Self-Similarity Matrix of Morphological Features for Motion Data

Analysis in Manufacturing Scenarios

Ant

´

onio Santos

1

, Jo

˜

ao Rodrigues

1,3 a

, Duarte Folgado

1,2 b

, Sara Santos

2 c

,

Carlos Fuj

˜

ao

3

and Hugo Gamboa

1,2 d

1

Laborat

´

orio de Instrumentac¸

˜

ao, Engenharia Biom

´

edica e F

´

ısica da Radiac¸

˜

ao (LIBPhys-UNL), Departamento de F

´

ısica,

Faculdade de Ci

ˆ

encias e Tecnologia, FCT, Universidade Nova de Lisboa, 2829-516 Caparica, Portugal

2

Associac¸

˜

ao Fraunhofer Portugal Research, Rua Alfredo Allen 455/461, 4200-135 Porto, Portugal

3

Volkswagen Autoeuropa, Quinta da Marquesa, 2954-024 Q.ta do Anjo, Portugal

Keywords:

Self-Similarity Matrix, Time Series, Industry, Musculoskeletal Disorders, Inertial Sensors, Segmentation,

Manufacturing, Unsupervised.

Abstract:

There is a significant interest to evaluate the exposure that operators are subjected throughout the working

day. The objective evaluation of occupational exposure with direct measurements and the need for automatic

annotation of relevant events arose. Using time series retrieved from inertial sensors, this work proposes a

method that is able to automatically: (1) detect anomalies, (2) segment the working cycles and (3) by means of

query-by-example, identify sub segments along the working cycle. In a short summary, this technique firstly

organizes the dataset provided by all inertial measurement units (IMUs) sensors placed over the dominant

upper limb. After this, it retrieves a wide variety of features to an organized matrix and then calculates the

respective self-similarity matrix (SSM). This method provides information by comparing each subsequence of

the time series with the remaining subsequences. As the identified structures will provide information about

how repetitive or anomalous is the behaviour of the data in function of time. The results show that the presented

method is capable of identifying anomalies on this dataset with an accuracy of 82%, detect working cycles

with a duration error of about 6% of the working cycle, and has the ability to find matches of sub-sequences

of the working cycle.

1 INTRODUCTION

Work-related disorders have a global impact on the

well being of individuals and their quality of life, as

well as being a burden for companies by decreas-

ing productivity, increasing absenteeism and promot-

ing early retirements. More specifically, work-related

musculoskeletal disorders (WMSDs) represent a sig-

nificant portion of the total sum, especially in manu-

facturing scenarios, where the repetitive nature of the

tasks increases the risk of WMSDs (Irastorza et al.,

2010). Several strategies have been implemented in

large industries to prevent WMSDs and decrease their

impact on individuals and companies, namely (1) the

inclusion of job rotation schedules that promote a

a

https://orcid.org/0000-0001-7320-511X

b

https://orcid.org/0000-0002-8481-6079

c

https://orcid.org/0000-0002-2554-3648

d

https://orcid.org/0000-0002-4022-7424

variation of the exposure throughout the working day

and (2) the implementation of ergonomic assessment

methods that support the evaluation of the occupa-

tional risk for a specific workstation (Rodrigues et al.,

2020). Nevertheless, the current approaches are far

from being optimal in the sense that these strategies

might (1) not be automated, depending on observa-

tional methods, which requires dedicated personnel

to observe or look into video records of operators

at work, (2) still rely on subjective opinions, (3) be

based on global indicators that do not take into ac-

count the variability among the population of oper-

ators, namely anthropometric variations, age, work-

ing experience, among others and (4) yield to single

score to represent the ergonomic risk of a worksta-

tion, which is insufficient to explain the factors that

contribute to this risk.

All these factors contribute to the high work-

load that is required in implementing these strate-

gies, hence being very difficult to employ them across

80

Santos, A., Rodrigues, J., Folgado, D., Santos, S., Fujão, C. and Gamboa, H.

Self-Similarity Matrix of Morphological Features for Motion Data Analysis in Manufacturing Scenarios.

DOI: 10.5220/0010252800800090

In Proceedings of the 14th Inter national Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2021) - Volume 4: BIOSIGNALS, pages 80-90

ISBN: 978-989-758-490-9

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

the complete operator’s population at manufacturing

sites. With the advent of Industry 4.0, more compa-

nies are using new strategies and improving the ones

currently applied by the addition of digital industry

technology, namely sensors, automation, dedicated

algorithms and machine learning methods (Romero

et al., 2016).

In this work, we highlight the interest in using in-

ertial sensors to have direct measures for a more spe-

cific assessment of occupational risk for each oper-

ator. In (Santos et al., 2020), inertial sensors were

used to evaluate the occupational exposure of several

operators performing different types of workstations.

The assessment was based on the RULA screening

tool that considers biomechanical and postural load

requirements on upper limbs. These are evaluated for

each working cycle, which represents the period dur-

ing which an operator performs a specific set of tasks

of a workstation, repeating the cycle of tasks during

the working period. Having data signals from wear-

able sensors that characterize the working period of

an operator, there is more control and flexibility on

the time periods that are selected for assessment. This

has several benefits because it is possible to (1) make

objective assessments for each working cycle, under-

standing how the occupational exposure varies from

the first working cycle to the last one; (2) compare,

for the same workstation, how was the occupational

exposure of different workers; (3) compare the occu-

pational exposure of different workstations performed

by the same worker and (4) compare the occupational

exposure of subsections of the working cycle, iden-

tifying which are the tasks that contribute more for

the exposure score on the working cycle. Still, meth-

ods for the detection of working cycles and anomalies

should be available. With such techniques available,

the flexibility and detail of analysis can have a great

impact on improving the ergonomic assessment, have

better strategies to design balanced workstations and

improve the design of job rotation plans. Therefore,

the design of algorithms and tools that promote this

flexible, quicker and more detailed analysis is of great

relevance to achieve the mentioned benefits.

In this work, we propose an unsupervised method

that uses the acquired inertial data to (1) automati-

cally detect anomalies in the working period, (2) au-

tomatically divide the working period into working

cycles and (3) use a sub-segment of the working cy-

cle to identify all the corresponding sub-segments in

the working period by means of a query-by-example

approach. The method is performed by computing a

self-similarity matrix based on the extraction of a list

of features of all signals acquired by employing a slid-

ing window process.

The document starts with a review of the related

work that shares the same contextual problem. Then,

the description of the dataset follows, and a detailed

description of the proposed method is presented. The

results are then presented and discussed. Finally, we

conclude and detail ideas for future work.

2 RELATED WORK

The problems regarded in this work involve essen-

tially the identification of cyclic information and

anomalies. Typically, algorithms developed for these

purposes may resort to (1) supervised machine learn-

ing (ML) methods, which require a certain level of

annotation beforehand and (2) unsupervised methods,

which are based on the similarity analysis of the sig-

nals or their features, without any prior information.

Several methods found, employed in the analysis of

inertial data, are used in the context of human ac-

tivity recognition (HAR). The list of supervised ML

methods is extensive and promising works are found

to achieve this purpose. The application of neural

networks (Lara and Labrador, 2013), hidden Markov

models (Zhu and Sheng, 2009), decision trees (Ja-

tob

´

a et al., 2008), bayesian networks (Jatob

´

a et al.,

2008), and semi-automatic process (Bota et al., 2019),

among others, are algorithms capable of detecting and

classifying various human actions. Nonetheless, most

of the work done in this context only looks to identify

previously defined actions like lying, standing, sitting

down, move upstairs, etc., that might not be cyclic and

rely on a significant amount of labelled data.

Several works that use unsupervised methods for

the identification of cyclic information and anoma-

lies are also found. The most simple method of cycle

detection is the use of point references on the work-

place to describe when a cycle starts and ends. Which

is usually considered a system subject to flaws with

a requirement for further adjustments steps (Bauters

et al., 2014; Bauters et al., 2018). Other more re-

liable alternatives analyze features of the signal and

search for periodic motion in those. An automated

algorithm of segmentation was able to separate com-

plex and multidimensional data into smaller segments

that can be described through harmonic models. This

algorithm revealed to be significantly useful to iden-

tify cyclic movement without any a priori knowledge

of the input data, using a combination of a recur-

sive least squares segmentation algorithm, a model

fitting of damped harmonics, and in the end, a clus-

tering analysis to classify the events (Lu and Ferrier,

2004; Lu and Ferrier, 2003). The usage of features is

of great relevance in unsupervised works, and meth-

Self-Similarity Matrix of Morphological Features for Motion Data Analysis in Manufacturing Scenarios

81

ods are found to select adequate features for detec-

tion and classification tasks, such as in (Machado

et al., 2015). Another example is the use of four-pass

UKF (unscented Kalman filter) to produce an unified

model with kinematic parameters. These may then be

segmented by analyzing the parameter’s zero crossing

velocity and in the end uses a clustering algorithm to

identify repetitive segments (Wang et al., 2015).

Other methods rely on a self-similarity approach,

namely (Nunes et al., 2011), where cyclic informa-

tion is segmented by searching for minimums, in the

convolution of a segment of the signal with itself. The

Matrix Profile (MP), which is a method that com-

pares all sub-sequences of a given time series with

themselves through an euclidean distance, has also

revealed promising results. In the end, it returns the

minimum value distance for each segment, highlight-

ing the moments of the time series which are similar

within themselves (Yeh et al., 2018). Additionally,

autocorrelation revealed itself an useful tool, as the

search over maximum values can infer the cyclic na-

ture of the data (Bauters et al., 2014). Finally, for

anomaly detection in industrial scenarios, an interest-

ing work applies an unsupervised method based on

the clustering of time series segments to detect the

execution of improper movements (Varandas. et al.,

2019).

The following work is inspired over an algorithm

for the detection of musical structures on audio sig-

nals (Foote, 2000; Paulus et al., 2010; Bello et al.,

2018) by means of a Self-Similarity Matrix (SSM).

This sort of analysis of self-similarity to collect infor-

mation about the periodicity has also been performed

over video datasets. This type of analysis usually

consists on a framework where a Fourier analysis is

performed on an SSM to characterize and highlight

the periodicity of the data from the video (Cutler and

Davis, 2002; Cutler and Davis, 1999).

3 DATASET

3.1 Participants

The in-field data used in this work was acquired in

the assembly lines of an automotive assembly plant

while the subjects were performing the tasks of a spe-

cific workstation. The context of the acquisition re-

garded the validation of an inertial system that would

guarantee access to direct measures. These were used

to deliver an ergonomic risk assessment based on the

angular information retrieved by the raw data of the

sensors (Santos et al., 2020). The dataset included

six participants, each monitored while working at two

different workstations. In this scenario, each work-

station has a specific set of tasks that have to be

performed by the worker. These tasks are repeated

throughout the working period, being divided into

working cycles.

3.2 Experimental Setup

The study was conducted by measuring data from the

dominant upper limb of the subjects. The system

comprehends a set of four 9-DoF inertial motion units

(IMUs) with each containing a triaxial accelerome-

ter, gyroscope and magnetometer. The IMUs were

attached on the upper dominant limb of the subjects,

namely:

• IMU 1 posterior side of the hand

• IMU 2 posterior side of the forearm (wrist)

• IMU 3 posterior side of the arm (elbow)

• IMU 4 thorax area

All devices were attached so that the alignment

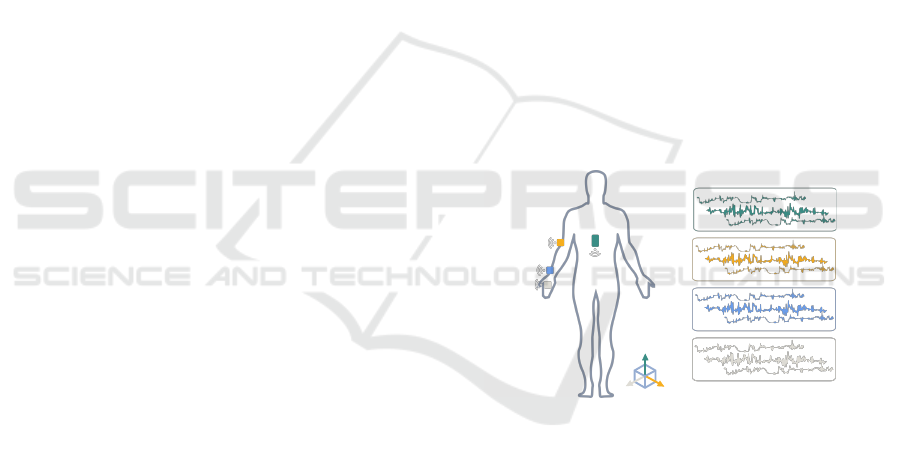

of Y-axis was pointed up. The Figure 1 presents the

main configuration of the acquisition setup and device

placement.

y

x

z

Acc

Gyr

Mag

Acc

Gyr

Mag

Acc

Gyr

Mag

Acc

Gyr

Mag

Figure 1: Schematic of the placement of Inertial sensors,

used for the dataset acquisition protocol. Based on (Santos

et al., 2020).

The signals available for analysis are the 3-axis

accelerometer, gyroscope and magnetometer of all

IMUs used, collected with a sampling rate of 100 Hz.

These data have multiple working cycles interca-

lated with resting moments. For the annotation of

these events, all signals were annotated by means of

video-records of the acquisition sessions.

4 METHODS

Signals acquired during a working period have a pe-

riodic nature, since the set of tasks of the worksta-

tion are repeated in each working cycle. Therefore,

each signal acquired has a recurrent pattern of the

BIOSIGNALS 2021 - 14th International Conference on Bio-inspired Systems and Signal Processing

82

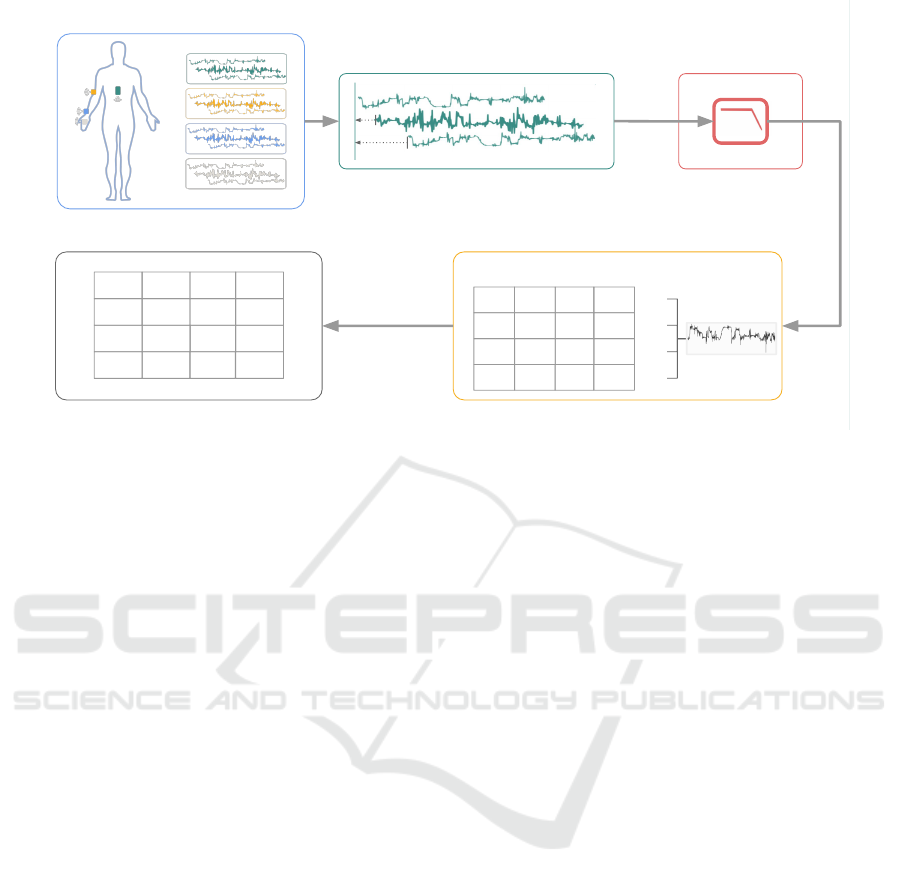

Raw Data Data Alignment Data Filtering

Feature ExtractionSelf-Similarity Matrix

F

1

F

2

...

F

N

F

11

F

12

... F

1N

F

21

F

22

... F

2N

... ... ... ...

F

N1

F

N2

... F

NN

F

M

F

M

T

F

M

S

11

S

12

... S

1N

S

21

S

22

... S

2N

... ... ... ...

S

N1

S

N2

... S

NN

Figure 2: Main schematic of the proposed method.

tasks performed during the working cycle. Neverthe-

less, being signals acquired in a real working context,

unexpected events occur and are present on the sig-

nal. Several anomalies can be found, namely (1) when

the operator stops working because of a break on the

working line, which can be caused by delays on other

workstations; and (2) when the operator takes more

time to perform a specific task or rather have to make

a significant amount of additional motions to perform

the working cycle. In this work, we are searching for

a method to unveil the periodic nature of the signal

and identify dissimilar moments.

The method proposed to identify (dis)similarity

on the signals acquired is inspired in a method em-

ployed to analyse several dimensions of musical

structures, namely homogeneity-based, novelty-based

and repetition-based (Paulus et al., 2010). The pro-

cess involves extracting a set of features that are able

to characterize the morphological dynamics of the

signal and how it varies over time, and compute a SSM

based on the features extracted (Paulus et al., 2010).

From the SSM we are able to extract a relevant set of

information.

The sequence of steps to calculate the SSM are

presented in Figure 2. The first row of steps shows

the preparation of the signals, namely the process for

data synchronization and alignment between signals

of different sensors, and filtering the signals with a

second order Butterworth low pass filter with a cut-

off frequency of 20 Hz. After the preparation of the

signals, the selected list of features are extracted from

all signals and organized in a matrix, from which the

SSM is computed.

4.1 Features Extraction

Extracting relevant features is of great importance to

have a rich characterization of the morphology of

each signal (Rodrigues et al., 2017). The features

were extracted employing a sliding window process.

With this method, a set of predefined features are ex-

tracted on each segment of the signal, selected in each

iteration. The window segment has a predefined size

window

s

and each iteration proceeds with a prede-

fined overlap percentage overlap

p

. We used the TS-

FEL (Barandas et al., 2020) Python library to extract

a set of features in the statistical, temporal and fre-

quency domains. We used all the available features

except the wavelet-based features to reduce the com-

putational time.

The window

s

and overlap

p

parameters have a

large influence on the results. The first defines the

time scale at which features are extracted, therefore

the higher is the size of the window, the larger is the

time scale at which feature values change. Regard-

ing the second parameter, it defines the resolution of

the resulting feature-signal, therefore the higher is the

overlap percentage, less information is lost and the

higher is the resolution.

After extracting the set of features, these are or-

ganized in a matrix F

M

. The rows are a feature rep-

resentation of the signal, and columns represent the

characterization of one sample of the signal by all fea-

tures extracted. The matrix is built with the features

extracted from all signals. At last, each extracted fea-

ture is z-normalized.

Self-Similarity Matrix of Morphological Features for Motion Data Analysis in Manufacturing Scenarios

83

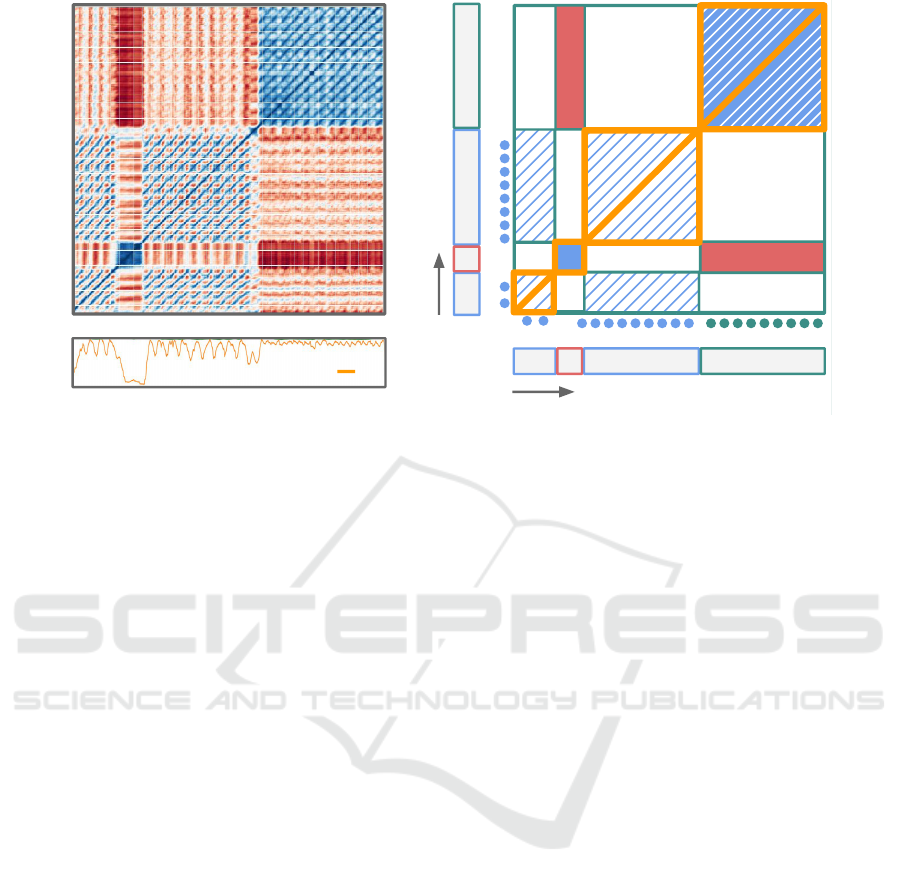

A

AB C

A

AB C

Time

Time

s

f

Figure 3: At the left is the SSM designed from the signals acquired while an operator was performing 2 different workstations.

At the right is a simplification of the original SSM, with highlights on the main structures present. Additionally, the orange

signal on the left plot is the similarity function, calculated by summing the values of the SSM column-wise.

4.2 Self-Similarity Matrix Analysis

The purpose of the SSM is to compare each sample

of the signals with all the other samples. In order to

calculate the SSM, the dot product between the trans-

posed F

M

and itself is performed. Therefore, each col-

umn of the matrix is compared with each other, giving

a similarity score. Columns that have feature values in

common have higher similarity scores, while columns

with diverging feature values will have lower simi-

larity scores (Paulus et al., 2010; Bello et al., 2018).

Each column of the matrix represents the characteri-

zation of each segment of the signal that was selected

during the sliding window process. By comparing

each column of the matrix with each other, we are

comparing each segment of the signal with each other,

hence creating a matrix that provides a rich visual in-

formation about how the signal is structured and how

it behaves over time.

In Figure 3 are illustrated the standard structures

encountered in a SSM (Paulus et al., 2010):

(1) Main Diagonal - The main diagonal is a result

of comparing each column of the transposed matrix

with the rows of the original matrix that correspond to

itself. The values of the main diagonal are the highest

similarity values;

(2) Blocks - Block structures represent areas of

the signal with an homogeneous behaviour. When a

block structure changes into a different block struc-

ture along the diagonal, it means the behaviour of the

signal changed. These structures help in identifying

significant changes in the signal. For instance, in Fig-

ure 3, block A changes to block B, then to block A

and finally to block C. These blocks are highlighted

in orange;

(3) Secondary Diagonals - As mentioned, the

main diagonal is created by comparing each column

of the matrix with itself. When other diagonals are

visible in the matrix apart from the main one, we can

infer that the columns and rows of the matrix seg-

mented by the secondary diagonal have similar prop-

erties. These structures are therefore a way of detect-

ing reoccurring patterns of the signal. For instance, in

Figure 3, secondary diagonals on blocks A and block

C, indicate that segments A and C are periodic. Ad-

ditionally, the pattern repeats on the instant the sec-

ondary diagonal starts, which is indicated by colored

circles under each segment.

From the SSM, we can extract the required infor-

mation by applying several methods. For the identifi-

cation of anomalies and the segmentation of working

cycles, we based the method on computing the simi-

larity function, which represents the column-wise ad-

dition of values from the SSM. Regarding the selec-

tion of similar sub-sequences of the working cycle,

we used a query-match by example approach on the

SSM, where the example is the selected sub-sequence

of the matrix. These methods will be further detailed

in the following subsections.

BIOSIGNALS 2021 - 14th International Conference on Bio-inspired Systems and Signal Processing

84

4.3 Anomalies and Working Cycles

Segmentation

Anomalies are, in this context, defined as being dis-

similar segments of the signals in comparison to the

average working cycle. These anomalies during the

working period will be assessed by means of identi-

fying the similarity levels in the signals with the sim-

ilarity function. The similarity function, sf, is calcu-

lated by summing the values of the SSM column-wise,

being each element of the sf calculated by:

s

f

(x) =

N

∑

i=0

SSM

ix

(1)

where j the column position for the sum, s f

j

the sam-

ple of the function at position j and N the size of the

SSM.

This function provides information about how

similar each sample of the signals is with the remain-

ing signals, therefore if samples belong to an anomaly

segment, the similarity values for the corresponding

column on the matrix will be lower. Therefore, the

sum of similarity values will also be lower than for

other segments of the matrix. With this process, seg-

ments of the similarity function with lower values in-

dicate the presence of the mentioned anomalies. This

can be visualized in Figure 3, where block B of the

SSM are associated with the lower values in the s

f

representing an anomaly.

Regarding to periodic signals, the sample values

of the similarity function will be very similar for equal

moments of each period, therefore creating a repeat-

ing pattern of similarity, which can be used to segment

working cycles. The process involved three stages:

(1) remove the anomalies, identified with the previous

method; (2) recompute the similarity function with

an SSM without the selected anomalies and (3) use

a peak detector to identify the cycles.

As previously mentioned, secondary diagonals in-

dicate the presence of similarity and reoccurring pat-

terns can be visualized on the SSM. The starting

point of these diagonals corresponds to the position at

which the cycle starts. By removing the encountered

anomalies, we can reject lower areas of the similarity

function, unveiling the periodic pattern of similarity.

The resulting similarity function has a prominent min-

imum at the position where diagonals start. Finally,

to segment and divide the working period in working

cycles, we have to identify the local minimums of the

function. This is illustrated in Figure 3 where the s

f

has repeating local minima at the position where the

secondary diagonals start, on blocks A.

4.4 Sub-segment of Working Cycle

Search

Another relevant purpose for the evaluation of the oc-

cupational exposure in industrial scenarios is to com-

pare the occupational risk of sub-segments of the

working cycle during the working period. As men-

tioned, this strategy helps professionals in identify-

ing which sequence of tasks of the working cycle are

more responsible for the occupational risk, and help

them understand if a workstation needs to be adapted,

i.e. having a more balanced set of tasks.

In this case, the search procedure is aided by sig-

nalling the desired sub-sequence in the signal, which

is given as an argument in the function. The search

procedure works by sliding the smaller column win-

dow (the example selected) along the SSM, one sam-

ple at a time. The distance, D, between the example

and the segment it slides over is calculated through

the sum of absolute differences:

D(x) =

x=M

∑

x=0

q

(SSM(x) − SSM

t

)

2

(2)

where SSM(x) the segment of the SSM over which

the example, SSM

t

, slides at moment x, starting from

0 to the size of the SSM, M. The resulting function

has minimums at the position where the example is

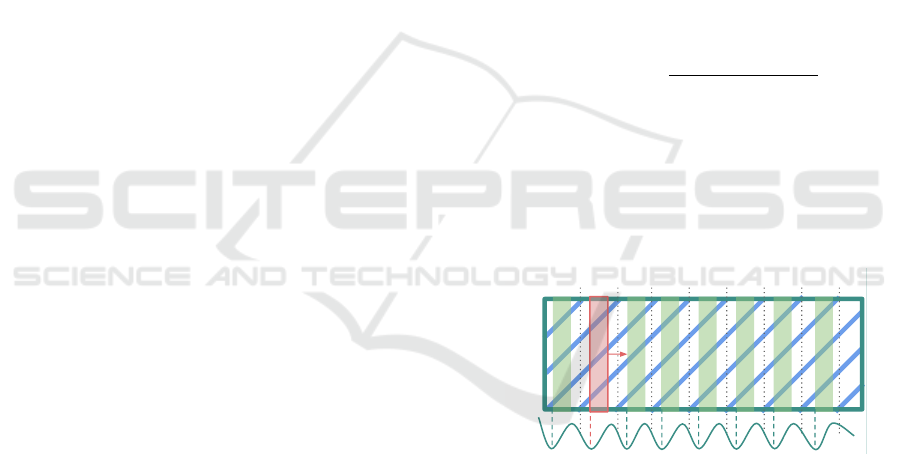

matched, as presented in Figure 4.

D(x)

1 2 3 4 5 6 7 8 9

Figure 4: The Figure illustrates a simplified representation

of a block structure of an SSM, with repeating secondary di-

agonals. The cycles are represented by order and their cor-

responding numbers, while also divided by the dotted lines.

The red highlighted segment represents the selected exam-

ple of the working cycle to match along the other periods of

the matrix. The green highlighted areas represent the per-

fect match along diagonals and has, therefore, a minimum

in the distance function (D(x)).

5 RESULTS AND DISCUSSION

In this section are presented the results of applying

the algorithm to the dataset for discovering anomalies,

working cycles and sub-sequence search. We present

an example of applying the proposed method to one

Self-Similarity Matrix of Morphological Features for Motion Data Analysis in Manufacturing Scenarios

85

of the acquisition sessions, whereas global results will

be shown for the entire dataset in Table ??.

5.1 Working Periods Identification

The detection of anomalies involved searching for ar-

eas with lower similarity. The areas with lower simi-

larity would represent segments of the working period

in which the operator would have different motion in-

formation than the most common during work. These

can correspond to the mentioned anomalies.

Table 1: Results of the detection of the mentioned anoma-

lies. The workstations (Wkstn) with no indicators reveal

no anomalies. Operator 6 was not considered because the

videos for the activity recorded only the beginning of the

task. TP-True Positives, FP-False Positives, FN-False Neg-

atives and A-Accuracy. TP, FP and FN are measured with a

resolution of seconds. (TN - True Negatives are not consid-

ered to not bias the results).

Signal Wkstn Detected TP FP FN A(%)

Operator 1

1 3/3 268 1 140 65.53

2 1/2 45 0 17 72.5

Operator 2

1

2/2 305 0 6 98.07

2 - - - - -

Operator 3

1 0/1 0 0 50 0

2 - - - - -

Operator 4

1 2/2 488 22 0 95.69

2 - - - - -

Operator 5

3 1/2 49 0 19 72.05

4 1/1 71 0 2 97.26

All 10/13 1226 23 234 82.67

Table 1 shows the results of applying a threshold

based method on the similarity function. Values under

the threshold would be considered anomalies of the

working period. The results are presented in terms

of how many anomalies were identified per working

period as well as how accurate was this detection, in

seconds, based on the values of TP, FP and FN.

Results show that the algorithm is able to detect

the majority of the anomalies. In cases where the

anomalies were short, the detection would not be pos-

sible. This might be a resolution problem, consider-

ing the window used to extract the features from the

signals, but further investigation should be made. The

error rate of the detection is still significant and is also

related with the resolution issue. Nevertheless, the

overall results are promising for using this technique

for these scenarios.

5.2 Working Cycles Identification

We applied the method of detecting the working cy-

cles by analysing the SSM. We evaluated the capabil-

ities of the algorithm by comparing its performance

with a well known algorithm proven to work in sim-

ilar problems, the Matrix Profile (MP). We applied

the MP algorithm to one signal of each acquisition

dataset. The MP algorithm receives only one param-

eter that defines the time scale of the repeating pat-

tern. For each session, the average size of the work-

ing cycle was taken into consideration for the usage

of the MP algorithm. We used the implementation

of the MP algorithm from stumpy (Law, 2019). Both

the MP and SSM algorithms have their performances

evaluated in terms of:

(1) Correct Detection of Cycles. A cycle seg-

ment is considered correct if the moments at which

the cycles are segmented correspond to a consistent

position on the signal. Even if the segmentation of cy-

cles occurs delayed from the ground-truth selection,

what is evaluated in this category is the consistency of

the algorithm in defining the working cycle. Here are

measured how many cycles are correctly segmented;

(2) Calculate the Error between the Ground-

truth Segmentation and the Algorithm’s Segmen-

tation. The ground-truth duration of cycles is com-

pared with the duration of the detected cycles by cal-

culating the absolute difference between durations.

This error is expressed in terms of seconds per cy-

cle and duration percentage of the cycle. In Fig-

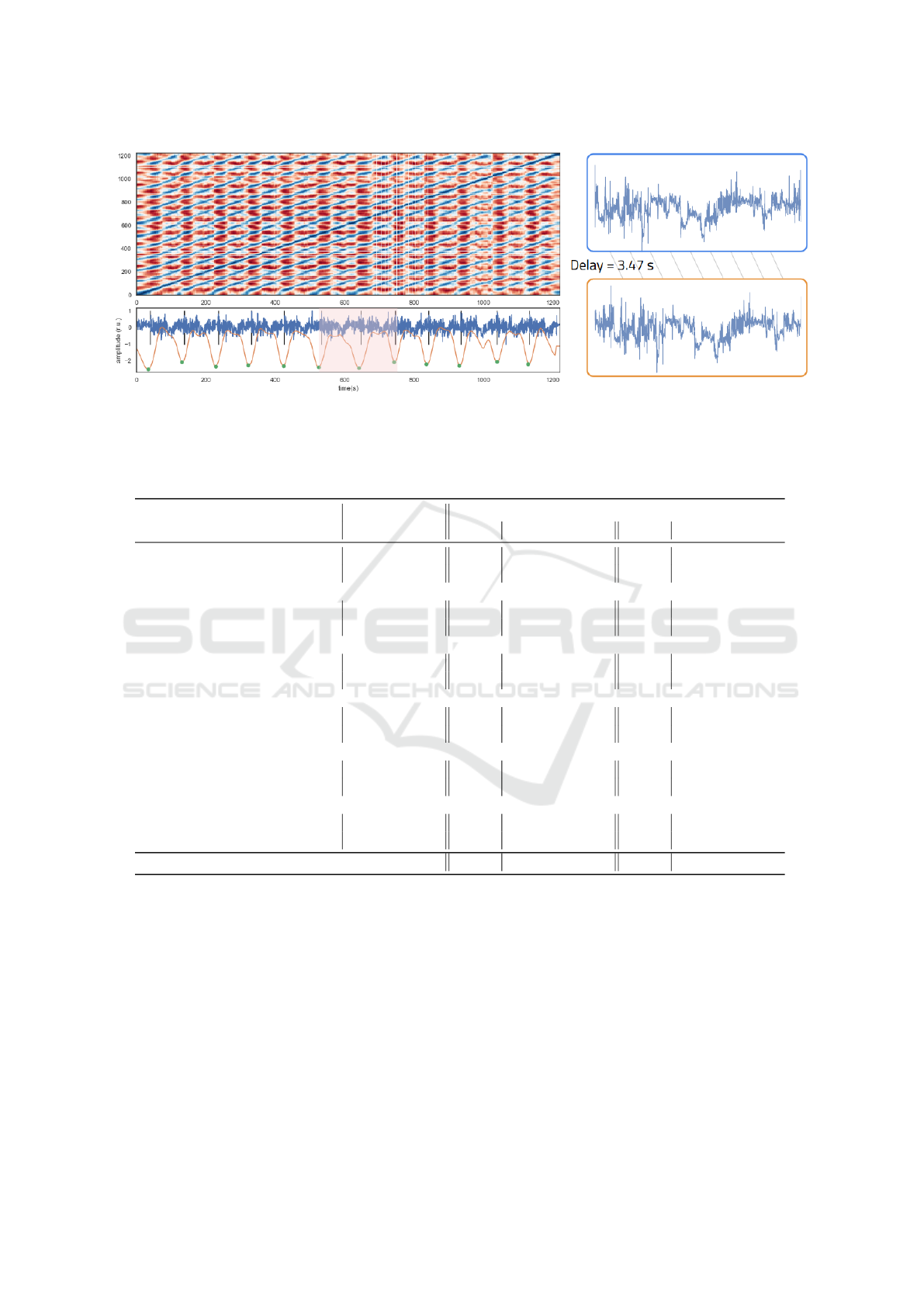

ure 5, the left plot illustrates an example of segment-

ing the working cycles by means of the similarity

function. The SSM function was calculated by a set

of features extracted with a time window of 50 sec-

onds and an overlap of 85%. The similarity function

was smoothed with a moving average window of 20

seconds. The first figure of the right plot shows the

ground-truth segmentation, and the second figure the

segmentation based on the similarity function.

Results presented in Table ?? show that the meth-

ods tested have equivalent performance to detect

working cycles in industrial data. Most cycles were

correctly detected by both algorithms, although there

is a delay in the detection. This delay is comprehen-

sible considering that the algorithm, being unsuper-

vised, does not have a reference of where the cycle

has the ”real” start. The algorithms take into consid-

eration the beginning of the data as a reference, which

would not always match with the instant the operator

would start the cycle. The lag detected does not have

an effect in the detection of the entire cyclic informa-

tion, since both algorithms are consistent with their

decision of where the ”start” is, and are able to iden-

tify the cyclic pattern. Moreover, they have a similar

BIOSIGNALS 2021 - 14th International Conference on Bio-inspired Systems and Signal Processing

86

Figure 5: Example of the detection of working cycles by means of the SSM after removing the anomalies. Black bars represent

the ground truth events, green circles are the detected cycles on the similarity function (orange), represented on the bottom

subplot. The X-accelerometer signal from the hand sensor is in blue.

Table 2: Results of searching for minimums in the similarity function, calculated based on the SSM. The proposed method is

compared with the Matrix Profile, by means of number of cycles detected and duration error.

Signal Workstation Cycles

SSM Matrix Profile

Cycles Duration Error Cycles Duration Error

Operator 1

1 11 11 3.26s (3.04%) 11 11.08s (10.34%)

2 15 14 16.97s (15.83%) 14 8.09s (7.55%)

Operator 2

1 14 14 6.45s (6.40%) 14 6.74s (6.70%)

2 11 11 8.48s (8.62%) 11 11.2s (11.39%)

Operator 3

1 16 16 12.35s (11.79%) 16 7.39s (7.05%)

2 13 13 8.81s (8.25%) 12 11.41s (10.68%)

Operator 4

1 14 14 1.05s (0.4%) 14 8.72s (8.24%)

2 11 11 3.42s (3.32%) 10 4.9s (4.75%)

Operator 5

3 12 12 2.83s (2.85%) 11 5.39s (5.43%)

4 10 11 3.47s (3.45%) 10 6.7s (6.69%)

Operator 6

5 15 14 3.79s (3.74%) 15 7.25s(7.15%)

6 15 14 5.79s (5.73%) 15 6.13s (6.06%)

All 157 154 6.12% 154 7.6%

performance in this regard.

The proposed algorithm also shows that it works

for several scenarios, namely different types of work-

stations made by the same worker as well as different

workers making the same workstation.

The duration error is mostly good as well, but still

significant in some of the cases. The duration was

calculated to be an indicator of the detection quality.

Even in cases where the detection is delayed from the

ground-truth annotation, the duration of the working

cycles should be the same. On average, the error rep-

resents 6% of the working cycle, which can be up to

6 seconds in working cycles of 100 seconds. This er-

ror might have contributions from the loss of resolu-

tion when extracting features, smoothing the similar-

ity function to detect the minimums and errors in the

manual annotation of the events. Nevertheless, the re-

sults are promising, showing that the algorithm is able

to segment the working cycles of a working period.

The difference in performance between the SSM

method and the Matrix Profile are not significant. The

slight difference in duration error might occur be-

cause of the smoothing factor used with Matrix Pro-

file, which was higher, and therefore increased the

Self-Similarity Matrix of Morphological Features for Motion Data Analysis in Manufacturing Scenarios

87

chance of errors in the duration of the working cycle.

Nevertheless, both had equal performance in dividing

the working period into cycles.

5.3 Sub-segment Search

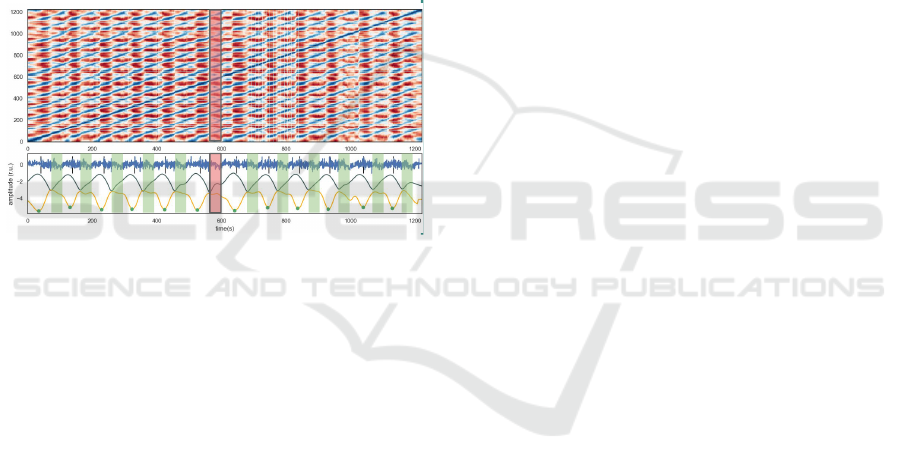

In the example presented in Figure 6 is demonstrated

how the SSM can be used to identify sub-segments

of the working cycle during the working period. The

detection is based on the match of columns (or diag-

onals), which results in a precise matching function.

The orange signal represents the similarity function

to demonstrate that the minimum values of the dis-

tance function are consistent with the cycle position.

Highlights are used on the image starting at the ex-

act minimum position, which is the place where the

sub-segment being searched starts.

4

Figure 6: Example of sub-segment search on the SSM. The

SSM is presented in the upper plot, with a sub-segment

highlighted between cycles 5 and 6. The blue signal is the

X-accelerometer of the hand sensor, the orange signal is the

similarity function and the grey signal represents the dis-

tance function. The red segment highlighted is the example

used to compute the distance, and the green segments are

the matches based on the distance function.

5.4 Overview

The results show that the SSM is fit for the problems

in demand. This method has the advantage of relying

on characteristics of the signal, giving a rich insight

about the signals being analysed. Additionally, using

this method enables the use of a multisignal approach,

not relying on the information extracted from a single

signal for the analysis of the entire dataset, or having

to analyse all signals individually to match the infor-

mation. Nevertheless, further tests should be made

to understand the clear benefits and disadvantages of

using a multisignal approach.

This method also has the advantage of giving so-

lutions to several questions at once. In this case, from

the SSM we were able to identify anomalies, search

for the cyclic pattern underneath the data and make a

sub-sequence match.

6 CONCLUSION AND FUTURE

WORK

In this work, we demonstrated that the application of

the proposed method on motion signals acquired in

cyclic tasks of the industrial context is possible. The

proposed method was able to identify (1) anomalies

during working periods, (2) segment the working pe-

riod in working cycles with similar performance to the

MP algorithm and (3) search for sub-segments of the

working cycle along the working period. The appli-

cation of this method in the ergonomic context can be

of great interest since it can improve the current ap-

proaches of ergonomic evaluations in these scenarios.

This strategy turns the process more flexible, allow-

ing to identify in the working cycle sources of risk

factors. Moreover, this allows not only to compare

the occupational exposure of different workstations

for the same worker but also to compare the occupa-

tional exposure throughout the working period. Fur-

thermore, our method has the potential to decreases

the workload associated with the manual identifying

of working cycles and anomalies while improving the

accuracy of the evaluation.

The proposed method is promising and further in-

vestigation should be made. Improvements can be

made, namely: (1) the size of the SSM can cause

memory errors for signals with a large number of

samples, increasing the memory by a quadratic func-

tion, and this should be optimized; (2) having to per-

form the extraction of a significant number of fea-

tures turns the process slower, so features should be

targeted for the type of signal being analysed; (3) be-

cause of (1) and (2), it was more indicated to not use a

total window overlap, losing resolution and (4) further

research should be made in the usage of multisignals.

The methods used to extract the overall informa-

tion from the SSM can still be improved. The detec-

tion using the similarity function is prone to some er-

rors, as presented in the results, and better methods

can be developed in further research to identify the

presence/absence of diagonals. Eventually, methods

inspired in image processing could be used.

Finally, the SSM could also be used to search for

relevant transitions between blocks. For instance, In

Figure 3, we can visually identify two different blocks

of repeating cycles, therefore the SSM can be used to

detect transitions between workstations as well.

ACKNOWLEDGEMENTS

This work was partly supported by Fundac¸

˜

ao

para a Ci

ˆ

encia e Tecnologia, under projects OP-

BIOSIGNALS 2021 - 14th International Conference on Bio-inspired Systems and Signal Processing

88

ERATOR (ref. 04/SI/2019) and PREVOCU-

PAI (DSAIPA/AI/0105/2019), and Ph.D. grant

PD/BDE/142816/2018.

REFERENCES

Barandas, M., Folgado, D., Fernandes, L., Santos, S.,

Abreu, M., Bota, P., Liu, H., Schultz, T., and Gam-

boa, H. (2020). TSFEL: Time series feature extraction

library. SoftwareX, 11:100456.

Bauters, K., Cottyn, J., Claeys, D., Slembrouck, M., Vee-

laert, P., and van Landeghem, H. (2018). Auto-

mated work cycle classification and performance mea-

surement for manual work stations. Robotics and

Computer-Integrated Manufacturing, 51:139–157.

Bauters, K., Van Landeghem, H., Slembrouck, M., Van

Cauwelaert, D., and Van Haerenborgh, D. (2014). An

automated work cycle classification and disturbance

detection tool for assembly line work stations. In

ICINCO 2014 - Proceedings of the 11th International

Conference on Informatics in Control, Automation

and Robotics, volume 2, pages 685–691. SciTePress.

Bello, J. P., Grosche, P., M

¨

uller, M., and Weiss, R. J. (2018).

Content-based methods for knowledge discovery in

music. In Bader, R., editor, Springer Handbook

on Systematic Musicology, pages 823–840. Springer,

Berlin, Heidelberg.

Bota, P., Silva, J., Folgado, D., and Gamboa, H. (2019). A

semi-automatic annotation approach for human activ-

ity recognition. Sensors, 19:501.

Cutler, R. and Davis, L. (1999). Real-time periodic motion

detection, analysis, and applications. Proceedings of

the IEEE Computer Society Conference on Computer

Vision and Pattern Recognition, 2:326–332.

Cutler, R. and Davis, L. (2002). View-based detection and

analysis of periodic motion. In Proceedings. Four-

teenth International Conference on Pattern Recogni-

tion, pages 495–500. Institute of Electrical and Elec-

tronics Engineers (IEEE). Cutler, R. and Davis, L. S.

(2000). Robust real-time periodic motion detection,

analysis, and applications. IEEE Transactions on Pat-

tern Analysis and Machine Intelligence, 22(8):781–

796.

Foote, J. (2000). Automatic audio segmentation using a

measure of audio novelty. In IEEE International Con-

ference on Multi-Media and Expo, pages 452–455.

Irastorza, E. S., Xabier, and Copsey, S. (2010). OSH in

figures: Work-related musculoskeletal disorders in the

EU — Facts and figures. European Agency for Safety

and Health at Work.

Jatob

´

a, L. C., Großmann, U., Kunze, C., Ottenbacher, J.,

and Stork, W. (2008). Context-aware mobile health

monitoring: Evaluation of different pattern recogni-

tion methods for classification of physical activity. In

Proceedings of the 30th Annual International Con-

ference of the IEEE Engineering in Medicine and

Biology Society, EMBS’08 - ”Personalized Health-

care through Technology”, volume 2008, pages 5250–

5253. IEEE Computer Society.

Lara,

´

O. D. and Labrador, M. A. (2013). A survey on human

activity recognition using wearable sensors. IEEE

Communications Surveys and Tutorials, 15(3):1192–

1209.

Law, S. M. (2019). STUMPY: A Powerful and Scalable

Python Library for Time Series Data Mining. The

Journal of Open Source Software, 4(39):1504.

Lu, C. M. and Ferrier, N. J. (2003). Automated Analysis of

Repetitive Joint Motion. IEEE Transactions on Infor-

mation Technology in Biomedicine, 7(4):263–273.

Lu, C. M. and Ferrier, N. J. (2004). Repetitive Motion Anal-

ysis: Segmentation and Event Classification. IEEE

Transactions on Pattern Analysis and Machine Intel-

ligence, 26(2):258–263.

Machado, I. P., Lu

´

ısa Gomes, A., Gamboa, H., Paix

˜

ao,

V., and Costa, R. M. (2015). Human activity data

discovery from triaxial accelerometer sensor: Non-

supervised learning sensitivity to feature extraction

parametrization. Information Processing & Manage-

ment, 51(2):204 – 214.

Nunes, N., Ara

´

ujo, T., and Gamboa, H. (2011). Two-modes

cyclic biosignal clustering based on time series anal-

ysis. In Proceedings of the International Conference

on Bio-inspired Systems and Signal Processing, pages

257–264.

Paulus, J., M

¨

uller, M., and Klapuri, A. (2010). Audio-based

music structure analysis. In Proceedings of the Inter-

national Conference on Music Information Retrieval

(ISMIR), pages 625–636, Utrecht, The Netherlands.

Rodrigues, J., Belo, D., and Gamboa, H. (2017). Noise de-

tection on ecg based on agglomerative clustering of

morphological features. Computers in Biology and

Medicine, 87:322 – 334.

Rodrigues, J., Gamboa, H., Mollaei, N., Os

´

orio, D.,

Assunc¸

˜

ao, A., Fuj

˜

ao, C., and Carnide, F. (2020).

A genetic algorithm to design job rotation sched-

ules with low risk exposure. In Camarinha-Matos,

L. M., Farhadi, N., Lopes, F., and Pereira, H., editors,

Technological Innovation for Life Improvement, pages

395–402, Cham. Springer International Publishing.

Romero, D., Stahre, J., Wuest, T., Noran, O., Bernus, P.,

Fasth, Fast-Berglund, A., and Gorecky, D. (2016). To-

wards an Operator 4.0 Typology: A Human-Centric

Perspective on the Fourth Industrial Revolution Tech-

nologies. In International conference on computers

and industrial engineering (CIE46) proceedings.

Santos, S., Folgado, D., Rodrigues, J., Mollaei, N., Fuj

˜

ao,

C., and Gamboa, H. (2020). Explaining the ergonomic

assessment of human movement in industrial contexts.

In Proceedings of the 13th International Joint Confer-

ence on Biomedical Engineering Systems and Tech-

nologies - Volume 4: BIOSIGNALS,, pages 79–88. IN-

STICC, SciTePress.

Varandas., R., Folgado., D., and Gamboa., H. (2019).

Evaluation of spatial-temporal anomalies in the anal-

ysis of human movement. In Proceedings of the

12th International Joint Conference on Biomedical

Engineering Systems and Technologies - Volume 4

BIOSIGNALS: BIOSIGNALS,, pages 163–170. IN-

STICC, SciTePress.

Self-Similarity Matrix of Morphological Features for Motion Data Analysis in Manufacturing Scenarios

89

Wang, Q., Kurillo, G., Ofli, F., and Bajcsy, R. (2015). Un-

supervised Temporal Segmentation of Repetitive Hu-

man Actions Based on Kinematic Modeling and Fre-

quency Analysis. In Proceedings - 2015 International

Conference on 3D Vision, 3DV 2015, pages 562–570.

Institute of Electrical and Electronics Engineers Inc.

Yeh, C. C. M., Zhu, Y., Ulanova, L., Begum, N., Ding, Y.,

Dau, H. A., Zimmerman, Z., Silva, D. F., Mueen, A.,

and Keogh, E. (2018). Time series joins, motifs, dis-

cords and shapelets: a unifying view that exploits the

matrix profile. Data Mining and Knowledge Discov-

ery, 32(1):83–123.

Zhu, C. and Sheng, W. (2009). Human daily activity recog-

nition in robot-assisted living using multi-sensor fu-

sion. In Proceedings - IEEE International Conference

on Robotics and Automation, pages 2154–2159.

BIOSIGNALS 2021 - 14th International Conference on Bio-inspired Systems and Signal Processing

90