Junction Temperature Measurement

in Optically-Controlled Power Mosfet

Sandro Rao

1

, Elisa D. Mallemace

1

, G. Cocorullo

2

, L. Dehimi

3,4

and Francesco G. Della Corte

1

1

Department of Information Engineering Infrastructures and Sustainable Energy (DIIES), Università Mediterranea,

89122, Reggio Calabria, Italy

2

Dipartimento di Ingegneria Informatica, Modellistica, Elettronica e Sistemistica (DIMES), Università della Calabria,

87036, Rende, Cosenza, Italy

3

Laboratory of Metallic and Semi-conducting Materials (LMSM), University of Biskra, BP 145, 07000 Biskra, Algeria

4

Faculty of Material Science, University of Batna, 05000 Batna, Algeria

Keywords: Optically-Controlled SiC Power MOSFET, Temperature Monitoring, Integrated-Fabry-Perot Cavity, Junction

Temperature.

Abstract: The temperature-dependent optical properties of silicon carbide (SiC), such as refractive index and

reflectivity, have been used for a direct monitoring of the junction temperature of a power MOSFET. In

particular, the optical response of a 4H-SiC MOSFET-integrated Fabry-Perot cavity to temperature changes

has been investigated through parametric optical simulations at the wavelength of 450 nm. The reflected

optical power exhibited oscillatory patterns caused by the multiple beam interference for which the MOSFET

epilayer, between the gate-oxide and the doped 4H-SiC substrate, acts as a Fabry-Perot etalon. These results

were used to calculate the refractive index change and, therefore, the optical phase shift of ∆φ= π/2

corresponding to a temperature variation that can be considered as a warning for the device “health”. In

practical applications, the periodic monitoring of the optic spectrum at the interferometric structure output

gives an essential information about the device operating temperature condition that, for high power

operations, may lead to device damages or system failure.

1 INTRODUCTION

The thermal control of any semiconductor device is

of extreme importance to achieve optimal

performance, reliability and durability. Temperature

has a strong influence on the main electrical

parameters and, for power devices or more complex

electronic modules, in particular, a thermal

management during the operating lifetime is

exploited as a damage indicator to prevent the system

failure.

In general, the thermal resistance of a device, R

T

,

is given by: R

T

=ΔT/P,

where ΔT is the rise in

temperature with respect to a specified reference

point, and P is the power dissipated by the device.

Ideally, the thermal resistance is a device

specification that permits the user to determine the

maximum temperature for any power level. In order

for a device manufacturer to specify and, for a user to

verify R

T

, an accurate, reliable method for measuring

the device internal temperature is required

(Blackburn & Berning, 1982).

The technology of silicon carbide (SiC) is today

recognized to be one of the most practical for pulsed-

power applications taking, moreover, advantage from

the high thermal conductivity of SiC which lowers the

thermal resistance for a given active area and current

density (Mazumder & Sarkar, 2009; Della Corte,

Giglio, Pangallo, & Rao, 2018).

4H-SiC-based switching devices, in particular,

can operate at high voltages and high currents up to

theoretical temperatures higher than 800°C

(Neudeck, 2006), however, the maximum allowed

operating temperature of commercialized SiC-

MOSFETs is usually lower than 175°C, limited by

metals contacts, passivating materials and packaging

technology (CREE, 2019).

Therefore, a continuous monitoring of the device

junction temperature (T

j

), with a minimum of

interference from the other device parameters, is

110

Rao, S., Mallemace, E., Cocorullo, G., Dehimi, L. and Della Corte, F.

Junction Temperature Measurement in Optically-Controlled Power Mosfet.

DOI: 10.5220/0010327001100114

In Proceedings of the 9th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2021), pages 110-114

ISBN: 978-989-758-492-3

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

essential to verify the power device “health” and to

prevent damages.

In literature, many methods have been proposed

for monitoring the power MOSFET temperature;

these can be divided in three main categories

(Blackburn, 2004): optical, physical contact and

electrical methods. The main solutions use

luminescence (Schuermeyer et al., 2000), Raman

spectroscopy (Kuball et al., 2002), liquid crystals

thermographic (Parsley, 1991), turn-on delay of

impulse signal (Shi et al., 2017)

or an external

temperature sensor (Rao, Pangallo, & Della Corte,

2015).

However, each of these approaches only provide

a global temperature whose value differs greatly from

the real device junction temperature, T

j

.

Recently, the linear relation between the body-

drain voltage of power MOSFETs and their junction

temperature has been experimentally investigated by

these authors in a wide range of bias currents in a

temperature range from about 22 up 150 °C

(Pangallo, Rao, Adinolfi, Graditi, & Della Corte,

2019). Moreover, a new method for measuring the T

j

of power light emitting diodes (LEDs), used for

lighting, has been presented (Pangallo et al., 2018)

together with a microcontroller-based circuit

designed and realized for a real-time monitoring

(Della Corte et al., 2020).

In this work, we present a new approach allowing

the junction temperature control of a 4H-SiC power

MOSFET through an optical signal. Optical

simulation results of the MOSFET-integrated Fabry-

Perot cavity, consisting of the gate oxide, the epilayer

and the doped substrate, show that the temperature-

induced refractive index change allows to calculate

the T

j

variation. The proposed optically-controlled

power MOSFET junction temperature can be done

during the lifetime of the device in order to alert the

user before its failure.

2 DEVICE STRUCTURE AND

SIMULATION RESULTS

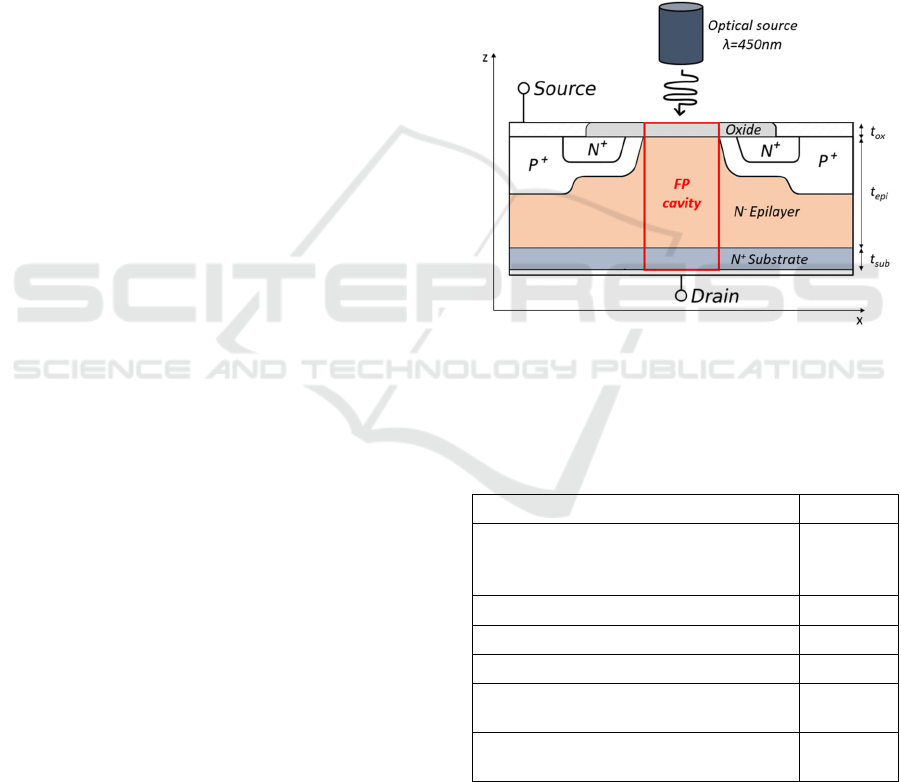

A 4H-SiC-based MOSFET structure has been

modeled using R-Soft CAD (RSoft, 2006), a photonic

device simulator using the beam propagation method,

to perform 3-D parametric optical simulations.

The MOSFET-integrated Fabry-Perot cavity, in

the <x,z> plane, where <z> is the optical propagation

direction, is shown in Figure 1. Simulations were

performed using a continuous laser optical beam, at

the wavelength of 450 nm, launched on top of the

gate-oxide layer. Layers thickness and optical data of

the materials used for simulations are listed in Table

1.

As shown in Figure 1, the optically-controlled

MOSFET has an optical window instead of the gate

electrode. When the light falls on it, no excess

carriers, at the considered wavelength of 450 nm, are

generated, therefore, the conductivity as well as the

drain current are not influenced by the optical signal

used for the device temperature monitoring. It is

worth noting that the control of T

j

is generally done

using a short pulse laser source with a repetition rate

comparable or lower than the slow thermal dynamics

of the device.

Figure 1: Schematic cross-section of an optically-controlled

4H-SiC MOSFET. The MOSFET-integrated FP cavity

consists of the 4H-SiC epilayer between the SiO

2

gate-oxide

and the 4H-SiC heavily-doped substrate.

Table 1: Optical and geometrical parameters of the

MOSFET-integrated FP cavity.

Silicon oxide thickness (t

ox

) [µm] 0.1

Channel length [µm] (Della Corte, De

Martino, Pezzimenti, Adinolfi, & Graditi,

2018)

6.5

Epilayer thickness (t

epi

) [µm] 10

Substrate thickness (t

sub

) [µm] 2.5

Silicon oxide refractive index (n

ox

) 1.44

Epilayer refractive index (n

epi

)

(Watanabe, Kimoto, & Suda, 2012)

2.73

Substrate refractive index (n

sub

) (Lim,

Manzur, & Kar, 2011)

2.65

From a technological point of view, the power

MOSFET fabrication requires a high quality of both

epilayer surfaces, therefore careful attention towards

the morphology of all stacked-layers is performed in

any industrial process. Optical microscopy (OM) is a

Junction Temperature Measurement in Optically-Controlled Power Mosfet

111

fast and non-destructive method, which is generally

used after each growth to determine the morphology,

uniformity and epilayer defects (Ager III, 1998).

Moreover, OM is carried out also to reveal any

presence of 4H-SiC domains when the growth is

performed on doped-SiC substrates.

Under these technological conditions, a

reflectance spectrum can be registered at the input of

the Fabry-Perot (FP) cavity consisting of the

smoothed gate-oxide/epilayer and epilayer/substrate

interfaces.

The interference fringes are detected, in case of

homoepitaxy, as in our structure, due to a difference

in refractive index between the epilayer and the

substrate (see Table 1). This difference is achieved by

the strong doping concentration discrepancy between

the 4H-SiC epilayer (N

D

-N

A

~10

16

cm

-3

) and the 4H-

SiC substrate, which has usually a nitrogen doping

concentration in the range 10

18

-10

19

cm

-3

(Della Corte

et al., 2018).

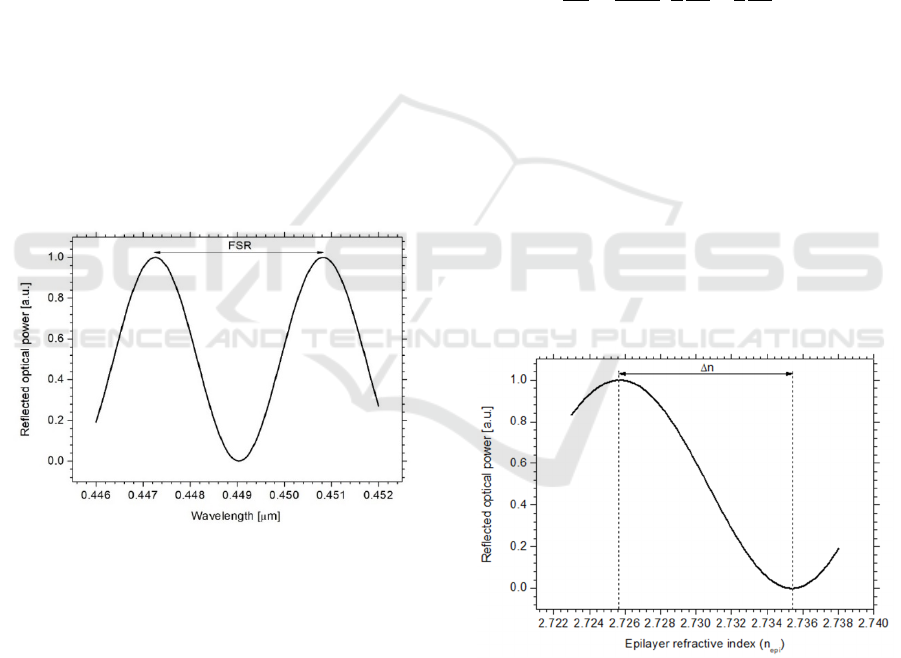

Figure 2 shows the simulated FP reflected

spectrum centered at the wavelengths of interest. The

corresponding calculated Free Spectral Range (FSR)

is 3.57 nm, in agreement with the theoretical value

(Agrawal, 2012).

Figure 2: Normalized-reflected output power vs.

wavelength. The FSR is the spacing in wavelength

calculated between two successive reflected optical

intensity maxima (or minima) of the FP cavity.

For the refractive index values considered in this

work (n

sub

=2.65, n

epi

=2.73), the modulation depth,

defined as M

%

= (I

MAX

– I

MIN

)/ I

MAX,

where I

MAX

and

I

MIN

are the maximum and minimum intensities of the

reflected signal, is 15.2%, varying from M

%

=24.2%

down to M

%

=5.4% for n

sub

=2.6 and n

sub

=2.7,

respectively.

Moreover, parametric simulations were

performed in order to verify the independence of the

gate oxide thickness, considered in this work from 50

to 500 nm, on the FP outputs. The used value of 100

nm is typical for commercial power MOSFETs.

As known, the temperature dependence of the

optical path length of a monochromatic light, incident

perpendicularly upon a device surface and traveling

through a FP cavity, is given by the product between

the refractive index of the cavity material, n, and its

length, L (Steimacher et al., 2004).

Due to the environmental and/or operating

conditions, a variation of the temperature, ΔT, induces

both n and L change and, therefore, the optical length

changes too, as well as the interference phase angle

of the oscillatory pattern, φ, as expressed by the

following equation (Mathew et al., 2015):

∆𝜑

∆𝑇

4𝜋𝑛𝐿

𝜆

1

𝑛

𝑑𝑛

𝑑𝑇

1

𝐿

𝑑𝐿

𝑑𝑇

(1)

where dn/dT and dL/dT are the thermo-optic

(TOC) (Faggio, Messina, Gnisci, Rao, & Malara,

2019) and the thermal-expansion coefficients,

respectively.

In our structure, the MOSFET-integrated FP

cavity length is the epilayer thickness, t

epi

, and the

corresponding refractive index is n

epi

. A phase shift of

Δφ=π/2 results in a complete tuning of resonance

wavelengths and, from equation 1, if we consider a

TOC of 7.8∙10

-5

at λ=450 nm (Watanabe et al., 2012),

and dL/dT = 2.2∙10

-6

(Nakabayashi, Fujimoto,

Katsuno, & Ohtani, 2006), the theoretical temperature

change is expected to be ΔT

π/2

=133.92°C.

Figure 3: Reflected output power vs. epilayer refractive

index. The difference of refractive index between a

maximum and a minimum value of the refrected power is

Δn=9.65∙10

-3

.

Figure 3 shows the parametric simulation results

of the MOSFET-integrated FP cavity spectrum where

the epilayer refractive index has been varied in a

range allowing a gradual and complete detuning of

PHOTOPTICS 2021 - 9th International Conference on Photonics, Optics and Laser Technology

112

the cavity, e.g., from a maximum to a minimum of the

reflected power at the gate-oxide output.

Assuming for 4H-SiC a TOC of 7.8∙10

-5

, it can be

calculated that a complete FP detuning is introduced

in our L=10 µm-thick 4H-SiC epitaxial layer by a

thermally-induced refractive index change of

Δn=9.65∙10

-3

corresponding to a temperature

variation of ΔT

π/2

=123.7°C.

It is worth noting that this temperature variation

mainly depends on the wavelength of the optical

signal and/or on the MOSFET epilayer thickness.

However, if the optical parameters, at a specific

wavelength, as well as the MOSFET geometry, are

not known, an easy pre-characterization of the

MOSFET-integrated FP cavity spectrum allows the

determination of the temperature change (ΔT

π/2

)

required for the output optical power to move from a

maximum (or minimum) to a subsequent minimum

(or maximum).

In a practical application, if we consider, e.g., an

external temperature of T

e

=30°C, the monitoring of

the multiple-beam interference signal, from its

resonance position, gives us the power device/system

operating temperature condition (T=T

e

+ΔT) that, for

high power operations, in particular, may lead to

permanent damage or performance variations.

3 CONCLUSIONS

In this paper, a new method for real-time monitoring

the junction temperature of a SiC-based power

MOSFET has been presented.

The MOSFET epilayer between the gate-oxide

and the heavily doped substrate naturally forms an

integrated Fabry-Perot (FP) cavity that can be

exploited to calculate the temperature variation

during the power device operating life.

Simulation results, performed at the wavelength

of 450 nm, showed that a complete FP detuning is

introduced in our L=10 µm-thick 4H-SiC epitaxial

layer by a thermally-induced refractive index change

of Δn=9.65∙10

-3

corresponding to a temperature

variation of 123.7°C. The optically-controlled

junction temperature increase is essential to prevent

the device overheating.

This method can be applied in many power

applications, including signal-conditioning circuits

for sensors (Rao, Pangallo, & Della Corte, 2016), and

for wide-band materials-based switching system

control where, changes in temperature above the

temperature limit, lead to a mean time to failure

reduction or device disruption.

REFERENCES

Blackburn, D. L., & Berning, D. W. (1982, June). Power

MOSFET temperature measurements. In 1982 IEEE

Power Electronics Specialists conference (pp. 400-

407). IEEE.

Mazumder, S. K., & Sarkar, T. (2009). SiC based optically-

gated high-power solid-state switch for pulsed-power

application. In Materials Science Forum (Vol. 600, pp.

1195-1198). Trans Tech Publications Ltd.

Della Corte, F. G., Giglio, I., Pangallo, G., & Rao, S.

(2018). Electro-optical modulation in a 4H-SiC slab

induced by carrier depletion in a Schottky diode. IEEE

Photonics Technology Letters, 30(9), 877-880.

Neudeck, P. G. (2006). Silicon carbide technology. The

VLSI handbook, 20061800.

CREE. C3M0021120K Silicon Carbide Power MOSFET,

Datasheet. 2019.

Blackburn, D. L. (2004, March). Temperature

measurements of semiconductor devices-a review. In

Twentieth Annual IEEE Semiconductor Thermal

Measurement and Management Symposium (IEEE Cat.

No. 04CH37545) (pp. 70-80). IEEE.

Schuermeyer, F., Fitch, R., Dettmer, R., Gillespie, J.,

Bozada, C., Nakano, K., ... & Liou, L. L. (2000,

August). Thermal studies on heterostructure bipolar

transistors using electroluminescence. In Proceedings

2000 IEEE/Cornell Conference on High Performance

Devices (Cat. No. 00CH37122) (pp. 45-50). IEEE.

Kuball, M., Hayes, J. M., Uren, M. J., Martin, I., Birbeck,

J. C. H., Balmer, R. S., & Hughes, B. T. (2002).

Measurement of temperature in active high-power

AlGaN/GaN HFETs using Raman spectroscopy. IEEE

Electron Device Letters, 23(1), 7-9.

Parsley, M. (1991, February). The use of thermochromic

liquid crystals in research applications, thermal

mapping and non-destructive testing. In 1991

Proceedings, Seventh IEEE Semiconductor Thermal

Measurement and Management Symposium (pp. 53-

58). IEEE.

Shi, B., Feng, S., Shi, L., Shi, D., Zhang, Y., & Zhu, H.

(2017). Junction temperature measurement method for

power MOSFETs using turn-on delay of impulse

signal. IEEE Transactions on Power Electronics, 33(6),

5274-5282.

Rao, S., Pangallo, G., & Della Corte, F. G. (2015). Highly

linear temperature sensor based on 4H-silicon carbide

pin diodes. IEEE Electron Device Letters, 36(11),

1205-1208.

Pangallo, G., Rao, S., Adinolfi, G., Graditi, G., & Della

Corte, F. G. (2019). Power MOSFET intrinsic diode as

a highly linear junction temperature sensor. IEEE

Sensors Journal, 19(23), 11034-11040.

Pangallo, G., Carotenuto, R., Iero, D., Mallemace, E. D.,

Merenda, M., Rao, S., & Della Corte, F. G. (2018,

September). A direct junction temperature

measurement technique for power LEDs. In 2018 IEEE

9th International Workshop on Applied Measurements

for Power Systems (AMPS) (pp. 1-5). IEEE.

Junction Temperature Measurement in Optically-Controlled Power Mosfet

113

Della Corte, F. G., Pangallo, G., Carotenuto, R., Iero, D.,

Marra, G., Merenda, M., & Rao, S. (2020).

Temperature Sensing Characteristics and Long Term

Stability of Power LEDs Used for Voltage vs. Junction

Temperature Measurements and Related Procedure.

IEEE Access, 8, 43057-43066.

RSoft, CAD,“User guide” RSoft Design Group, 200

Executive Blvd. Ossining, 2006.

Della Corte, F. G., De Martino, G., Pezzimenti, F., Adinolfi,

G., & Graditi, G. (2018). Numerical simulation study of

a low breakdown voltage 4H-SiC MOSFET for

photovoltaic module-level applications. IEEE

Transactions on Electron Devices, 65(8), 3352-3360.

Watanabe, N., Kimoto, T., & Suda, J. (2012). Thermo-optic

coefficients of 4H-SiC, GaN, and AlN for ultraviolet to

infrared regions up to 500° C. Japanese Journal of

Applied Physics, 51(11R), 112101.

Lim, G., Manzur, T., & Kar, A. (2011). Optical response of

laser-doped silicon carbide for an uncooled midwave

infrared detector. Applied optics, 50(17), 2640-2653.

Ager III, J. W. (1998, November). Overview of optical

microscopy and optical microspectroscopy. In AIP

Conference Proceedings (Vol. 449, No. 1, pp. 641-

652). American Institute of Physics.

Agrawal, G. P. (2012). Fiber-optic communication systems

(Vol. 222). John Wiley & Sons.

Steimacher, A., Medina, A. N., Bento, A. C., Rohling, J. H.,

Baesso, M. L., Reynoso, V. C. S., ... & Hewak, D. W.

(2004). The temperature coefficient of the optical path

length as a function of the temperature in different

optical glasses. Journal of non-crystalline solids, 348,

240-244.

Mathew, J., Schneller, O., Polyzos, D., Havermann, D.,

Carter, R. M., MacPherson, W. N., ... & Maier, R. R.

(2015). In-fiber Fabry–Perot cavity sensor for high-

temperature applications. Journal of Lightwave

Technology, 33(12), 2419-2425.

Faggio, G., Messina, G., Gnisci, A., Rao, S., & Malara, A.

(2019, June). Thermo-optic Effect of 4H-silicon

Carbide at Fiber-optic Communication Wavelengths. In

2019 PhotonIcs & Electromagnetics Research

Symposium-Spring (PIERS-Spring) (pp. 658-662).

IEEE.

Nakabayashi, M., Fujimoto, T., Katsuno, M., & Ohtani, N.

(2006). Precise determination of thermal expansion

coefficients observed in 4H-SiC single crystals. In

Materials science forum (Vol. 527, pp. 699-702). Trans

Tech Publications Ltd.

Rao, S., Pangallo, G., & Della Corte, F. G. (2016).

Integrated amorphous silicon pin temperature sensor

for CMOS photonics. Sensors, 16(1), 67.

PHOTOPTICS 2021 - 9th International Conference on Photonics, Optics and Laser Technology

114