Hydrothermally Fluorinated Graphene Oxide Chemiresistive Sensor

for Detecting NH

3

and Acetone under Atmospheric Conditions

Ivan Amor, Bruno Gamero, Siziwe Bebe and Ravi Prakash*

Department of Electronics Engineering, Carleton University, Ottawa, Canada

Keywords: Biosensor, Health Monitoring, Electronic Sensor, Chemiresistor, Graphene Oxide, Exhaled Breath Detection,

Multi-analyte Sensing.

Abstract: Emergence of graphene-derived highly functional materials has transformed chemical and bio sensing, with

several novel approaches utilizing chemical modification of graphene oxide (GO). These materials have been

implemented in device fabrication for the detection of biomolecules, volatile organic compounds (VOC), and

other chemical analytes. The detection methods rely on using specificity of the modified graphene material to

target selective and quantifiable electrical responses. In this work, we report ultra-low-level detection of NH

3

(1-10 ppm) and extend the same chemiresistor sensor to additionally detect acetone and distinguish between

their individual transient responses. The low-level detection of both these gaseous analytes is highly relevant,

and the comparable physiological detection range of these analytes makes the device suitable for continuous

health monitoring and detecting specific gas molecules in exhaled breath. The sensor system is compactly

designed to make it low cost and ideal for wearable health monitoring and environmental monitoring, using

an in-house hydrothermal fluorination technique to synthesize fluorinated-GO (FGO) suspension, and its

solution-phase deposition onto interdigitated chrome electrodes to create the chemiresistive gas sensor. The

sensor device reported a highly linear detection range for NH

3

, ranging over 1 – 10 ppm and was additionally

able to detect acetone in a similar low concentration range, whilst distinguishing the two gases based on its

rapid transient response.

1 INTRODUCTION

Chemiresistors, along with electrochemical sensors,

are widely used as gas sensing devices, and for a

variety of chemical sensing applications (Yadava et

al., 2012; Sanchez et al., 2006; Lin et al., 2015).

Electrochemical sensors adequately target

metabolites and electrolytes through enzymatic, ion-

selective, electroactive reactions (Zhao et al., 2020).

However, there are several disadvantages to their

implementation for non-invasive and continuous

health applications (Gargiulo et al., 2020). Their

dependence on elaborate patterning steps and

temperature sensitivity results in higher complexity.

Chemiresistors on the other hand, offer the benefit of

sensing various analytes due to the configurable layer

properties of the sensor. In addition, chemiresistive

sensors are simpler to fabricate, require less operating

power, and possess a longer operational life span than

electrochemical detectors (Sanchez et al., 2006; Lin

et al., 2015; Zampolli et al., 2007). They prove to be

excellent candidates for ultra-low molecular

concentration detection in a non-invasive, continuous

health care monitoring approach, to potentially

observe and indicate important physiological

conditions by identifying target gaseous analytes

(Majumder et al., 2017). Chemiresistors are

commonly implemented using metal oxide (MOx)

sensitive films such as tin or titanium oxide and

require high temperature for gas detection (Wang et

al., 2010; Ponzoni et al., 2017). This is achieved using

a thermistor integrated into the device, or a sensing

layer is deposited on a micro-hot plate for optimal

operating temperature (Lin et al., 2015; Manginell et

al., 1997).

Graphene has attracted great attention among

available 2-D materials for both chemical sensing

applications. Its morphological characteristics,

especially its high surface to volume ratio has been

attractive for gas sensing applications. Graphene

contains high electronic charge mobility, Young’s

modulus, and thermal conductivity, which makes it an

ideal candidate material for integrated circuitry,

energy storage, and chemical and bio-electronic

Amor, I., Gamero, B., Bebe, S. and Prakash, R.

Hydrothermally Fluorinated Graphene Oxide Chemiresistive Sensor for Detecting NH3 and Acetone under Atmospheric Conditions.

DOI: 10.5220/0010241200990106

In Proceedings of the 14th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2021) - Volume 1: BIODEVICES, pages 99-106

ISBN: 978-989-758-490-9

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

99

sensors. During the oxidation process of graphene,

sp

3

bonding is heavily interrupted and makes

electrical conductivity of graphene oxide (GO)

decrease drastically compared to pristine graphene

(Zaaba et al., 2017). GO can be modified to produce

functionalized GO (FGO), which has lower or higher

conductivity properties than pristine graphene and

GO (Huang et al., 2011; Kavinkumar et al., 2015).

This makes FGO a suitable candidate for replacing

MOx in chemiresistors. Another benefit is that FGO

can be produced using cost-effective chemical

methods, and in high yields from the inexpensive

graphite raw material. In addition, due to its

hydrophilic nature, stable aqueous colloids can be

formed to facilitate the assembly of macroscopic

structures by simple, low-cost solution deposition

processes (Park et al., 2016; Chronopoulos et al.,

2017). Reducing graphene oxide by fluorination

offers several advantages, owing to the low polarity

of C–F bonds and the high polarity of oxygenic

groups, characteristics of FGO could be tuned by

controlling the C–F and C–O ratios. Oxygen or

fluorine atom concentration can be tuned for different

end-product usage (Karlický et al., 2013). The main

advantage of FGO for sensing is its high

electrocatalytic activity (augmented electron

transfer), and specificity toward certain analytes due

to the presence of C–F bonds (Urbanova et al., 2016;

Lu et al., 2009). It has been observed that low

fluorinated graphene exhibits excellent sensing

properties for a range of studied biomolecules -

including ionized (NH4+), unionized ammonia

(NH

3

), and gaseous NH

3

, nicotinamide adenine

dinucleotide (NADH), ascorbic acid (AA), uric acid

(UA), and dopamine (DA). The low fluoride (F)

content that augments the electron transfer from

electrode to biomolecule (or vice versa) will neither

significantly affect the electrical conductivity nor the

wetting properties of graphene (Zhu et al., 2019;

Huang et al., 2012). Exploration of ammonia sensing

using graphene-based platforms is rapidly evolving

(Huang et al., 2012; Schedin et al., 2007). Recent

Discrete Fourier Transform (DFT) studies by Yeon

Hoo Kim et al. predicted that the binding of GO with

NH

3

molecules can be enhanced by decreasing

electron density of GO (Kim et al., 2017).

In this work, we have demonstrated a small

footprint, low-cost, FGO based chemiresistive gas

sensor, implemented on a variety of substrate

materials, for rapid and ultra-low concentration

detection of NH

3

(~ 1 – 10 ppm). The operating

principle of our chemiresistive sensor relies on

adsorption of gas molecules in a sensitive 2-D film

and the resultant change in electrical resistance

(Manginell et al., 1997; Bârsan et al., 1995; Zhao et

al., 2019; Briand et al., 2000). In our approach, a layer

of chemically functionalized graphene oxide thin film

material was deposited onto the interdigitated metal

electrodes. To render the graphene oxide selective to

target gas molecules, functional groups were added

through chemical modification. We furthermore

investigated detection of Acetone to establish the

multi-analyte sensing capability of our system. We

chose ammonia as the target analyte due to its

importance in diverse biological processes.

Commercial sensors exist for detecting ammonia in

ranges above 10 ppm, but they are not adequately

sensitive for healthcare centric applications. Samples

of ammonia that are discharged from the body are

used to monitor systemic ammonia levels (Gafare et

al., 2014). Multi analyte detection of acetone is also

crucial for monitoring conditions such as diabetes.

Studies have shown that persons with diabetes would

exhibit an ultra-low concentration of acetone (>

1.8ppm) in exhaled breath (Xiao et al., 2014).

2 MATERIALS AND METHODS

XtalFluor-E (XtalFluor), hydrofluoric acid (HF),

sodium hydrogen carbonate, poly-(3,4-

ethylenedioxythiophene polystyrene sulfonate

(PEDOT:PSS), polyvinyl alcohol (PVA) and poly-

methyl methacrylate (PMMA) were acquired from

Sigma Aldrich. De-ionized water was gathered from

the local micro fabrication lab on-site regeneration

system.

A specialized Teflon beaker with a specially

formulated stabilized poly-tetrafluoro ethylene

(PTFE) carbon base to aid in heating was obtained

from Canada wide Scientific (Dynalon Labware) for

the synthesis process.

Surface oxidized (passivated) silicon (pSi) and

silicon (Si) substrates with chromium Interdigitated

Electrodes (IDEs) were fabricated at the Carleton

University micro-fabrication lab. Nitrogen (N

2

) and

NH

3

gas were obtained from Praxair Canada Inc.

2.1 In-house FGO Synthesis

Two different synthesis methods were used to make

FGO. A commercial chemical agent and an in-house

hydrothermal process were synthesized using the

FGO preparation method. The commercial

fluorination agent, XtalFluor-E 2 g of and 2 mL of 2

mg ml

-1

GO solution were chemically modified by

dissolving them in 48% HF solution. The

consolidated solution is then boiled at 180

0

C for 2 h.

BIODEVICES 2021 - 14th International Conference on Biomedical Electronics and Devices

100

The reaction was quenched with sodium hydrogen

carbonate (5%), washed thoroughly with de-ionized

water and sample dried.

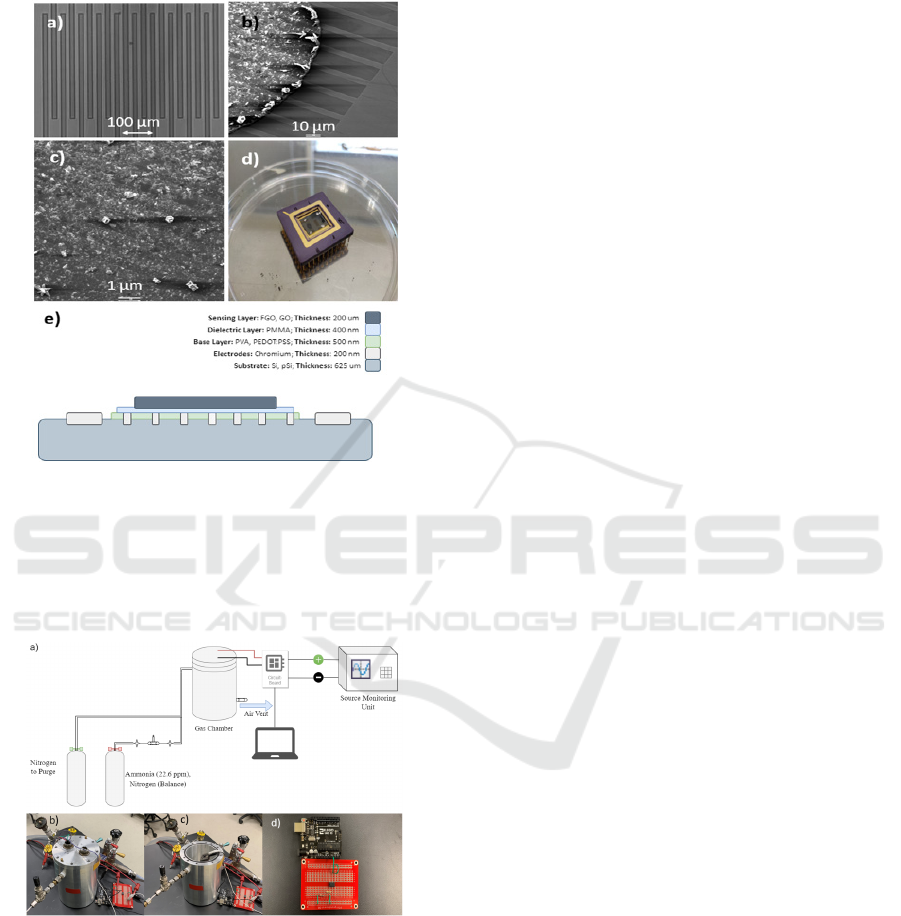

Figure 1: Micrographs showing a) Optical microscope

image of IDE chrome structure, b) Scanning Electron

Microscope (SEM) image of drop casted FGO film on the

IDE structure, c) SEM micrograph showing distribution of

FGO micro-particles on sensor surface and, d) a fully

packaged FGO NH

3

gas sensor device, e) Device Cross-

Sectional diagram.

Figure 2: a) Schematic of the experimental setup. b) Closed-

lid chamber and c) Open-lid chamber setup. d) Amplifier

circuit for voltage monitoring and capture.

A relatively low-cost in-house hydrothermal FGO

preparation method was developed and tested. Here,

GO (50 mg) was dispersed in 20 ml of deionized

water ultrasonically, and 5 ml of HF (49%) was added

with moderate stirring. The mixture was stirred on a

hot plate at 150 °C for 20 h. The resulting solution

was quenched using sodium hydrogen carbonate

(5%), centrifuged and washed several times with de-

ionized water. The final product was then freeze-

dried.

2.2 IDE Chemiresistive Sensor

Fabrication

The IDEs used in this experiment were

micropatterned using standard photolithography of

200 nm chrome layer, deposited on Si and pSi

substrates in Fig. 1a).

The IDE structures on the pSi substrate were

layered with PEDOT: PSS (conductive) and PMMA

(di-electric). A homogenous suspension of GO and

the different samples of FGO (0.2mg/ml) were drop

coated using a micro-pipette on each of the different

devices (Fig. 1b, c).

The sensor microchip was wire bonded onto a

package shown in Fig. 1d), that was then used to

connect the device to the circuit for measurements.

The packaged sensors were exposed to NH

3

and other

target gases for an established period under both

controlled and normal environmental conditions at

ATM as seen in Figure 2b) and c). The experiments

were repeated to verify reproducibility, reversibility,

and sensor behaviour.

2.3 Experimental Setup

The initial experimental setup is shown in Figure 2a).

NH

3

and N

2

gases were released into the stainless-

steel test chamber and used to verify the concept of

targeted gas sensing in an ideal, controlled

environment. The packaged sensor was placed inside

the gas chamber. A vacuum pump was used to

achieve a chamber pressure of ≤ 0.00533 kPa (40

mTorr). The ammonia gas cylinder with a rated

concentration of 22.6 ppm, was then attached to the

chamber with a needle valve to control the flow of gas

released into the chamber with added precision. A

flow of ammonia gas was released for 3 minutes by

opening the needle valve at around 15%. The nitrogen

gas was used to dilute the ammonia and return to

atmospheric baseline readings. In certain control

experiments, a commercial Honeywell Ammonia Gas

flow sensor (MIDAS-E-NH3) was introduced in the

setup to measure and correlate the ammonia

concentration to the response of the chemiresistor gas

sensor.

The sensor device was connected in series as the

second resistor in a voltage divider circuit to feed the

input voltage, V

in

from the SMU for the

instrumentation amplifier AD 620. The voltage

measurements were then recorded over time.

Hydrothermally Fluorinated Graphene Oxide Chemiresistive Sensor for Detecting NH3 and Acetone under Atmospheric Conditions

101

•

2.4 Experimental Procedure: Data

Capture and Analysis

The data was captured with respect to the voltage of

the amplifier V

O

over time and was used to

characterize the normalized change in resistance

defined as |ΔR/R| (%): where ΔR is the resistance

change with respect to the baseline resistance R

before exposure to ammonia.

The sensing mechanism was exposed to a steady

flow of ammonia in a closed environment then

extensively verified in an open chamber in an ambient

setting to mimic practical health monitoring

applications. Responsiveness and selectivity of the

devices in these conditions were validated, in

significantly lower gas concentrations. Experiments

were repeated in an open chamber with ammonia gas

flow at concentrations below 2.26 ppm on top of the

sensor surface, to mimic exhaled breath sensor

response under atmospheric pressure conditions.

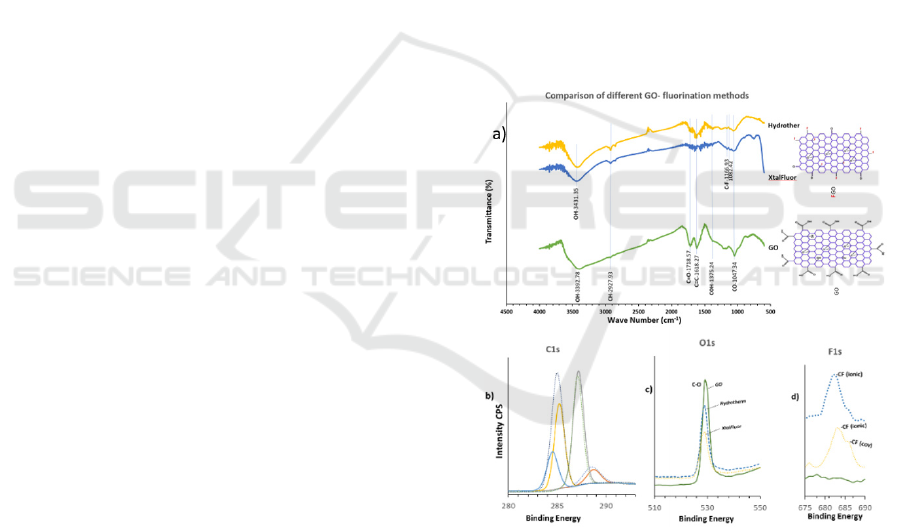

2.5 Material Characterization for FGO

Fourier transform infrared spectroscopy (FTIR) is

performed on several GO and FGO (XtalFluor) and

FGO (In-house) samples using a KBr pellet method,

scanning from 400 to 4000 cm

-1

. Absorption and

Transmittance spectra are analyzed to compare

efficacies of GO functionalization methods.

The X-ray photoelectron spectroscopy (XPS) data

was collected using AlK

α

radiation at 1486.69 eV

(150 W, 10 mA), charge neutralizer and a delay-line

detector (DLD) with three multi-channel plates.

Survey spectra are recorded from -5 to 1200 eV at a

pass energy of 160 eV (number of sweeps: 2) using

an energy step size of 1 eV and a dwell time of 100

ms. High resolution spectra for F1s, O1s, and C1s are

recorded in the appropriate regions at a pass energy

of 20 eV (number of sweeps: F1s, 15; O1s, 5; C1s, 5)

using dwell time of 300 ms and 0.1eVstep size.

Characterization results from the FTIR and XPS

are detailed in the results and discussion section.

3 RESULTS AND DISCUSSIONS

3.1 Characterization Results for FGO

Analysis of the obtained spectra for the GO and the

FGO showed that the C–O bond at Wavenumber

~1052 cm

-1

diminishes and is subsequently replaced

by another peak at ~1166 cm

-1

. Based on literature

and results obtained previously, the resulting peak

indicated the formation of a C-F bond, hence

fluorination of the GO. A vibration characterizing a

carbonyl group C=O at wavenumber ~1720 cm

-1

,

which is originally present in the GO sample,

diminishes upon the fluorination reaction using both

methods (HF thermally, and the HF/Xtal Fluor). The

shift of wave numbers was also noted for the bond

vibration of –C=C-, ~1618 cm

-1

with a marked

decrease in the intensity of transmittance. Intensity of

the peaks associated with the carbon oxygen bonds

decrease and a strong peak at ~1166 cm

-1

,

corresponding to covalent C–F bond, appears in the

FTIR spectrum of FGO (Gong et al., 2012), indicating

that oxygen-containing functional groups are

replaced by fluorine. The bond C–F (sp

3

) vibrates at

the wave number ~ 1082 cm

-1

and is observed in the

FGO spectrum. The peak at wavenumber ~2928 Is

X=C=Y, where X and Y can be either C or O. C–F

formation was obtained from the results of the XPS

data analysis. Differences between the GO and FGO

decomposition XPS spectra in Fig. 3 a) C1s, b) O1s

and c) F1s confirmed fluorination.

Figure 3: a) FTIR spectra of GO fluorination with XtalFluor

and with hydrothermal (Hydrother) fluorination in HF. The

GO spectrum is a reference showing the different peaks that

are formed due to the fluorination. The two molecular

structures of GO and FGO are representative structures,

showing likely fluorination positions, b) The XPS figures

show the comparison between GO before Fluorination and

after Fluorination for C1s, c) O1s and d) F1s. In addition,

c) and d) show comparison of the different synthesis

products.

BIODEVICES 2021 - 14th International Conference on Biomedical Electronics and Devices

102

Comparison of the XPS C1s spectra

decomposition showed characteristic peaks at: C=C,

284 eV, Csp3, Csp2, –CH 285 eV, C–O 287 eV and

O–C=O 288 eV. The peak intensities of C–O and

C=C/C–C display a significant increase due to the

formation of various C-F bonds. This confirmed the

reduction of the C=O in the FTIR spectrum and the

appearance of the C–F peak. Observed in XPS C1s of

the C=O is an increase and shift in the FGO spectrum.

F1s spectra Fig. 3d) shows the presence of semi-ionic

C–F bonds and the covalent C–F bonds corroborated

by the significant increase of C1s, Csp3, Csp2, –CH

peak in the FGO spectrum compared to the GO, with

no notable increases in C=O and –C–O.

From the experimental results spectra, C–F bond

formation was observed in both fluorination

processes and that using the in-house method of

synthesis would equally facilitate the formation of the

FGO–NH

3

complex molecule. A comparison of the

inhouse thermal synthesis of FGO and use of the

commercial chemical XtalFluor is shown in figure 3c.

The depletion and shift of the HC–O at 532 eV was

observed as it is consumed in the production of C–F

bonds. The graphs in figure 3c), d) also show a

comparison of the two FGO synthesis methods

products with that of GO, where the appearance of the

C–F (ionic) bond is observed at 682 eV and C–F

(covalent) bond at 687 eV for both synthesis methods

while there is no peak at all for GO. The C–F covalent

bonding is noted in the XtalFluor synthesis,

suggesting superior fluoride doping, however, the

simplicity and high yield of the inhouse thermal

process makes it more desirable.

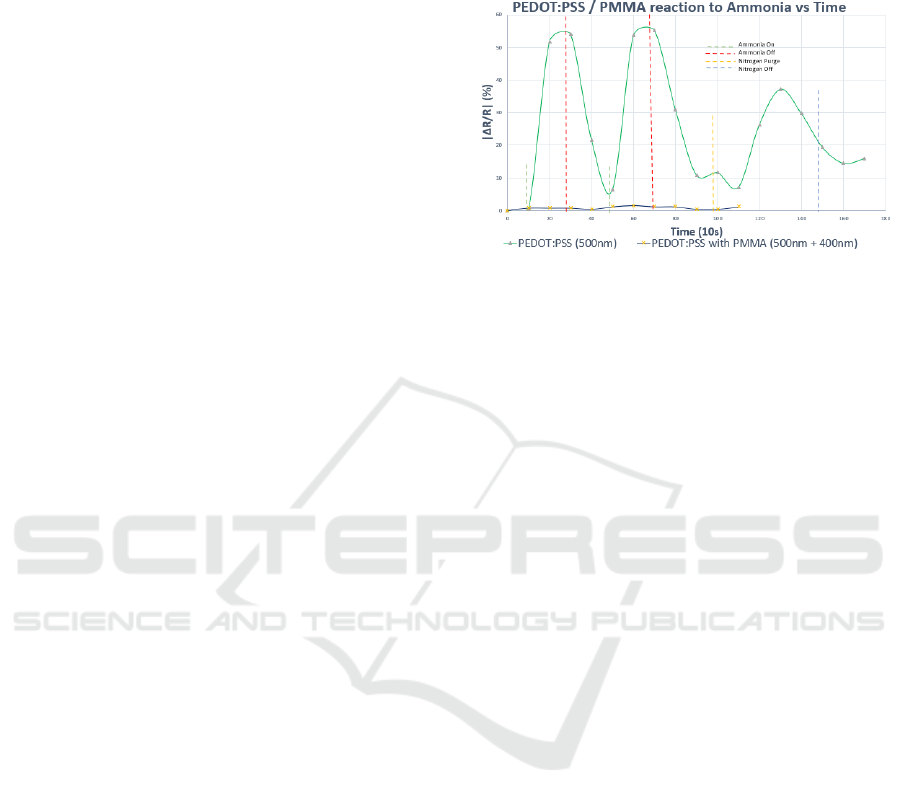

3.2 Substrate Selection for IDEs

A novel component of our chemiresistor sensor is the

ability to use a readily available, inert substrate. We

used pSi in our tests due to its low cost, non-

conductive nature. PEDOT:PSS has a proven

conformal contact with textured silicon, and was used

as a thick hydrophobic conductive film, with high

porosity (Jiang et al., 2018; Vosgueritchian et al.,

2012).

We observed that PEDOT:PSS was effective in

lowering the baseline resistance from bare pSi at 1.2

MΩ to 133.3 kΩ, however its response to ammonia

gas was undesirable (see Fig. 4), and necessitated

another coating layer to prevent the interaction

between the target molecules and PEDOT:PSS.

PMMA was chosen due to its fibrous composition

and very low chemical affinity. The thin film stack

aids in the retention of gas molecules, possess

excellent dielectric properties (Zhang et al., 2014),

and therefore proved helpful in trapping analyte

molecules and facilitated interaction of FGO with

NH

3

.

Figure 4: Substrate responsiveness coated with

PEDOT:PSS (500 nm), PEDOT:PSS & PMMA (500 nm +

400 nm) with respect to ammonia exposure over time

(sampled every 10s).

The results in Fig. 4, confirmed that adding an

adequately thick layer of PMMA on to the

PEDOT:PSS base layer renders it dormant. Having a

high surface to volume ratio also enhanced the

effectiveness of PMMA as it covers the layer of

PEDOT:PSS and limits interaction with the exposed

gas molecules.

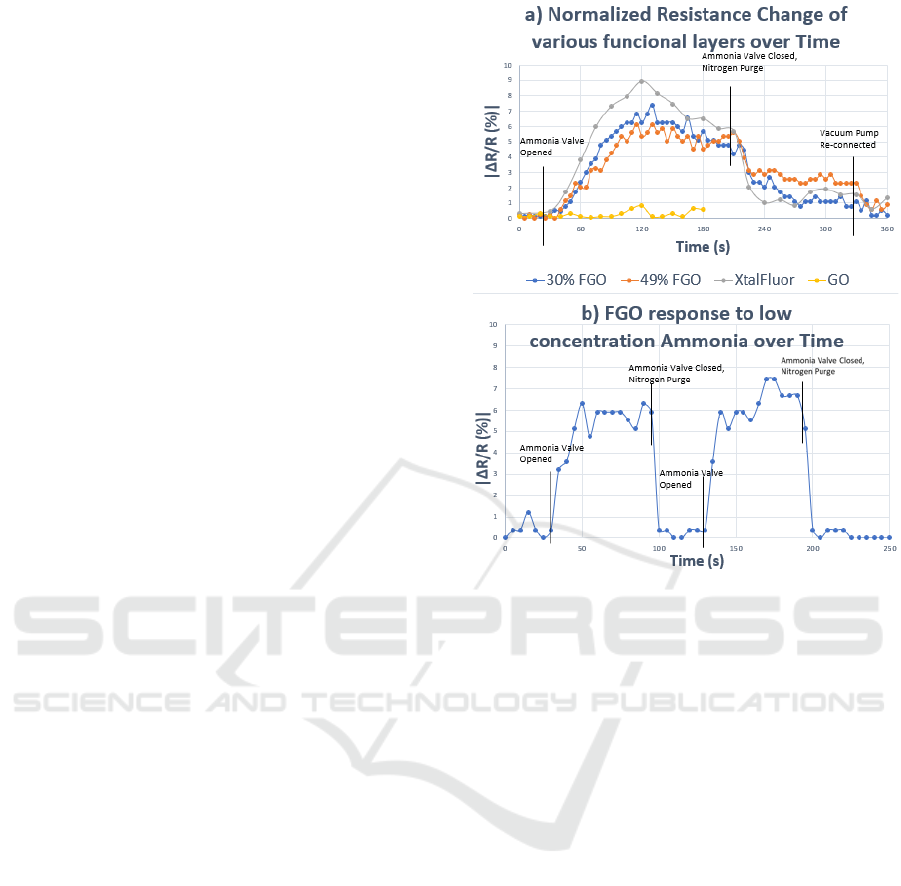

3.3 Sensor Performance

The initial transient results of the four tested

structures were captured and delineated, as shown in

Fig. 5a). The traditional graphene oxide

demonstrated no response to the presence of ammonia

as expected. All three functionalized graphene oxide

sensors were measured in terms of absolute

percentage change and demonstrated a visible

response to the presence of ammonia. After the

nitrogen purge, the voltage output approached

nominal readings.

The graphene oxide demonstrated no discernible

change in resistance upon initial exposure, whilst the

three functionalized sensors all reacted within the first

10 s. The resistance change would continue to rise

for the first 90 s of each test, at which point gas

concentration then diminished. The two

hydrothermally processed FGO sensors had similar

maximum resistance changes, with the peaks being at

7.4% for 30% HF and 6.1% for the 49% HF sensors.

The XtalFluor processed sensor demonstrated a

larger resistance shift with a peak change of 8.9%.

and demonstrated the fastest drop in resistance,

indicating quick molecular discharge from the

sensing film. In Figure 5a) the 49% FGO (FGO49)

had the slowest drop in percent change, indicating

Hydrothermally Fluorinated Graphene Oxide Chemiresistive Sensor for Detecting NH3 and Acetone under Atmospheric Conditions

103

that the stronger affinity causes a retention of

ammonia particles.

Following the nitrogen purge, the FGO49 also had

the least amount of variation, further indicating its

affinity for stronger retention with ammonia particles,

while the other sensors dropped rapidly. Within the

first minute of turning the vacuum pump back on, all

sensors had returned close to the original resistance.

The results demonstrate that the functionalization

process introduced an electrical sensitivity in the

previously unmodified graphene oxide device.

3.3.1 Validation of Sensor Performance

All investigations for sensor performance validation

was done using our in-house synthesized FGO. A

commercially available ammonia sensor (Honeywell

MIDAS-E- NH3) was tested in conjunction with the

FGO sensor at atmospheric pressure to calibrate the

chemiresistor sensor response. Ammonia was

released into the chamber until it reached a

concentration of 19 ppm.

The functionalized gas sensor responds to the

ammonia within seconds of exposure while the

commercial sensor only responds after the

concentration has reached 9 ppm. The linear response

of the chemiresistive gas sensor peaks at

approximately |ΔR/R| = 8% at 19 ppm, indicating a

sensitivity of 0.42% ΔR/R per ppm.

Both sensors showed an immediate response to

the decreasing ammonia concentration, with the FGO

chemiresistive sensor having a slower response.

Within five minutes of non-exposure, the

chemiresistive sensor returned to its baseline value.

The response of the chemiresistive gas sensor is seen

to be linearly proportional to the concentration of

ammonia on the sensor coating.

Figure 5b) demonstrates the sensor exposed to a

flow of an ultra-low concentration (2.26 ppm) of

ammonia gas. The peak response was around 8%, and

the overall change was a |ΔR/R| of ~3.54% per ppm.

The adjusted scaled percentages corresponded to the

same linear response that was modelled from

previous experiments conducted in ideal conditions.

This data validates that the sensor response remains

linear over a broad concentration range and the

sensitivity is reproducible for ultra-low

concentrations (~ 1-2 ppm).

Figure 5: a) Response of FGO (30 and 49%), XtalFlour, and

GO to high concentration ammonia. b) Response of FGO to

low concentration ammonia.

3.3.2 Multi-analyte Sensing Capabilities of

Our FGO Chemiresistive Sensor

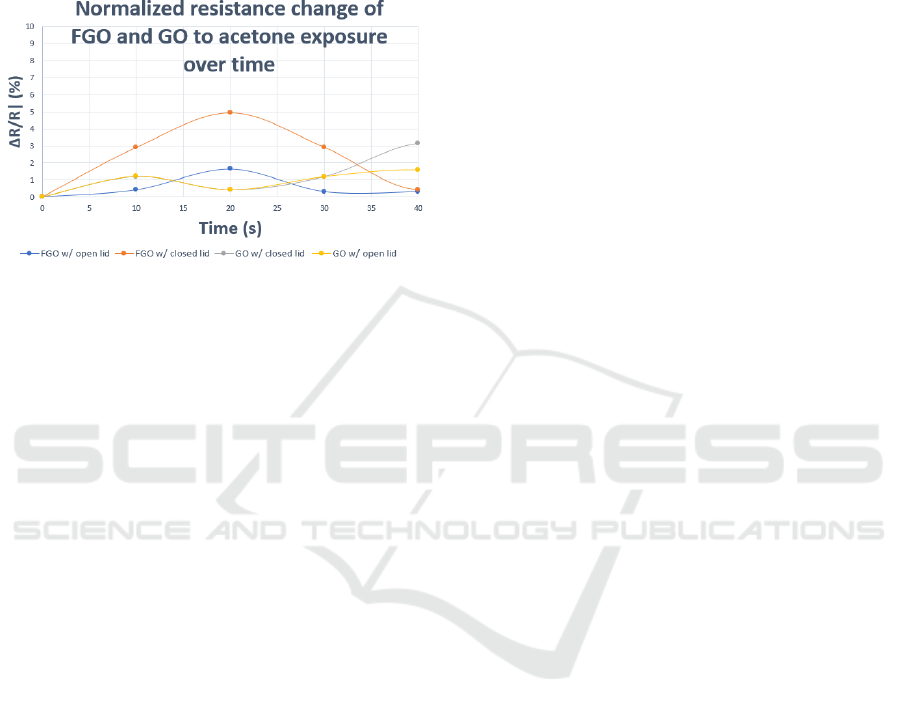

The FGO sensor was exposed to acetone to verify its

cross-sensitive performance. Acetone possesses

enhanced binding mechanisms with FGO. Its

chemical features are consistent with previously

tested analytes, as interaction with weakly bound

fluorine ions change the electronic properties of the

sensor. In this case, it provides an opposite, but

equivalent response. The experiment was conducted

in a controlled environment with both the FGO and

GO sensors exposed to acetone in closed, and open

lid situations to verify performance under ideal, and

ambient conditions.

The acetone was heated on a hot plate at 56 °C and

was placed into the sensing chamber. In Fig. 6, device

exposure to acetone vapour demonstrated the

expected, opposite response. The overall

responsiveness to ammonia |ΔR/R| (%), equal cross-

sensitivity and linear correlation of the sensor was

predictable and remained unchanged. The trend

showed that the peak exposure from the acetone

vapour occurred at 20 s.

The change in |ΔR/R| (%) reached a maximum of

5% for the FGO sensor in a closed chamber. The FGO

BIODEVICES 2021 - 14th International Conference on Biomedical Electronics and Devices

104

sensor in ambient conditions as well as the GO sensor

in both open and closed environments demonstrated

limited response. The device henceforth proved

capable of targeting multiple, opposite analytes, and

shows a distinct, predictable trend which can be

attributed to the selectivity of the chemiresistor

response.

Figure 6: FGO and GO response to acetone.

The change in |ΔR/R| (%) reached a maximum

value of 5% for the FGO sensor in a closed chamber.

The FGO sensor in ambient conditions as well as the

GO sensor in both open and closed environments

demonstrated limited response. The device

furthermore proved capable of targeting multiple,

opposite analytes, and shows a distinct, response

which can be attributed to the selectivity of the

chemiresistor device at an ultralow concentration

range. Since concentration ranges of acetone in

exhaled breath of people with diabetes can be as low

as ~ 1.8 ppm, the sensor response fits well within the

physiological monitoring range.

To further verify the sensing capabilities of the

coatings, the FGO and GO coated sensors were

exposed to a slow, timed-release of isopropyl alcohol

(IPA) and ethanol. Neither the GO nor FGO sensor

responded to IPA or ethanol. It furthermore proves to

be extremely promising for being highly selective

towards specific analytes in ultralow concentrations.

4 CONCLUSIONS

In this work, we achieved ultra-low-level detection

(~1-10 ppm) of NH

3

using an in-house synthesized

FGO coated chemiresistive gas sensor. The device

performance was superior to a commercial

electrochemical NH

3

sensor in detection limit,

sensitivity, and linearity. The design of these

chemiresistor devices can be configured in a way that

the sensing layer and substrate are interchangeable,

which makes them advantageous. Passivated silicon

emulated a low-cost, robust polymer substrate. In the

future, these devices will be printed on lower cost

substrates, with low production cost. The conductive

layers of, PEDOT:PSS and PMMA would provide

necessary conductivity and limit interaction with the

targeted gas. We demonstrated the miniature footprint

of the packaged device which would evolve into a

point-of-care, wearable, continuous monitoring

exhaled breath sensor. The chemiresistive sensor

device was extended to detecting another relevant

target gaseous analyte, acetone. Acetone was detected

by virtue of a different type of chemical interaction

between the FGO and the analyte molecule. Our

experiments suggested that the sensor could handle

concentrations of acetone in the ~ 1.0 -10 ppm range,

which is ideal for physiological monitoring of

diabetes. Extensive experimental validation using a

commercial gas sensor as control and ultra-low

concentration of gaseous analytes validated that our

FGO chemiresistive gas sensor has a unique, target

specific, transient response that can be easily

analysed using simplified techniques, illustrating the

versatility of these sensors over traditional electro-

chemical sensors. This work furthermore establishes

a roadmap to fabricate such sensors on a low-cost

polymer surface with configurable sensing layers, to

identify presence of multiple gaseous analytes in

ultra-low concentration range of 1 – 10 ppm. The

small footprint of the device also serves useful for

smart wearable type health monitoring applications.

ACKNOWLEDGEMENTS

The authors acknowledge Mr. Brian Kennedy at the

KennedyLabs (Ottawa, Canada) for providing

graphene and GO samples, and NSERC Canada for

the supporting the reported work through the NSERC

Engage Grant.

REFERENCES

Yadava, L., et al. (2012). Detection and sensing mechanism

of acetone with modeling using Pd/TiO2/Si structure.

Thin Solid Films, 520(7), 3039–3042.

Sanchez, J.-B., et al. (2006). A selective gas detection

micro-device for monitoring the volatile organic

compounds pollution. Sens. Act. B: Chem., 119(1),

227–233.

Lin, C., et al. (2015). Evaluation and calibration of

Aeroqual series 500 portable gas sensors for accurate

Hydrothermally Fluorinated Graphene Oxide Chemiresistive Sensor for Detecting NH3 and Acetone under Atmospheric Conditions

105

measurement of ambient ozone and nitrogen dioxide.

Atm. Env., 100, 111–116.

Zampolli, S., et al. 2007. A supramolecular approach to

sub-ppb aromatic VOC detection in air. Chem. Com.

2790–2792.

Majumder, S., et al. (2017). Wearable Sensors for Remote

Health Monitoring. Sensors (Basel, Switzerland),

17(1), 130.

Zhao, Y. et al. (2020). A wearable freestanding

electrochemical sensing system. Science Advances,

6(12).

Gargiulo, V., et al. (2020). Graphene-like layers as

promising chemiresistive sensing material for detection

of alcohols at low concentration. Food Re. Intl.,

Volume 119., May 2019, 99-109

Wang, C., et al. (2010). Metal Oxide Gas Sensors:

Sensitivity and Influencing Factors. Sensors, 10(3),

2088–2106.

Ponzoni, A. et al. (2017). Metal Oxide Gas Sensors, a

Survey of Selectivity Issues Addressed at the SENSOR

Lab, Brescia (Italy). Sensors, 17(4), 714

Manginell, et al. (1997). Overview of micromachined

platforms for thermal sensing and gas detection. In V.

K. Varadan & P. J. McWhorter (Eds.), Smart Structures

and Materials 1997: Smart Electronics and MEMS.

SPIE.

Bârsan, N., & Tomescu, A. (1995). The temperature

dependence of the response of SnO2-based gas sensing

layers to O2, CH4 and CO. Sens. Act. B: Chem., 26(1–

3), 45–48.

Zhao, W.-J., et al. (2019). A Low-Temperature Micro

Hotplate Gas Sensor Based on AlN Ceramic for

Effective Detection of Low Concentration NO2.

Sensors, 19(17), 3719.

Briand, D., et al. (2000). Design and fabrication of high-

temperature micro-hotplates for drop-coated gas

sensors. Sens. Act. B: Chem., 68(1–3), 223–233.

Zaaba, N. I., et al. (2017). Synthesis of Graphene Oxide

using Modified Hummers Method: Solvent Influence.

Procedia Engineering, 184, 469–477.

Huang, X., et al. (2011). Graphene-Based Materials:

Synthesis, Characterization, Properties, and

Applications. Small, 7(14), 1876–1902.

Kavinkumar, T., et al. (2015). Effect of functional groups

on dielectric, optical gas sensing properties of

graphene oxide and reduced graphene oxide at room

temperature. RSC Advances, 5(14), 10816–10825.

Park, M.-S., et al. (2016). NH

3

gas sensing properties of a

gas sensor based on fluorinated graphene oxide.

Colloids and Surf. A: Phys. Eng. Asp., 490, 104–109.

Chronopoulos, D. D., et al. (2017). Chemistry, properties,

and applications of fluorographene. App. Mat. 9, 60–

70

Zhao, F.-G., et al. (2014). Fluorinated graphene: facile

solution preparation and tailorable properties by

fluorine-content tuning. J. Mater. Chem. A, 2(23),

8782–8789.

Karlický, F., et al. (2013). Halogenated Graphenes:

Rapidly Growing Family of Graphene Derivatives.

ACS Nano, 7(8), 6434–6464.

Urbanova, V., et al. (2016). Fluorinated graphenes as

advanced biosensors - Effect of fluorine coverage on

electron transfer properties and adsorption of

biomolecules. Nanoscale.

Lu, G., et al. (2009). Reduced graphene oxide for room-

temperature gas sensors. Nano., 20(44), 445502.

Zhu, W., et al. (2019). Solvent-free preparation of

hydrophilic fluorinated graphene oxide modified with

amino-groups. Materials Letters, 237, 1–4.

Huang, X., et al. (2012). Graphene-based composites.

Chem. Soc. Rev., 41(2), 666–686.

Schedin, F., et al. (2007). Detection of individual gas

molecules adsorbed on graphene. Nature Materials,

6(9), 652–655.

Kim, Y. H. et al. (2017). Chemically fluorinated graphene

oxide for room temperature ammonia detection at ppb

levels. Jou. Mat. Chem.A, 5(36), 19116–19125.

Gafare, M., et al. (2014). Detection of ammonia in exhaled

breath for clinical diagnosis- A review. 3RD INTL.

CONF. FUND. AND APP. SCI. (ICFAS 2014): Inn.

Res. App. Sci.

Xiao, T., et al. (2014). Highly sensitive and selective

acetone sensor based on C-doped WO3 for potential

diagnosis of diabetes mellitus. Sens. Act. B: Chem. 199,

210-219.

Gong, P., et al. (2012). One-pot sonochemical preparation

of fluorographene and selective tuning of its fluorine

coverage. J. Mater. Chem. 22(33), 16950.

Jiang, X., et al. (2018). High Performance of

PEDOT:PSS/n-Si Solar Cells Based on Textured

Surface with AgNWs Electrodes. Nano. Res. Let., 13(1).

Vosgueritchian, M., et al. (2012). Highly Conductive and

Transparent PEDOT:PSS Films with a

Fluorosurfactant for Stretchable and Flexible

Transparent Electrodes. Adv. Fun. Mat.

Zhang, H., et al. (2014) High-sensitivity gas sensors based

on arranged polyaniline/PMMA composite fibers. Sens.

Act. A: Phys. 219, 123-127.

BIODEVICES 2021 - 14th International Conference on Biomedical Electronics and Devices

106