A Decision Guidance System for Optimal Operation of Hybrid Power

Desalination Service Network

Bedor Alyahya and Alexander Brodsky

a

Department of Computer Science, George Mason University Fairfax, VA 22030, U.S.A.

Keywords:

Desalination, Water Management, Optimization, Decision Guidance, Operational Performance, Service

Network.

Abstract:

While modeling and optimization of desalination systems’ operation have been extensively studied, current

approaches are hard-wired to specific designs and performance metrics, without the flexibility to reuse or

extend these models. Bridging this gap, reported in this paper is the development of a formal analytic model

and a decision guidance system for desalination service networks that can be applied to a broad range of

desalination designs and architectures. The model and the system are based on an extensible repository of

atomic component models, initially including models for pumps, renewable energy sources, water and power

storage, and reverse osmosis units. An experimental study is conducted to demonstrate the flexibility of the

model and system, and its scalability to support realistic size problems.

1 INTRODUCTION

The world is facing a great challenge in satisfying in-

creasing water demand. To deal with the challenge,

the United Nations has formed a plan in its 2030

Agenda to ensure availability and sustainable man-

agement of water for all (UN, 2015). In an attempt

to align with the plan requirements, many solutions

have been proposed to meet the increasing demand

for fresh water while minimizing its negative environ-

mental impacts.

The current trend toward solving the shortage

in freshwater is by combining renewable energy

sources with desalination systems. However, renew-

able sources of energy are intermittent in their sup-

ply of electric power. The uncertainty in both de-

mand and, especially, supply of power creates a new

challenge in operating interconnected system com-

ponents to maximize financial, social and environ-

mental benefits. There has been work on optimiz-

ing desalination systems, from a desalination unit

(Ahmed et al., 2019) through hybrid desalination sys-

tem (Mokheimer et al., 2013) to fully integrated wa-

ter and power supply chains (Al-Nory, 2019; Ab-

delshafy et al., 2018). Also, several studies have

examined strategical challenges in combining renew-

able energy with desalination systems. In (Genc¸o

˘

glu

a

https://orcid.org/0000-0003-1694-0913

and Merzi, 2016), the authors focus on strategical de-

cisions in water desalination supply chain by using

mathematical modeling to optimize investment terms.

Al-Nory and El-Beltagy (2015) focuses on minimiz-

ing the interruption of the power supply by select-

ing optimal pumped hydro storage as well as power

storage (e.g., batteries.) Azhar et al. (2017) propose

an efficient desalination system design combined it

with renewable sources to produce water and energy.

Marques et al. (2014) optimize the investment in wa-

ter infrastructures by adapting a flexible water sys-

tem plan using decision trees. However, these models

are either (1) limited in their focus on specific units

or technologies rather than optimizing the desalina-

tion system as a whole, (2) hard-wired to specific de-

signs and objectives which limit its usability in solv-

ing other designs or optimizing other performance

metrics (Mokheimer et al., 2013; Al-Nory, 2019; Al-

Nory and Brodsky, 2014), or (3) focused on long-

term investment in desalination system infrastructures

while making simplifying assumptions on, rather than

accurately modeling the operation of, the underlying

infrastructures over the time horizon (Al Nory and

Graves, 2013). We believe, however, that accurately

modeling the resource flows, such as of power and

water, within and across the system components over

the given operational period can reveal unseen saving

in both operation and investment.

To bridge the gap, we propose an approach that

416

Alyahya, B. and Brodsky, A.

A Decision Guidance System for Optimal Operation of Hybrid Power Desalination Service Network.

DOI: 10.5220/0010265204160424

In Proceedings of the 10th International Conference on Operations Research and Enterprise Systems (ICORES 2021), pages 416-424

ISBN: 978-989-758-485-5

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

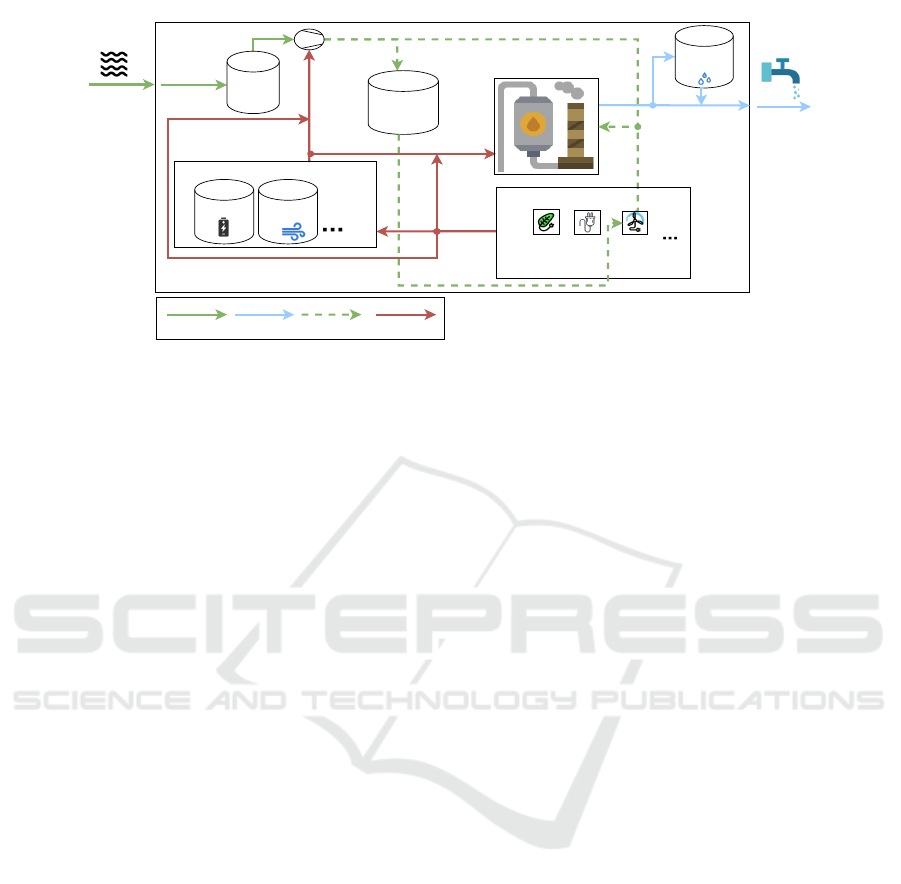

Pure Water

Sea Water

Power Storage(s)

RO plant

water

Storage(s)

low

Reservoir(s)

High

Reservoir(s)

Renewable

source(s)

Hydro

generator(s)

Grid

Power Source(s)

Water Desalination System

Sea Water Pure Water

Water under

pressure

Power Line

Compressed

Air

Batteries

Pump

Station

Figure 1: Desalination Service Network.

helps decision makers optimize desalination system

operation over a given operational window (e.g., 72

hours) without the need to hard-wire the model to

a specific desalination design, architecture or perfor-

mance metrics. More specifically, the contributions

of this paper are threefold. First, we develop a formal

Analytic Model (AM) for desalination Service Net-

works (SN) that can be applied to a broad range of

desalination designs and architectures.

Second, we develop an extensible repository of

analytic models for desalination system components,

which initially includes pumps, renewable energy

sources, water and energy storage and Reverse Os-

mosis (RO) plants. Unlike hard-wired models, our

frameworks allows extending model repository with

additional components, and instantiating an arbi-

trary desalination service network, without any other

model modifications.

Third, based on the developed model repository,

we develop a Decision Guidance System (DGS) that

(1) allows desalination system engineers to instanti-

ate their specific desalination design/architecture, (2)

performs iterative optimization over operational time

windows for the selected objective, such as minimiz-

ing CO

2

-adjusted operational cost, while satisfying

the system and demand constraints; and, (3) makes

actionable recommendations to desalination system

operators/control system on precise controls of each

desalination system component for every time inter-

val. The system is based on Decision Guidance An-

alytics Language (DGAL) (Brodsky and Luo, 2015)

and the Decision Guidance Management System ar-

chitecture (Unity DGMS) proposed in (Nachawati

et al., 2017).

Finally, we conduct a preliminary experimental

study to demonstrate the flexibility of the system ap-

plied to four examples of desalination design, and its

scalability to handle realistic size optimization prob-

lems.

The paper is organized as follows. Section 2 il-

lustrates the concept of desalination service network

using an example. Section 3 overviews a high-level

architecture of the developed Desalination Decision

Guidance system and methodology. Section 4 for-

malizes the desalination service network model. Sec-

tion 5 discusses the results of the experimental study.

Finally, Section 6 presents concluding remarks and

briefly outlines directions for future work.

2 DESALINATION SERVICE

NETWORK BY EXAMPLE

The purpose of the Service Network Desalination

Model (SNDM) is to solve a scheduling optimiza-

tion problem for different desalination system designs

and performance metrics. We use a generic struc-

ture called a service network (SN) to allow the model

to handle different designs. The SN, as described in

(Brodsky et al., 2017), is a hierarchy of services that

are connected together to capture the flow of com-

modity over the network. By using a Service Net-

work, we can create different desalination system de-

signs, and through the use of the desalination Ana-

lytical Model AM, we can optimize the performance

metrics of these designs.

To illustrate this concept, consider an example of

the service network for a hybrid energy system with

Reverse Osmosis (RO) desalination plant system de-

picted in Fig 1. The root of the service hierarchy is

the Water Desalination System. Within it there are

sub-services for a Pump Station, Low Reservoir, High

Reservoir, Power Sources, Power Storage. These ser-

vices are connected together to produce fresh water.

A Decision Guidance System for Optimal Operation of Hybrid Power Desalination Service Network

417

In the figure, each arrow indicates the flow of some re-

source (such as sea water, water under pressure, fresh

water and power) between these services. A com-

posite service, such as Power Sources, contains other

sub-services, such as Renewable Sources and Power

Grid, which are atomic services (i.e., do not have sub-

services.) Both atomic and composite services are op-

tional. Now, we can create many designs by extend-

ing the hierarchy with other sub-services that mimic

the system we intend to represent.

In order for a system to satisfy fresh water de-

mand for a given operational window, it should pro-

duce fresh water by setting the right amount of flows

throughout the system while minimizing the produc-

tion cost and the carbon emissions for a given oper-

ational window. Optimization is based, as described

in Section 4, on an analytic model (AM) which com-

putes metrics such as cost and CO2 emissions, as well

as feasibility constraints, for a given operational win-

dow (e.g., of 72 hours), as a function of operational

controls for each component and time interval (e.g., of

1 hour.) In the model computation, the flows and fea-

sibility have to be aggregated bottom-up, for all inter-

vals, by recursively calling each composite service its’

sub-services starting with the root service until reach-

ing the atomic services at the bottom of the hierarchy.

At that point, the AM uses the type of the atomic ser-

vice to refer to the corresponding atomic AM in the li-

brary of atomic analytical Models (AMs) which then

calculates the flows and feasibility for that atomic ser-

vice. Then, we repeat the same process given the out-

put from the first step but this time we aggregate and

calculate the metrics for the whole periods as well as

some additional constraints described in section 4.

3 DESALINATION DECISION

GUIDANCE SYSTEM

The developed Desalination Decision Guidance Sys-

tem (DGS) (1) allows desalination system engi-

neers to instantiate their specific desalination de-

sign/architecture, (2) performs iterative optimization

over operational time windows for the selected ob-

jective, such as minimizing CO

2

-adjusted operational

cost, while satisfying the system and demand con-

straints; and, (3) makes actionable recommenda-

tions to desalination system operators/control sys-

tem on precise controls of each desalination sys-

tem component for every time interval. The system

is based on Decision Guidance Analytics Language

(DGAL) (Brodsky and Luo, 2015) and the Decision

Guidance Management System (Unity DGMS) pro-

posed in (Nachawati et al., 2017), which in turn is

based on the concept proposed in (Brodsky and Wang,

2008).

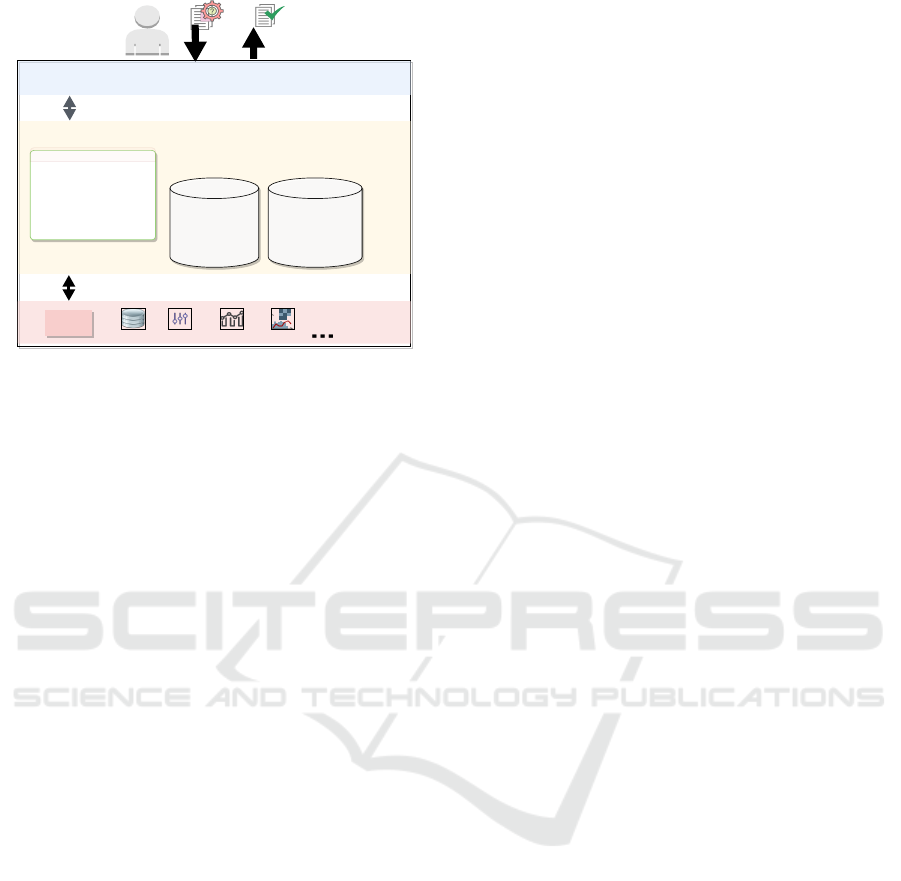

Figure 2 depicts the high-level architecture of De-

salination DGs. The middle layer represent the de-

cision guidance management system that contains

a repository of reusable, modular, and composable

models. Through the Graphical User Interface (GUI),

the user can construct many desalination designs.

Through the analytical engine, the DGMS hides

from the user the complexity in dealing with exter-

nal tools to perform different analytical tasks (such

as optimization, learning and prediction). For ex-

ample, to perform optimization for desalination ser-

vice network, the analytics engines machine generates

a mixed-integer linear programming (MILP) model

from the simulation-like analytic model (formalized

in Section 4), which was written in Python. The in-

put required for DG optimization includes (1) an an-

alytic model, (2) an analytic model input annotated

to indicate which input values serve as decision vari-

ables, and (3) indication of which of the computed

model metrics serves as optimization objective and

constraints.

For desalination plant users, we envision the fol-

lowing workflow for using Desalination DGS:

1. A desalination plant engineer interacts with the

DGS to create an instance of the plant’s design

and architecture.

2. An desalination plant engineer interacts with the

DGS to instantiate additional system parameters,

such as the length of operational window (e.g., 72

hours), and the frequency of re-optimization (e.g.,

at the top of every hour)

3. A plant operator, on a periodic basis, updates the

demand for fresh water. The system performs op-

timization and makes actionable recommendation

on precise controls of every system component,

every operational interval. Some of these con-

trols can automatically actuate the underlying sys-

tem components, whereas some other will be dis-

played to the plant operator, who can approve and

actuate plant controls.

4 FORMALIZATION OF

SERVICE NETWORK

DESALINATION MODEL

4.1 High-level Optimization Problem

The desalination operational optimization is based on

the analytic performance model (AM), which com-

ICORES 2021 - 10th International Conference on Operations Research and Enterprise Systems

418

Input

Output

Decision Guidance Management System

Graphical User Interface

Optimize

Learn

Predict

Simulate

Estimate

...

Analytical Engine

Atomic Models: Composite Models:

Optimization Learning simulationDBMS

Reusable, Extensible, Modular Model Repository

Destination SN

...

Pump

OR

Solar panels

local generator

...

Tools

Figure 2: Desalination Guidance System Architecture.

putes performance metrics, such as cost and carbon

emissions, as well as feasibility constraints, as a func-

tion of fixed and control (decision) parameters of the

desalination service network over the operational time

window. More formally, the analytic performance

model AM is a function:

AM : IN → OU T (1)

The AM forms a valid output instance out ∈ OUT

of performance metrics, such as operational cost or

waste, from a valid input in ∈ IN of fixed and con-

trolled operational parameters.

Then, the desalination optimization problem is:

min

in ∈ IN

ob j(AM(in))

s.t. C(AM(in))

(2)

where

• Ob j : OUT → R is an objective function, which

gives the real objective value in R given a valid

output instance of the AM.

• C : OUT → {T, F} is a constraint function C,

which gives True or False given a valid output in-

stance of the AM.

In contrast of hardwired models, we describe the

objective and constraints as a function of analytical

model AM output. By doing that we loosening the

tightly connected model, so that same AM can be

used to formulate multiple desalination optimization

problems using different system designs and objective

functions.

In the following, we will use the following nota-

tion for a set of key-value pairs:

m ={key

1

: value

1

, key

2

: value

2

,

. . . key

n

: value

n

}

(3)

where the keys are unique identifiers. Note that this

set represents a mapping

m : {key

1

, . . . , key

n

} −→ ∪

n

i=1

D

i

from the set of keys to union of the domains so

that m(key

i

) ∈ D

i

for all i = 1, . . . , n. We will use

the notation keys(m) = {key

1

, . . . , key

n

} to denote

the set of all keys associated with the set m of key-

value pairs.

Now using the above notations we can describe all

of the components above; starting with a valid ser-

vice network desalination model output instance out

in section 4.2, followed by the input instance in in sec-

tion 4.3, and finally, we describe the analytic model

which is a function that computes an output instance

from the input instance.

4.2 Service Network Desalination

Instance: The Model Output

A valid SN desalination output instance out is a set of

key:value pairs:

{config : h config parametersi

rootServiceID : root service id,

services : h set of servicesi,

constraints : ”True”or”False”,

metrics : h set of metricsi}

(4)

where:

• config value is a set of:

{operationalInterval : value,

operationalWindow :w}

where config value defines the time horizon us-

ing the operationalInterval string that repre-

sents the unit of time in which the system oper-

ates (e.g, hour). The operationalWindow (w)

represents the number of intervals, so that op-

erational decisions can be made over these in-

tervals.

• rootServiceID: is the id of a service in services

designated as a root service.

• Services: is a set optional key:value pairs of the

form:

A Decision Guidance System for Optimal Operation of Hybrid Power Desalination Service Network

419

{powerService :{energyContracts : service

1

,

renewableEnergy : service

2

,

other : service

3

},

lowReservoirs :service

4

,

powerStorage :service

5

,

pumpStation :service

6

,

highReservoirs :service

7

,

desalinationPlant :service

8

,

waterStorage :service

9

}

(5)

where each key represent service id which

uniquely identifies that service and each

service

i

∈ {service

1

. . . service

9

} is either a

composite or an atomic service. As each com-

posite service, such as powerService, contains

at least one subservice, it includes the IDs of

these services under subService. So, each com-

posite service has the following form:

{type : ”composite”,

inFlow :{inF

1

: hf-value i,

inF

2

: hf-value i, . . . },

outFlow :{OutF

1

: hf-value i,

OutF

2

: hf-value i, . . . },

metrics :{cost : hm-value i,

CO

2

: hm-value i, . . . },

constraints :”True”or”False”,

subServices :{set of service ids }}

(6)

where each inFlow and outFlow contains a set

of f

i

and h f-value i pairs that represent the

flows going in and out each service. The form

of each hf-valuei can be express as follow:

{ qty: [num

1

. . . num

w

],

total: numeric value}

where the qty is a sequence that shows the

quantities of flow at each operational inter-

val while the total shows the total flow for

the whole operational window.

In the same manner, the metrics value contains

as set of metrics (such as cost or CO

2

) with

their corresponding hm −valuei in the form of:

{perInt: [num

1

. . . num

w

],

total : numeric value}}

(7)

where the perInt is a sequence that shows

the metric per interval while the total

shows the summation for all intervals.

The constraints value indicates whether the

service satisfies its constraints.

• The metrics shows the metrics for the rootService.

• The constraints indicates whether all the con-

straints of the rootservice are satisfied.

The atomic service has the similar form except that:

• There is no subServices key:value pair.

• The type refers to one of the atomic analytical

model in the library.

• Additional set of key:value pair:

onFlag : [Boolean

1

, . . . ,Boolean

w

]

where each boolean value in the list indicate if the

service is running ”1” or not ”0” at each interval

of the operational window (w).

• An optional set of key value pair:

typeSpecific:{ set of key:value pairs }

where typeSpecific value represents, using a

key:value pairs , the parameters that are needed

by the atomic analytic model type to calculate its

metrics and constraints.

• An optional set of key:value pairs:

state : {st

1

: [num

1

. . . num

w

],

st

2

: [num

1

. . . num

w

], . . . }

where the set keys (state) represent the tem-

poral elements inside the service. So, each

st

i

, i maps to a list of numeric values that cap-

ture the state of the service in each interval.

In the next section, we describe a valid input model

needed to compute the output instance.

4.3 Service Network Desalination

Instance: The Model Input

The model input (in) follow the same structure as the

output, but with some modification:

• No metrics and constraints objects.

• Instead of having a list to describe qty for each

flow in the composite service, we replace it with a

list of lower bound (LB).

• For an atomic service:

– Instead of having a list to depict the state, we

replace it with a single value that depicts the

state at the beginning of the operational win-

dow:

state : {st

1

: num

initial

,

st

2

: num

initial

, . . . }

ICORES 2021 - 10th International Conference on Operations Research and Enterprise Systems

420

4.4 Analytic Model (AM)

To describe how analytical model forms the valid out-

put (out) from a valid input (in), we indicate how the

differences between the out (in form 4) and the in are

computed:

let

x = out(rootServiceID) = in(rootServiceID)

then

out(constraints) = out(services)(x)(constraints)

out(metrics) = out(services)(x)(metrics)

out(services) =

[

id∈ID

mOut

opOut

in(services)(id)

Below, we describe how the (opOut) and (mOut)

functions construct the out(services) form from the

input composite and atomic services in(services). In

section 4.4.1, we show how the operationOut (opOut)

calculates out(services) without the metrics. Then,

the result is used, by mertricOut (mOut), to calculate

the metrics in section 4.4.2.

4.4.1 operationOut (opOut)

In this section, we show how the operationOut

(opOut) calculates the inFLow and outFlow quanti-

ties over the operational window as well as some flow

constraints.

The composite service: As in form 6, for every com-

posite service the quantity (qty) of every inFlow and

outFlow is expressed recursively as:

let

SU B = cs(subService)

qtyIn(id, x, y) =

out(services)(id)(inFlow)( f

x

)(qty)[y]

qtyOut(id, x, y) =

out(services)(id)(outFlow)( f

x

)(qty)[y]

then

∀cs ∈ CS, i ∈ keys(inFlow),

j ∈ keys(outFlow), k ∈ {1, . . . , w}

cs(inFlow)( f

i

)(qty)[k] =

∑

sub∈SUB

qtyIn(sub, i, k) − qtyOut(sub, j, k)

cs(outFlow)( f

j

)(qty)[k] =

∑

sub∈SUB

qtyOut(sub, j, k) − qtyIn(sub, i, k)

Therefore, the (total) for every inFlow and outFlow

are:

cs(inFlow)( f

i

)(total) =

w

∑

k=1

services(cs)(inFlow)( f

i

)(qty)[k]

cs(outFLow)( f

j

)(total) =

w

∑

k=1

services(cs)(outFlow)( f

j

)(qty)[k]

Also, for every composite service cs ∈ CS, the

(constraints) expressed as a conjunction of demand-

Constraint(cs), boundConstraint(cs), and subService-

Constraints(cs). Each constraint is expressed recur-

sively as follows:

let SUB = cs(subService)

inKeys(id) = keys(id(inFlow))

outKeys(id) = keys(id(outFlow))

• domandConstraint(cs) ≡

∀sub ∈ SUB, k ∈ {1, . . . , w}

∀i ∈

n

[outKeys(sub)∪ inKeys(sub)]

− [inKeys(cs)∪ outKeys(cs)]

o

qtyIn(sub, i, k) ≥ qtyOut(sub, i, k)

• boundConstraint(cs) ≡

∀i ∈{outKeys(sub)∪ inKeys(sub)}, k ∈ {1 . . . w}

in(cs)(services)(inFlow)(i)(LB)[k]

≥ qtyIn(cs, i, k)

• subServiceConstraints(cs) ≡

∀sub ∈SUB

sub(constraints)

The atomic service (as): For every atomic service

the quantity (qty) of every inFlow and outFlow is cal-

culated by calling the analytical model of its type

(see appendix). Additionally, every atomic con-

straints is expressed as a conjunction of bound Con-

straint, on Flag Constraint. The boundConstraint(as)

is expressed as in the composite service boundCon-

straint(cs), while onFlagConstraint(as) is expressed as

follows:

boundConstraint(as) ≡

∀i ∈ {outKeys(as) ∪ inKeys(as)}, k ∈ {1, . . . , w}

as(onFlog) = 0

→ qtyOut(as, i, k)

A Decision Guidance System for Optimal Operation of Hybrid Power Desalination Service Network

421

Table 1: The optimization time and objective value for the four desalination designs.

Design High

Reservoir

Hydro

generator

Power

Storage

Water

Storage

CPU

time

(s)

Objective

Value

Peak

demand

bound

(k)

Average

power

consump-

tion (KW)

A Yes Yes Yes Yes 3.4 426.54 44.5 9.43

B No No Yes Yes 1.52 472.51 41.71 9.43

C Yes No No No 0.46 436.42 21.00 11.23

D No No No Yes 0.84 472.51 41.71 9.43

The state(as,i) for ∀s ∈ AS and ∀k ∈ {1, . . . , w} is ex-

pressed as:

state(as, i) =

newState(as, k, state(as, k − 1)) , k > 1

as(state) , k = 1

where newState is a function that returns the new state

from a given state for a service with id ∈ AS, and in-

terval i ∈ {1, . . . , w}. Further, the atomic analytical

model updates the serviceSpecific key:value pairs by

adding some information that are needed later on to

calculate the metrics which need larger intervals. For

example, the desalination system operate per hour,

while calculating some metrics like the cost for ener-

gyContract need the knowledge of average consump-

tion for the last two months.

4.4.2 metricOut (mOut)

In this section, we show how the metricOut (mOut)

calculates the metrics over the operational window as

in form 7.

The composite service: For every composite service

every metric (such as cost and CO

2

) are expressed re-

cursively as:

let

mIn(id) = opOut(in(services)(id))

mPerInt(id, x) =

mOut(mIn(id)(metrics)(cost)(perInt)[x])

mTotal(id) =

mOut(mIn(id)(metrics)(cost)(total))

then

∀cs ∈ CS, k ∈ {1, . . . , w}

mPerIn(cs, k) =

∑

sub∈SUB

mPerIn(sub, k)

mTotal(cs) =

∑

sub∈SUB

mTotal(sub)

The atomic service (as): The metrics and constraints

for the atomic services are calculated by calling the

analytical model of its type. Due to page limitation

we omit the formalization of the atomic analytic mod-

els(AMs). More can be found in (Bedor Alyahya,

2020).

5 EXPERIMENTATION

In this section, we show how the proposed desali-

nation AM can support diverse desalination systems.

We run an experimentation that aim to asses the capa-

bility of the model in solving realistic problems using

a machine with a 1.8 GHz Intel Core i5 processor and

8 GB of DDR3 memory executed at 1600 MHz. We

used CPLEX 12 as an optimization tool. We imple-

ment the system using the architecture proposed in

section 3. Then, we create a design that includes low

reservoir, pump, RO plant and power source which

in turn includes renewable source (solar panels) and

the grid. We assume a time horizon of 24 hours and

generate a random supply of renewable energy source

(solar panels), that follow the normal bell shape curve

during the first 12 hours and 0 otherwise. We also use

a power contract agreement which charges extra fee

over its fixed fee using the following formula:

Extra = (k − Avg) ∗ r (8)

where Avg is the average of power consumption over

the time horizon, k is the peak demand bound and r is

the rate of extra kilowatt per hour.

Table 1 shows four different architectures (A, B,

C, D). In architecture A, we add the high reservoir

connected with hydro generator and power and wa-

ter storage to produce the variable demand. In archi-

tecture B, we add power and water storage. while in

architecture C, we only add the high reservoir and in

architecture D we did not add any extra component.

We then specify for each component we added its type

specific parameter (like the maximum capacity for the

water storage). Then, we optimize the the flows of

power and water as well as the peak demand bound

against the following objective function:

Total cost of operation + 0.2 * Total carbon emission

ICORES 2021 - 10th International Conference on Operations Research and Enterprise Systems

422

Table 1 shows the objective values for the four de-

signs. These architectures use different storage tech-

nologies to store excess supplies during intervals of

low demand to satisfy the fluctuations in demand. We

can see that architecture A and C achieve better re-

sults than C and D under the same input assumption.

These comparison can lead to useful insight in know-

ing which component can contribute to the system the

most.

For the purposes of evaluating the model in solv-

ing realistic size problems, we generate four differ-

ent instances from architecture A by varying two di-

mensions:(1) The number of atomic services (AS)

and (2) The number of intervals in the time horizon

(w). Table 2 shows the number of atomic services,

the number of intervals and the time it take the solver

to solve each instance. We can see that when we set

the time horizon (w) to 24 hour, we reach the optimal

solution in 16 seconds and 3 minutes when the num-

ber of atomic services are 78 and 306, respectively.

Whereas, when we use 168 intervals we converge to

near optimal solution within 0.43% gap in 25 seconds

and 1.29% gap in 45 seconds when the number of

atomic services are 42 and 78, respectively. As an

initial step, the solution time to optimality is practical

to operate on an interval (e.g., 1 hour).

Table 2: Shows different variation of problem sizes.

Intervals

(w)

Atomic

Services

(AS)

Gap

(%)

Time

(s)

24 78 0 16

24 306 0 183

168 42 0.03 105

168 78 0.03 693

6 CONCLUSIONS AND FUTURE

WORK

We reported on the development of a formal ana-

lytic model and a decision guidance system for de-

salination service networks that can be applied to a

broad range of desalination designs and architectures.

The model and the system are based on an extensible

repository of atomic component models, initially in-

cluding models for pumps, renewable energy sources,

water and power storage, and reverse osmosis units.

We conducted an experimental study to demonstrate

the applicability of the model and the system to a

range of desalination designs, using four examples,

and the scalability of the solution to realistic size

problem. As future work, we plan to expand the ex-

perimentation to study a realistic water supply chain

using our proposed model. Additionally, we plan to

develop a modular investment model based on the ac-

curate operational model developed in this paper.

REFERENCES

Abdelshafy, A. M., Hassan, H., and Jurasz, J. (2018). Op-

timal design of a grid-connected desalination plant

powered by renewable energy resources using a hy-

brid pso–gwo approach. Energy Conversion and Man-

agement, 173:331–347.

Ahmed, F. E., Hashaikeh, R., Diabat, A., and Hilal, N.

(2019). Mathematical and optimization modelling in

desalination: State-of-the-art and future direction. De-

salination, 469:114092.

Al-Nory, M. (2019). Optimal decision guidance for the

electricity supply chain integration with renewable en-

ergy: Aligning smart cities research with sustainable

development goals. IEEE Access, PP:1–1.

Al Nory, M. and Graves, S. (2013). Water desalination sup-

ply chain modeling and optimization.

Al-Nory, M. T. and Brodsky, A. (2014). Towards optimal

decision guidance for smart grids with integrated re-

newable generation and water desalination. In 2014

IEEE 26th International Conference on Tools with Ar-

tificial Intelligence, pages 512–519.

Al-Nory, M. T. and El-Beltagy, M. (2015). Optimal selec-

tion of energy storage systems. In 2015 Saudi Arabia

Smart Grid (SASG), pages 1–6.

Azhar, M. S., Rizvi, G., and Dincer, I. (2017). Integration of

renewable energy based multigeneration system with

desalination. Desalination, 404:72 – 78.

Bedor Alyahya, A. B. (2020). A decision guidance sys-

tem for optimal operation of hybrid power desalina-

tion service network. Technical Report GMU-CS-TR-

2020-3, Department of Computer Science, George

Mason University, 4400 University Drive MSN 4A5,

Fairfax, VA 22030-4444 USA.

Brodsky, A., Krishnamoorthy, M., Nachawati, M. O., Bern-

stein, W. Z., and Menasc

´

e, D. A. (2017). Manufactur-

ing and contract service networks: Composition, op-

timization and tradeoff analysis based on a reusable

repository of performance models. In 2017 IEEE In-

ternational Conference on Big Data (Big Data), pages

1716–1725.

Brodsky, A. and Luo, J. (2015). Decision guidance analyt-

ics language (dgal). In Proceedings of the 17th Inter-

national Conference on Enterprise Information Sys-

tems - Volume 1, ICEIS 2015, pages 67–78, Portugal.

SCITEPRESS - Science and Technology Publications,

Lda.

Brodsky, A. and Wang, X. S. (2008). Decision-guidance

management systems (dgms): Seamless integration

of data acquisition, learning, prediction and optimiza-

tion. In Proceedings of the 41st annual Hawaii inter-

national conference on system sciences (HICSS 2008),

pages 71–71. IEEE.

A Decision Guidance System for Optimal Operation of Hybrid Power Desalination Service Network

423

Genc¸o

˘

glu, G. and Merzi, N. (2016). Trading-off constraints

in the pump scheduling optimization of water distribu-

tion networks. Journal of Urban and Environmental

Engineering, 10(1):135–143.

Marques, J., Cunha, M., and Savi

´

c, D. (2014). Decision

support for optimal design of water distribution net-

works: A real options approach. Procedia Engineer-

ing, 70:1074 – 1083. 12th International Conference

on Computing and Control for the Water Industry,

CCWI2013.

Mokheimer, E. M., Sahin, A. Z., Al-Sharafi, A., and Ali,

A. I. (2013). Modeling and optimization of hybrid

wind–solar-powered reverse osmosis water desalina-

tion system in saudi arabia. Energy Conversion and

Management, 75:86 – 97.

Nachawati, M. O., Brodsky, A., and Luo, J. (2017). Unity

decision guidance management system: Analytics en-

gine and reusable model repository. In ICEIS (1),

pages 312–323.

UN (2015). Transforming our world : the 2030 agenda for

sustainable development : resolution /. page 35 p. Is-

sued in GAOR, 70th sess., Suppl. no. 49.

ICORES 2021 - 10th International Conference on Operations Research and Enterprise Systems

424