Development of a Purchasing Portfolio Model for the Health Sector:

A Case Study of a Central Hospital

Amílcar Arantes

1a

and Andreia Frias Alhais

2

1

CERIS, CESUR, Instituto Superior Técnico, Universidade de Lisboa, Av. Rovisco Pais, Lisboa,1049-001, Portugal

2

DEG, Instituto Superior Técnico, Av. Prof. Dr. Cavaco Silva, Porto Salvo, 2744-016, Portugal

Keywords: Purchasing Portfolio, Kraljic Portfolio Matrix, Analytic Hierarchy Process, Health Sector.

Abstract: Over the years, the purchasing area has taken on an essential role in the management of companies in all

activity sectors. In the health sector, purchasing medicines is highly important considering the amounts

involved, the impact on the service quality, and the wide variety of purchased products. This research work

combined action research with a case study and aims to apply to a Central Hospital a Purchasing Portfolio

Model based on the Kraljic Purchasing Matrix (KPM). The KPM allows for the classification of different

classes of medicines in accordance with their impact on profits and supply risk dimensions, making it possible

to define differentiated purchasing strategies. This application used the Analytical Hierarchical Process (AHP)

tool for criteria prioritization and used direct measurement for criterion rating. By applying the model to a

Central Hospital, this study seeks to increase the areas of applicability of purchasing portfolio models.

Moreover, the results confirmed the model's value in defining medicine purchasing strategy at the Central

Hospital and also gave rise to guidelines for applying the model.

1 INTRODUCTION

In recent years in Portugal, the health sector has

evolved, in both the public and private sectors,

through the implementation of a set of structural

reforms, the reinforcement of the health care network,

and a process of modernization and digital

transformation (Ministério da Saúde, 2018). In 2018

total health expenditure (public and private)

represented about 9.1% of the Portuguese Gross

Domestic Product, with the general public spending

about 4.4%. These values demonstrate the importance

of the health sector in the Portuguese economy.

The hospital procurement of medicines involves a

wide range of financial resources and time. It carries

certain risks, especially in terms of storage, as most

handled products are fragile and must not be defective

when they are used. Furthermore, given the large

quantity and variety of products and services that

have to be purchased, not all medicines should be

managed and purchased in the same way. According

to Medeiros & Ferreira (2018), the purchase portfolio

can be an excellent tool for strategic management

hospital purchases.

a

https://orcid.org/0000-0003-1207-5854

The most recognized and commonly used

Purchasing Portfolio Model (PPM) was introduced by

Kraljic (1983). This model is considered an important

advance in purchasing area development and

considers a matrix that classifies product item classes

into four categories: non-critical, bottleneck,

leverage, and strategic; and according to two

dimensions – profit impact, and supply risk. This

matrix allows for the definition of purchasing

strategies according to the characteristics of each

product item class (Gelderman, 2003). A set of

criteria must be defined for each of the Kraljic

Purchasing Matrix (KPM) dimensions and be

weighted using the Analytic Hierarchy Process

(AHP) tool. The Kraljic matrix has already been

applied in several areas. However, in the literature the

number of reported applications in the health sector is

limited.

This paper is organized as follows: firstly, the

portfolio approach based on the Kraljic model is

presented; secondly, the research method is

described, then, thirdly, the selected case study is

summarily described; fourthly, the PPM is developed

with the help of the AHP for criteria prioritization;

Arantes, A. and Alhais, A.

Development of a Purchasing Portfolio Model for the Health Sector: A Case Study of a Central Hospital.

DOI: 10.5220/0010225903290337

In Proceedings of the 10th International Conference on Operations Research and Enterprise Systems (ICORES 2021), pages 329-337

ISBN: 978-989-758-485-5

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

329

fifthly, there is a report on the results obtained and

discussion thereof; and finally, in the conclusions, the

main findings and implications are presented.

2 LITERATURE REVIEW

The healthcare supply chain is a complex and

fragmented process, and management thereof

encompasses managing suppliers, procuring

resources, and delivering goods and services to

providers and patients. Moreover, the customer

service level of the healthcare supply chain is of

paramount importance, given the direct impact it has

on the health and safety of the patients (Uthayakumar

& Priyan, 2013).

Hospitals have many different departments

provide healthcare services, requiring a wide range of

products (and services) that the procurement area

seeks to provide, including consumables such as

medicines, and permanent material, such as medical

equipment (Almeida & Lourenço, 2009). Medicines

constitute the highest costs in running a hospital; they

usually account for between 40% and 60% of the

public sector budget (Medeiros & Ferreira, 2018).

Management of these products is critical because they

must be transported and stored in specific conditions,

there can be no stockout, and they come with an

expiration date. Thus, the purchasing experts must

carefully decide which products to order, in what

quantities, and when to place orders, so as to serve

patients in a timely and efficient way (Uthayakumar

& Priyan, 2013). Furthermore, considering the vast

differences in the characteristics of the products,

often it is necessary to organize and categorize them

in order to define adequate purchasing strategies. For

this, PPMs are useful tools to manage medicine

purchases strategically in accordance with the

specific characteristics of each product (Medeiros &

Ferreira, 2018).

Kraljic (1983) created the most frequently used

and recognized portfolio approach to purchasing

(Pardo et al., 2011). The KPM considers the strategic

impact and supply risk dimensions. It can be

beneficial to management, namely in having a

trustworthy insight into supply risk and negotiating

power and making it possible to define the most

appropriate purchasing strategies. Kraljic (1983)

highlights a matrix that classifies products (or classes

of products) purchased by a company in four

categories: non-critical, bottleneck, leverage, and

strategic; and according to two dimensions – the

supply risk and the profit impact (Table 1). However,

some authors have introduced changes to the matrix

dimensions in order to adjust them to their own

applications.

Table 1: Kraljic matrix (Kraljic, 1983).

Strategic impact Supply Risk

Low High

Low Non-critical Bottleneck

High Leverage Strategic

The non-critical category represents products that

are purchased frequently and are low in value;

however, they take up 80% of purchasing department

time and account for less than 20% of the purchasing

volume. The bottleneck category represents products

whose suppliers have a dominant position due to

supply shortage (Caniëls & Gelderman, 2005). The

leverage category represents products that are used

regularly and in large quantities. Finally, strategic

items represent products with a small number of

suppliers in the market and a high strategic impact

(Gelderman & Van Weele, 2003). Each category has

a set of recommended strategies that can be found in

the literature (Caniëls & Gelderman, 2005; Kraljic,

1983). In order to allow purchasers to get to know

their bargaining power better and identify an

appropriate strategy to reduce corporate risk and

increase purchasing efficiency, Kraljic (1983)

defined a set of criteria for each matrix dimension

(Ferreira et al., 2015; Kraljic, 1983). Kraljic (1983)

took the volume of purchases or the total costs into

consideration in assessing the strategic impact. In

determining supply risk, he recommended

incorporating the supply market complexity, which

includes supply shortage, technological advances,

substitute products, entry barriers, logistics costs, and

monopoly and oligopoly conditions. Montgomery et

al. (2018) assert that the Kraljic approach is the most

important diagnostic and prescriptive tool in

purchasing management. Gelderman & Van Weele

(2003) consider KPM an innovative procurement

practice.

Gelderman & Mac Donald (2008) applied the

KPM to a logistics infrastructure developed within an

oil company. Arantes et al. (2014) used the KPM in

two branches in markets with differing characteristics

in which a multinational construction company

operates and compared the results. Botes et al. (2017)

investigated mechanisms whereby the buyer-supplier

relationship enables the petrochemical industry's

resilience. These examples in the literature confirmed

the versatility of the Kraljic matrix, as it can be

applied to a wide range of areas and contexts, some

of them very distinct.

ICORES 2021 - 10th International Conference on Operations Research and Enterprise Systems

330

Accordingly, this study aims to expand the

applicability of the PPMs in the health sector by

applying the KPM to a Central Hospital (CH) in

Portugal using a simplified model (practitioner wise),

combined with an action research approach.

3 RESEARCH METHOD

This study combined Action Research (AR) with a

case study in a CH in Portugal and had the main

objective of supporting the change to a more

structured process in defining medicine purchasing

strategies for the CH, integrating supply risk and

strategic impact. Due to difficulties in medicine

purchasing, namely the perceived misalignment

between purchasing strategies and product

characteristics, the CH invited the researchers to

develop a process of establishing suitable and

practicable purchasing strategies.

The CH under study comprises six hospital units,

with the Purchasing, Logistics and Distribution

Department (PLDD) responsible for medicine

purchases for all units. In hospitals, the purchase

processes are complex, given that they deal with a set

of constraints; for this reason, they are continually

looking for new solutions (Serrou & Abouabdellah,

2016). The supply policy must meet the

organizational and patient needs (Almeida &

Lourenço, 2009). In 2017, the CH's purchases

exceeded 144 million euros, about 52% of the total

annual budget, with medicines accounting for around

46% of the volume of purchases. This figure is in line

with Medeiros & Ferreira (2013), who stated that,

generally speaking, medicines make up about 45% of

total hospital purchases.

Combining Action Research (AR) with a case

study in a CH in Portugal, this research project is

exploratory in nature. AR is used to solve existing

problems in organizations in a group decision

context, and it is centered on solving issues (Rytter,

Boer, and Koch, 2007). Kurt Lewin (1946) defines

AR as “comparative research on the conditions and

effects of various forms of social action and research

leading to social action”. Middel et al. (2006) claimed

that the use of AR models contributes to research on

collaborative and continuous improvements,

contributing both to the body of knowledge and

practitioners’ concerns.

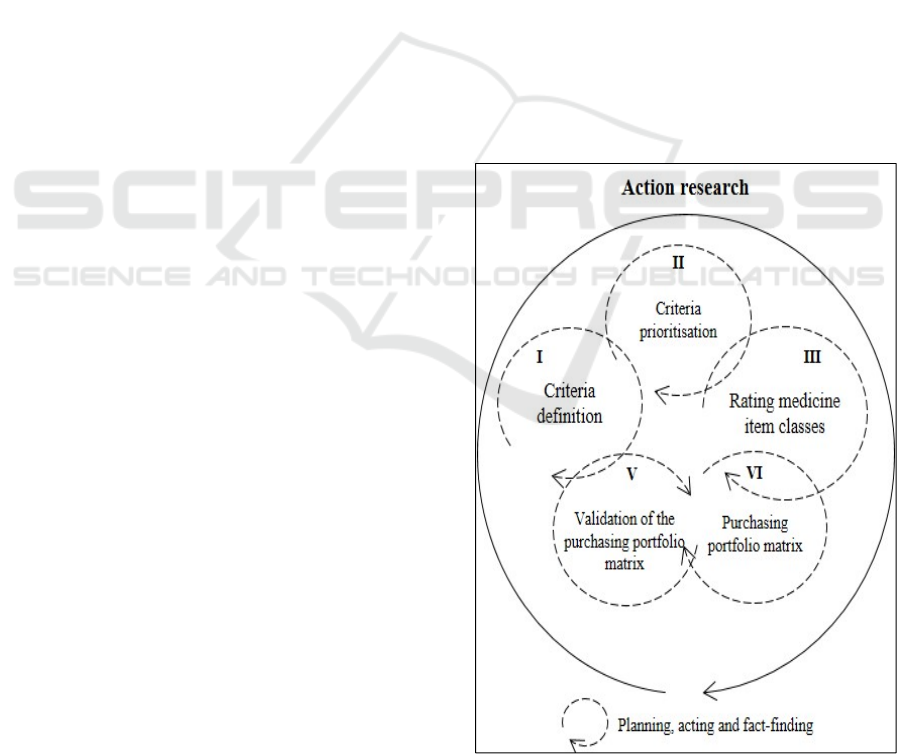

The research method presented in Figure 1, made

up of five phases, required close collaboration

between the researchers and six representatives from

the CH divided into two independent groups, Group

1 (G1) and Group 2 (G2). The utilization of two

groups allows for the consistency and validity of

results (Lee & Drake, 2010; Padhi et al., 2012):

G1 is used to define the dimension criteria (Phases

I and II);

And, G2 to apply the criteria to the products under

analysis, develop the PPM and validate it (Phases

III, IV, and V).

The research lasted for eight months, and several

group sessions were held for data collection,

development, and results validation. In the sessions,

all group members had equal weight in decision-

making processes, and the session coordinator (one of

the researchers) always endeavored to reach a

consensus. When consensus was not reached, the

final decision was by majority vote.

Finally, the list of the CH’s medicines contains

over 2000 items with different characteristics, which

was too much to be dealt with in this study. Hence, an

ABC analysis was carried out to classify medicines’

importance by purchasing cost, whereby only those in

category A were considered in this research,

accounting for 5.3% of the medicines and 80.09% of

the amount spent. Lastly, category A medicines were

grouped according to their characteristics, resulting in

22 Medicine item classes (MICs) (Table 2).

Figure 1: Research method based on AR principles (adapted

from Ferreira et al. (2015)).

Development of a Purchasing Portfolio Model for the Health Sector: A Case Study of a Central Hospital

331

Table 2: MICs by the total annual amount spent.

Medicine item class Purchase Volume

Antivirals 29.50%

Antiretrovirals 15.13%

Immunomodulators A 14.38%

Immunomodulators B 10.45%

Hemostatics A 6.42%

Cytotoxic 3.61%

Immunoglobulins 3.28%

Enzymes 2.26%

Medicinal Gases 2.21%

Hemostatics B 1.87%

Eye disorders medicines 1.67%

Nervous system 1.65%

Antifungals 1.26%

Tyrosinacinase inhibitors 1.25%

Antibacterials 0.98%

Plasma substitutes 0.97%

Hypothalamic hormones 0.96%

Electrolyte Changes 0.80%

Intoxications antidotes 0.65%

Cardiovascular system medicines 0.25%

Breathing system medicines 0.25%

Medical ultrasound 0.19%

4 PURCHASING PORTFOLIO

MODEL

To apply the Kraljic matrix required the use of a

multiple criteria decision-making tool, which is

essential in problem-solving situations characterized

by various actors, criteria, and objectives (Kumar et al.,

2017). This tool’s main goal is to support decision-

makers, as there is usually not just one optimal solution

for problem-solving, and it’s is often necessary to

differentiate between existing solutions (Saaty, 1980).

Analytical Hierarchical Process (AHP) is a

technique that supports reducing the uncertainty in

subjective assessments (Saaty, 1980). Complex

decision-making requires the establishment of

different “trade-offs” between criteria. The decision

elements are compared with each other and weights

assigned to define the priorities in the decision-

making process (Subramanian & Ramanathan, 2012).

In this study, an AHP model with four levels is the

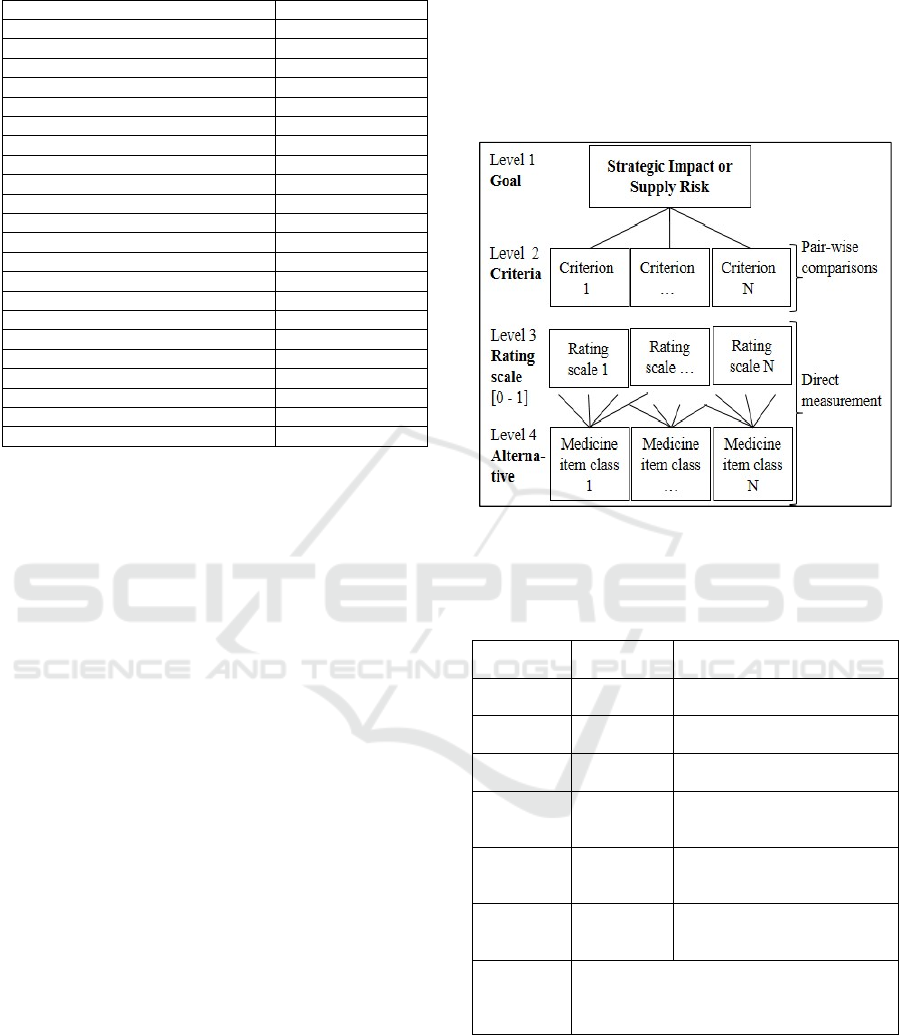

basis for the development of the KPM (Figure 2). At

Level 1, the goal provides the overall score of each

MIC in terms of the two dimensions of the KPM,

namely strategic impact and supply risk (chosen by

the G1 experts).

The criteria that the experts considered relevant

for measuring the strategic impact or supply risk are

located at Level 2. Level 3 contains the rating scale

for measuring each MIC in each criterion. Finally,

Level 4 includes alternative MICs. To find the

relative weight of the criteria, pair-wise comparisons

based on a “1 to 9” relative importance scale were

utilized (Table 3). To score each alternative (MIC) for

each criterion, a direct (or absolute) measurement was

chosen, which is an advantage over pair-wise

comparisons, which would require a high and

impractical number of comparisons (Bruno et al.,

2012; Drake & Lee, 2009).

Figure 2: AHP model for each KPM dimension (adapted

from Ferreira et al. (2015)).

Table 3: Pair-wise comparisons “1 to 9” scale for AHP

(adapted from Saaty (2008)).

Intensity of

importance

Definition Explanation

1

Equal

importance

Two criteria contribute equally

to the objective

3

Moderate

importance

Experience and judgment

slightly favor one over another

5

Strong

importance

Experience and judgment

strongly favor one over another

7

Very strong

importance

A criterion is strongly favored,

and its dominance is

demonstrated in practice

9

Absolute

importance

The importance of one over

another is recognized

unassailably.

2, 4, 6, 8

Intermediate

values

Used to represent a

compromise between the

priorities listed above

Reciprocals o

f

above

If criterion i has one of the above non-zero

members assigned to it when compared with

criterion j, then j has the reciprocal value when

compared with i.

4.1 Criteria Definition

The choice of the dimension criteria in PPMs was a

complicated matter. In this study, the criteria and

respective assessment scales were developed by the

G1 experts in accordance with their experience and

knowledge (stages I and II of the research method).

ICORES 2021 - 10th International Conference on Operations Research and Enterprise Systems

332

4.1.1 Strategic Impact

From criteria found in the application of KPM

available in the literature, experts selected a set of

three criteria as appropriate for classifying the

strategic impact of the MICs. Moreover, two criteria

were adjusted, and a new criterion was added

(importance of the product in the patient’s life),

considering that they must be comprehensive, non-

redundant, operational, thrifty, and independent

(Saaty, 1980).

To complete the definition of the strategic impact

criteria, the experts were requested to develop a rating

scale for each qualitative criterion (Table 4). The first

criterion chosen was the ‘purchase volume’, as a

generic criterion suggested by Kraljic (1983). The

second was ‘importance of the product in the patient’s

life,’ giving that a lack of certain medicines can

endanger patients’ lives. Finally, ‘expected growth in

demand’ allowed the experts to anticipate changes in

purchasing strategies in the long-term.

Table 4: Criteria rating scales for the Strategic Impact (SI)

dimension. (*) The final rating is presented on a 0 to 1 scale.

Criteria Rating scale

SI1 - Purchase volume

(Purchase Volume/Maximum

Purchased Volume)^2

SI2 - Expected growth in

demand (%)

1: Lower; 2; 3: Remains equal;

4; 5: Higher

SI3 - Importance of the

product in the patient’s

life (*)

1: No risk; 2; 3: Medium; 4; 5:

High risks

4.1.2 Supply Risk

For classifying the supply risk dimension, four

criteria were selected by the experts (Table 5). For the

first criterion, experts agreed that the ‘number of

suppliers’ is key, as in hospitals the trade-off between

price and quality depends on the number of potential

suppliers available on the market (Medeiros &

Ferreira, 2018). The second criterion is ‘substitute

products’ because alternative medicines, for example,

can help to solve some of the problems that managers

face daily, such as delays in delivery, damaged

products, suppliers’ stockouts. The third is ‘logistic

proximity,’ given that, for hospitals, the logistics risk

is a mix between distance and complexity if the

supply chain, which is highlighted by the fact that the

medicines purchased come from Portugal and all over

the world. Lastly, the criterion ‘transportation

requirements’ is essential, given that certain

medicines require specific packaging and conditions

during transportation.

Table 5: Criteria rating scales for the supply risk dimension.

(*) The final rating is presented on a 0 to 1 scale.

Criteria Rating scale

SR1 - Number of

suppliers

Number of suppliers^-1.1

SR2 - Substitute

products (*)

1/(n+1)

n – average number of acceptable

substitutes in the MIC

SR3 - Logistic

proximity (*)

1: Local; 2; 3: Distant or

complex; 4; 5: Distant and

complex

SR4 - Transportation

requirements (*)

1: None; 2; 3: Some complexity;

4; 5: Specific and complex

4.2 Criteria Prioritization

The next step was determining the relative weights of

each criterion, which must reflect their “importance”

in the dimensions of the PPM (Olsen & Ellram,

1997). For calculating the weights, the pair-wise

comparisons inherent in the AHP application were

carried out as a team exercise in sessions with G1.

The final results were reached by consensus (Table 6

and Table 7).

According to the results, the most important

criterion in the strategic impact dimension is the

“purchase volume,” which has a relative weight of

63.5%, as was already expected. However, in the

literature, the values found for similar criteria lie at

around 50% (Lee & Drake, 2010; Padhi et al., 2012).

Next, the second most important criterion is the

“importance of the product in the patient’s life” which

has a weight of 28.7%, reflecting hospitals’ primary

goal of ensuring efficient treatment for all their patients

by providing quality services (Medeiros & Ferreira,

2018). Lastly, the criterion “expected growth in the

demand”, which has a weight of 7.8%, is the least

important criterion. The consistency ratio (CR) for the

strategic impact criteria is 9.8%, which is acceptable,

as it is less than the threshold of 10% (Saaty, 1980).

As far as the supply risk dimension is concerned,

the “number of suppliers” is the most important

criterion, having a relative weight of 54.6%. This

figure can be explained by the high impact that the

number of suppliers has on the hospital service level,

given that the hospitals are responsible for supplying

the required products for health care activities and

treatment of the patients. In second place, experts

considered the “substitute products” criterion, which

has a 29.5% relative weight, because it is important

to have alternative medicines so that the supply of

medicines does not fail. In third place comes the

“logistic proximity” criterion with 11.3%; in last

place is the criterion “transportation requirements”,

with 4.6%. In the supply risk dimension, CR is 8.8%,

which is an acceptable value, as it is less than 10%.

Development of a Purchasing Portfolio Model for the Health Sector: A Case Study of a Central Hospital

333

Table 6: Relative weights of the strategic impact criteria.

Criteria SI1 SI2 SI3 Weight

SI1 - Purchase volume 1 6 3 63.5%

SI2 - Expected growth in

demand

1/6 1 1/5 7.8%

SI3 - Importance of the product

in the patient’s life

1/3 5 1 28.7%

Consistency Ratio (CR) = 0.098

Table 7: Relative weights of the supply risk criteria.

Criteria SR1 SR2 SR3 SR4 Weight

SR1 - Number of

suppliers

1 3 5 7 54.6%

SR2 - Substitute

products

1/3 1

4

7 29.5%

SR3 - Logistic proximity 1/5 1/4 1 4 11.3%

SR4 - Transportation

requirements

1/7 1/7 1/4 1 4.6%

Consistency Ratio (CR) = 0.088

Table 8: Classification of medicines item classes according

to both matrix dimensions.

Medicine item class

Supply

risk

Strategic

impact

Antivirals 0.48 0.96

Antiretrovirals 0.10 0.51

Immunomodulators A 0.44 0.26

Immunomodulators B 0.27 0.17

Hemostatics A 0.38 0.29

Cytotoxic 0.43 0.34

Immunoglobulins 0.41 0.06

Enzymes 0.55 0.12

Medicinal Gases 0.52 0.01

Hemostatics B 0.53 0.19

Eye disorders medicines 0.70 0.01

Nervous system 0.39 0.16

Antifungals 0.52 0.05

Tyrosinacinase inhibitors 0.08 0.30

Antibacterials 0.13 0.22

Plasma substitutes 0.57 0.22

Hypothalamic hormones 0.35 0.18

Electrolytes 0.45 0.07

Intoxications antidotes 0.96 0.14

Cardiovascular system medicines 0.88 0.22

Breathing system medicines 0.96 0.18

Medical ultrasound 0.84 0.04

5 RESULTS AND DISCUSSION

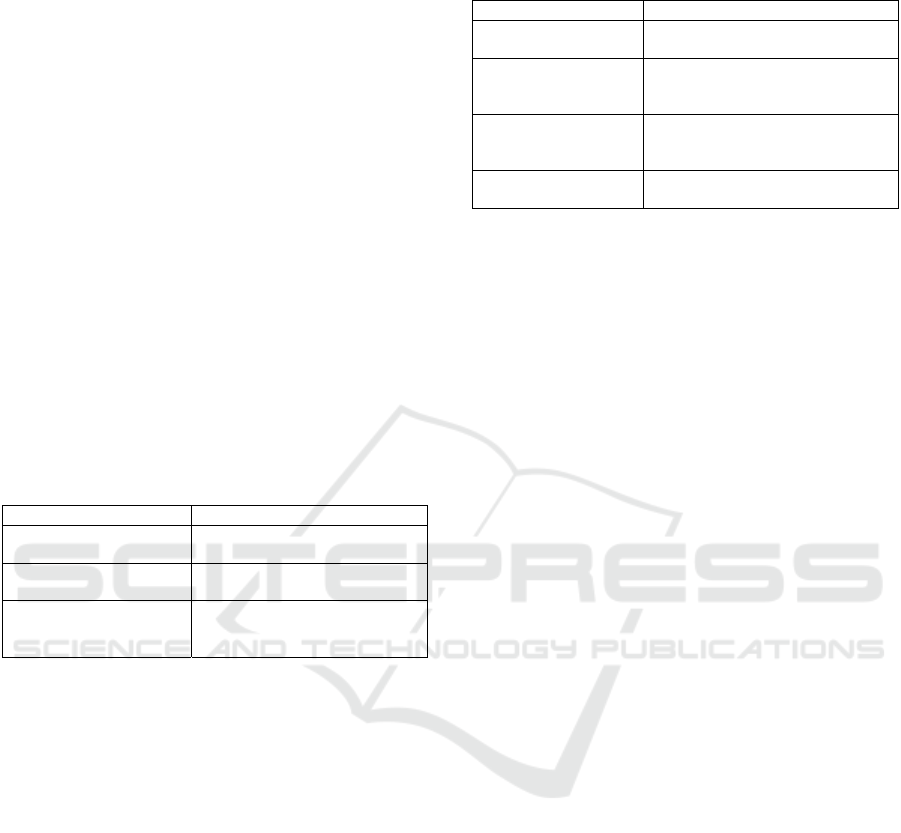

Once the criteria and prioritization of the PPM’s

dimensions have been defined, the next step is to rate

all 22 MICs using the rating scales presented in

Tables 4 and 5 (stage III of the research method). For

the qualitative criteria, the experts in G2 met and used

direct measurement. When it came to the quantitative

criteria, the rating scales were used. Finally, after

accounting for the weights of the criteria defined in

the AHP model (Tables 6 and 7), the results are

presented (stage IV of the research method):

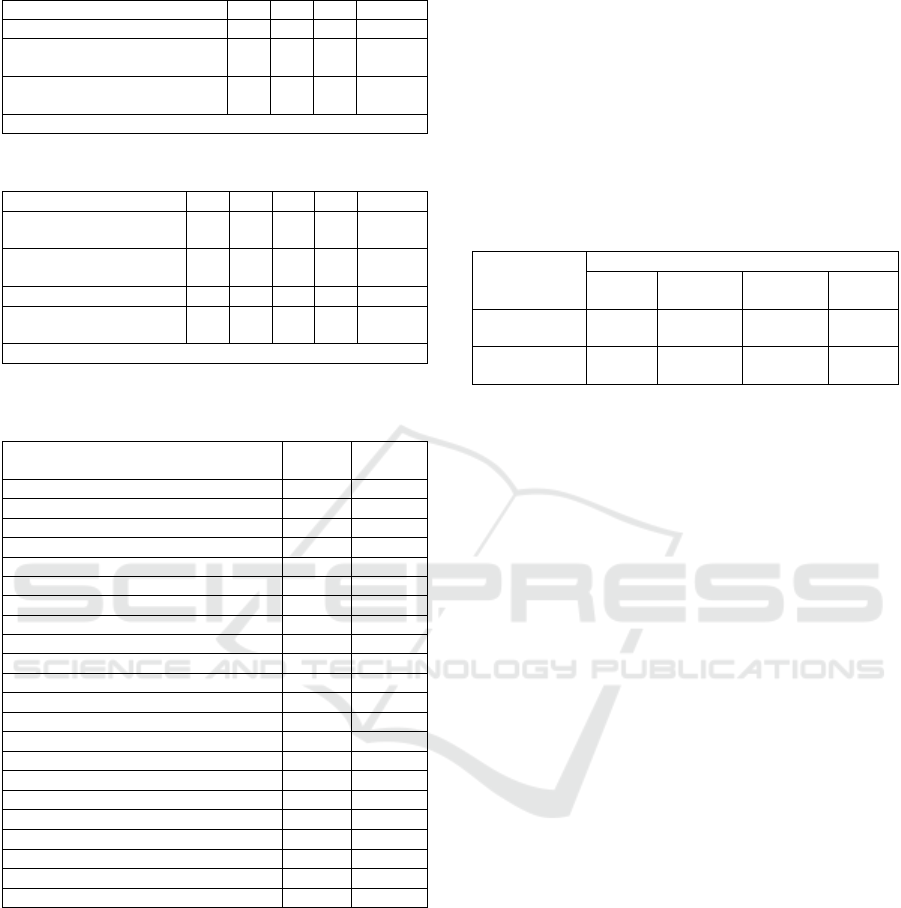

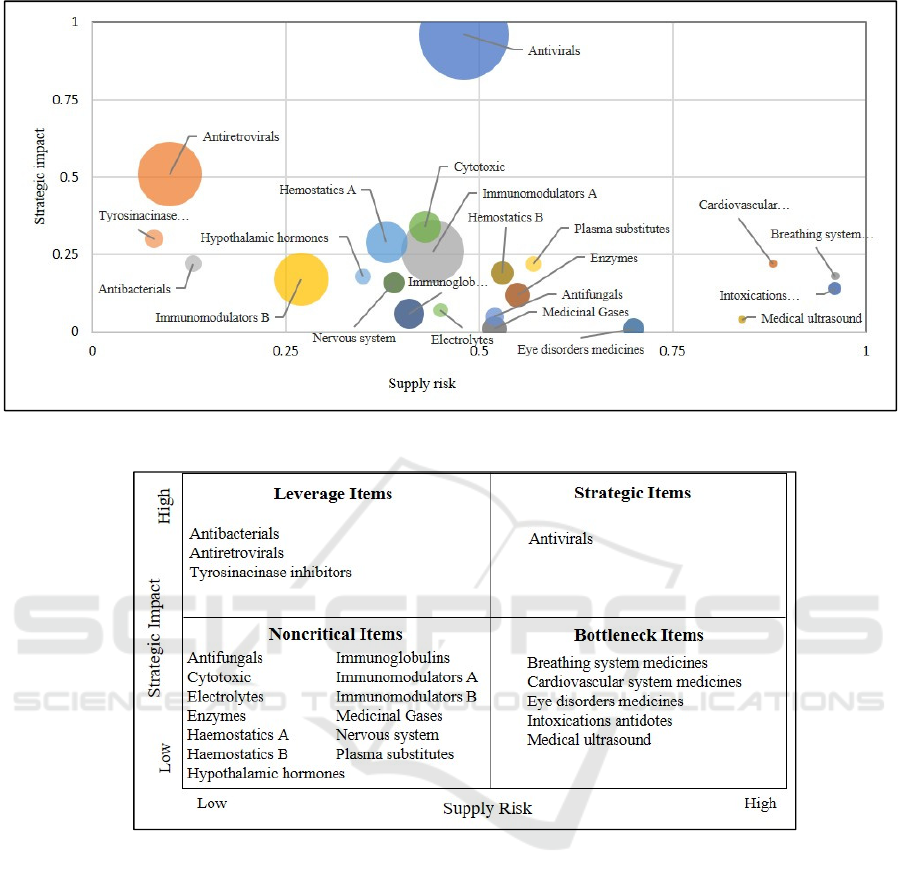

The classification of MICs according to Strategic

impact and Supply risk (Table 8);

The distribution of the purchasing amount in the

quadrants of the PPM (Table 9);

The PPM plot (Figure 3);

And, the mapping of the MICs in the quadrants of

the PPM (Figure 4).

Table 9: Distribution of the purchased amount among the

four categories.

Categories

Strategic Leverage Bottleneck

Non-

critical

No. of classes

(%of 22)

1

(4.5%)

3

(13.7%)

5

(22.7%)

13

(59.1%)

Purchasing

volume

29.5% 17.4% 3.0% 50.1%

However, at first glance the results in Figure 3

seem misleading. Distributing the MICs across the

PPM quadrants can be both challenging and

subjective. The MultiDimensional Scaling (MDS)

approach was adopted to position the MICs in the

PPM (Padhi et al., 2012). Considering the Euclidean

distances between MICs, calculated using the scores

presented in Table 8, MDS looks for possible clusters,

which contain MICs that are inter-related, and

provides a visual representation of the pattern of

proximities. This approach allowed for a clear link

between these clusters and the four purchasing

categories, as shown in Figure 4.

In the final G2 session, the experts had the

opportunity to discuss and comment on the results

presented in Figure 5 (phase V of the research

method), based on their specific and practical

expertise. They helped explain the results and

confirmed PPM’s potential, as developed for their

hospital, while also showing its general applicability

to the health sector, thus satisfying this study’s main

objective.

The non-critical category has the largest number

of MICs, accounting for 50.1% of the total purchasing

volume (Table 9). These MICs are of low supply risk,

mainly due to the existence of many suppliers and

substitute products, and a low strategic impact, given

the small purchase volumes for each MIC. Thus, for

these MICs, it is recommended that one reduce

logistical and administrative complexity through

standardization and aggregation with a view to

reducing transaction costs (Caniëls & Gelderman,

2005).

ICORES 2021 - 10th International Conference on Operations Research and Enterprise Systems

334

Figure 3: PPM plot (bobble proportional to the amount spent).

Figure 4: Mapping of the MICs in the quadrants of the PPM.

Despite having the second-largest number of

MICs, the bottleneck category has the lowest volume

of purchases (3%). These classes present a high

supply risk on account of the reduced number of

suppliers and the fact that there is no substitute in case

of need. They also have a low strategic impact due to

their low purchase volumes and the low impact of

growing demand on the organization. Accordingly,

the recommendation is to guarantee availability of

these medicines through larger stocks at the CH or

suppliers, the latter being preferable (Caniëls &

Gelderman, 2005).

The leverage category comprises three MICs

corresponding to 17.4% of the total purchasing

volume. These MICs are characterized by low supply

risk, which can be explained by the fact that there are

several substitute medicines and many suppliers

located in Portugal. Furthermore, the high strategic

impact of this category on the CH is due to the high

purchase volumes for the MICs. The recommendation

for the CH is to use purchasing strategies that exploit

its buying power through price negotiation, such as

competitive bidding (Lee & Drake, 2010). The

experts stated that they are already using this strategy;

however, they recognize they may not be applying it

to the right medicines.

Finally, the strategy category has only one MIC

(Antivirals) but one that has a high relative weight

(29.5%) in the total purchasing volume. This MIC has

a high strategic impact, as it presents a high

purchasing volume, demand is expected to grow in

the near future, and also represents an increased risk

Development of a Purchasing Portfolio Model for the Health Sector: A Case Study of a Central Hospital

335

in patients’ lives in cases of stockout. Furthermore,

the number of suppliers or substitute medicines is

small. Accordingly, experts recommend establishing

long-term contracts with the suppliers of this

category’s medicines based on information exchange

(at operational and strategic levels), ensuring that

there are guarantees of supply, and sharing updated

information concerning the CH’s medicines demand,

present and future.

6 CONCLUSIONS

The contribution of this study deals with the

identified research gap regarding the application of a

PPM to the health sector, particularly medicine

purchasing, and successful criteria prioritization

using the AHP technique in both dimensions of the

matrix. The purchasing process at the CH was studied

and analyzed. It was concluded that the misalignment

between the medicine’s characteristics and CH’s

purchasing strategy is one of the root causes of the

problems identified in purchasing medicines.

Furthermore, the CH’s current medicines purchasing

strategy is based only on the purchasing price

criterion. In this sense, KPM is a fundamental tool

because it considers more criteria defined according

to the CH and clients’ interests. Its application

allowed us to position the 22 item classes in the

KPM's most appropriate quadrant, permitting the CH

to develop adequate purchasing strategies. The results

show that 13 of the MICs are in the non-critical

category, representing 59.1% of the purchased

volume of medicines; the main strategy proposed to

the CH is to reduce logistical and administrative

complexity through standardization and aggregation

of medicines. With regard to the bottleneck category,

which includes five MICs and accounts for only 3%

of the purchased amount, the proposed strategy is to

guarantee medicines’ availability through having

larger stocks at the CH or, preferably, the suppliers.

Regarding the leverage category, which comprises

only three MICs but accounts for 17.4% of the

purchased volume, the proposed strategy is

competitive bidding, exploiting the CH’s buying

power. Finally, for the critical category, which only

includes one MIC but accounts for almost 30% of the

purchased volume, the recommended strategy points

to establishing long-term contracts with the suppliers

based on information exchange, at operational and

strategic levels.

This study has also shown that the combination of

AHP and MDS is a practical way of dealing with

PPM’s critical issue – its subjectivity – while keeping

it simple and usable by the CH employees. The CH

management agreed on the value of taking a

structured approach to developing purchasing

strategies in the CH, so that supply risk and strategic

impact are integrated into the purchasing decision

process. They also recognized the value of the new

approach in the process of defining purchasing

strategies for each category. They recommended its

application regularly. Nevertheless, they also agreed

that it is crucial to interpret and reflect on the results.

The construction of the PPM matrix should not be the

end of the portfolio analysis. Discussions offer more

in-depth understanding and may lead more quickly to

decisions grounded in consensus. Lastly, the CH

management agreed that the PPM facilitates strategic

talks to a large degree, taking purchasing to a strategic

level.

The main limitation of the present study is that

only one case was used, so caution must be taken

when generalizing the findings to the whole health

sector. Despite that limitation, the principal objective

of the study was achieved, having developed and

applied the purchasing portfolio model to a hospital

and simultaneously shown its value.

Lastly, by way of future work, it was suggested to

the CH management that they expand the application

of the KPM to products/services other than

medicines, so that their buyers can manage their

acquisition effectively and economically. The

development of the CH’s information systems and the

implementation of a more powerful warehouse

management system was also recommended.

ACKNOWLEDGMENTS

The authors would like to express their profound

gratitude to all Central Hospital experts for their

participation and support in developing the

Purchasing Portfolio Model.

REFERENCES

Almeida, A., & Lourenço, L. (2009). As diferenças

regionais ao nível das práticas de aprovisionamento nos

hospitais públicos portugueses. Revista Portuguesa De

Saúde Pública, 27(1), 81–94.

Arantes, A., Ferreira, L. M. D. F., & Kharlamov, A. (2014).

Application of a Purchasing Portfolio Model in a

Construction Company in Two Distinct Markets.

Journal of Management in Engineering, 30(5),

04014020. https://doi.org/10.1061/(ASCE)ME.1943-

5479.0000290

ICORES 2021 - 10th International Conference on Operations Research and Enterprise Systems

336

Botes, A., Niemann, W., & Kotzé, T. G. (2017). Buyer-

supplier collaboration and supply chain resilience: A

case study in the petrochemical industry. South African

Journal of Industrial Engineering, 28(4), 183–199.

https://doi.org/10.7166/28-4-1736

Bruno, G., Esposito, E., Genovese, A., & Passaro, R.

(2012). AHP-based approaches for supplier evaluation:

Problems and perspectives. Journal of Purchasing and

Supply Management, 18(3), 159–172.

https://doi.org/10.1016/j.pursup.2012.05.001

Caniëls, M. C. J., & Gelderman, C. J. (2005). Purchasing

strategies in the Kraljic matrix—A power and

dependence perspective. Journal of Purchasing and

Supply Management, 11(2), 141–155.

https://doi.org/https://doi.org/10.1016/j.pursup.2005.1

0.004

Drake, P. R., & Lee, D. M. (2009). Component

prioritisation for strategic purchasing and the case study

of a South Korean elevator manufacturer. International

Journal of Advanced Manufacturing Technology, 43(9–

10), 883–895. https://doi.org/10.1007/s00170-008-

1766-0

Ferreira, L. M. D. F., Arantes, A., & Kharlamov, A. (2015).

Development of a purchasing portfolio model for the

construction industry: an empirical study. Production

Planning & Control, 26(5), 377–392.

https://doi.org/10.1080/09537287.2014.906679

Gelderman, C. J. (2003). A Portfolio Approach to the

Development of Differentiated Purchasing Strategies.

https://doi.org/10.6100/IR569453

Gelderman, C. J., & Mac Donald, D. R. (2008). Application

of Kraljic’s purchasing portfolio matrix in an

undeveloped logistics infrastructure: The staatsolie

suriname case. Journal of Transnational Management,

13(1), 77–92.

https://doi.org/10.1080/15475770802059610

Gelderman, C. J., & Van Weele, A. J. (2003). Handling

measurement issues and strategic directions in Kraljic’s

purchasing portfolio model. Journal of Purchasing and

Supply Management, 9(5–6), 207–216.

https://doi.org/10.1016/j.pursup.2003.07.001

Kraljic, P. (1983). Purchasing must become supply

management. Harvard Business Review, September-

(83509), 109–117. https://doi.org/10.1225/83509

Kumar, A., Sah, B., Singh, A. R., Deng, Y., He, X., Kumar,

P., & Bansal, R. C. (2017). A review of multi criteria

decision making (MCDM) towards sustainable

renewable energy development. Renewable and

Sustainable Energy Reviews, 69(October 2016), 596–

609. https://doi.org/10.1016/j.rser.2016.11.191

Lee, D. M., & Drake, P. R. (2010). A portfolio model for

component purchasing strategy and the case study of

two South Korean elevator manufacturers.

International Journal of Production Research, 48(22),

6651–6682.

https://doi.org/10.1080/00207540902897780

Lewin, K. (1946). Action Research and Minority Problems.

Journal of Social Issues, 2(4), 34–46.

https://doi.org/10.1111/j.1540-4560.1946.tb02295.x

Medeiros, M., & Ferreira, L. (2018). Development of a

purchasing portfolio model: An empirical study in a

Brazilian hospital. Production Planning and Control,

29(7), 571–585.

https://doi.org/10.1080/09537287.2018.1434912

Middel, R., Coghlan, D., Coughlan, P., Brennan, L., &

McNichols, T. (2006). Action research in collaborative

improvement. International Journal of Technology

Management, 33(1), 67–91.

https://doi.org/10.1504/IJTM.2006.008192

Ministério da Saúde. (2018). Retrato da Saúde 2018,

Portugal.

Montgomery, R. T., Ogden, J. A., & Boehmke, B. C.

(2018). A quantified Kraljic Portfolio Matrix: Using

decision analysis for strategic purchasing. Journal of

Purchasing and Supply Management, 24(3), 192–203.

https://doi.org/10.1016/j.pursup.2017.10.002

Olsen, R. F., & Ellram, L. M. (1997). A portfolio approach

to supplier relationships. Industrial Marketing

Management, 26(2), 101–113.

https://doi.org/10.1016/S0019-8501(96)00089-2

Padhi, S. S., Wagner, S. M., & Aggarwal, V. (2012).

Positioning of commodities using the Kraljic Portfolio

Matrix. Journal of Purchasing and Supply

Management, 18(1), 1–8.

https://doi.org/10.1016/j.pursup.2011.10.001

Pardo, C., Missirilian, O., Portier, P., & Salle, R. (2011).

Barriers to the “key supplierization” of the firm.

Industrial Marketing Management, 40(6), 853–861.

https://doi.org/10.1016/j.indmarman.2011.06.029

Rytter, N. G., Boer, H., & Koch, C. (2007).

Conceptualizing operations strategy processes.

International Journal of Operations and Production

Management, 27(10), 1093–1114.

https://doi.org/10.1108/01443570710820648

Saaty, T. L. (1980). The Analytic Hierarchy Process:

Planning, Priority Setting, Resource Allocation

(Decision Making Series). 287.

Serrou, D., & Abouabdellah, A. (2016). Logistics in the

hospital: Methodology for measuring performance.

ARPN Journal of Engineering and Applied Sciences,

11(5), 2950–2956.

Subramanian, N., & Ramanathan, R. (2012). A review of

applications of Analytic Hierarchy Process in

operations management. International Journal of

Production Economics, 138(2), 215–241.

https://doi.org/10.1016/j.ijpe.2012.03.036

Uthayakumar, R., & Priyan, S. (2013). Pharmaceutical

supply chain and inventory management strategies:

Optimization for a pharmaceutical company and a

hospital. Operations Research for Health Care, 2(3),

52–64. https://doi.org/10.1016/j.orhc.2013.08.001

Development of a Purchasing Portfolio Model for the Health Sector: A Case Study of a Central Hospital

337