Catalyzing the Agility, Accessibility, and Predictability of the

Manufacturing-Entrepreneurship Ecosystem through Design

Environments and Markets for Virtual Things

Alexander Brodsky

a

, Yotam Gingold

b

, Thomas D. LaToza

c

, Lap-Fai Yu

d

and Xu Han

e

Department of Computer Science, George Mason University, 4400 University Drive, Fairfax, U.S.A.

Keywords: Product and Service Networks, Manufacturing, Design Environments, Markets, Decision Optimization.

Abstract: Proposed is a fundamentally new approach to manufacturing as a service based on a market of virtual things:

parameterized products and services that can be searched, composed and optimized, while hiding the

underlying complexity of product designs and manufacturing service networks. The approach includes (1) a

mathematical framework, composition and decision guidance for virtual things; (2) bootstrapping the market

with novel computational techniques and tools to reuse the distributed wealth of existing product and process

designs by generalizing them into models of virtual things; and, (3) intelligent computational design tools for

entrepreneurs. The goal is to catalyze the agility, accessibility and predictability of the manufacturing-

entrepreneurship ecosystem, transforming the Future of Manufacturing.

1 INTRODUCTION

There is a critical disconnect between entrepreneurs

who envision new products and manufacturers who

might build them. To bridge the disconnect, in this

position paper we propose a fundamentally new

approach to manufacturing as a service based on a

market of virtual things: parameterized products and

services that can be searched, composed and

optimized, while hiding the underlying complexity of

product designs and manufacturing service networks.

Our approach bootstraps the market with novel

computational techniques and tools to reuse the

distributed wealth of existing product and process

designs by generalizing them into models of virtual

things. This will catalyze the agility, accessibility and

predictability of the manufacturing-entrepreneurship

ecosystem, transforming the Future of

Manufacturing.

Entrepreneurs use their domain knowledge and

market insights to conceptualize innovative products,

but may fail to realize their ideas due to insufficient

a

https://orcid.org/0000-0002-0312-2105

b

https://orcid.org/0000-0002-5381-2104

c

https://orcid.org/0000-0002-9564-3337

d

https://orcid.org/0000-0002-2656-5654

e

https://orcid.org/0000-0002-3347-3627

design and manufacturing knowledge. They lack

agility (getting a product to market fast), access (to

manufacturing and supply chain resources), and

predictability. Manufacturers’ specialized knowledge

in their vertical domains amounts to a distributed

volume of existing expert-crafted product and process

designs, which assure predictable outcomes.

However, they lack agility and access to markets and

revenue opportunities provided by entrepreneurial

ideas outside of existing rigid supply-chain pyramids.

As a result, both entrepreneurs and manufacturers,

especially small and medium enterprises (SMEs),

miss opportunities to create value.

There has been significant research in

manufacturing product and process design (Gingold,

Igarashi, and Zorin, 2009; Yu, Yeung, Tang,

Terzopoulos, Chan, and Osher, 2011; LaToza,

Shabani, and Van Der Hoek, 2013; Shin, Kim, Shao,

Brodsky, and Lechevalier, 2017), analysis and

optimization (Egge, Brodsky, and Griva, 2013; Shao,

Brodsky, and Miller, 2018). Recently, a number of

startups have taken important complementary steps to

bridge this gap. Companies such as Xometry offer

264

Brodsky, A., Gingold, Y., LaToza, T., Yu, L. and Han, X.

Catalyzing the Agility, Accessibility, and Predictability of the Manufacturing-Entrepreneurship Ecosystem through Design Environments and Markets for Virtual Things.

DOI: 10.5220/0010310802640272

In Proceedings of the 10th International Conference on Operations Research and Enterprise Systems (ICORES 2021), pages 264-272

ISBN: 978-989-758-485-5

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

easy access to manufacturing as a virtual service,

where entrepreneurs may enter a CAD file and

receive a price and commitment in real time. Behind

the scenes, this is enabled through an accurate

predictive pricing model and a network of

manufacturers with various capabilities, such as CNC

machining, injection molding, and 3D printing.

However, combining these unit processes into a

composite manufacturing process to come up with a

finished consumer product is out of their scope.

Companies like Kerfed improve agility in

manufacturing response to customer demand by

accepting a CAD design of an assembly out of

standard components, and performing analysis to

discover the characteristics of its components and

their interconnection so that they can be (semi-)

automatically sourced from suppliers, and so that the

assembled product could be priced for a customer

order. Companies like Physna boost manufacturers’

agility in responding to customer demand by

searching for similar CAD designs in a large design

database using not only meta-data of existing designs,

but also their geometric and functional properties,

significantly simplifying the creation of a new CAD

design via re-use. CAD/CAM software, like

OnShape, has been widely used for product and

process design in increasingly more diverse vertical

domains, enabling designers to specify the blueprints

of their idea with high precision.

However, major challenges remain. First,

entrepreneurs do not typically have CAD modelling

skills; even when starting from a similar design, they

may not understand the design complexity and intent,

and still need to rely on professional CAD designers.

Second, when using a fixed CAD product design for

sourcing manufacturers, the design is typically not

optimized to consider manufacturability and supply

chain and manufacturing costs. Yet it is often

possible, via small modifications to a product's CAD

design, to make manufacturing significantly simpler

and less expensive with little or no effect on desirable

customer-facing product characteristics. Third, and

perhaps most important, US manufacturers,

especially SMEs, are still primarily selling low-

margin manufacturing capacity, because they face

stiff competition due to lower labor costs and

increasing quality of foreign, especially East and

South-East Asian, manufacturing. Manufacturing

SMEs typically do not offer new innovative products

with high profit margins because they lack access to

these innovative product ideas and the agility to

respond to the market opportunities they present.

This paper is organized as follows. In Section 2

we overview our approach; in Section 3 we illustrate

the approach by a real-world example. We discuss a

range of research questions to be addressed to realize

the new approach in Section 4, and conclude in

Section 5.

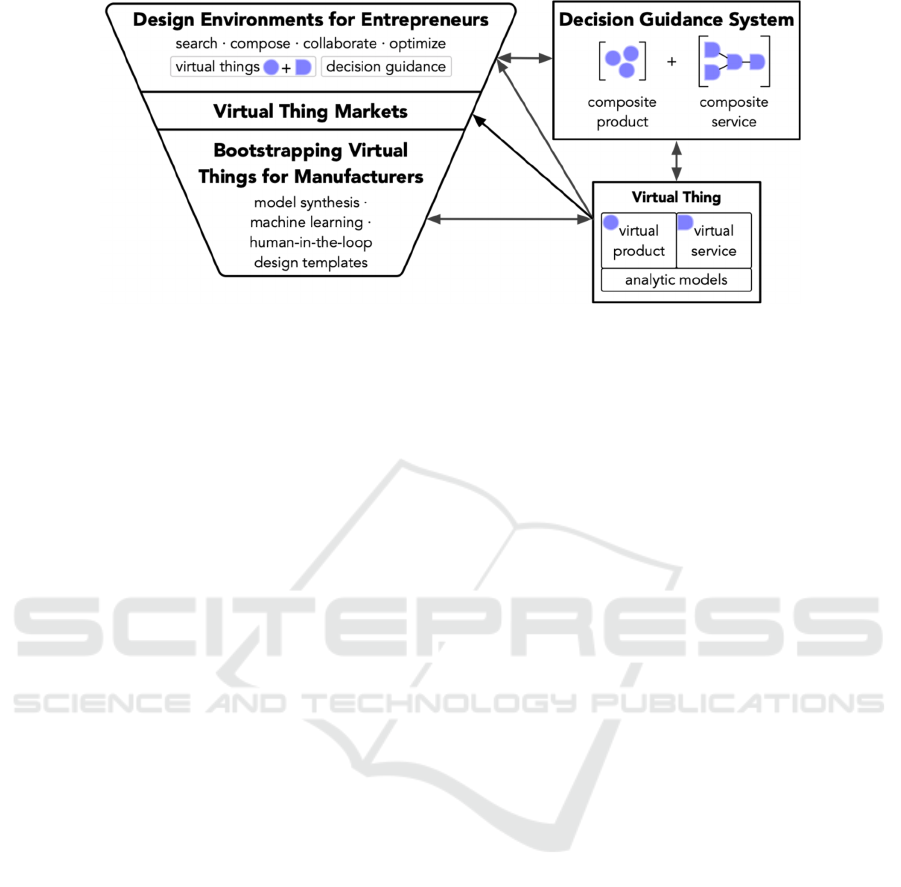

2 OUR APPROACH

We propose a fundamentally new approach to, and a

novel productivity framework for, the manufacturing-

entrepreneurship ecosystem based on bootstrapped

markets of virtual products and services (see Figure

1, middle funnel layer), which we collectively call V-

things. A virtual product is represented by a

parameterized CAD design, e.g., to characterize a

customizable consumer product, part or raw material.

A virtual service represents a parameterized

transformation of virtual products into other virtual

products, e.g., to characterize a customizable

manufacturing process, supply, transportation,

logistics or a composed service network. Each V-

thing—product or service—is associated with an

analytic model that describes the product and/or

service’s feasibility and customer-facing

characteristics (e.g., weight, durability, strength,

volume for a product; and cost, delivery time and

default risk for a service) as a function of the product

and/or service’s decision and fixed parameters (e.g.,

dimensions, position of fixtures, type and properties

of materials for a product; and settings for

manufacturing processes, selection of and ordered

quantities from suppliers and manufacturers).

The purpose of the Decision Guidance System

over a repository of V-things (Figure 1) is to enable

manufacturers and entrepreneurs to (1) search for

relevant V-things (products and services) in the

market, (2) compose them into more complex V-

things (e.g., assembled products or service networks)

and, most importantly, (3) guide decisions, activity

that involves model training, predictions,

optimization and trade-off analysis, i.e.,

recommending users Pareto-optimal choices on V-

thing parameter instantiation (corresponding to

specific products and services), while eliciting and

acting on preferences among possibly competing

objectives, such as cost, reliability and time to market.

To manufacturers, V-thing markets offer an order-

of-magnitude more agility in response to customer

demand and access to entrepreneurs with ideas. More

speculatively, V-thing markets may allow

manufacturers to expand their business model, from

selling low-margin manufacturing capacity to agile

supply of high-margin on-demand products in their

vertical markets, boosting their global

Catalyzing the Agility, Accessibility, and Predictability of the Manufacturing-Entrepreneurship Ecosystem through Design Environments

and Markets for Virtual Things

265

Figure 1: The funnel of the manufacturing/entrepreneurship ecosystem.

competitiveness. To scale up the creation of V-

things—products and services—beyond the

traditional limits of generative design, we envision

research and development of novel computational

techniques and V-thing design tools for

manufacturers (see bottom part of the funnel in Figure

1). These techniques and tools will support search,

reuse, and generalization of manufacturers’ existing

product and process designs into models of V-things,

leveraging their domain expertise to manufacture

similar things. We envision an extensive use of

repositories of examples created in a CAD system as

well as physically scanned examples. The creation of

new V-things will also need to leverage available V-

things in the market. We envision associating virtual

things with multi-aspect descriptions to aid their

discovery by entrepreneurs.

To entrepreneurs, V-thing markets offer the

agility to realize their ideas for a new product or

service through flexible search, composition,

optimization and Pareto trade-off analysis using

available V-things, while hiding the complexity of

underlying product designs and manufacturing

service networks—both process and supply chain.

We expect to design and develop Intelligent Design

Tools for Entrepreneurs (see the top layer of the

funnel in Figure 1), as possible extensions to existing

CAD/CAM tools, using paradigms such as design-

by-sketch and by example, and leveraging V-thing

markets. This agility will drive manufacturing

demand.

3 MOTIVATING EXAMPLE

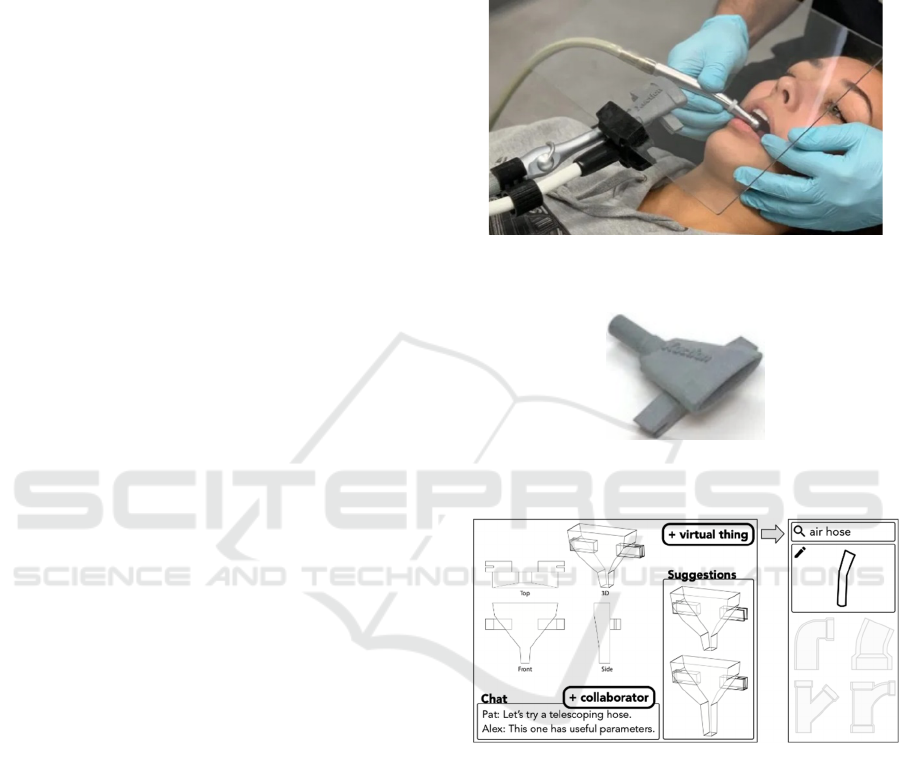

Dentists re-opening their practices after closures due

to COVID-19 need to overcome a major exposure

risk. Many dental procedures—those that require the

use of a high-speed handpiece or an ultrasonic

scaler—generate a pressurized spread of aerosol,

which may carry microorganisms, including the novel

coronavirus. The main mitigating solution offered by

dental suppliers is an extra-oral suction, based on

repurposed dust vacuums. This is too bulky, noisy,

and expensive for a dental operator. A dentist

entrepreneur comes up with a much smarter idea: she

wants to repurpose an existing HVE (high-volume

evacuation) line already available in the dental unit

and normally used for dental suction—but not for the

collection of aerosol in the air. What is missing is a

specially designed funnel (Figures 2 & 3) that can be

attached to an existing HVE line and be held in close

proximity to the patient's mouth during a dental

procedure. This funnel must satisfy a number of

properties: (1) it must be of geometry and size that

maximize the suction of aerosol (too small will not be

effective for aerosol cloud; too big will not generate

sufficient suction pressure); (2) it must be light, yet

strong and autoclavable, i.e., withstand sterilization

temperatures of 175°C; and (3) it must be attachable

to both a cheek retractor and an external adjustable

arm. In addition, the adjustable arm (Figure 2) must

be designed to hold the funnel attached to the HVE

line in the required position to enable hands-free

operation, as well as an optional transparent shield.

The entrepreneur dentist envisions that, if introduced

to the market quickly, this new aerosol collection

funnel can easily be sold for $70-80 per part, which is

a small fraction compared to $2000-3000 per one

bulky and noisy extra-oral suction device currently on

the market. She and her dentist colleagues would

certainly find this offering extremely useful and

relatively inexpensive.

This motivating example was found in the wild,

suggested by a dentist in a Facebook group for

dentists. However, that dentist’s idea would never get

anywhere beyond a Facebook post. Xuction Dental—

ICORES 2021 - 10th International Conference on Operations Research and Enterprise Systems

266

a start-up company in Virginia—invested significant

engineering, material science and manufacturing

expertise to implement it.

As lead users, dentists are very familiar with their

needs and current technologies, but are generally not

technical in the sense of manufacturers or engineers

(Hippel, 1988). The road to idea realization has high

barriers to entry. Expertise is distributed and siloed:

The entrepreneur must find product designers and

manufacturers with whom to partner. Communication

is difficult and tools are inaccessible: Everyone must

communicate their capabilities and their needs to each

other, using very different languages and

perspectives. Entrepreneurs cannot participate in the

digital design of the product. Product designers may

not have access to manufacturing decisions. Siloed

decision-making results in sub-optimal designs.

Work is wasted: The work of designers and

manufacturers is delivered bespoke for a particular

product. Without opportunities for discovery and re-

use of designs and processes, productivity is

suppressed and capacity is underused.

In our vision, the dentist entrepreneur uses an

accessible Intelligent Design Environment for

Entrepreneurs (Figure 4) in collaboration with other

innovators (such as product designers) who may

suggest improvements. The entrepreneur creates a

rough sketch of their product vision (e.g., the aerosol

suction funnel) and provides some free text

describing it. The design tool constructs a 3D model

approximating the funnel sketch and uses it to search

for relevant V-products (e.g., for vacuum polymer

funnels) and associated V-services (e.g.,

manufacturer who produces them) in the V-thing

market. The dentist explores one V-product that looks

relevant, and the design tool displays a 3D-model of

the V-product fitted to the dentist’s sketch. The 3D

depiction is annotated with customer-facing

characteristics, which can be used to express known

constraints and objectives/criteria to be considered.

For example, the dentist may provide funnel product

constraints, such as the diameter of connecting hose,

the maximum allowed weight, the minimal

temperature of 175°C to withstand, and service

constraints such as the number of units to be produced

and the maximum delivery time window. She also

chooses objectives to be considered, such as

vacuuming efficiency, weight, cost-per-unit and

delivery time. The design tool leverages the V-service

and V-product analytic models and uses the Decision

Guidance System to recommend and display a few

Pareto-optimal alternatives in terms of the specified

objectives while soliciting comparison responses.

After a number of iterations, the dentist converges to

a specific instance of a vacuum funnel and specific

service terms. The dentist initially orders a couple of

samples, tries them out, makes adjustments, and then

places a production order of 10,000 units to the V-

service provider to be sold to dental practices.

Figure 2: Dental aerosol funnel connected to HVE suction

line. © Xuction Dental.

Figure 3: Dental aerosol collection funnel. © Xuction

Dental.

Figure 4: The Entrepreneur Design Environment.

The creator of the vacuum polymer funnel V-

product and associated manufacturing V-service may

be a small injection molding manufacturer, who

happen to produce similar products, and who decided

to extend its business model from selling

manufacturing (injection molding) capacity to

wholesale of some V-products, such as on-demand

vacuum polymer funnels. To do that, the

manufacturer uses in-house and/or hired expertise to

specify V-product and V-service designs, leveraging

many specific expert-crafted CAD/CAM product and

process designs of similar things produced in the past.

Design Tool for V-things helps manufacturers to

search for relevant specific designs, and generalize

Catalyzing the Agility, Accessibility, and Predictability of the Manufacturing-Entrepreneurship Ecosystem through Design Environments

and Markets for Virtual Things

267

them with analytic model, that expresses feasibility

and customer facing characteristics such as

vacuuming efficiency, weight, cost-per-unit and

delivery time as a function of internal product and

process parameters: geometry, dimensions, type and

density of polymer material, as well as process

settings. While this task requires expertise, even with

the help of the V-thing Design Tool, the outcome is

highly reusable and allows the manufacturer

significant agility and access to otherwise unavailable

markets, such as for the dental aerosol collection

funnel, which can be sold at much higher profit

margins. In turn, the manufacturer may use some

other existing V-things in the market, e.g., polymer

material V-product and associated V-service. The

manufacturer of polymer material, in turn, leverages

its expertise in designing and producing special

polymers with unique properties, such as low density

and the ability to withstand high temperature. Of

course, behind V-things in the market may also be

engineering and technology firms that want to expand

their business model from selling consulting to

becoming virtual manufacturers, while generating

demand for manufacturing capacity in the external

service network.

4 TECHNICAL PROBLEMS

To realize this new paradigm, we need to overcome a

number of mathematically and computationally

challenging research problems.

4.1 V-things Math Framework,

Composition, Search and Decision

Guidance

The framework will include mathematical

formalization of V-things—products and services—

including their design specs, customer facing specs,

customer requirements specs, and the notions of

feasible and optimal parameter instantiation based on

analytic models associated with V-things. To support

the creation of V-things by manufacturers one needs

to design recursive compositional models—e.g., for

product assembly and service networks—in such a

way that compositions would be easy (e.g.,

graphically) to specify by (non-mathematical)

domain users, yet can be interpreted as formal

analytic models by the system.

We envision a virtual product to be represented by

a parameterized CAD design, e.g., to characterize a

customizable consumer product, part or raw material.

A virtual service represents a parameterized

transformation of virtual products into other virtual

products, e.g., to characterize a customizable

manufacturing process, supply, transportation,

logistics or a composed service network. Each V-

thing—product or service—is associated with an

analytic model that describes the product and/or

service’s feasibility and customer-facing

metrics/characteristics as a function of the product

and/or service’s (fixed and decision) parameters. For

V-products, examples of customer-facing metrics

include external dimensions, weight, durability and

vacuum efficiency; while examples of internal

parameters include internal dimensions, position of

fixtures, and type and properties of materials. For V-

services, examples of customer-facing metrics

include cost-per-unit, total ordered quantities per

item, delivery time, carbon emissions per unit, and

default risk; while examples of internal parameters

include settings for unit manufacturing processes

(e.g., CNC machining, injection molding or 3D

printing) and selection of and ordered quantities from

suppliers and manufacturers. Intuitively, V-things’

customer-facing metrics are all that customers care

about when selecting products and services; whereas,

customers do not care about, or even understand, V-

thing parameters outside the set of customer-facing

metrics.

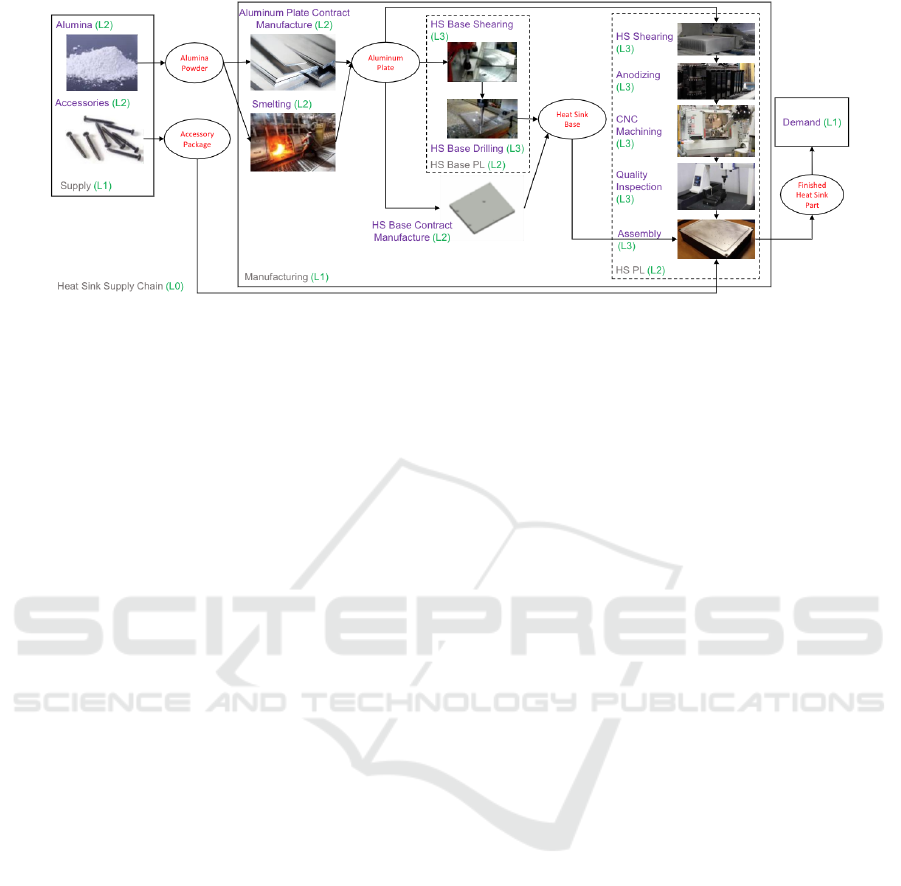

Consider an example of a manufacturing service

network (Figure 5) for a heat sink product (Brodsky,

A., Krishnamoorthy, M., Nachawati, M. O.,

Bernstein, W. Z., and Menascé, 2017; Brodsky,

Nachawati, Krishnamoorthy, Bernstein, and

Menascé, 2019), produced by Birmingham

Aluminum Ltd. This product is an assembly of

aluminum and the covering plastic frame using

accessories. Both the product and the service are

composite. The service to produce the finished heat

sink product (HS) involves a hierarchical service

network, which includes supply, manufacturing and

demand services; in turn, manufacturing is also a

service network, composed of aluminum plate

contract manufacturer, smelting, HS base production

line, HS base contract manufacturer and HS

production line. In turn, HS production line is a

service network composed of HS shearing, anodizing,

CNC machining, quality inspection, and final

assembly, etc. The challenge here is to avoid hard-

wired and time-consuming development of analytic

models for every composition of V-products (like the

assembled heat sink) and V-services (like the heat

sink service network). To address this challenge, one

needs to design (re-usable) recursive compositional

models—across both product assembly and service

ICORES 2021 - 10th International Conference on Operations Research and Enterprise Systems

268

Figure 5: Example of manufacturing service network for heat sink product.

network compositional hierarchies—in such a way

that compositions would be easy to specify (e.g.,

graphically) by (non-technical) domain users, yet can

be interpreted as formal analytic models by the

system. To achieve this goal, we envision leveraging

techniques from the Factory Optima system, which

was designed and developed for NIST (Brodsky,

Krishnamoorthy, Bernstein, and Nachawati, 2016;

Brodsky et al, 2017; Brodsky et al, 2019; Brodsky,

Shao, Krishnamoorthy, Narayanan, Menascé, and

Ak, 2016), but which has not considered

parameterized or composed product designs.

While searching for V-things in the market

repository is conceptually similar to searching for

regular products and services, it is fundamentally

different and more challenging computationally. Just

a match between a user requirement spec and a

particular V-thing customer facing spec is a constraint

satisfaction problem, which, like the corresponding

optimization problem, may be both non-linear and

combinatorial in high-dimensional space.

To scale up online optimization for practical size

problems within manageable computational time, one

idea is to design pre-processing algorithms that

generate differentiable surrogates for (combinatorial

components of) analytic models used in optimization

problems. To scale-up search for V-things, we will

need to design offline pre-processing algorithms to

generate bounding polyhedral set approximations that

are amenable to efficient (multi-dimensional)

indexing techniques for search. Another major

challenge we need to overcome has to do with the fact

that composable and modular analytic models—

against which optimization is applied—are expressed

using object-oriented code (e.g., in Python); yet the

best mathematical programming algorithms require,

as input, a closed-form-arithmetic (“white-box”)

optimization model (as opposed to simulation-like

“black-box” model). This can be done by leveraging

and further developing symbolic computation

techniques to machine generate closed-form-

arithmetic optimization models from software code in

order to use the best existing, as well as develop

extensions to, mathematical programming algorithms

(Brodsky and Wang, 2008; Brodsky and Luo, 2015).

4.2 Design Tools for Virtual Things for

Manufacturers

The goal is to design computational techniques to

generalize manufacturers’ existing designs (products

and services) as V-things. Bootstrapping the v-things

repository involves identifying its decision

parameters and analytic models that express

feasibility and customer-facing characteristics as a

function of these parameters. The challenge is that

black-box data-driven approaches may fail to find

straightforward and reliable shape designs or

governing equations. To solve this problem, we

envision the need to leverage and extend the

techniques of program synthesis (Solar-Lezama,

2008) to enable the creation of analytic models by

non-programmers, resulting in “grey-box” models

that are partly physics-based and partly data-driven.

Since there are many model and non-decision

parameter alternatives, we envision the use of

machine learning algorithms to train, validate, and

select the best model alternatives.

We propose example-based techniques for

generating parametric CAD models. Rather than

requiring manufacturers to re-train with a new design

tool, we envision the need to analyze a set of existing

shapes and semi-automatically find parameters to

define a family of shapes comprising a V-product. For

example, an engineer with CAD experience could

create multiple instances of a design with their

favorite CAD tool. Alternatively, a machine operator

can create multiple variations of a physical object. We

Catalyzing the Agility, Accessibility, and Predictability of the Manufacturing-Entrepreneurship Ecosystem through Design Environments

and Markets for Virtual Things

269

envision the need to analyze and filter these shapes

and propose variables. For example, parameters could

be continuous like repeated lengths, which may

appear in whole multiples, or discrete like symmetry

relationships or choice of materials.

We envision developing approaches for enabling

users to author models expressing performance

characteristics of v-things, such as strength, stability,

manufacturing expense and feasibility, and material

waste. The metrics associated with each v-thing can

be used for e.g., Pareto front discovery and

optimization. The metrics can measure mass, strain

under load, manufacturing material waste, torque, etc.

Users can design finite element simulations involving

the part. Importantly, it is desirable for metrics to be

differentiable when possible, allowing their use in

gradient-based optimization applications (e.g.,

decision guidance, Pareto front discovery, and deep

learning).

Rather than requiring knowledge of

programming, which manufacturers may not possess,

we envision creating novel end user programming

techniques which enable performance models to be

created through examples. To solve this problem, one

idea is to use “grey-box” models that are partly

analytical or physics-based and partly data-driven. To

do that one can leverage and extend the techniques of

program synthesis (Solar-Lezama, 2008) to enable

the creation of analytic or physics-based models with

meaningful parameters by non-programmers. The

resulting programs will have an overly large set of

parameters. We propose to put the user in charge of

suggesting and filtering possible parameters to be

user-facing. To do this, one can explore Programming

by Demonstration approaches (Cypher and Halbert,

1993; Lieberman, 2001). Users can describe

examples of performance for specific inputs or mark

measurements (solo or repeated) and components

with a symmetry relationship. Since there are many

model and non-decision parameter alternatives, we

will use machine learning regression and

classification algorithms to train, validate, and select

the best model alternatives. It is also important to

explore ways in which shapes and performance

characteristics can be visualized, helping

communicate the effects of choices on the model.

Manufacturer’s knowledge and experience in

manufacturing also make them uniquely well-suited

to create v-services for a v-product's creation. The v-

service for manufacturing a v-product entails

sourcing raw materials and arranging the

manufacturing process. We propose to leverage our

prior work using flow diagrams to specify v-services.

This will be integrated into the v-thing designer,

allowing manufacturers to design a shape's

parameters simultaneously with its manufacturing

process. To enable manufacturers, who are not

expected to be programmers, to design the analytical

models for the v-services, we envision the use and

exploration of Programming by Demonstration

approaches (Cypher and Halbert, 1993) (see End-

User Authoring of Performance Analytic Models).

4.3 Intelligent Computational Design

Tools for Entrepreneurs

Intelligent computational design tools for

entrepreneurs and their collaborators must enable

them to turn ideas into virtual things and then into

prototypes without having expertise in CAD or

engineering. We envision intuitive search approaches

based on sketching, similar-product search, and

assembly-based modelling to enable entrepreneurs to

find and compose virtual things within the

marketplace intuitively. Such approaches will also

encourage the reuse and adaptation of existing virtual

things to unleash their potential. The computational

design tools driven by decision guidance will also

perform optimization and Pareto trade-off analysis to

automatically suggest design alternatives.

Entrepreneurs will be able to select between

alternatives, providing preferences which the system

uses to iteratively elicit the utility function and use it

to generate new alternatives, and collaborate with the

tools in the ideation process.

Sketching is a natural, straightforward way of

expression for illustrating creative ideas. Compared

to using traditional, sophisticated CAD software (e.g.,

3ds Max) for creating 3D model designs, which

requires a steep learning curve to master, it is much

easier for people to sketch their ideas on a tablet. A

sketch-based design interface allows people to focus

on envisioning the design of their products rather than

operating the sophisticated interface of CAD

software. There are many challenges in creating a

convenient and effective sketch-based design interface.

One challenge is due to the irregularity of sketches:

most people are not artists and they can only sketch

their ideas roughly. One approach to tackle this

problem is to devise machine learning approaches for

inferring a clean and valid design from a user’s

sketches. Recent work using generative adversarial

networks (GAN) for inferring 3D models from

sketches provides a promising solution (Guérin, Digne,

Galin, Peytavie, Wolf, Benes, and Martinez, 2017;

Portenier, Hu, Szabó, Bigdeli, Favaro, and Zwicker,

2018). Sketch-based interfaces have also been

proposed for creating furniture designs (Xie, Xu,

ICORES 2021 - 10th International Conference on Operations Research and Enterprise Systems

270

Mitra, Cohen-Or, Gong, Su, and Chen, 2013) (Figure

6).

Figure 6: A sketch-based interface for furniture design.

For most people, it is much simpler to design a

virtual service or product guided by suggestions. For

example, when renovating homes, people often refer

to a magazine showing many examples of home

renovation projects to get inspiration, rather than

designing from scratch. Akin to this, we envision

suggestive design interfaces to help entrepreneurs

with design. For instance, consider the design of a

chair. A suggestive user interface may work like this:

1) The user first specifies the high-level goals of

the chair design, such as the style (e.g., classic or

modern?), context of use (e.g., a dining chair or a desk

chair?), physical properties (e.g., dimensions,

weights), and functionalities (e.g., adjustable?). The

user may also sketch his or her rough idea or provide

an existing similar design.

2) According to the user’s specification from step

(1), the system samples a number of feasible design

solutions that match with the user’s preference;

3) The user chooses one of the suggestions;

4) The user may modify the suggested design to

better match with the user envisions;

5) The system generates new suggestions based

on the specified modifications.

6) Repeat steps (3) to (5) until the user obtains a

desired final design.

Here, the research challenge lies in inferring what

the user wants from the high-level description or

rough sketch in step 1). A promising strategy to

overcome such a challenge involves applying a data-

driven approach to learn statistical patterns of design

from a large database of existing designs. For

example, given a database of 3D chair designs, one

can train machine learning classifiers to determine

perceptual shape style similarity (Lun, Kalogerakis,

and Sheffer, 2015). Given a rough sketch or a

partially finished chair design, a suggestive interface

can infer and recommend possible full designs

according to styles and assembly schemes learned

from existing chair designs (Xie et al, 2013).

Another promising strategy to help entrepreneurs

create designs is assembly-based 3D modeling. The

idea is to provide users with simple primitive shapes

that they can assemble into a complex object.

Another promising strategy to help entrepreneurs

create designs is assembly-based 3D modeling. The

idea is to provide users with simple primitive shapes

that they can assemble into a complex object. Akin to

the furniture design of IKEA, the algorithm

automatically decomposes a furniture product (e.g., a

chair) into a number of manufacturable, modular

components which customers can easily assemble

into the full products. Compared to the traditional

approach of creating 3D objects from scratch using

low-level mesh or primitive manipulation tools in

CAD software, assembly-based modeling is much

simpler to learn and perform.

A major research challenge of realizing assembly-

based modeling lies in designing a set of compatible

primitive shapes that the user can conveniently

assemble into many objects. A trivial solution is to

design a set of very general-purpose primitive shapes,

like LEGO bricks of different dimensions, which give

a high-degree of freedom and hence high flexibility

with respect to the objects they can assemble.

However, it typically takes many very general-

purpose primitive shapes to assemble a desired

object, and hence the physical assembly process

could be time-consuming and complex.

To tackle such challenges, we will employ a

recently devised approach called “hands-on

assembly-based modeling” (Duncan, Yu, and Yeung,

2016). The key idea is to create an algorithm to

automatically extract and generate a set of

compatible, interchangeable, and semantically

meaningful primitive shapes given a set of existing

objects. Such primitive shapes can be used for

assembling many variations of the original objects.

Given a small set of chair 3D models, which can be

easily found on the Internet, the algorithm

automatically decomposes the chairs into a set of

compatible, interchangeable, and 3D-printable

primitive components—such as legs, bases, and

backs—that a lay user can easily assemble into

different new chairs.

It is important to impose physical and functional

constraints on the generated primitive shapes, as well

as the final product assembled using these primitive

shapes. Such constraints have practical implications.

For example, realized as virtual products that are

traded on our platform, the primitive shapes should be

compact and regular to facilitate manufacturing,

packaging, and transportation; while the final object

assembled should possess desirable physical

properties (e.g., the assembled chair must be sturdy).

Catalyzing the Agility, Accessibility, and Predictability of the Manufacturing-Entrepreneurship Ecosystem through Design Environments

and Markets for Virtual Things

271

5 CONCLUSIONS

We envision new design environments and markets

for virtual things as the bridge over the gap between

unmatched entrepreneurial initiatives and

manufacturing capabilities of the value creation

ecosystem today. The goal is to catalyze the agility,

accessibility, and predictability of the ecosystem. As

discussed in Section 3, significant research problems

need to be overcome, including (1) V-things Math

Framework, Composition, Search and Decision

Guidance; (2) Design Tools for V-things for

Manufacturers; (3) Intelligent Computational Design

Tools for Entrepreneurs.

ACKNOWLEDGEMENTS

Lap-Fai Yu is supported by an NSF CAREER grant

(award number: 1942531) in this work.

Yotam Gingold was supported by the United

States National Science Foundation (IIS-1453018)

and a gift from Adobe Systems Inc.

REFERENCES

Gingold, Y., Igarashi, T., and Zorin, D., 2009. Structured

annotations for 2D-to-3D modeling. In ACM

SIGGRAPH Asia’09.

Yu, L-F., Yeung, S. K., Tang, C-K., Terzopoulos, D., Chan,

T. F., and Osher, S., 2011. Make it home: automatic

optimization of furniture arrangement. In ACM

transactions on graphics 30, 4: 86.

LaToza, T. D., Shabani, E., and Van Der Hoek, A., 2013. A

study of architectural decision practices. In 6th

International Workshop on Cooperative and Human

Aspects of Software Engineering’13 (CHASE), 77–80.

Shin, S., Kim, D. B., Shao, G., Brodsky, A., and

Lechevalier, D., 2017. Developing a decision support

system for improving sustainability performance of

manufacturing processes. In Journal of Intelligent

Manufacturing 28, 1421–1440.

Shao, G., Brodsky, A., and Miller, R., 2018. Modeling and

Optimization of Manufacturing Process Performance

using Modelica Graphical Representation and Process

Analytics Formalism. In Journal of intelligent

manufacturing 29, 6: 1287–1301.

Egge, N., Brodsky, A., and Griva, I., 2013. An Efficient

Preprocessing Algorithm to Speed-Up Multistage

Production Decision Optimization Problems. In 46th

Hawaii International Conference on System

Sciences’13.

Hippel, E., 1988. The Sources of Innovation, Oxford

University Press. USA.

Brodsky, A., Krishnamoorthy, M., Nachawati, M. O.,

Bernstein, W. Z., and Menascé, D. A., 2017.

Manufacturing and contract service networks:

Composition, optimization and tradeoff analysis based

on a reusable repository of performance models. In

2017 IEEE International Conference on Big Data.

Brodsky, A., Nachawati, M. O., Krishnamoorthy, M.,

Bernstein, W. Z., and Menascé, D. A., 2019. Factory

optima: a web-based system for composition and

analysis of manufacturing service networks based on a

reusable model repository. In International Journal of

Computer Integrated Manufacturing 32, 206–224.

Brodsky, A., Krishnamoorthy, M., Bernstein, W. Z., and

Nachawati, M. O., 2016. A system and architecture for

reusable abstractions of manufacturing processes. In

2016 IEEE International Conference on Big Data.

Brodsky, A., Shao, G., Krishnamoorthy, M., Narayanan,

A., Menascé, D. A., and Ak, R., 2016. Analysis and

Optimization based on Reusable Knowledge Base of

Process Performance Models. In International Journal

of Advanced Manufacturing Technology: 1–21.

Solar-Lezama, A., 2008. Program Synthesis by Sketching.

University of California, Berkeley.

Cypher, A., Halbert, D. C., 1993. Watch what I Do:

Programming by Demonstration. MIT Press.

Lieberman, H., 2001. Your Wish is My Command:

Programming By Example. Elsevier.

Guérin, É., Digne, J., Galin, É., Peytavie, A., Wolf, C.,

Benes, B., and Martinez, B., 2017. Interactive example-

based terrain authoring with conditional generative

adversarial networks. In ACM Transactions on

Graphics 36, 1–13.

Portenier, T., Hu, Q., Szabó, A., Bigdeli, S. A., Favaro, P.,

and Zwicker, M., 2018. Faceshop: deep sketch-based

face image editing. In ACM Transactions on Graphics

37, 1–13.

Xie, X., Xu, K., Mitra, N. J., Cohen-Or, D., Gong, W., Su,

Q., and Chen, B., 2013. Sketch-to-design: Context-

based part assembly. In Computer Graphics Forum,

233–245.

Lun, Z., Kalogerakis, E., and Sheffer, A., 2015. Elements

of style: learning perceptual shape style similarity. In

ACM Transactions on Graphics’15.

Duncan, N., Yu, L-F., and Yeung, S-K., 2016.

Interchangeable Components for Hands-On Assembly

Based Modelling. In ACM transactions on graphics 35,

6.

Brodsky, A., Wang, X. S., 2008. Decision-Guidance

Management Systems (DGMS): Seamless Integration

of Data Acquisition, Learning, Prediction and

Optimization. In Proceedings of the 41st Annual

Hawaii International Conference on System Sciences

(HICSS 2008), 71.

Brodsky, A., Luo, J., 2015. Decision Guidance Analytics

Language (DGAL): Toward Reusable Knowledge Base

Centric Modeling. In 17th International Conference on

Enterprise Information Systems (ICEIS 2015).

ICORES 2021 - 10th International Conference on Operations Research and Enterprise Systems

272