Towards Self-adaptive Defect Classification in Industrial Monitoring

Andreas Margraf

1 a

, J

¨

org H

¨

ahner

2

, Philipp Braml

2

and Steffen Geinitz

1

1

Fraunhofer IGCV, Am Technologiezentrum 2, 86159 Augsburg, Germany

2

Institute for Computer Science, Augsburg University, Eichleitnerstr. 30, 86159 Augsburg, Germany

philipp.georg.braml@student.uni-augsburg.de

Keywords:

Unsupervised Learning, Image Processing, Stream Clustering, SVM, Carbon Fibres.

Abstract:

The configuration of monitoring applications is usually performed using annotations created by experts. Un-

like many industrial products, carbon fiber textiles exhibit low rigity. Hence, surface anomalies vary to a great

extend which poses challenges to quality monitoring and decision makers. This paper therefore proposes an

unsupervised learning approach for carbon fiber production. The data consists of images continously acquired

using a line scan camera. An image processing pipeline, generated by an evolutionary algorithm is applied to

segement regions of interest. We then cluster the incoming defect data with stream clustering algorithms in

order to identify structures, tendencies and anomalies. We compare well-known heuristics, based on k-means,

hierarchical- and density based clustering and configure them to work best under the given circumstances.

The clustering results are then compared to expert labels. A best-practice approach is presented to analyse

the defects and their origin in the given image data. The experiments show promising results for classifica-

tion of highly specialised production processes with low defect rates which do not allow reliable, repeatable

manual identification of classes. We show that unsupervised learning enables quality managers to gain better

insights into measurement data in the context of image classification without prior knowledge. In addition,

our approach helps to reduce training effort of image based monitoring systems.

1 INTRODUCTION

Enterprise databases that store large numbers of im-

ages require efficient algorithms to provide enough

insights for searching, classification and interpreta-

tion. In the field of production engineering, sensor

data is often stored for quality assurance, yet some-

times without defining their purpose in advance. This

leaves many open question to data scientists and qual-

ity managers who see themselves confronted with a

large source of information but equipped with lim-

ited tools for analysis. Given enough samples are pro-

vided, artificial neural networks (ANN) in general and

deep learning in particular outperform most related

classification algorithms to date. However, the rising

need for annotated samples shifts the effort from algo-

rithm design towards data collection and preparation.

Unsupervised learning instead aims for assigning data

points to classes without prior knowledge or user in-

put. We therefore combine AI with decision sup-

port by implementing an evolutionary programming

approach (CGP) to segment the image data acquired

a

https://orcid.org/0000-0002-2144-0262

by a camera sensor. In a second stage we then apply

clustering algorithms on the regions of interest (ROI)

in order to distinguish the defects by unique fea-

tures. Since we act without prior-knowledge, the ap-

proach can only approximate the classification. How-

ever, it is beneficial for decision makers in the con-

text of process and quality monitoring since it can be

applied without prior knowledge or time-consuming

data preparation.

1.1 Motivation

Many real-world applications, especially those in-

volving online process monitoring (OPM) with op-

tical sensors, call for classification of pre-processed

data. Given a camera system with an on-board

segmentation algorithm returns areas that potentially

contain anomalies but no expert knowledge is avail-

able, how can the data still be analyzed efficiently?

In order to answer this question we propose a clus-

tering based approach for unsupervised learning on

a representative industrial image dataset. The images

contain a top view of a carbon fibre surface (see figure

3). The data was acquired using a high resolution line

318

Margraf, A., Hähner, J., Braml, P. and Geinitz, S.

Towards Self-adaptive Defect Classification in Industrial Monitoring.

DOI: 10.5220/0009893003180327

In Proceedings of the 9th International Conference on Data Science, Technology and Applications (DATA 2020), pages 318-327

ISBN: 978-989-758-440-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

scan camera mounted in the production environment

above the material. Further details on the experimen-

tal setting are given in section 5.

1.2 Relation to Organic Computing

The increasing complexity of multi-sensor systems

allows for new strategies to process data and derive

recommendations for actions. In this paper, we pro-

pose an unsupervised learning approach based on Or-

ganic Computing (OC) (M

¨

uller-Schloer and Tom-

forde, 2017) principles. OC is a recent paradigm

for engineering systems that exhibits so-called self-

x properties e. g., self-adapting, self-configuring or

self-learning. In the present study, we will discuss

strategies for 1) unsupervised model-learning and 2)

self-optimization in an online process monitoring con-

text. Furhermore, the proposed approach is inspired

by the Automated Design of Processing Pipelines

(ADPP) (Stein et al., 2018), a top-level concept which

illustrates the combination and implementation of dif-

ferent learning algorithms.

1.3 Structure

The remainder of this paper is structured as follows:

section 2 gives an overview of the state of the art in

unsupervised learning and clustering algorithms. It

is followed by the problem statement and description

in section 3. We then discuss our approach of unsu-

pervised model learning with stream clustering and

model training for the classification of carbon fibre

defects in section 4. Furthermore, we examine the ap-

plication scenario in an industrial context in section 5

and discuss the results in section 6 before closing by

summing up the scientific findings and giving a per-

spective on future research topics in section 7.

2 RELATED WORK

The following section will give an overview of pub-

lications and scientific work in related fields of re-

search.

In the field of carbon fiber monitoring, Geinitz et

al. and Margraf et al. implemented a testing device

for surface inspection and proposed a machine vision

algorithm in respective publications (Geinitz et al.,

2016), (Margraf et al., 2017a). Besides, Margraf et

al. presented a cartesian genetic programming (CGP)

approach for the design of image filters in monitor-

ing systems (Margraf et al., 2017b). Both works fo-

cus on image processing for the segmentation of de-

fects in carbon fibres whose results provide the data

used in this paper. Also, correlations between the

electric charging properties and the structure of non-

woven fabrics has been exaimed by (Teodorescu et al.,

2013). Unsupervised learning is preferred when per-

forming exploratory tasks with data. As such, Trivedi

et al. discussed the utility of clustering in prediction

tasks (Trivedi et al., ). Furthermore, Xu et al. (Xu

and Wunsch, 2005), Anil K. Jain (Jain, 2010) and

Grira et al. (Grira et al., 2004) examined the ben-

efits of data clustering in several application scenar-

ios. Based on this work, clustering algorithms like

DBSCAN or k-means++ have been introduced (Es-

ter et al., 1996; Arthur and Vassilvitskii, 2007; Schu-

bert et al., 2017). Based on data provided by (Margraf

et al., 2017b) and (Geinitz et al., 2016) this study ex-

plores the possibility to use clustering as suggested

by (Xu and Wunsch, 2005; Jain, 2010; Grira et al.,

2004) to generate interpretable classification models

for carbon fibre defects. Combining clustering with

other machine learning concepts has been examined

- among others - by Chester et al. and Quoc V. Le

(Chester and Ratsaby, 2013; Le, 2013; Ji et al., 2019).

Studies using SVM for classification rely on cluster-

ing algorithms to create the training set, such as (Fin-

ley and Joachims, 2005) or Clustered SVM (Gu and

Han, 2013). Likewise, Yu et al. used hierarchical

clustering (Yu et al., 2003) while Gan et al. applied

k-means (Gan et al., 2017) to train an SVM in the

context of unsupervised classificaiton. Furthermore,

the potential fo ensemble learners on SVM models in

the context of imbalanced data was examined by (Lee

and Lee, 2014). In contrast, stream data is generated

locally from e. g. different sensors and need to be pro-

cessed in short time frames since their value of infor-

mation declines with time. Unsupervised learning al-

gorithms allow for short-term exploration of patterns,

insights and tendencies in data streams. Well-known

heuristics comprise ‘BIRCH’, ‘StreamKM++’, ‘DB-

Stream’ and ‘evoStream’ (Zhang et al., 1996; Ack-

ermann et al., 2010; Hahsler and Bola

˜

nos, 2016;

Carnein and Trautmann, 2018). An overview on the

current state-of-the-art can be found in Carnein et al.

who recently published an extensive survey on stream

clustering (Carnein and Trautmann, 2019). Further-

more, several publications discuss training support

vector machines (SVM) incrementally on successive

subsets (Joachims, 1999; Chen et al., 2003; Laskov

et al., 2006). Furthermore, joining clustering with

ANNs has not been discussed in this study. However,

the authors are well aware of the potential.

Towards Self-adaptive Defect Classification in Industrial Monitoring

319

Table 1: CGP configuration for pipeline evolution.

Parameter Value

µ + λ 1 + 4

Mutation rate 0.38

Termination 200 generations

3 PROBLEM STATEMENT

In general, image processing comprises different

phases which vary from one application to another.

We define the following steps as common among vi-

sion systems: 1) image acquisition, 2) image pre-

processing, 3) filtering and segmentation, 4) classi-

fication and 5) interpretation. In this paper, we fo-

cus exlusively on phases 4 and 5, but still give an

overview on the context of the proposed approach.

In our application scenario, images are acquired

by a line scan camera mounted in a carbon fibre pro-

duction environment (for details see (Geinitz et al.,

2016)). The processing pipeline is generated by

an genetic algorithm denoted cartesian genetic pro-

gramming (CGP). This algorithm evolves image filter

pipelines for the segmentation of regions of interest

(ROI). The configuration is presented in table 1 and

is based on previous work by Margraf et al. (Margraf

et al., 2017b).

In contrast to conventional Genetic Programming

(GP), programs are evolved from nodes on a ge-

netic grid and represented by a directed acyclic graph

(DAG). The DAG constitutes both the genotype and

the phenotype. In CGP, the genetic operators are ap-

plied to a specific genotype representation – an integer

list encoding the DAG. The grid itself now represents

the phenotype. In our example, the genotype consists

of a collection of image filters.

The phenotype is represented by the image filter

pipeline. Therefore, the evolved pipeline consists a

sequence of fine-tuned thresholds, filters, morpholog-

ical and mathematical operators. All filter operators

are taken from the commercial library MVTec HAL-

CON (MVTec, 2018). This pipeline is applied on car-

bon fibre textile images acquired using the aforemen-

tioned line scan camera. As for this study, the result-

ing binary images serve as input data for the classi-

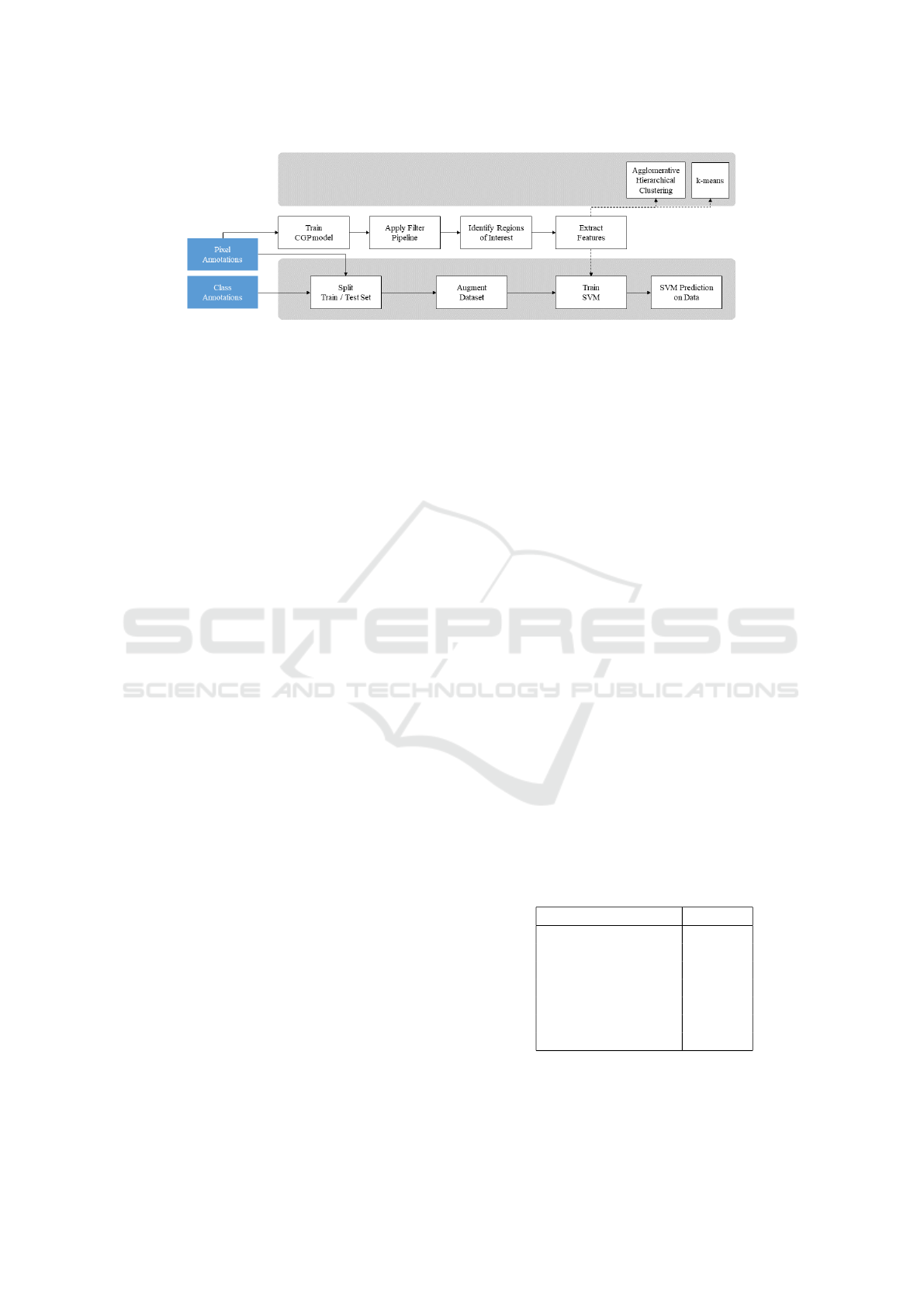

fication model. Figure 1 illustrates the overall work-

flow of our monitoring system.

However, ROIs allow for counting but not classi-

fying defects. The number of anomalies may serve

as a quality indicator. Still, shape and structure usu-

ally carry more information for error search and help

reveal problems with machine configurations. Train-

ing a supervised classifier would take a large amount

of annotated data. In addition, the classification of fi-

bre defects often leaves much room for interpretation.

Therefore, we propose a more independent, ‘neutral’

approach for defect classification with as little human

interference as possible.

3.1 Data Preparation

Unsupervised learning demands data preparation

which can be achieved best by following a proven and

tested workflow. Halkidi et al. suggest the following

order of actions (Halkidi et al., 2001): given a well-

defined dataset, we start by selecting features for the

different clustering heuristics. We follow by validat-

ing the clustering model and close by evaluating the

results.

Thereby feature selection is performed using cor-

relation coefficients (cf. figure 7) in order to iden-

tify parameters that best describe the characteristics

of each data point. As for carbon fibre defects, we

use the ROI to construct all features. The classifica-

tion model is defined as an algorithm that groups data

into partitions. All regarded clustering algorithms use

a proximity measure. However, their input parame-

ters vary from one to another. Validating the plaus-

ability and correctness of a cluster algorithm will be

performed using quality metrics as described in sec-

tion 3.2. These four phases are necessary to generate

plausible class assignments for carbon fibre defects.

3.2 Theoretical Foundations

Clustering can be generally divided into two major

areas:

1. Stationary data clustering (‘offline’)

2. Non-stationary data clustering (‘online’)

Algorithms for stationary data clustering are the more

wide-spread and well-known kind. In times of unla-

belled data streams with large databases in the back-

ground, clustering becomes more important in order

to understand and interpret big data and deduce de-

cisions. Application domains such as social media,

marketing or sales are among the most important ar-

eas in which stream clustering plays a key role. Of

course, there are further areas like the finance and IT

sector in which anomaly or fraud detection, IT secu-

rity, data security and intrusion detection are common

tasks. Furthermore, industries such as e-commerce,

banking or (tele)marketing make heavy use of clus-

tering techniques for transaction data. According

to (Carnein and Trautmann, 2019) stream clustering

algorithms can be gouped into the following cate-

gories: distance-based, grid-based, model-based and

projected

DATA 2020 - 9th International Conference on Data Science, Technology and Applications

320

Figure 1: Flowchart of image processing tasks as usually performed for supervised learning.

One of the main aspects of these kind of algo-

rithms is their ability to incorporate concept drift.

Conventional clustering algorithms run periodically,

which means they are subsequently applied on data

batches which produces ever-changing clustering

‘rules’. Also, periodical repetition means they are

complex and computationally expensive. Stream

clustering, though, are optimized for fast computation

in a continuous flow of data. K-means is a distance-

based algorithm and stands out by its low complexity.

It only takes one parameter k as input. On startup,

k random cluster centres are chosen by selecting k

random data points as cluster centres. Based on the

minimal distance of each data point to a cluster cen-

ter, data points are added to a cluster c

i

. The eu-

clidean distance is used to compute the proximity. In

each iteration, k-means tries to optimize the within-

cluster sum-of-squares criterion (Huang, 1998). In

this study, we dedicate the most attention to k-means

as one of the core methods to process data fast. Hi-

erarchical clustering comprises a family of cluster-

ing algorithms that build clusters by merging or split-

ting partitions. This nested structure of clusters is

often represented in a so called dendrogram, a tree

like structure which plots the degree of merging of

clusters (Gan et al., 2007). Grid-based clustering is

an alternative to density-based approaches. However,

they tend to be more computationally expensive than

density-based clustering. For this reason they are not

further considered in this paper. The field of model-

based clustering is deemed less relevant to this study

and therefore will not be considered in detail.

3.3 The Benefits of Stream Clustering in

Production Monitoring

Stream clustering is used to process data pack-

ages. Production environments often provide a steady

stream of data just as it is the case for carbon fibre

monitoring. During the production process, the cam-

era system continuously acquires and transfers image

data to the vision computer. In a first instance, image

filters are applied so that only ROIs remain for feature

extraction. The complexity of fibre defects calls for

unsupervised data processing. In addition, the data

changes over time in unpredictable ways. Contrast,

shape and size of defects vary depending on the pre-

cursor (the incoming raw material), configuration or

possible malfunctions. This leads to expected anoma-

lies and unkown, therefore unexpected anomalies. It

should be possible to identify tendencies and actual

changes from data streams over time. However, the

outcome cannot be trained in a model, so data stream

clustering remains the most practical solution.

The authors are aware of the variety of available

stream clustering algorithms which potentially fit the

task described in this paper. For reasons of efficieny

we examine one of the most promising clustering al-

gorithms and apply it to the problem at hand. In addi-

tion, we propose a novel approach to create an inter-

pretable SVM model which is adapted over time.

4 APPROACH

As a start, the images are segmented using a series of

filters and morphological operations to derive regions

of interests (ROI). The classes are then used to clas-

sify the segmented regions with a variety of methods.

Table 2: Features computed from each ROI with corre-

sponding intervalls.

Feature Intervall

Aspect Ratio [0, ∞[

Extent [0, ∞[

Solidity [0, ∞[

Equivalent Diameter [0, ∞[

Orientation Angle [0, 360]

Perimeter [0, ∞[

Circularity [0,1.0]

After image filtering, we select the defect fea-

tures based on the extracted ROIs. The feature values

are used for later assignment to one of the categories

Towards Self-adaptive Defect Classification in Industrial Monitoring

321

Figure 2: Flowchart of online clustering with updated SVM performed on the dataset.

which comprise fuzzball, filament crack, misaligned

filament, loop, contaminant, artefact and other. All

features are listed in table 2 with corresponding inter-

vals. Except for circularity, all features are based on

contour properties computed with functions from the

OpenCV framework. The circularity is computed as

follows:

circularity =

4 · π · area

perimeter

2

(1)

In earlier experiments, we found that defects

are difficult to distinguish reliably and consistently.

Among experts we noticed contradictions and incon-

sistencies when asked to classify fibre defects man-

ually. The study was conducted based on Gauge

Repeatability and Reproducability (Gauge R&R), a

method adopted from the six sigma standard (Baner-

jee et al., 1999). The results are discussed in section

6. The need to classify data without a priori knowl-

edge finally encouraged the implementation of unsu-

pervised learning techniques.

4.1 Definition of KM-SVM

The algorithm is defined as follows: a score is com-

puted and compared against a predefined threshold to

determine the number of clusters created by a cluster-

ing algorithm. The number of clusters is recomputed

in constant intervalls. This value then serves as an in-

dicator for critical changes in the data structure, e. g.

occurrence of new anomalies.

For the determination of the number of clusters the

algorithm relies on the silhouette score s(o), a score

that varies between -1 and 1. It describes the the dif-

ference of distances of object o to cluster center A

(nearest cluster) and B (intra cluster distance) over the

maximum of the distance dist(A, o) and dist(B, o) and

is therefore defined as follows:

S(o) =

dist(A, o) − dist(B, o)

max{dist(A, o), dist(B, o)}

(2)

Furthermore, the silhouette coefficient s

C

represents

the arithmetic mean of all n

c

silhouettes of cluster C:

s

C

=

1

n

C

∑

o∈C

S(o) (3)

All subsequent data batches are then processed

using the new SVM model. The algorithm as pre-

sented in listing 1 is continuously run on the batch

to determine the best number of clusters under the

current condition. If the proposed number of clus-

ter best n deviates from the moving average MA(K)

with ±δ · MA(K) over N iterations, the SVM model

is recreated. By using the moving average as a ref-

erence, the effect of outliers on model training is

flattened. Only high impact changes in the series

of values for k over several consecutive iterations

will trigger an SVM model update. Experiments on

the dataset revealed, that the most stable curve was

achieved for N = 20. The deviation parameter δ is

set to 0.1. The SVM implementation used for the ap-

proach is based on the library libSVM and the python

library sklearn. The SVM is set to use rbf for the

kernel, a regularization parameter C = 1.0 and ‘scale’

for gamma. Furthermore, k-means++ is applied to

cluster the data from features on the first batch. The

incoming data stream is processed in batches of the

same size. For the experiments the batch size is set to

200 data points to be processed in each iteration. The

batch processing function is defined as algorithm 1.

The silhouette coefficient s(k) usually declines

with increasing k. However, a global maximum is

likely to be found for higher values of k. Therefore,

k is incremented as long as s(k) increases. Also, in

order to avoid an infinite loop, a termination criterion

of max k = 20 is defined. In addition, if s(k) drops

below a value of 0.7 or below 90% of the maximum

silhouette value to this iteration, the search is termi-

nated because no more improvements are expected.

The heuristic is implemented as described in the al-

DATA 2020 - 9th International Conference on Data Science, Technology and Applications

322

Algorithm 1: Process batch with KM and SVM.

Input: Batch, Model, δ

set K = {}, P = {} set M = {};

Determine the best number of clusters best k

for Batch;

Add k

best

to K;

if |M| > 1 then

Compute the Moving Average

MA(K, N, k) of K over N iterations and

insert it in M;

end

if n

i

! = k

i

∧ n

i

! = N

i−1

∧ MA(K, N, k)! =

MA(K, N, k

i−1

) then

Compute cl f

km++

with ‘k-means++’ of

Batch with best k;

Compute predictions Pred

km++

of Batch

with cl f

km++

;

end

if Model Is not Empty ∧

best k ∈ [(1 − δ) · MA(K), (1 + δ) · MA(K)]

then

Create predictions Pred

SV M

with

Model(Batch);

insert Pred

SV M

in P;

else

Train Model

SV M

with SVM(Batch,

Pred

c

);

end

return P, Model

gorithm listing 2.

For the time-critical environment we prefer

density-based algorithms over grid-based and model-

based approaches. They are computationally inexpen-

sive and suit the given clustering task well. This is the

main reason for choosing k-means++ for algorithm

2. Furthermore, implementations for the selected al-

gorithms are applicable with little effort. We therefore

denote this approach KM-SVM.

In summary, we deem the approach proposed in

this paper superior to traditional clustering in terms

of flexibility, reproducability and interpretability. The

experiments are designed to test this hypothesis. In

section 5, the experimental setup is explained in detail

while in section 6 the results are critically reflected.

5 EXPERIMENTS

The evolved image processing pipeline consists of

the following operators: sobel edge detector, gradi-

ent threshold, erosion using circle geometry and con-

nected component filtering. The camera was set to

Algorithm 2: Find best number of clusters.

Input: F, max iter = 20, min s = 0.7,

min delta = 0.9

set s(k) = 0, n = 2, best n = 2;

set Deltas = {}, Silhouettes = {};

while nb iter < max iter do

set Labels = ‘k-means++’ from F with

k = n;

Compute s(Labels) with

metric =

0

euclidian

0

;

Insert s(Labels) in Silhouettes;

if |Silhouettes| ≥ 3 then

∆s(i) = s(i) − s(i − 1) ;

insert ∆s(i) in Deltas;

for i ← 0 to |Deltas| do

if s(i) − max{s} > s(i − 1) then

set best n = n;

end

if s(i) − max{Deltas} <

min delta · max{Deltas} ∨

s(i) < min s then

return;

end

end

else

insert 0 in Silhouettes;

end

increment n;

end

return k, s(k)

scan the surface of carbon fibres. In result, the im-

ages showed a hetergenous structure of carbon fibres

aligned from top to bottom due to the tension from

the spooling system. Every time a single fibre cracks,

its tension rapidly declines which enables it to bounce

back and rest on the surface of the fibre carpet. Fur-

thermore, degenerated material from other rovings or

even alien material may form fuzzballs, a bulky col-

lection of textiles which also rest on the surface. An

example of fibre defects as they occurr in the images

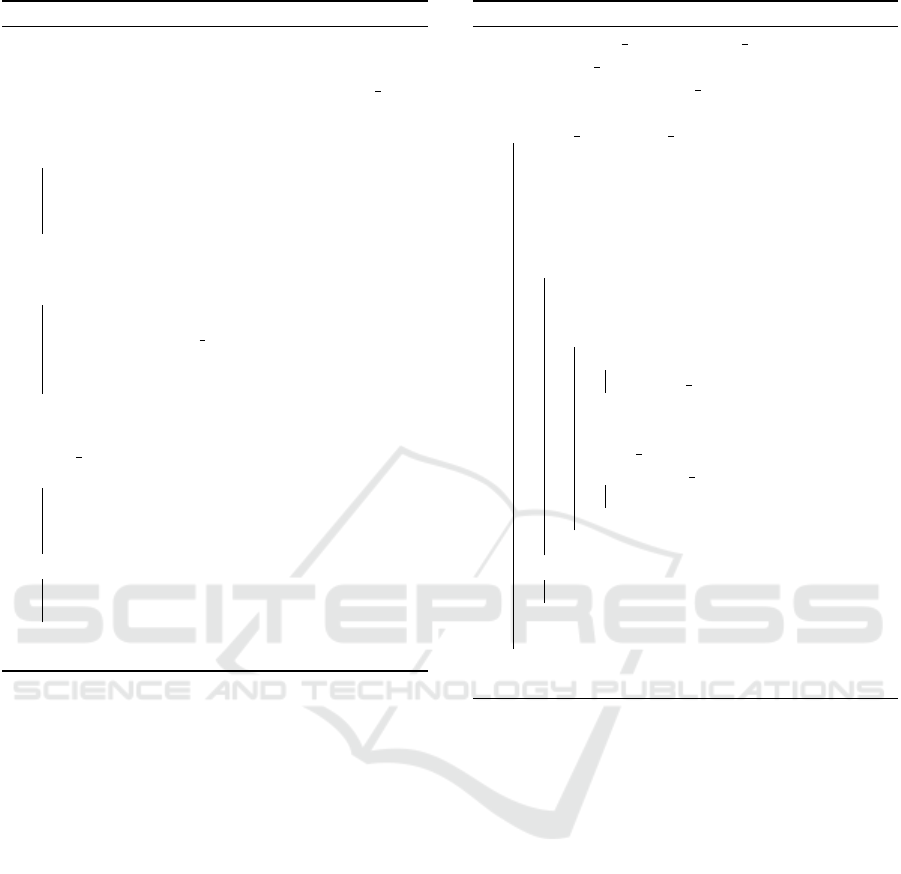

can be seen in figure 3.

5.1 Interrater Agreement Study

We conducted an interrater agreement study to test

the reliability of the measurement equipment for de-

fect classification. Five experts from our institution

who were not directly involved in the project kindly

agreed to manually classify defects from the test set.

The experiment was conducted as follows: 5

classes were defined prior to the study. Then 19 im-

ages acquired from the camera in which the defects

were already segmented by an image filter pipeline

Towards Self-adaptive Defect Classification in Industrial Monitoring

323

Figure 3: View of a carbon fiber roving sample with seg-

mented and clustered defects. The colored areas represent

regions of interest which are feed to the algorithm as binary

images.

were presented to 5 appraisers. Each appraiser was

asked to assign each defect to a given class without

exchanging information with the other appraisers nor

asking questions to the study supervisors. Each ap-

praiser had to repeat the manual classification three

times, each time without being allowed to view previ-

ous ratings. The level of agreement within the ap-

praisers, denoted interrater agreement, can be de-

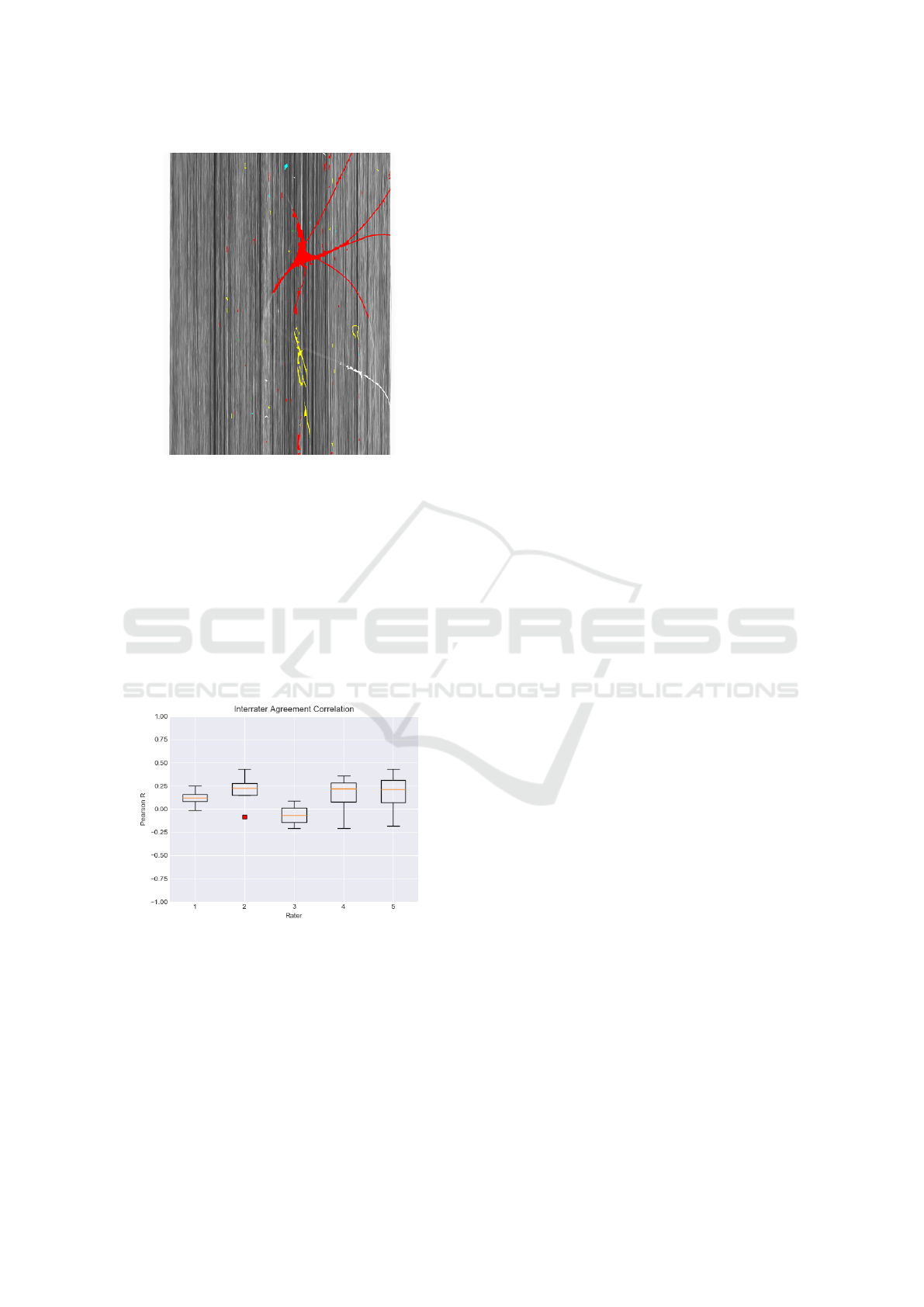

duced from the statistical results given in figure 4.

Figure 4: Interrater agreement analysis showing the statisti-

cal spread of the pearson correlation value ρ for 5 indepen-

dent raters over 3 rounds.

In general, the pearson correlation coefficient

ranges between +1 and −1 where 1 represents lin-

ear correlation and high agreement, 0 is no linear cor-

relation and −1 indicates negative linear correlation,

therefore maximum disagreement. As can be seen in

figure 4, the correlation coefficient ρ never exceeds

0.4, but drops below 0 for 3 appraisers. Although the

mean ranges between 0 and 0.025, for one appraiser it

is slightly below 0. Two out of five, appraisers 4 and

5, show substantial statistical spread which suggests

contradictions in their own evaluation.

The Fleiss’ kappa calculation on interrater data

returned the following κ values for rounds 1 to 3:

κ

1

= −0.063, κ

2

= −0.061, κ

3

= −0.062. Over all

rounds, a total Kappa value of κ

total

= −0.060 was

returned.

In summary, all values of ρ are close to ρ = 0 and

all values of kappa are κ < 0 which shows little to no

correlation between appraisers and therefore poor in-

terrater agreement. This data raises the question how

even trained raters can be as inconsistent when assess-

ing carbon fibre defects. As mentioned before, shape,

structure and occurrence of fibre anomalies vary to

a large extent. Due to little redundancy, no defect

catalogue or golden sample could be collected so far.

This suggests that a reliable and reproducible classifi-

cation of defects cannot be guaranteed in this context.

We therefore strive for a transparent, independent and

automated approach to generate classification models

that can be used for decision support as provided by

our novel algorithm.

6 RESULTS AND DISCUSSION

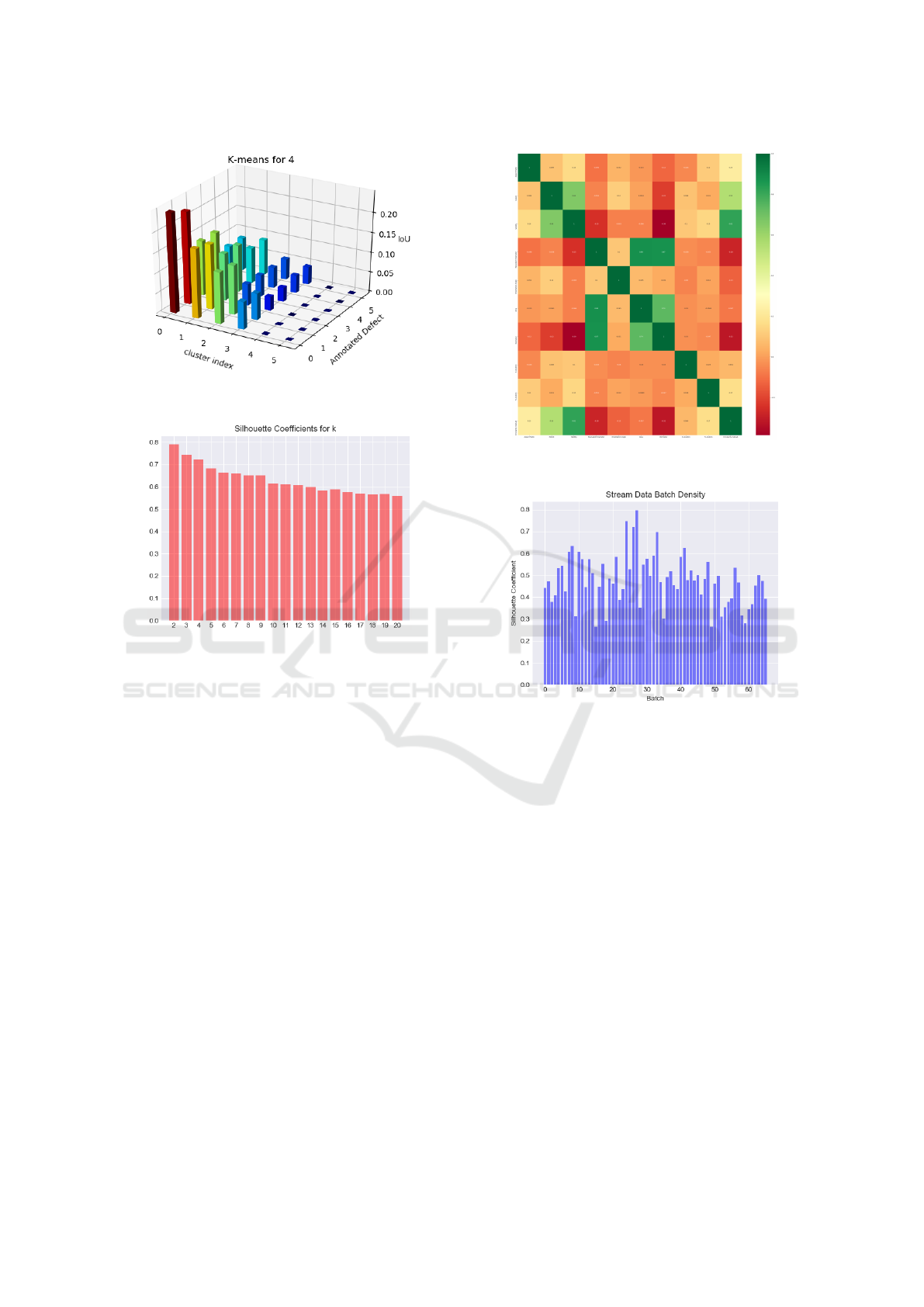

After applying the k-means clustering algorithms on

the dataset, we evaluate the cluster quality and com-

pare it to expert annotations. Likewise, we then apply

KM-SVM. For better understanding, we plot the data

points of the most important features and illustrate the

cluster results by adding colors.

6.1 Evaluation of Clustering Algorithms

For deeper insights into the dataset, the similarity of

the clusters with the expert annotations from the ref-

erence dataset is computed. For this experiment, k-

means++ is run on the whole dataset. As a similarity

score, IoU is computed to measure the similarity as

defined in section 3.2. The similarity results of each

cluster compared to each of the manually annotated

defect class are presented in figure 5 for k = 4 since

this is the number of clusters returned by KM-SVM

for the majority of batches.

As figure 8 suggests, the silhouette coefficient s(k)

decreases from a value of 0.8 for k = 2 to a value

of 0.6 for k = 20. Not surprisingly, s(k) returns the

highest value at k = 2, but the second highest value

of 0.7 occurs for k = 4. This is a comparably high

density score for k > 2.

DATA 2020 - 9th International Conference on Data Science, Technology and Applications

324

Figure 5: IoU for annotations on the carbon fibre dataset

and k-means clustering with k = 4.

Figure 6: Silhouette coefficients for 2 ≤ k ≤ 20 on the whole

dataset.

Figure 7 shows the correlation between the fea-

tures computed on the ROIs. The highest positive cor-

relation with ρ

X,Y

> 0.8 can be measured between the

following features: circularity and solidity, area and

equivalent diameter, perimeter and equivalent diam-

eter. The closest value to inverse correlation, which is

defined as ρ

X,Y

= −1.0, was computed for the follow-

ing features with ρ

X,Y

< −0.30: perimeter and solid-

ity, circularity and perimeter.

6.2 Batch Data Processing and

Clustering

For the batch processing we set a batch size of 50 de-

fects and a silhouette coefficient threshold of 0.7 as

suggested in section 4. The cluster density is mea-

sured using the silhouette coefficient s(b

i

) for each

batch b

i

as depicted in figure 8. The curve peaks

for batch i = 27 at a value of s(b

27

) = 0.8. In gen-

eral, s(b

i

) ranges between 0.27 and 0.8. 49 out of 66

batches reach a silhouette coefficient of s(b

i

) > 0.4,

17 out of 66 exceed a value of 0.5. This indicates

that overall the data points are well matched to their

cluster centres in the individual batches.

Figure 7: Correlation matrix for all high-level features ac-

quired from the image dataset.

Figure 8: Silhouette coefficient values for clusters of

batches 1 − 66.

The number of clusters peaks at batches 4 and 49

at k = 10 as can be seen in figure 9. For 25 out of

66 batches, the suggested value for k ranges between

5 and 8. For the remaining 39 batches the algorithm

suggests k = 4.

As can be seen in figure 9 the moving average

smoothes potential outliers and still reveals the over-

all trend. A model update is initiated for batches

{17, 30, 39, 40, 55, 65} as in these cases the moving

average exceeds the running value of k with MA(k) >

k + 1. Thereby, updating the SVM model is only trig-

gered if the general trend continues for several iter-

ations, therefore shows an underlying change in the

data distribution.

KM-SVM appears more flexible with little con-

figuration effort compared to neural network ap-

proaches or regular linear SVM. The algorithm read-

justs k only if a stable trend is detected. In real-

world environments where stream data needs to be

constantly processed, it might be beneficial to com-

pute feature extraction on GPU or FPGA processors

Towards Self-adaptive Defect Classification in Industrial Monitoring

325

Figure 9: Number of clusters computed for batches 1 − 66

with moving average (red).

to increase performance. This will be part of future

work.

7 SUMMARY AND OUTLOOK

7.1 Conclusions

This study points out that for specific use cases

a goal-oriented use of unsupervised learning may

improve understanding of multi-dimensional data

spaces. From the presented results we can conclude

that clustering allows for an actual unsupervised clas-

sification of defects on textile surface images. The

study indicates that application of clustering creates

promising outcomes and supports quality assurance

decisions. The approach avoids high annotation effort

which would be necessary for supervised models. The

proposed clustering algorithms give more detailed in-

sights into the structure of the data and help to set lim-

its to a) the depth of classification and b) the balance

of the data set.

Furthermore, especially complex models decrease

transparency and render it difficult to trace back single

decisions in order to adapt the model.

7.2 Future Research

Future research will be conducted using OC tech-

niques in order to design systems with an even higher

level of self-adaptation. For this reason, our research

work is focused on classifiers which can be trained

and configured using very little data. In addition, this

paper has not sufficiently examined the benefits of ac-

tive learning. The option of human involvement as

an e. g. partial supervisor might help to compen-

sate some general flaws of clustering strategies and

improve the overall classification results. This would

fall under the umbrella of semi-supervised or active

learning which aims to combine the best of both, the

supervised model training and unsupervised learning.

In the field of online classification, the integration and

implementation of a self-adapting and self-learning

unit to enable clustering to work in changing environ-

ments, e. g. a running production line, will be at the

centre of interest in future projects.

ACKNOWLEDGEMENT

This research and development project is partly

funded by the German Federal Ministry for Economic

Affairs and Energy (BMWi) within the research pro-

gram ”LuFo V-2” managed by the German Aerospace

Center (DLR). The authors would like to thank SGL

Carbon GmbH for their contribution.

REFERENCES

Ackermann, M., Lammersen, C., M

¨

artens, M., Raupach,

C., Sohler, C., and Swierkot, K. (2010). Streamkm++:

A clustering algorithms for data streams. volume 17,

pages 173–187.

Arthur, D. and Vassilvitskii, S. (2007). k-means++: The

advantages of careful seeding. In Proceedings of the

eighteenth annual ACM-SIAM symposium on Discrete

algorithms, pages 1027–1035. Society for Industrial

and Applied Mathematics.

Banerjee, M., Capozzoli, M., McSweeney, L., and Sinha,

D. (1999). Beyond kappa: A review of interrater

agreement measures. Canadian Journal of Statistics,

27(1):3–23.

Carnein, M. and Trautmann, H. (2018). evostream — evo-

lutionary stream clustering utilizing idle times. Big

Data Research, 14:101 – 111.

Carnein, M. and Trautmann, H. (2019). Optimizing data

stream representation: An extensive survey on stream

clustering algorithms. Business & Information Sys-

tems Engineering, 61(3):277–297.

Chen, Y., Wang, G., and Dong, S. (2003). Learning with

progressive transductive support vector machine. Pat-

tern Recognition Letters, 24(12):1845–1855.

Chester, U. and Ratsaby, J. (2013). Machine learning

for image classification and clustering using a uni-

versal distance measure. In Brisaboa, N., Pedreira,

O., and Zezula, P., editors, Similarity Search and Ap-

plications, pages 59–72, Berlin, Heidelberg. Springer

Berlin Heidelberg.

Ester, M., Kriegel, H.-P., Sander, J., Xu, X., et al. (1996).

A density-based algorithm for discovering clusters in

large spatial databases with noise. In Kdd, volume 96,

pages 226–231.

Finley, T. and Joachims, T. (2005). Supervised clustering

with support vector machines. In Proceedings of the

22nd international conference on Machine learning,

pages 217–224.

DATA 2020 - 9th International Conference on Data Science, Technology and Applications

326

Gan, G., Ma, C., and Wu, J. (2007). Data clustering: theory,

algorithms, and applications, volume 20. Siam.

Gan, J., Li, A., Lei, Q.-L., Ren, H., and Yang, Y. (2017).

K-means based on active learning for support vector

machine. In 2017 IEEE/ACIS 16th International Con-

ference on Computer and Information Science (ICIS),

pages 727–731. IEEE.

Geinitz, S., Margraf, A., Wedel, A., Witthus, S., and Drech-

sler, K. (2016). Detection of filament misalignment in

carbon fiber production using a stereovision line scan

camera system. In Proc. of 19th World Conference on

Non-Destructive Testing, Munich, Germany.

Grira, N., Crucianu, M., and Boujemaa, N. (2004). Unsu-

pervised and semi-supervised clustering: a brief sur-

vey. A review of machine learning techniques for pro-

cessing multimedia content, 1:9–16.

Gu, Q. and Han, J. (2013). Clustered support vector ma-

chines. In Artificial Intelligence and Statistics, pages

307–315.

Hahsler, M. and Bola

˜

nos, M. (2016). Clustering data

streams based on shared density between micro-

clusters. IEEE Transactions on Knowledge and Data

Engineering, 28(6):1449–1461.

Halkidi, M., Batistakis, Y., and Vazirgiannis, M. (2001). On

clustering validation techniques. Journal of intelligent

information systems, 17(2-3):107–145.

Huang, Z. (1998). Extensions to the k-means algorithm for

clustering large data sets with categorical values. Data

mining and knowledge discovery, 2(3):283–304.

Jain, A. K. (2010). Data clustering: 50 years beyond k-

means. Pattern recognition letters, 31(8):651–666.

Ji, X., Henriques, J. F., and Vedaldi, A. (2019). Invariant

information clustering for unsupervised image classi-

fication and segmentation. In Proceedings of the IEEE

International Conference on Computer Vision, pages

9865–9874.

Joachims, T. (1999). Transductive inference for text classi-

fication using support vector machines. In Icml, vol-

ume 99, pages 200–209.

Laskov, P., Gehl, C., Kr

¨

uger, S., and M

¨

uller, K.-R. (2006).

Incremental support vector learning: Analysis, imple-

mentation and applications. Journal of machine learn-

ing research, 7(Sep):1909–1936.

Le, Q. V. (2013). Building high-level features using large

scale unsupervised learning. In 2013 IEEE interna-

tional conference on acoustics, speech and signal pro-

cessing, pages 8595–8598. IEEE.

Lee, J. and Lee, J.-H. (2014). K-means clustering based

svm ensemble methods for imbalanced data prob-

lem. In 2014 Joint 7th International Conference on

Soft Computing and Intelligent Systems (SCIS) and

15th International Symposium on Advanced Intelli-

gent Systems (ISIS), pages 614–617. IEEE.

Margraf, A., Geinitz, S., Wedel, A., and Engstler, L.

(2017a). Detection of surface defects on carbon fiber

rovings using line sensors and image processing algo-

rithms. In Proceedings of the SAMPE Europe Confer-

ence 2017 Stuttgart.

Margraf, A., Stein, A., Engstler, L., Geinitz, S., and H

¨

ahner,

J. (2017b). An Evolutionary Learning Approach to

Self-configuring Image Pipelines in the Context of

Carbon Fiber Fault Detection. In Proceedings of

the 16th IEEE International Conference for Machine

Learning and Applications.

M

¨

uller-Schloer, C. and Tomforde, S. (2017). Organic Com-

puting: Technical Systems for Survival in the Real

World. Autonomic Systems. Birkh

¨

auser, Cham, 1st

edition.

MVTec (2018). Halcon a product of mvtec.

Schubert, E., Sander, J., Ester, M., Kriegel, H. P., and Xu,

X. (2017). Dbscan revisited, revisited: why and how

you should (still) use dbscan. ACM Transactions on

Database Systems (TODS), 42(3):19.

Stein, A., Margraf, A., Moroskow, J., Geinitz, S., and

H

¨

ahner, J. (2018). Toward an organic computing ap-

proach to automated design of processing pipelines. In

ARCS Workshop 2018; 31th International Conference

on Architecture of Computing Systems, pages 1–8.

Teodorescu, H.-N., Dascalescu, L., Hulea, M., and Plo-

peanu, M. C. (2013). Correlations between the elec-

tric charging properties and the optically determined

structure of non-woven fabrics. Journal of Electro-

statics, 71(4):635–647.

Trivedi, S., Pardos, Z. A., and Heffernan, N. T. The utility

of clustering in prediction tasks.

Xu, R. and Wunsch, D. C. (2005). Survey of clustering

algorithms.

Yu, H., Yang, J., and Han, J. (2003). Classifying large data

sets using svms with hierarchical clusters. In Proceed-

ings of the ninth ACM SIGKDD international confer-

ence on Knowledge discovery and data mining, pages

306–315.

Zhang, T., Ramakrishnan, R., and Livny, M. (1996). Birch:

an efficient data clustering method for very large

databases. ACM Sigmod Record, 25(2):103–114.

Towards Self-adaptive Defect Classification in Industrial Monitoring

327