Measuring Sustainability Performance in the Product Level

Qinru Wang

a

, Qing Yang

b

and Mingxing Chang

c

School of Economics and Management, University of Science and Technology Beijing, 30 Xueyuan Road, Beijing, China

Keywords: Sustainability, Measurable Indicator, Product Level, Life Cycle, DSM (Design Structure Matrix).

Abstract: Sustainability is becoming increasingly important in new product development as modern society demands

technicality, customer satisfaction, and economic efficiency during a product’s life cycle. Previous papers

have commented more on the environmental aspects of sustainability in project management, whereas less

attention has been paid to the measurable indicators of products. The knowledge about the product process

structure is beginning to use sustainability indicators as part of the approach. Based on this idea, this paper

suggests a combination of measurable indicators of sustainability that can be used in the product process

structure of the construction industry. The aim is to identify a product process structure that is compatible

with sustainable project management. The idea of product design structure matrix (DSM) will be introduced

to identify the sustainability of products. By analysing the different dimensions of the measurable indicators,

the sustainable products can be compared. This provides an integrated view of the product process structure

when developing new products. This approach will then be applied to the smartphone industry as an illustrate

example, which will provide ideas to improve the sustainability of new smartphone development.

1 INTRODUCTION

Sustainability has been a major source of discussion

for some years. Shareholders use the term

‘sustainable’ to describe their products and activities.

They all state that they are trying to protect natural

resources and the global environment. Indeed, the

manufacturing industry has actually been achieving

some form of sustainability (Eskerod and Huemann,

2013). The creation of high-quality products at

competitive prices is what makes manufacturers

profitable. As a result, throughout history,

manufacturers have been trying to find ways to make

the machining process more efficient and cost-

effective, including the continuous development of

advanced and sophisticated production machinery

and improved cutting tools, and the optimization of

the entire cutting system (Silvius and Schipper,

2014). Specific strategies that have been developed

include high-speed, high-feed, high-performance,

and digital machining.

Sustainability is generally divided into three

dimensions: economic, environmental, and social. In

a

https://orcid.org/0000-0002-3267-7804

b

https://orcid.org/0000-0002-7529-9065

c

https://orcid.org/0000-0003-4672-9406

the manufacturing factory, the sustainability of the

production process and the sustainability of the

conveyance are both essential as they can have

significant social and environmental effects (Pimmler

and Eppinger, 1994; Browning, 2001). A sustainable

product process structure is specifically relevant for

industries that have a large output with a lot of waste.

In the multi-product life cycle, it is also a system that

is turn to concentrate on sustainability, but the

absorption is more on the environmental dimension

of the product itself. Sustainability has dominated

international attention, due largely to the society that

unfavorable environmental effect is increasingly

concentrated (Ma and Kremer, 2016; Okudan et al.,

2013).

Sustainability is an essential project purpose

equilibrating other aspect of costs and earnings.

Sustainability in the production process means the use

of practices that ensure the process is economically,

socially and environmentally acceptable throughout

its life cycle (Silvius and Schipper, 2014). Sustainable

project management relates and develop on

stakeholder pattern (Eskerod and Huemann, 2013),

includes life cycle considerations and development

Wang, Q., Yang, Q. and Chang, M.

Measuring Sustainability Performance in the Product Level.

DOI: 10.5220/0010301102410247

In Proceedings of the 10th International Conference on Operations Research and Enterprise Systems (ICORES 2021), pages 241-247

ISBN: 978-989-758-485-5

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

241

(Labuschagne and Brent, 2005), and ensures the three

dimensions’ measurable indicators of sustainability

are adhered to products (Silvius and Schipper, 2014).

Klakegg (2009) implied different thinking for the

demand of sustainability in project management: lack

of interest, lack of participation from main

stakeholders, low profits of sustainability compared

to the required investment, and dynamic

environment.

The relationship between sustainability and the

product is being discussed in an increasing number of

papers (Silvius and Schipper, 2014; Aarseth et al.,

2017), with ‘green’ or ‘sustainable’ products having

been determined as one of the most important

international topics (Alvarez-Dionisi et al., 2016).

Product development activities typically begin by

recording customers’ requirements and society’s

demands (Eppinger et al., 1994; Browning, 2001).

By investigating the production process in the

manufacturing industry, decision makers can

determine the sustainability of different products. The

product design structure matrix (DSM) is a matrix-

based analytical method created by Steward (1981)

and developed by Pimmler and Eppinger (1994) to

aid with multi-project management. A matrix

representation is also used to indicate different

manufacturing of three dimensions (Pimmler and

Eppinger, 1994). Furthermore, in the project process

structure, developments in manufacturing industry

have been indicated as communication system of

interacting new product that generate their profits for

more earnings (Sosa et al., 2004; Cataldo et al., 2006).

2 MEASURABLE INDICATORS

OF SUSTAINABILITY AND

THE MANAGEMENT LIFE

CYCLE BASED ON PRODUCT

2.1 Sustainability of the Product Life

Cycle

Sustainability based on the production process

structure is a comprehensive, time-based method,

which indicates the structural performance based on

the three measurable indicators of sustainability

throughout the product’s life cycle. A life cycle

analysis has the ability to evaluate the social,

economic, and environmental impacts of the product

process structure throughout its entire life cycle,

allowing it to determine the most suitable product that

meets a customers’ needs.

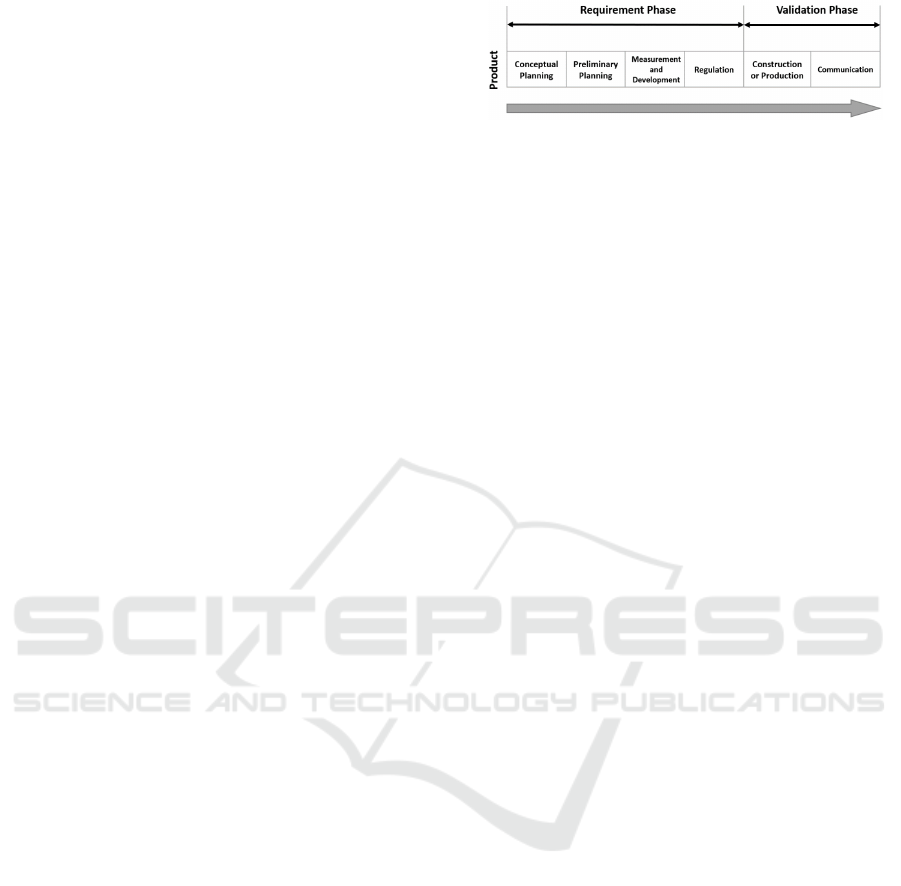

Figure 1: Sustainability of the Product Life Cycle.

The main goal for developing a new product is to

design a product or to alter the production industry to

meet the demands of the customers. The procedure

phase of the product life cycle is in the product of the

manufacturing industry (Silvius and Schipper, 2014).

In recent years, product life cycles have played an

essential role in life cycle assessments (LCA), which

are used to estimate the performance of different

products. An LCA examines six stages in a product’s

life cycle. These stages (conceptual planning,

preliminary planning, measurement and

development, regulation, construction or production,

and communication) are split into two phases: the

requirement phase, and the validation phase. The

difference between these two phases is that the first

focuses on the supply chain, and includes the

planning and measurement of a product, while the

second starts the life cycle of a product with the

construction in industry and includes the supply chain

activities as part of the validation phase.

In the requirement phase, measurement indicators

are used to give guidance to for initial planning and

regulation. In the validation phase, measurement

indicators are used for production and final

coordination.

2.2 Identifying Indicators That Can Be

used to Measure the Sustainability

Evaluation Criteria

Some researchers include three dimensions of

sustainability jointly in product selection.

Labuschagne and Brent (2005) specified three aims

of a sustainable product process structure, including

social equity, economic efficiency, and

environmental performance. They stated that

sustainability is a compound term, including social,

economic, and environmental aspects. The three

dimensions of sustainability for an enterprise are

people, income, and earth, each of which represents

the social, economic, and environmental aspects in

turn (Daneshpour, 2016). Each dimension includes

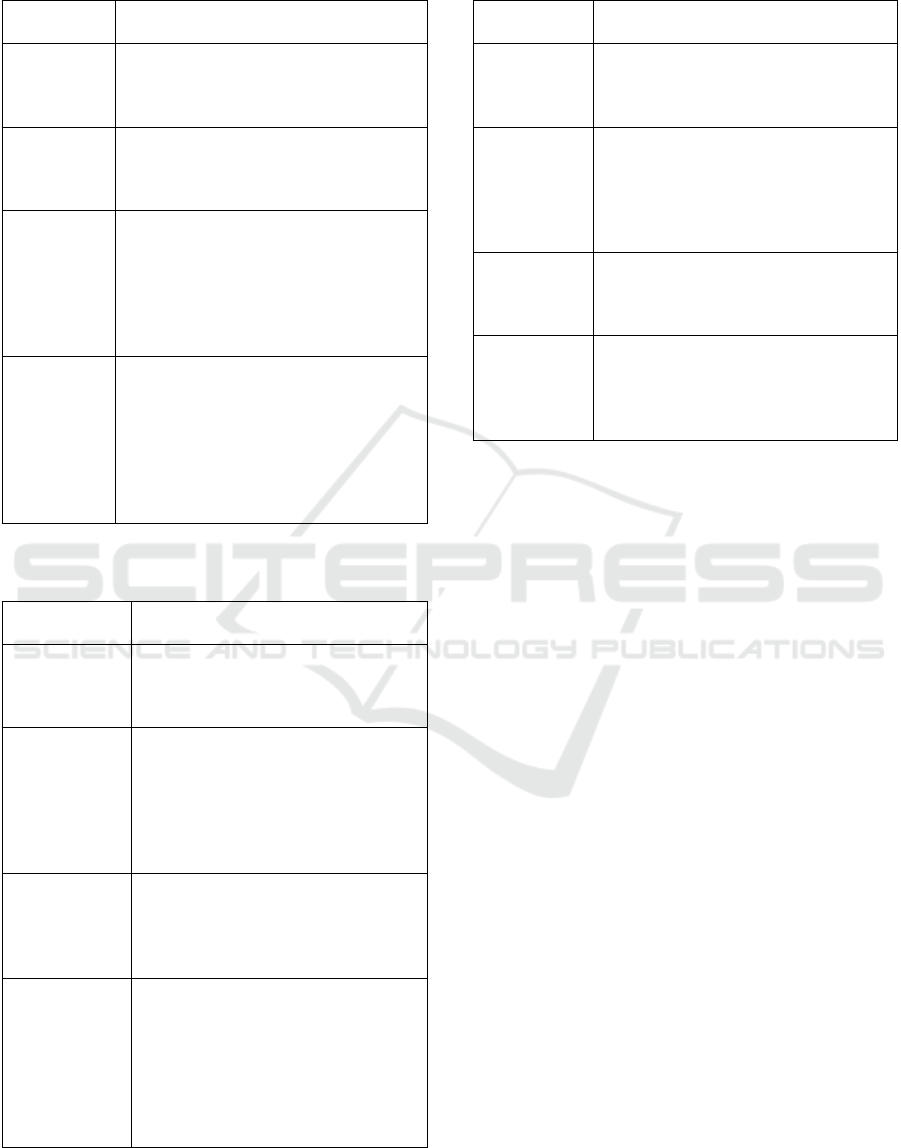

many different measurable indicators. Table 1, 2 and

3 list the three dimensions (economic, environmental

and social) of these measurable indicators.

ICORES 2021 - 10th International Conference on Operations Research and Enterprise Systems

242

Table 1: Economic Indicators of Sustainability for Products

in the Manufacturing Industry.

Economic

Indicator

Description

Indicator A:

Level of

Stakeholder

involvement

Satisfying stakeholders’ needs and

interests by involving them in the

development of the project, leading to

the successful delivery of projects.

Indicator B:

Financial

performance

Financial performance: An objective

measure that concerns the return on

investments, and the creditworthiness,

viability, and cash flow of a project.

Indicator C:

Sustainable

pricing

Every business faces the challenge of

setting sustainable prices for its goods

or services. The price must be high

enough to cover costs and generate

profit, but must still be low enough to

attract customers in a competitive

market.

Indicator D:

Customer

satisfaction

Customer satisfaction is a key element

for sustainable economic development.

What customers care about is when

their order will be delivered. Customers

start to calculate the delivery date as

soon as the order is placed. The

delivery time does not just include the

production time.

Table 2: Environmental Indicators of Sustainability for

Products in the Manufacturing Industry.

Environmental

Indicator

Description

Indicator E:

Waste and

measurement

To reduce waste and save resources,

it is necessary to understand the

characteristics of the material being

used and the processing technology.

Indicator F:

Reducing

energy

consumption

Sustainable processing can minimize

the energy consumption per cubic

millimeter or cubic inch of material.

Minimizing energy consumption will

reduce energy waste and make the

processing process more

environmentally friendly.

Indicator G:

Level of

environmental

responsibility

This indicator refers to the equity

between members of different

generations, and to their ability to

cooperate to improve the quality of

the environment.

Indicator H:

Correlation of

the life cycle

of products

and services to

reduce

environmental

impacts

This indicator is measured through a

lifecycle analysis, a product

disassembly analysis, post-sale

tracking, and reverse logistics.

Table 3: Social Indicators of Sustainability for Products in

the Manufacturing Industry.

Social

Indicator

Description

Indicator I:

Social

responsibility

level

It refers to competition and pricing

policies, compliance with

anticorruption practices and

contribution to social campaigns.

Indicator J:

Sustainable

levels of

employment

This indicator concerns the

empowering of young people through

the provision of better job

opportunities, the creation of

environmentally friendly jobs, and the

conditions needed to create them.

Indicator K:

Level of

Social

impact

This indicator is measured through an

analysis of the statistics showing

society’s views of a specific project.

Indicator L:

Public

acceptance

towards a

product

This indicator refers to the willingness

of society to embrace a product or

service.

The economic dimension focuses on increasing

profits, minimizing expenditure, and increasing

income (Huntzinger and Thomas, 2009). The main

goal of a project is to make profit for the shareholders.

Brones and Carvalho (2015) stated the importance of

the economic dimension, as it protects the assets of

the shareholders. As a result of the shift from a

commodity exchange system to a currency-based

economy, organizations and individuals need money

to obtain the resources they need. Expenditure in

investment in an enterprise ensures growth in the

manufacturing industry invested into the enterprise to

make sure that the manufacturing industry arrive

growth. The economic aspect of sustainability is

commonly used in product selection. Profitability is

more important than returns or expenditure, although

there are many other indicators that can be used to

measure this aspect.

Environmental sustainability is primarily

concerned with the protection of the environment

(Gore, 2006; Higgins, 2010). The environment has

been adversely affected by the processes that have

been developed by people (Gore, 2006; Higgins,

2010; Ludwig et al., 1993). Environmental protection

needs to be included as part of product selection.

Researches initiate to connect environmental

assessment into product, such as manufacturing

industry (Labuschagne and Brent, 2005). In most

cases, environmental demonstration is integrated as a

condition to approve decision-making in the product.

The social dimension involves the ownership in

which enterprise manipulate as well as the workers of

Measuring Sustainability Performance in the Product Level

243

the enterprise (Dempsey et al., 2011). The workers

are the people who produce the consequences of the

industry and should be valued by the shareholders.

The products of the enterprise are also reliable on how

the society influence the enterprise (Harik et al.,

2015). However, social sustainability deserves much

more attraction, as it focuses on daily life and has an

important effect on society. There are four indicators

that can be used to measure social sustainability:

social responsibility, sustainable employment, social

impact, and public acceptance of the product.

3 BUILDING A

SUSTAINABILITY

EVALUATION MODEL BASED

ON DESIGN STRUCTURE

MATRIX

3.1 A Structured Approach to Identify

and Validate Selective Products

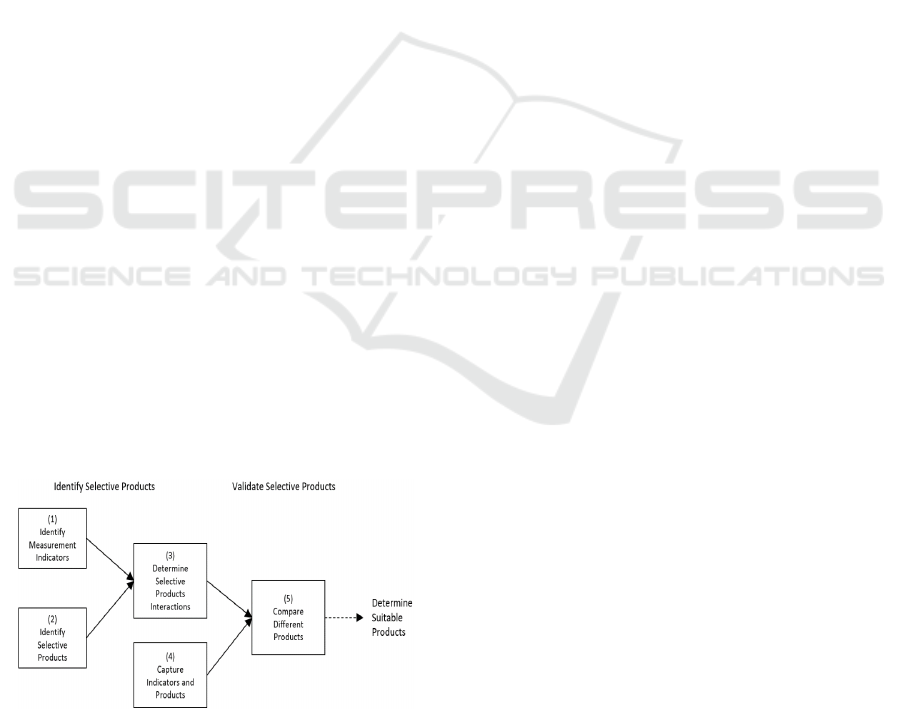

In order to rank the sustainability of different

products in the manufacturing industry, this paper

introduces a five-step approach to identify and

validate selective products, split into two phases (see

Figure. 2). The first phase (steps 1, 2, and 3) focuses

on identifying selective products based on the

measurable indicators, and then examines the

sustainability of the selected products (Ghadimi et al.,

2012). The second phase (steps 4 and 5) focuses on

validating the products identified during the first

phase by comparing them in order to determine the

most sustainable products. The introduction of the

product DSM (P) in step 2 is fundamental to this

approach, as it allows data on the measurable

indicators to be captured.

Figure 2: A Structured Approach to Identify and Validate

Selective Products.

The basic assumption behind this the first phase

of the approach is that selective products between

measurable indicators generate coordination

requirements. The first phase focuses on identifying

the set of interactions that could, potentially, take

place to coordinate the selective products that are

being measured.

In order to determine the most sustainable

product, it is necessary to identify the sustainability

of each of the selected products. This type of product

network is identified by asking the product

developers (m) about their level of involvement in the

design of each of the product components (n). This

information is documented in the product DSM (P).

is a rectangular matrix, in which the rows are

labeled with the selected product and the columns

are labeled with the measurable indicator. Cell

indicates the degree of involvement of product i in the

design of indicator j. The rows are ordered based on

the formal organisational structure, with the

individual developers split into groups so that group

members are sequenced together.

The selected product matrix (

) can be

defined as a function of the product DSM (P) as

follows:

(1)

The product DSM () can be used in a similar way

to determine the number of measurable indicators to

whose determine products contribute. In such a case,

the rows within the product DSM should be

compared, so that

1 if both products i

and j meet the measurable indicators. In this manner,

the selected product interaction matrix (

) can

be defined as follows:

(2)

To determine the sustainability of products i and j,

the entries of both the measurable indicator Domain

Mapping Matrix (DMM) (M) and the product DSM (P)

need to be examined. More specifically, product i

would look for sustainability from product j (

0)

if indicator K influencing product i (

0) depends

on indicator L (

0) which is influencing product j

(

0). Therefore, (

0) if (

0), (

0),

and (

0). Moreover, if M and P are binary

matrices, then the number of times that products i and

j need to coordinate measurable indicators interfaces

between products to which they contribute needs to be

measured. In other words, the number of times that

=

=

= 1 needs to be counted for products i and

j. This can be determined using the following equation:

(3)

ICORES 2021 - 10th International Conference on Operations Research and Enterprise Systems

244

Once this has been done, the validate product

matrix (

) can be formally defined, allowing

it to record the relationship between the selective

products with sustainability. This matrix is a function

of both the product DSM (P) and the measurable

indicator DMM (M). The validated product matrix

can be generated using the following equation:

(4)

3.2 Determine the Sustainability

Evaluation Model

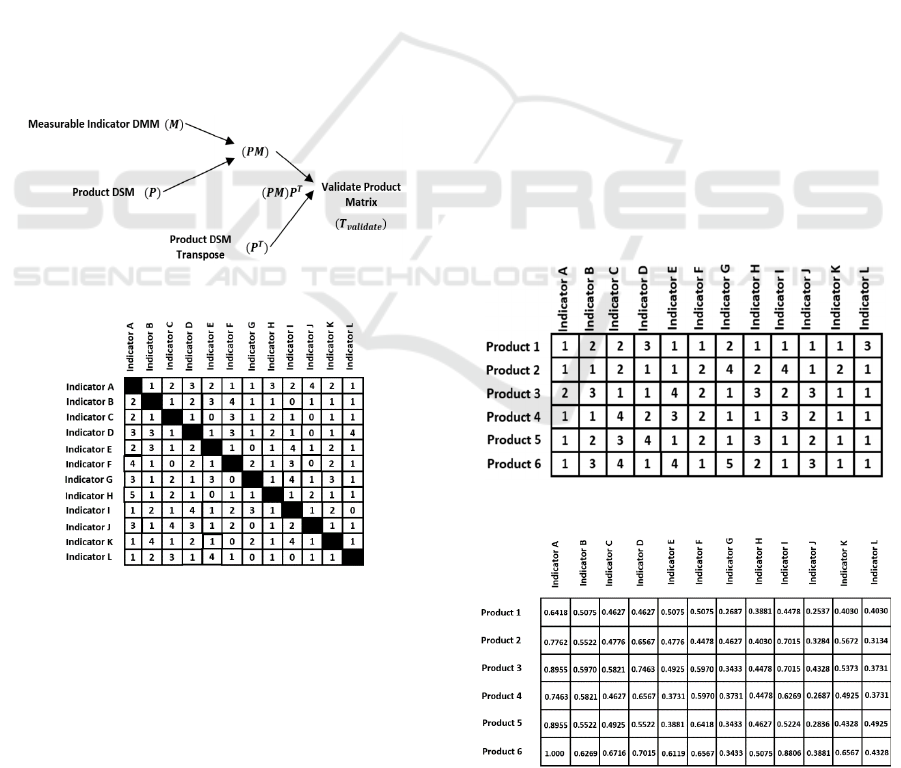

To illustrate the rationale behind Equation (4), Figure

3 shows the measurable indicator DMM (M) for the

12 indicators that can be used to compare the similar

products in the manufacturing industry which were

identified by the product DSM (P). The product PM

produces a rectangular matrix in which non-zero cells

capture the number of products with which product I

is involved, imposing sustainability constraints on

product j. The

can be estimated in the end

for further analysis.

Figure 3: Sustainability Evaluation Model.

Figure 4: Measurable Indicator DMM (M).

The measurable indicator DMM (M) was scored

by the Delphi method, also known as the expert

investigation method. It is essentially a feedback

anonymous inquiry method. The general process is to

obtain expert opinions on the problem to be predicted.

Figure 4 shows the impact of sustainability of

measurable indicators on the same type products in

the manufacturing industry and the comparison

within different measurable indicators of three

different dimensions.

4 AN ILLUSTRATIVE EXAMPLE

A certain company mainly produced computer

software and hardware, and entered the smartphone

industry later. It implemented technology with strong

innovation capabilities.

In this paper, this smart phone development

project is used as an example in order to analyze the

sustainability of mobile phones. The project

developed six mobile phone models, labelled Product

1 to Product 6, respectively, in order to compare the

mobile phones of sustainability could be put into

production, saving resources and offering the highest

number of benefits.

Each mobile phone was evaluated based on the

materials that were used for each part, the power

consumption, the impact they had on the

environment, their recyclability, and other aspects.

According to the sustainability evaluation model

constructed in the previous chapter, the expert scored

evaluation from 12 standards such as Indicator A. The

scoring matrix of the six selective products (product

DSM) (P) shown in Figure 5 was obtained through

interviews with the project manager and other experts

in the field of sustainability.

Figure 5: Product DSM (P).

Figure 6: PM Matrix.

Measuring Sustainability Performance in the Product Level

245

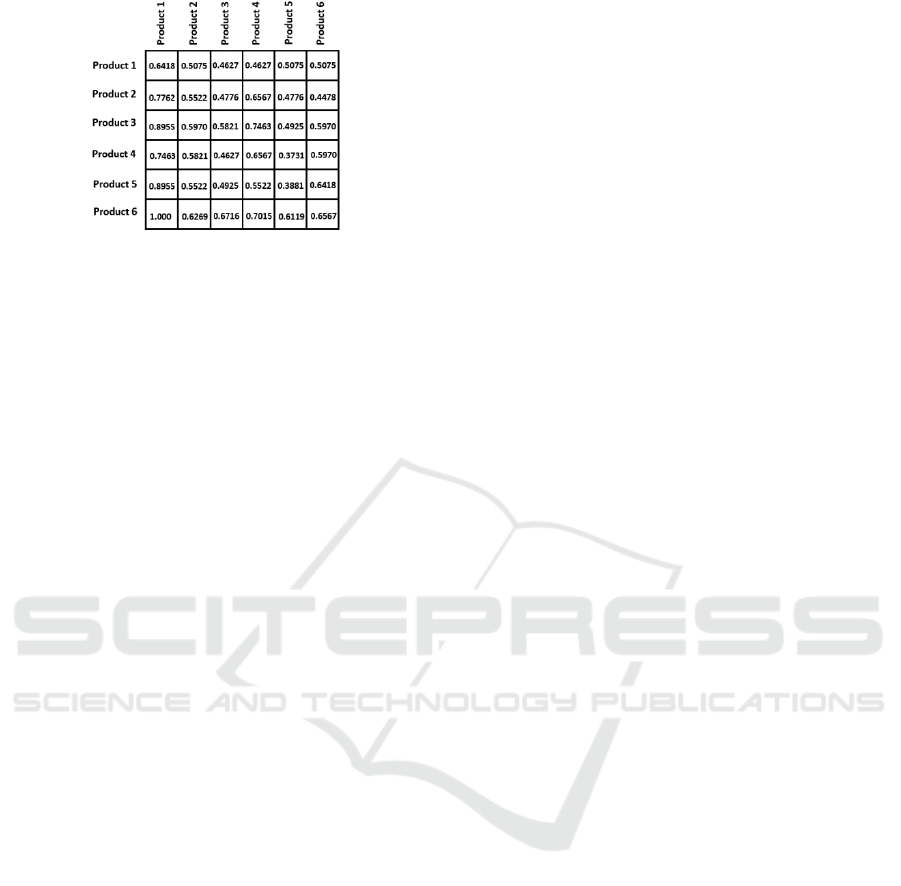

Figure 7: Validate Product Matrix (

.

Then results of PM and

ma tr ixe s wer e

shown in comparison (see Figure 6 and 7), both

matrixes were normalized matrixes. By analyzing and

comparing these two matrixes, the sustainability of

these six products can be examined. However,

different shareholders considered different

dimensions of the measurable indicators, so it is

difficult to directly determine which product to

choose.

5 CONCLUSIONS

In order to explore the sustainability of products,

three dimensions (economic, environmental, and

social) were used in this article, giving a total of 12

measurable indicators. All of the measurable

indicators were scored by experts for further

exploration. The knowledge domain of product

process structure is compounding sustainability

indicators into its approaches. This paper introduced

a five-step approach, which was split into two phases

(predicting and validating). After identifying a

number of products based on the measurable

indicators and determining the sustainability of the

selected products in the first phase, the second phase

(steps 4 and 5) concentrated on validating the selected

products by comparing the sustainability of the

similar products. In the first phase, the two matrices

(the product DSM (P) and the measurable indicator

DMM (M)) were introduced to capture the

measurable indicators. In the second phase, the

function of the validated product matrix was defined

in order to compare the level of sustainability of each

of the different products. Through this process, the

sustainable products were compared and even chosen

for different demand.

The application of this approach was shown with

the smartphone industry being used as an example.

This provided relevant insights about the challenges

associated with the development of new smartphones.

Through the measurement of product sustainability,

more environmentally friendly products will have

more advantages, and consumers will favour these

products more, thus counter-promoting the selection

of raw materials by merchants and manufacturers and

the recycling of subsequent products. The

measurement of products by multiple indicators also

reflects different requirements for product

sustainability. Different consumers can choose

products that are more suitable for them according to

their own requirements, which increases the

satisfaction experience for consumers.

6 LIMITATIONS AND

RECOMMDATIONS

In fact, there are different categories of sustainability

measurement indicators. This article only classifies

12 indicators into three categories. In the illustrative

example, only six types of mobile phones were

measured. Therefore, these measurement methods

may not be suitable for large quantities of goods such

as fast-moving goods.

Through the sustainable development of the

product, the product itself can achieve continuous

development in performance or function, and meet

the market demand of different performance, thereby

extending the service life, maximizing the recycling

use of the limited resources of the brothers, and

achieving the circular economy goal of utilization and

recycling. Through the transformation and upgrading

of modern industrial technology methods and

concepts, the application of multiple life cycles and

multiple performance modes of products can be

realized.

For future work, we will expand more categories to

consider the sustainability of products, and

understand consumer needs through statistics and

other methods. These measurement methods will also

be applied to more fields, such as clothing. We will

also optimize the model so that the measurement

indicators better reflect the sustainability of the

product.

ACKNOWLEDGEMENTS

This study was supported by the National Natural

Science Foundation of China (No. 71929101 and

71872011).

ICORES 2021 - 10th International Conference on Operations Research and Enterprise Systems

246

REFERENCES

Aarseth, W., Ahola, T., Aaltonen, K., Økland, A.,

Andersen, B., 2017. Project sustainability strategies: a

systematic literature review. International Journal of

Project Management (in press).

Alvarez-Dionisi, L. E., Turner, R., & Mittra, M., 2016.

Global project management trends. International

Journal of Information Technology Project

Management, 7(3), 54–73.

Brones, F., and Carvalho, M. M., 2015. From 50 to 1:

Integrating literature toward a systemic ecodesign

model. Journal of Cleaner Production, 96(1), 44-47.

Browning, T.R., 2001. Applying the design structure matrix

to systemdecomposition and integration problems: a

review and new directions. IEEE Transactions on

Engineering Management, 48(3):292–306.

Cataldo, M., Wagstrom, P., Herbsleb, J.D., Carley, K.M.,

2006. Identification of coordination requirements:

implications for the design of collaboration and

awareness tools. In Proceedings of ACM conference on

computer-supported cooperative work, Banff Canada,

353–362.

Daneshpour, H., 2016. The key drivers of sustainability. In

Proceedings of IEEE Conference. DOI: 978-1-5090-

2320-2/16.

Dempsey, N., Bramley, G., Power, S., Brown, C., 2011.

The social dimension of sustainable development:

Defining urban social sustainability. Sustainability

Development, 19 (5):289–300.

Eskerod, P., & Huemann, M., 2013. Sustainable

development and project stakeholder management:

what standards say. International Journal of Managing

Projects in Business, 6(1), 36–50.

Ghadimi, P., Azadnia, A. H., Yusof, N. M., & Saman, M.

Z. M., 2012. A weighted fuzzy approach for product

sustainability assessment: a case study in automotive

industry. Journal of Cleaner Production, 33, 10-21.

Gore, A., 2006. An inconvenient truth: The planetary

emergency of global warming and what we can do

about it, Rodale, New York.

Harik, R., El Hachem, W., Medini, K., & Bernard, A., 2015.

Towards a holistic sustainability index for measuring

sustainability of manufacturing companies.

International Journal of Production Research, 53(13),

4117−4139.

Higgins, P., 2010. Eradicating ecocide: laws and

governance to prevent the destruction of our planet,

Shepheard Walwyn Publishers Ltd., London.

Huntzinger, D. N. and Thomas, D. E., 2009. A life-cycle

assessment of Portland cement manufacturing:

comparing the traditional process with alternative

technologies. Journal of Cleaner Production, 17(7),

668-675.

Klakegg, O.J., 2009. Pursuing relevance and sustainability:

improvement strategies for major public projects.

International Journal of Managing Projects in

Business, 2:499–518.

Labuschagne, C., Brent, A.C., 2005. Sustainable project life

cycle management: the need to integrate life cycles in

the manufacturing sector. International Journal of

Project Management, 23:159–168.

Ma, J., and Kremer, G., 2016. A sustainable modular

product design approach with key components and

uncertain end-of-life strategy consideration.

International Journal of Advanced Manufacturing

Technology, 85(1), 741-763.

Okudan Kremer, G.E., Ma, J., Chiu, M-C., and Lin, T-K.,

2013. Product modularity and implications for the

reverse supply chain. Supply Chain Forum: An

International Journal. 14(2), 54-69.

Pimmler, T.U., Eppinger, S.D., 1994. Integration analysis

of product decompositions. In ASME conference on

design theory and methodology, Minneapolis, 343–351.

Silvius, A.J.G., Schipper, R.P.J., 2014. Sustainability in

project management: a literature review and impact

analysis. Society Business, 4:63–96.

Sosa, M.E., Eppinger, S.D., Rowles, C.M., 2004. The

misalignment of product architecture and

organizational structure in complex product

development. Management Science, 50(12):1674–

1689.

Steward, D., 1981. The design structure matrix: a method

for managing the design of complex systems. IEEE

Transactions on Engineering Management, 28(3):71–

74.

Measuring Sustainability Performance in the Product Level

247