suppliers without automating the complete pro-

cess, and it is meant to be integrated as a decision-

making component within an ERP system, see, e.g.,

(Pek

ˇ

sa and Grabis, 2018).

Database

Supplier Selection

Simulator

Repeat for each day d in the period of the simulation

Supplier Evaluator

Provide

contracts

of day d

Provide all

suppliers

Update

Scores

Update

Contracts

Weights

Provide

Scores

Simulation

Results

Extract results

Figure 2: DSS architecture.

6 COMPUTATIONAL

EVALUATION

The greedy heuristic algorithm presented in Section

5 was used to perform extensive simulations. We

used different values for δ and a database of contracts

associated with real-data from a seven-year period.

The resulting assignments were evaluated by means

of the aforementioned average score S

f

and average

distance score D

c f

.

Note that the generic distance d

c f

between the fa-

cility of customer c ∈ C and the branch of supplier

f ∈ F was evaluated using the following haversine

formula:

d

c f

= R arccos(cos λ

c

cosϕ

c

cosλ

f

cosϕ

f

+

cosλ

c

sinϕ

c

cosλ

f

sinϕ

f

+ sin λ

c

sinλ

f

), (10)

where R is the Earth radius, λ

c

and ϕ

c

respectively,

the latitude and the longitude (in radians) relative to

the facility of customer c ∈ C, and λ

f

and ϕ

f

, respec-

tively, the latitude and the longitude (in radians) rela-

tive to the branch of supplier f ∈ F.

In our simulations, we experimented with δ ∈

[0.1,0.9], thus resulting in a series of alternative solu-

tions, which compose the Pareto set shown in Figure

A Decision Support System to Evaluate Suppliers in the Context of Global Service Providers

427

Algorithm 1: Greedy heuristic algorithm pseudo-code.

1: Set a value of the multiplier δ

2: for t = 1,2,...,T do

3: Get the sub-list C of contracts to assign in day t

4: if C 6=

/

0 then

5: for f = 1, 2, . . . , F do

6: Update ASC macro criterion

7: Recompute supplier score s

f

8: end for

9: Normalize and scale the scores S

f

in the interval [0,100]

10: for c = 1, 2, . ..,C do

11: for f = 1, 2, . . . , F do

12: Evaluate the branch of supplier f having the shortest distance d

c f

13: end for

14: Normalize and scale the distance scores D

c f

in the interval [0,100]

15: for f = 1, 2, . . . , F do

16: Compute the assignment score δ S

f

+ (1 − δ) D

c f

17: end for

18: Assign contract c to supplier f having the highest assignment score

19: end for

20: end if

21: Update the average simulation score S

f

22: Update the average simulation distance score D

c f

23: Update the average simulation distance d

c f

24: end for

3. Each point in the chart represents a particular solu-

tion identified by an average score S

f

and an average

distance d

c f

retrieved at the end of the simulation. For

visual clarity, the average distance d

c f

is expressed in

kilometers, instead of using the normalized distance

score D

c f

computed in the weighted function (9).

Figure 3: Pareto set resulting from different rounds of sim-

ulation.

Typically, the choice of the most desirable solution

should be made by the decision maker at the GSP, ac-

cording to what is considered the best trade-off be-

tween the average supplier score S

f

and the average

distance d

c f

. Note that, the two squared points iden-

tify likewise dominated solutions, so they are not even

candidates to be the most desirable solution.

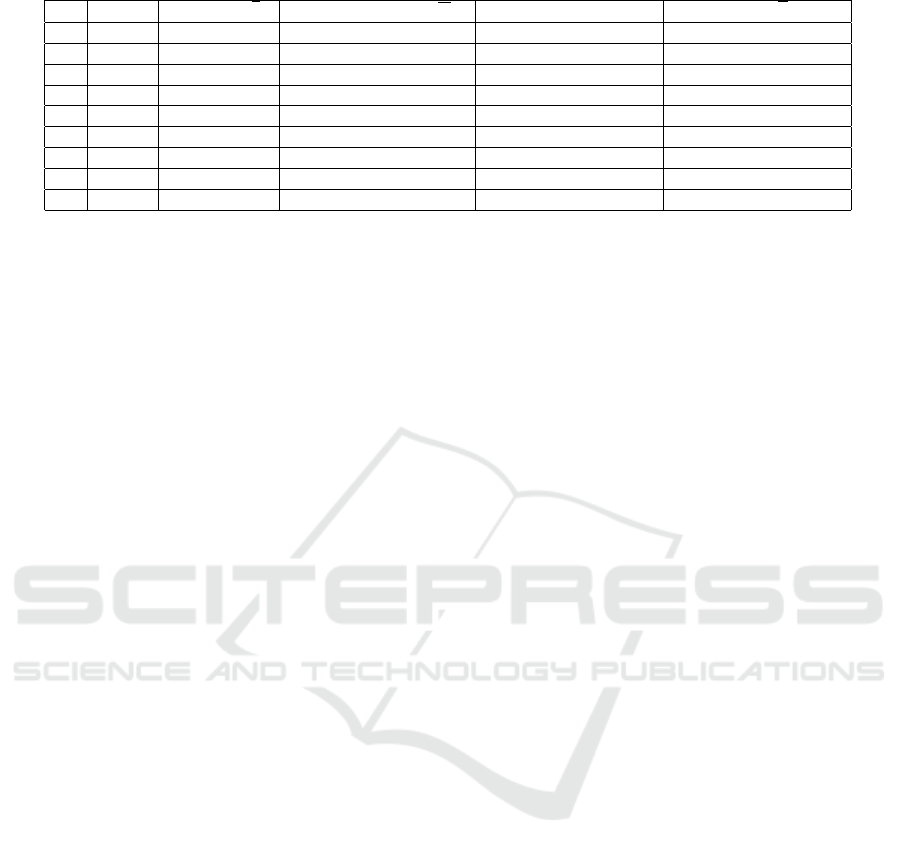

Table 4 reports the detailed results obtained by

means of the extensive simulations performed for

each multiplier δ. For example, looking at the column

of the average assignment score, a decision maker

might be willing to choose the solution identified by

δ = 0.6 as a good trade-off between the average sup-

plier score S

f

and the average distance d

c f

. Other

good solutions are identified by δ = 0.3, δ = 0.4, and

δ = 0.5.

The results obtained from each round of simula-

tion were duly shared with the company, compared to

the incumbent assignments, and validated.

7 CONCLUSIONS

In this paper, we presented a supplier selection prob-

lem for a global service provider and proposed a de-

cision support system to aid the decision makers at

H2H Facility Solutions S.p.A. in the process of sup-

plier evaluation and selection. In particular, the eval-

uation of suppliers was made by means of a thorough

multi-criteria decision analysis performed in partner-

ship with the company which led to the definition of

a multi-level tree of criteria. The weights of crite-

ria were computed by implementing a simplified an-

alytic hierarchy process and a revised Simos’ pro-

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

428

Table 4: Extended computational results.

δ (1 − δ) Avg. Score S

f

Avg. Distance Score D

c f

Avg. Assignment Score Avg. Distance d

c f

[km]

0.1 0.9 56 94 150 24

0.2 0.8 60 94 154 27

0.3 0.7 62 93 155 31

0.4 0.6 64 91 155 38

0.5 0.5 64 91 155 42

0.6 0.4 65 90 155 46

0.7 0.3 65 88 153 51

0.8 0.2 67 84 151 65

0.9 0.1 69 72 141 148

cedure. The results obtained with the two methods

turned out to be reasonably similar. The DSS was im-

plemented in a three-module architecture, where the

first module is a database that stores information re-

garding contracts and suppliers. The second module

is responsible for evaluating the score of each sup-

plier, and the third simulates the assignment of con-

tracts to suppliers based on a greedy heuristic algo-

rithm and a weighted function, which evaluates an ag-

gregated assignment score. The effectiveness of the

proposed DSS was tested by means of extensive sim-

ulations over a seven-year period of real-data, identi-

fying a series of alternative solutions. Given these al-

ternative solutions, a decision maker can then choose

the most appropriate one based on his/her experience.

In general, we found that the proposed approach is

extremely flexible and highly repeatable. Therefore,

it could possibly be adapted with some adjustments

to other real-world supplier evaluation and selection

problems, in different contexts as well. Indeed, in

case of adaptation to other companies and industries,

the proposed criteria should be slightly reconsidered

in order to describe the problem of supplier selection

in another context. However, once redefined the tree

of criteria, the methodology might be fully replied.

As future work, we intend to perform a deeper

computational evaluation of our methods, as well as

to further investigate the selection of macro, micro

and nano criteria, in order to express a few dimen-

sions of the multiple criteria evaluation more exhaus-

tively. In particular, it might be the case of refining

the Economic indicators (ECI) in such a way that a

more careful selection of micro criteria might lead to

a more significant evaluation of economic soundness

of suppliers. Then, with the aim of performing a de-

tailed comparative evaluation, we intend to further de-

velop the greedy heuristic algorithm, including addi-

tional dynamical aspects of the problem, such as an

acceptable saturation level range for suppliers, a tar-

get number of active suppliers, and a proposal of orga-

nizational structure variations for suppliers in order to

improve their score and, consequently, the probability

to be selected. We also plan to develop more elabo-

rated heuristic strategies. Finally, given the rising im-

portance of GSPs in several sectors and the easy ap-

plicability of the proposed methodology, we are inter-

ested in implementing analogous DSSs, possibly em-

bedding tailored heuristics, for other real-world appli-

cations.

ACKNOWLEDGEMENTS

This research was funded by the University of Mod-

ena and Reggio Emilia, grant FAR 2018. The sup-

port is gratefully acknowledged. Bruno P. Bruck

also acknowledges financial support by Brazilian re-

search agency Conselho Nacional de Desenvolvi-

mento Cient

´

ıfico e Tecnol

´

ogico [Grant 432014/2018-

7].

REFERENCES

Acz

´

el, J. and Saaty, T. (1983). Procedures for synthesizing

ratio judgements. Journal of Mathematical Psychol-

ogy, 27(1):93–102.

C¸ ebi, F. and Bayraktar, D. (2003). An integrated approach

for supplier selection. Logistics Information Manage-

ment, 16(6):395–400.

Chai, J., Liu, J., and Ngai, E. (2013). Application of

decision-making techniques in supplier selection: A

systematic review of literature. Expert Systems with

Applications, 40(10):3872–3885.

Dweiri, F., Kumar, S., Khan, S., and Jain, V. (2016). De-

signing an integrated AHP based decision support sys-

tem for supplier selection in automotive industry. Ex-

pert Systems with Applications, 62:273–283.

Figueira, J. and Roy, B. (2002). Determining the weights of

criteria in the ELECTRE type methods with a revised

Simos’ procedure. European Journal of Operational

Research, 139:317–326.

Ghodsypour, S. and O’Brien, C. (1998). A decision support

system for supplier selection using an integrated ana-

lytic hierarchy process and linear programming. Inter-

national Journal of Production Economics, 56:199–

212.

A Decision Support System to Evaluate Suppliers in the Context of Global Service Providers

429

Ghodsypour, S. and O’Brien, C. (2001). The total cost

of logistics in supplier selection, under conditions

of multiple sourcing, multiple criteria and capacity

constraint. International Journal of Production Eco-

nomics, 73:15–27.

Goffin, K., Szwejczewski, M., and New, C. (1997). Man-

aging suppliers: when fewer can mean more. Inter-

national Journal of Physical Distribution & Logistics

Management, 27(7):422–436.

Govindan, K., Rajendran, S., Sarkis, J., and Murugesan, P.

(2015). Multi criteria decision making approaches for

green supplier evaluation and selection: a literature

review. Journal of Cleaner Production, 98:66–83.

Ho, W. (2008). Integrated analytic hierarchy process and its

applications–A literature review. European Journal of

Operational Research, 186(1):211–228.

Ho, W. and Ma, X. (2018). The state-of-the-art integrations

and applications of the analytic hierarchy process. Eu-

ropean Journal of Operational Research, 267(2):399–

414.

Ho, W., Xu, X., and Dey, P. (2010). Multi-criteria deci-

sion making approaches for supplier evaluation and

selection: A literature review. European Journal of

Operational Research, 202:16–24.

Ishizaka, A. and Labib, A. (2011). Review of the main de-

velopments in the analytic hierarchy process. Expert

Systems with Applications, 38:14336–14345.

Ishizaka, A. and Nemery, P. (2013). Multi-Criteria Decision

Analysis: Methods and Software. John Wiley & Sons,

Ltd., 1st edition.

Kull, T. and Talluri, S. (2008). A supply risk reduction

model using integrated multicriteria decision mak-

ing. IEEE Transactions on Engineering Management,

55(3):409–419.

Mafakheri, F., Breton, M., and Ghoniem, A. (2011). Sup-

plier selection-order allocation: A two-stage multi-

ple criteria dynamic programming approach. Interna-

tional Journal of Production Economics, 132(1):52–

57.

Pek

ˇ

sa, J. and Grabis, J. (2018). Integration of decision-

making components in ERP systems. In Sci-

ence and Technology Publications, pages 183–189.

SCITEPRESS.

Saaty, T. (1990). How to make a decision: The analytic

hierarchy process. European Journal of Operational

Research, 48:9–26.

Wang, G., Huang, S., and Dismukes, J. (2004). Product-

driven supply chain selection using integrated multi-

criteria decision-making methodology. International

Journal of Production Economics, 91(1):1–15.

Ware, N., Sing, S., and Banwet, D. (2012). Supplier selec-

tion problem: A state-of-the-art review. Management

Science Letters, 2(5):1465–1490.

Weber, C., Current, J., and Benton, W. (1991). Vendor se-

lection criteria and methods. European Journal of Op-

erational Research, 50(1):2–18.

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

430