Towards Customized Medicine with Open-source Applications in

Developing Countries: Foot Drop and Transtibial Prosthesis

Livingston D. Castro Valladares

1 a

, Juan Lam

´

an

1

, Xavier Riccio

1

, David Aucancela

1

,

Francis R. Loayza

1 b

and Gilbert Sotomayor

2

1

Facultad de Ingenier

´

ıa en Mec

´

anica y Ciencias de la Producci

´

on, Escuela Superior Polit

´

ecnica del Litoral,

Guayaquil, Ecuador

2

Hospital de Especialidades Teodoro Maldonado Carbo, Guayaquil, Ecuador

gsotomay dr@hotmail.com

Keywords:

Biomechanics, Ankle-foot-orthosis, Transtibial Prosthesis, 3D-printing.

Abstract:

Alterations in the normal gait can be enhanced to improve patients’ quality of life. Although several devices

improve these conditions, the technology to diagnose and create solutions is expensive. The present work

focuses on developing a methodology to use free software and hardware to create solutions. The process starts

gathering and analyzing the patient’s clinical data; then analyze the human motion kinematics of the patient,

so it is possible to customize and manufacture either an orthotic or prosthetic device. With the aim of imple-

menting the methodology, two cases of study are presented in this work. The patient with foot drop presented

an angular difference between the ankle and the toe of 10.10

◦

± 4.76

◦

, which was corrected throughout the

spring-like behavior of the material used for the 3D printing process. Further, the prosthetic device was a

design with an ankle joint that allows the plantarflexion and dorsiflexion angles of 30° and 25°, respectively.

Therefore, this methodology allows the diagnosing of the angular difference between joints during the normal

gait and how to create either orthotic or prosthetic devices to reduce them. Hence, the present work aims to

open doors towards the customization of medicine and rehabilitation, especially in developing countries.

1 INTRODUCTION

The foot drop is a gait abnormality commonly as-

sociated with several causes such as weakness of

the plantar flexors or the dorsiflexor muscles, lesion

of the peroneal nerve, spinal cord trauma, abnor-

mal anatomy, and neurological dysfunction (Stewart,

2008). A patient uses an orthosis or prosthesis as an

extension of their body to help to improve the gait.

This interaction and its complexity can be seen as a

biomechanical system that needs to be attended by

physical therapists and engineers during the rehabil-

itation process. Hence, it is necessary to develop

methodologies for the rehabilitation process that con-

sider the entire biomechanical interaction and the or-

thosis or prosthesis (Bedotto, 2006; Stewart, 2008).

Among the alternatives to improve this condi-

tion, the use of the ”L” shaped foot-up ankle sup-

port (ankle-foot orthosis AFO) has proved to be a

non-surgical resourceful option (Lenhart and Sumar-

a

https://orcid.org/0000-0002-6253-3553

b

https://orcid.org/0000-0002-6283-3679

riva, 2008; Bedotto, 2006; Stewart, 2008). Another

method uses a cuff placed around the ankle, a top-

side spring, and hook installed under the shoelaces.

The hook connects to the ankle cuff and lifts the shoe

when the patient walks. We can also find complex

mechanical solutions using a passive actuator com-

posed mainly of a gas spring and a cam to lift the foot

(Rodriguez et al., 2018), or using superelastic springs

based on nickel-titanium alloys (Amerinatanzi et al.,

2017; Rodriguez et al., 2018).

On the other hand, another lower limb disabil-

ity condition is transtibial amputation. This proce-

dure is performed to fully remove the lower limb (be-

low the knee) damaged due to trauma, congenital dis-

ease, or diseases like diabetes. Most commercial-

ized transtibial prostheses are energetically passive,

whose main disadvantages are nonsymmetrical gait

patterns and walking at lower speeds. Additionally,

the metal ankle joints provide a characteristic weight

to the prosthesis, which produces around 20% to 30%

more metabolic energy consumption for the amputees

(Au et al., 2009). In this line, some solutions based

762

Valladares, L., Lamán, J., Riccio, X., Aucancela, D., Loayza, F. and Sotomayor, G.

Towards Customized Medicine with Open-source Applications in Developing Countries: Foot Drop and Transtibial Prosthesis.

DOI: 10.5220/0010393507620767

In Proceedings of the 14th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2021) - Volume 5: HEALTHINF, pages 762-767

ISBN: 978-989-758-490-9

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reser ved

on powered transtibial prostheses are actually gaining

popularity. However, its main disadvantages are the

high price and the requirement of an additional source

of energy. Other little-explored alternatives for the

fabrication of transtibial prostheses are those based on

additive manufacturing. In this line, the development

of new materials and the feasibility to elaborate com-

plex forms makes them a promising technology.

Healthcare is moving towards the philosophy of

being predictive, preventive, personalized, and partic-

ipatory, which is commonly known as P4 medicine

(Hood, 2008). This is achieved by digitalizing med-

ical information and processing this information in

real-time (Flores et al., 2013; Morley and Vellas,

2017; Pulciani et al., 2017). Thus, it may be possi-

ble to improve patients with lower limb disabilities by

implementing patient-centered methodologies (Creyl-

man et al., 2013; Salles and Gyi, 2012; Salles and

Gyi, 2013). For the design and manufacturing of pros-

thesis and orthosis, the computer-aided design (CAD)

and modern manufacturing techniques appeal to a

particular interest like the 3D printing techniques, due

to their versatility to create complex geometries that

may not be feasible with other manufacturing tech-

niques (Telfer et al., 2012; Dombroski et al., 2014;

Jin et al., 2015; Baronio et al., 2016). Although the

cost of these technologies can be a considerable re-

striction, especially in developing countries, it may

be possible to overcome these difficulties with open

source technologies (de Souza et al., 2017; Loayza

et al., 2018; Tack et al., 2016).

This work aims to develop a methodology to cus-

tomize the design and manufacture of orthotic and

prosthetic devices for patients with foot drop and

transtibial amputation. Besides, the entire method-

ology is developed with free software and hardware.

The present study was carried out in collaboration

between the ESPOL Polytechnic University and the

Teodoro Maldonado Carbo Hospital (hTMC), from

Guayaquil, Ecuador.

2 MATERIALS AND METHODS

The methodology implemented in this work considers

the next steps: 1.) Patients clinical data, 2.) Human

motion kinematics, 3.) Data analysis, 4.) Customized

design, and 5) Implementation and Validation.

2.1 Patients Clinical Data

The first patient was a 45-year-old man with a height

of 1.65 m and 88.6 kg of weight. The patient presents

a foot drop at his right foot, which was diagnosed as

an alteration in the nervous systems by an expert trau-

matologist (GS). Besides, we recruited a control sub-

ject to obtain the motion kinematics data: a 24- year-

old male volunteer with a height and weight of 1.64

m and 73 Kg, respectively. The second patient, a 60-

year-old man, 72kg. of weight and 1.68 m. height,

presents a transtibial amputation of 15 cm. below the

right knee, this due to complications produced by dia-

betes type II. Patients and control subjects signed the

informed consent approved by the university review

board.

2.2 Human Motion Kinematics

The analysis of the human motion kinematics plays

an important role in characterizing the normal gait of

the patient. This analysis was performed only for the

patient with foot drop. We used motion capture tech-

nology to obtain the motion parameters of the subject.

Human motion measures were assessed during multi-

ple trials of treadmill walking of the foot drop patient

and the control subject. Walking speeds were initially

determined by the patient at speeds that he felt com-

fortable walking with running shoes at 0.5 m/s, with

increments and decrements from 1.0 m/s to 2.0 m/s.

Normal speed was 1.0 m/s because, for speeds of 1.5

m/s and 2.0 m/s, the patient had to hold on the tread-

mill to be able to walk.

Previous to the AFO customized design, we as-

sess the patient motion kinematics to obtain the angle

and force required for the design and the conventional

shoe measurements. To assess the influence of the

AFO on the behavior of the lower limb joint angle, the

patient performed two walking trials with four mark-

ers placed along each leg: at the hip, the kneecap,

the heel, and at the toe. These markers were placed

carefully at each joint as a reference for further cal-

culus and analysis. During the first trial, used as a

control, the subject walked without the AFO and us-

ing his conventional shoes. For the second trial, the

patient wore the AFO on the left foot. The data ac-

quisition was performed using an iPhone 8 camera of

1080 pixels located over a tripod at a 2 m distance

from the treadmill. The camera was recording at 60

frames per second (FPS) for both legs. The recordings

were made on both sides of the subject to get a bet-

ter perspective of the movements of both legs. Each

recording of the elapsed time for each leg was of 20

seconds, equivalent to approximately ten gait cycles.

2.3 Data Analysis

For the data analysis, we used the software Tracker®

(Tracker video analysis and modeling tool) and

Towards Customized Medicine with Open-source Applications in Developing Countries: Foot Drop and Transtibial Prosthesis

763

Python®. The software tracker® let us analyze the

regular gait video, display the markers, and discretize

the positions within the recording time. Python was

used for the corresponding analysis and plotting re-

sults. For each recording (6 previous and 6 wearing

the AFO), we measured each angular position of the

joint, frame by frame. The measured data was plot-

ted to select a time window of 10 gait cycles after re-

viewing it for a constant period (Figure 1). Further,

each gait cycle was split out, and then we obtained

the average and standard deviation for each angular

data point of each joint, previously checking for its

normal distribution. Finally, the average of the angu-

lar position and its corresponding standard deviation

of the data points were plotted by using Python® as

is shown in Figure 2. to obtain the average values

of the angles and standard deviation and calculate the

necessary angular compensation of the foot drop in

reference to the healthy foot.

2.4 Customized Design of the Orthosis

With the dimensions of the leg and the food, it is

possible to adapt an orthotic device to the anthropo-

morphic characteristics of the patient. The orthotic

device dimensions were defined with the CAD soft-

ware, which allows parametrizing and easily making

changes. The manufacture of the design was executed

with a 3D printer (Creality®, model CR-3040s). The

orthosis was divided into six parts, where five of them

work as rigid components printed with PLA at 40% of

triangles infill, at 200

◦

C, 0.2 mm resolution, 1.2 mm

wall thickness and 8 hours of print time. The flexi-

ble component, which works as spring-like behavior,

was 3D printed with TPU at 50% infill at 235ºC, 0.2

mm resolution, 0.8 mm wall thickness, and 10 hours

of print time. All components were designed using

FreeCad and then exported as STL format.

2.5 Orthosis Implementation and

Validation

Once the device was implemented, the gait of the

gait was recorded to process the information in the

tracker® analysis software and plot the data obtained

in Python® to compare the three cases: foot drop

without orthosis, foot drop with the orthosis, and the

healthy subject.

2.6 Prosthesis Design

king anthropometric measures of the left leg. This lets

us design the prosthesis according to their anthropo-

metric measurements.

The prosthesis was divided into two elements:

the foot and the shank joined via a bolted joint at

the ankle. According to the requirements, the com-

plete shank, including the socket, was designed to be

printed as a rigid component with PLA or ABS. The

foot, instead, including the ankle, was designed to be

printed as a flexible component. The idea was to take

advantage of the flexibility of the material to provide

an adequate rotation at the joints, of both the toes and

the ankle, as well as vertical cushioning.

To design both components, we used Blender soft-

ware version 2.8. The shank was designed as a solid

element down to the socket base, as shown in figure

5A. The prosthetic right foot was designed base on the

anatomy of the left foot. To give it flexibility and ro-

tation in the ankle and toe joints, like a flexible hinge,

some groves were made in both sides of the instanta-

neous center of rotation, as shown in figure 5B. These

flexible hinges were tested in the first design under

the working condition with the weight of the patient.

After several tests, we found that the flexible hinges

deteriorated only at the ankle joint, due to the verti-

cal load. After two additional iterations and tests, the

final design of the flexible joint at the ankle was the

incorporation of two S-like springs that can work as

tendons and ligaments attached to the shank, as shown

in figure 5B-2.

Before printing the final foot, we estimated the

printing parameters according to (Mutlu et al., 2016).

Additionally, we performed two experiments to esti-

mate the percent of infill. For that, we created a foot

part that includes only the flexible knee joint. Then,

this part was printed twice with two different infill set-

tings: 50% and 20%. Further, those parts were sub-

jected to rotational deformation with the application

of different torsion loads.

The manufacture of the components of the pros-

thesis was performed with the 3D printer (Creality®,

model CR-3040s) with the following parameters: the

shank was printed in one piece with PLA, and 30% of

triangles infill at 200ºC, 0.4 mm resolution, 1.2 mm

wall thickness and 53 hours of print time. The foot

was printed with TPU with 25% of triangles infill at

235ºC, 0.2mm resolution, 0.8 mm wall thickness, and

55 hours of print time.

3 RESULTS

This section describes the results for the two patients,

the foot drop and the amputee patient.

HEALTHINF 2021 - 14th International Conference on Health Informatics

764

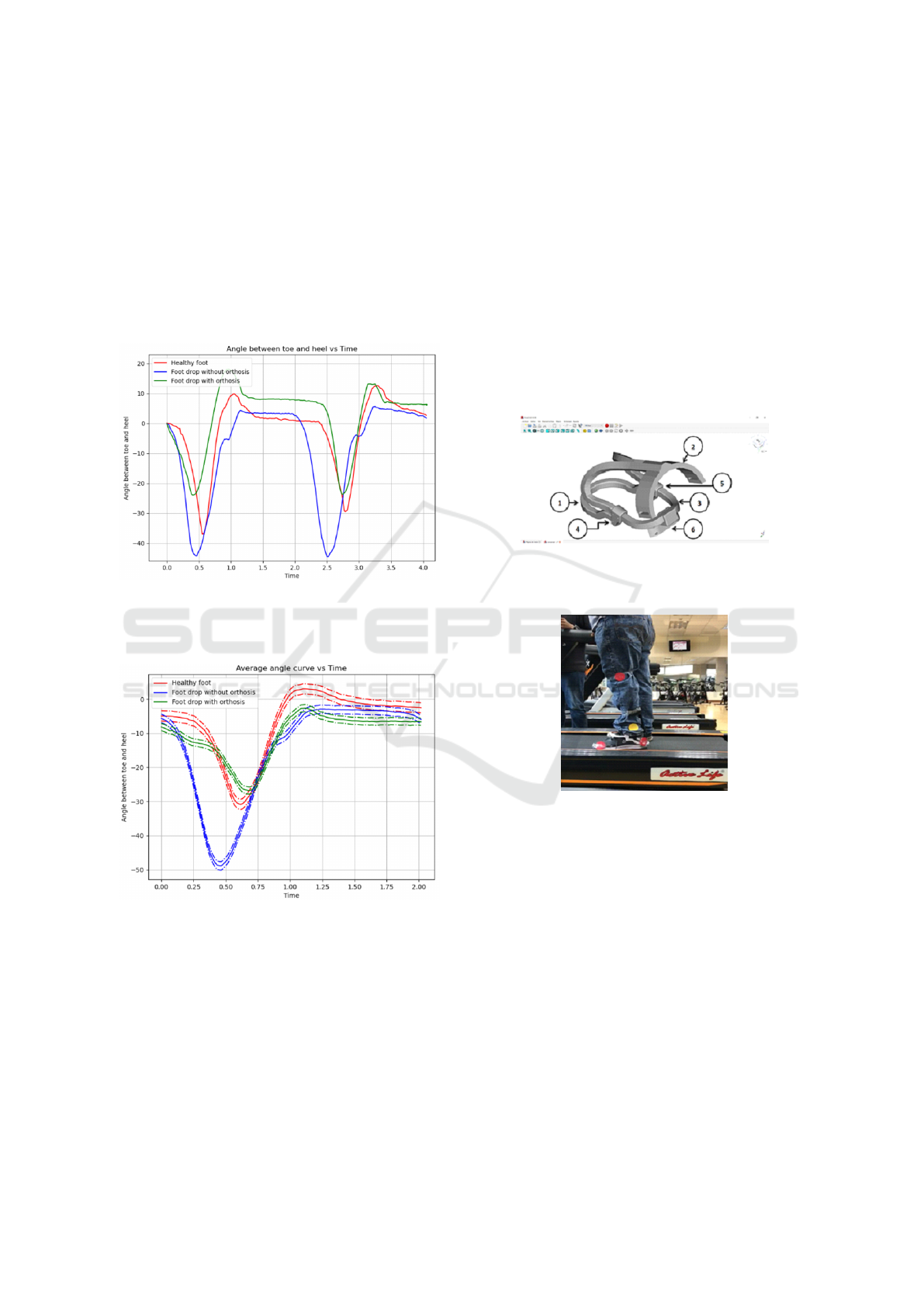

3.1 Foot Drop Patient

The normal gait of the patient was recorded at 1 km/h,

where the curve represents the angle of the ankle dor-

siflexion/plantar flexion. Three different cases are

plotted in figure 1 and 2 for this study; healthy foot,

drop foot without orthosis, and drop foot with an or-

thosis. Additionally, the orthosis 3D model is pre-

sented in figure 3 and 4 shows the patient wearing

the AFO on the treadmill.

Figure 1: The curve of the angle between toe and heel vs.

time. The red line corresponds to a healthy foot. The blue

line corresponds to the foot drop patient without orthosis.

The green line corresponds to the foot drop with an orthosis.

Figure 2: The average curve of the angle between toe and

heel vs. time. The red line corresponds to a healthy foot.

The blue line corresponds to the foot drop patient without

orthosis. The green line corresponds to the foot drop with

an orthosis.

The measurements of the normal gait were

recorded at 1 Km/h to feel comfortable during the

recording process. The peak values of the angles

of each curve were chosen to calculate the aver-

age and its standard deviation, and both angles were

subtracted to obtain the necessary compensation of

the foot drop. The difference between the patient’s

healthy foot compared to his dropped foot is in the

value of the angle that the toe presented with respect

to the heel, causing a difference of 10.1 degrees be-

tween both cases. This occurs because the dropped

foot causes a person to drag their foot while walk-

ing, which increases the angle between the toe and

the heel.

It was necessary to correct the angular difference

because continuing to drag the foot during walking

may cause the thigh to rise at the moment of the march

as if one were climbing stairs. This causes the foot to

hit the floor with every step. As in most patients, the

upper skin part on the foot and toes is sensitive to the

impact created by the movement.

Figure 3: Shows the design of the prosthetic device per-

formed in FreeCad. This model was then exported in STL

format, which was 3D printed in a flexible material (TPU).

Figure 4: Depicts the tracking measures performed with the

foot drop patient using the treadmill.

The angular difference between both feet was re-

lated to the deformation that flexible material can

have so that the angles of the toes of both feet will be

similar. To achieve this, it was necessary to consider

the force required to maintain the foot in the natural

position during the normal gait; thus, the drop foot

moves approximately like the healthy foot.

3.2 Amputee Patient

After removing the support material in both 3D

printed elements, the following table summarizes the

results. Besides, the prototype is shown in figure 5.

The plantarflexion and dorsiflexion angles ob-

tained for the ankle joint were 30º and 25º, respec-

Towards Customized Medicine with Open-source Applications in Developing Countries: Foot Drop and Transtibial Prosthesis

765

Table 1: main settings of the printed elements.

Element Foot Shank

Print time (h) 55 53

Print temperature (ºC) 235 200

Material TPU PLA

Resolution (mm) 0.2 0.4

% infill 25 30

Infill type triangle triangle

Weight (g) 490 220

tively as is shown in figure 6. For the toe joint, the

angular rotation for this flexible hinge was 36º in both

directions. The total cost of printing both items was

USD 80.00, including the material and the printing

itself.

Figure 5: Panel A depicts the assembling of both elements.

Panel B shows the foot printed with flexible material where

1 is the flexible hinge for the toe, 2 the flexible hinge for the

ankle, 3 the cushioning element, and 4 two slots are shown

with their respective holes that allow an elastic band to be

added by screws on each side to complement the elasticity

of the ankle joint if necessary. Panel C shows the printed

foot.

Figure 6: Upper left, it is shown the plantarflexion angle

and, on the right, the dorsiflexion angle. The bottom picture

shows the patient wearing the prosthesis.

4 DISCUSSION AND

CONCLUSIONS

In this work, two customized solutions 3D printed are

presented. The first solution was an orthotic device

for a patient with a foot drop, and the second solution

consists of a transtibial prosthetic device for an am-

putee patient. In both cases, we used a combination

of flexible and rigid material printed with the FDM

technique.

Currently, there are several designs and methods

to manufacture lower limb orthosis. Nevertheless, not

all of them represent viable options due to the cost

of software and manufacturing equipment. Thus, the

choice of using free software and hardware is appeal-

ing for these types of applications, especially in de-

veloping countries. For example, the manufacturing

cost of this case study was USD 55. In the same line,

the majority of commercial transtibial prostheses are

manufactured using expensive techniques and mate-

rials that, in many cases, are unaffordable for low-

income patients.

Even though the free software helps achieve the

objectives of this project, it always is possible to im-

prove the designs. Current applications in this area

use active parts, which represent a significant advan-

tage towards rehabilitation. Nevertheless, the cost

increments, and the more components are used, the

higher is the probability of failure during operation.

Therefore, the present work considers the use of sim-

ple components and designs. Additionally, as the

manufacturing price has dropped considerably, it is

possible to create different designs with the purpose

of rehabilitation and testing. Although, it is necessary

to make a trade-off between potential environmental

effects of the manufacturing and the designs before

moving forward in this direction.

It is important to mention that only the case of the

patient with foot drop was validated through a human

motion kinematics analysis. The case of the transtib-

ial amputation was not possible to evaluate the human

motion kinematics because the patient was within the

phase of physical rehabilitation and was still getting

used to the prosthetic device.

For future work, the methodology presented in

this work needs to be applied to a larger number of

cases, of each type of medical condition, either foot

drop or transtibial amputation. Thus, it may be possi-

ble to make a clinical analysis.

4.1 Conclusion

With the proposed methodology in this work, it is

possible to fabricate orthotic and prosthetic devices

HEALTHINF 2021 - 14th International Conference on Health Informatics

766

through 3D printing techniques, taking advantage of

the characteristics of different materials available in

the market. Further, devices that can improve the foot

drop and amputee problems using free software and

hardware are suitable for developing countries.

ACKNOWLEDGEMENTS

We thank the two patients who voluntarily collabo-

rated with this study.

REFERENCES

Amerinatanzi, A., Zamanian, H., Shayesteh Moghaddam,

N., Jahadakbar, A., and Elahinia, M. (2017). Appli-

cation of the superelastic niti spring in ankle foot or-

thosis (afo) to create normal ankle joint behavior. Bio-

engineering, 4(4):95.

Au, S. K., Weber, J., and Herr, H. (2009). Powered ankle–

foot prosthesis improves walking metabolic economy.

IEEE Transactions on Robotics, 25(1):51–66.

Baronio, G., Harran, S., and Signoroni, A. (2016). A critical

analysis of a hand orthosis reverse engineering and 3d

printing process. Applied bionics and biomechanics,

2016.

Bedotto, R. A. (2006). Biomechanical assessment and treat-

ment in lower extremity prosthetics and orthotics: a

clinical perspective. Physical Medicine and Rehabili-

tation Clinics, 17(1):203–243.

Creylman, V., Muraru, L., Pallari, J., Vertommen, H., and

Peeraer, L. (2013). Gait assessment during the ini-

tial fitting of customized selective laser sintering ankle

foot orthoses in subjects with drop foot. Prosthetics

and orthotics international, 37(2):132–138.

de Souza, M. A., Schmitz, C., Pinhel, M. M., Setti, J. A. P.,

and Nohama, P. (2017). Proposal of custom made

wrist orthoses based on 3d modelling and 3d print-

ing. In 2017 39th Annual International Conference of

the IEEE Engineering in Medicine and Biology Soci-

ety (EMBC), pages 3789–3792. IEEE.

Dombroski, C. E., Balsdon, M. E., and Froats, A. (2014).

The use of a low cost 3d scanning and printing tool

in the manufacture of custom-made foot orthoses: a

preliminary study. BMC research notes, 7(1):1–4.

Flores, M., Glusman, G., Brogaard, K., Price, N. D., and

Hood, L. (2013). P4 medicine: how systems medicine

will transform the healthcare sector and society. Per-

sonalized medicine, 10(6):565–576.

Hood, L. (2008). Systems biology and systems medicine:

from reactive to predictive, personalized, preventive

and participatory (p4) medicine. In 2008 30th Annual

International Conference of the IEEE Engineering in

Medicine and Biology Society, pages cliv–cliv. IEEE.

Jin, Y., Plott, J., Chen, R., Wensman, J., and Shih, A.

(2015). Additive manufacturing of custom orthoses

and prostheses—a review. procedia cirp 36: 199–204.

Lenhart, R. L. and Sumarriva, N. (2008). Design of im-

proved ankle-foot orthosis.

Loayza, F. R., Sola-Mora, J., Castro-Valladares, L., Litardo,

J., Nu

˜

nez-Idrovo, L., and Mora, H. (2018). Pre-

operative patient-specific alloplastic implant design

and manufacturing: cranioplasty application. In

2018 IEEE Third Ecuador Technical Chapters Meet-

ing (ETCM), pages 1–5. IEEE.

Morley, J. E. and Vellas, B. (2017). Patient-centered (p4)

medicine and the older person. Journal of the Ameri-

can Medical Directors Association, 18(6):455–459.

Mutlu, R., Alici, G., in het Panhuis, M., and Spinks, G. M.

(2016). 3d printed flexure hinges for soft monolithic

prosthetic fingers. Soft Robotics, 3(3):120–133.

Pulciani, S., Di Lonardo, A., Fagnani, C., and Taruscio,

D. (2017). P4 medicine versus hippocrates. Annali

dell’Istituto superiore di sanita, 53(3):185–191.

Rodriguez, K., de Groot, J., Baas, F., Stijntjes, M., van der

Helm, F., van der Kooijl, H., and Mugge, W. (2018).

Passive ankle joint stiffness compensation by a novel

ankle-foot-orthosis. In 2018 7th IEEE International

Conference on Biomedical Robotics and Biomecha-

tronics (Biorob), pages 517–522. IEEE.

Salles, A. S. and Gyi, D. E. (2012). The specification of per-

sonalised insoles using additive manufacturing. Work,

41(Supplement 1):1771–1774.

Salles, A. S. and Gyi, D. E. (2013). An evaluation of per-

sonalised insoles developed using additive manufac-

turing. Journal of Sports Sciences, 31(4):442–450.

Stewart, J. D. (2008). Foot drop: where, why and what to

do? Practical neurology, 8(3):158–169.

Tack, P., Victor, J., Gemmel, P., and Annemans, L. (2016).

3d-printing techniques in a medical setting: a system-

atic literature review. Biomedical engineering online,

15(1):115.

Telfer, S., Pallari, J., Munguia, J., Dalgarno, K., McGeough,

M., and Woodburn, J. (2012). Embracing additive

manufacture: implications for foot and ankle orthosis

design. BMC musculoskeletal disorders, 13(1):84.

Towards Customized Medicine with Open-source Applications in Developing Countries: Foot Drop and Transtibial Prosthesis

767