Control of Sewer Flow using a Buffer Tank

K. M. Nielsen

1

, T. S. Pedersen

1

, C. Kallesøe

1

, P. Andersen

2

, L. S. Mestre

2

and P. K. Murigesan

2

1

Automation & Control, Department of Electronic Systems, Aalborg University, Aalborg, Denmark

2

Control & Automation, Aalborg University, Denmark

Keywords:

Sewer Flow Modelling, Model Predictive Control.

Abstract:

Flow variations of the inlet to a wastewater treatment plant (WWTP) are problematic due to the biological

purification process. A way to reduce variations from industrial areas is to insert a buffer tank. Traditionally

the only on-line measurement is the inlet flow to the wastewater treatment plant and reliable measurements in

the system are difficult to establish. A control scheme using only one on-line measured variable is shown to

be able to give considerable reduction in the flow variations. To implement the control scheme two models

are introduced. A linear model (delay model) from the buffer tank to the wastewater treatment plant and an

autonomous model describing the daily variations in the household sewer flow. A Model Predictive Controller

has been designed and tested in a laboratory set-up with good results.

1 INTRODUCTION

The topic within this paper is flow control for opti-

mization of wastewater treatment systems. The sewer

system drains wastewater from industries and pri-

vate households. A sewer system network consists

of gravity pipes, pressurized pipes, pumps, manholes,

weirs etc. making up a complex system. In this work,

the sewer network in the Danish city Fredericia with

approximately 50000 inhabitants is in focus.

The wastewater is comprised of different pollu-

tants like phosphor, nitrogen and biologically degrad-

able components characterized by Chemical Oxygen

Demand (COD). The inlet to the WWTP is varying

due to daily variations in household wastewater, vary-

ing industrial outlets and different time delays from

these sources to the WWTP inlet. In addition, precip-

itation causes irregular variations. In Fredericia in dry

periods 60 % to 70 % of the wastewater comes from

industries. The sewer system as well as the biologi-

cal processes are complex and further it is difficult to

make on-line measurements of the pollutants. A de-

tailed description of all phenomena is extremely com-

prehensive as seen in e.g. the simulation tool WATS

(T. Hvitved-Jacobsen et al., 2013),(DHI, 2017) and is

not well suited for controller design. In this work,

only COD is taken into account and furthermore it

is assumed that no biological processes takes place

in the sewer network. Therefore, a simple model de-

scribing the main dynamics is formulated.

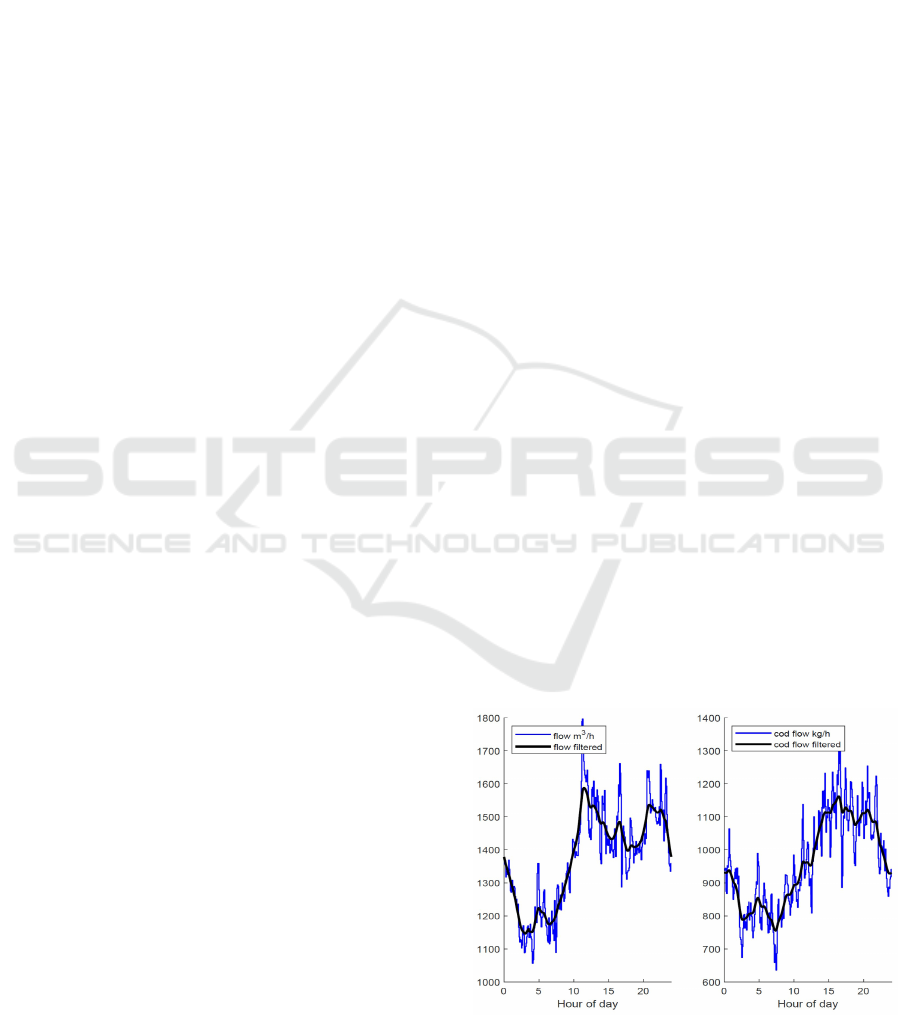

In Fredericia the only available real time on-line

measurement is the inlet flow to the WWTP. Off-

line measurements of COD, nitrate and phosphor are

available from October 2017. The average and fil-

tered average of the total flow as well as the COD

flow in October 2017 are shown in Fig.1. Flow and

COD measurements are sampled from the inlet to the

WWTP. As seen in Fig.1 the shape of the COD and

flow inlet are similar, therefore only control of the

flow to WWTP is investigated in this work. Varia-

tion in the COD-flow can be considered in a similar

way and will be considered in a continuation of the

work.

Figure 1: 24 hours average flow and COD based on mea-

surements from 30 days at the inlet to Fredericia WWTP.

(Schlutter, 1999). Here, it is assumed there is no infiltration

by the groundwater into the sewer system.

Nielsen, K., Pedersen, T., Kallesøe, C., Andersen, P., Mestre, L. and Murigesan, P.

Control of Sewer Flow using a Buffer Tank.

DOI: 10.5220/0009871300630070

In Proceedings of the 17th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2020), pages 63-70

ISBN: 978-989-758-442-8

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

63

A way to minimize the flow variations is to insert

buffer tanks in the sewer network and control the out-

puts from these. At the moment no buffer tanks are

available in the sewer system in Fredericia but are to

be planned. A logical place for a buffer tank is close

to the industrial outlets. An algorithm to control the

outflow from the buffer tank in order to minimize flow

variations at the inlet to WWTP is developed. Control

of sewer systems are described in (Ocampo-Martinez,

2005), (Marinaki and Papageorgiou, 2005), (Over-

loop, 2006), (Pilgaard and Pedersen, 2018), (Mestre

and Murugesan, 2019).

To design a controller, models of the buffer tank,

the sewer network, the household flows and industrial

flows are necessary.

A simple tank model based on a mass balance is

used. A dynamic model describing main character-

istics of the sewer network is formulated; here it is

shown that the Saint-Venant equations under certain

assumptions can lead to a delay model. The model

describing the flows from households to the WWTP

is an autonomous state space model where the coef-

ficients are based on the Fourier transform of mea-

surements from one month Fig. 1. The outflow from

industry is estimated from 24 hours measured time se-

ries.

A Model Predictive Controller (MPC) with a per-

formance function aiming to minimize the variance

of inlet flow to the WWTP has been formulated given

buffer tank volume constraints.

To test the benefit of a buffer tank inserted in the

sewer system a laboratory setup (Smart Water Lab) is

used.

In section 2 the Fredericia sewer system is de-

scribed. Section 3 considers the control concept. The

sewer system modelling is described in section 4.

Section 5 is a description of the actual control of the

buffer tank output. The control concept is tested in the

laboratory which is described in section 6 and finally

the conclusion is in section 7.

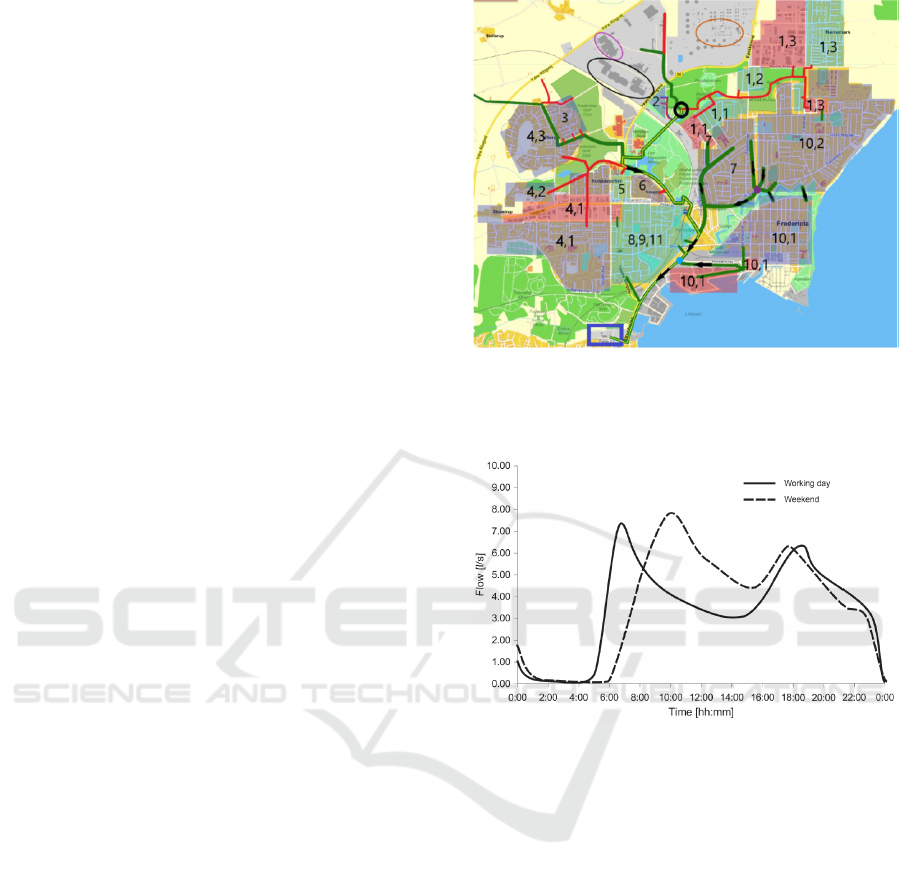

2 FREDERICIA SEWER SYSTEM

Fredericia wastewater treatment plant covers the town

of Fredericia, nearby villages and industrial areas

north and west of the town. The total sewer net is

among the largest in Denmark. Households and in-

dustrial areas north and west of the town dominate the

wastewater in Fredericia. The map shows the north-

ern part of Fredericia divided in subareas. A large

number of pipes leads to the WWTP. In this work, the

pipes from the industrial areas to the WWTP are con-

sidered. These are indicated in the map Fig. 2.

Figure 2: Main sewer system in Fredericia, (Pilgaard and

Pedersen, 2018). The blue square is the WWTP, oval shapes

are industrial areas, black circle is inlet from industry to the

main pipe.

Figure 3: 24 hours average household flow from 2000 in-

habitants Wastewater production from a small village Fre-

jlev, Denmark, Here, it is assumed there is no infiltration by

the groundwater into the sewer system (Schlutter, 1999).

Household wastewater is predictable with regard

to flow. Fig. 3 shows typical average emission from

2000 inhabitants in an area without industries. As

seen in Fig. 2, the area covered by the wastewater

plant is large and the sewer network is split into nu-

merous branches implying that the shape of the inflow

from the households to the wastewater treatment plant

is influenced by varying delays in flow.

In the WWPT, the quality of the wastewater treat-

ment and biogas production are dependent on the in-

flow, as the biological processes need time for scal-

ing. Control of the inlet flow will potentially improve

the quality of the WWTP processes. A case study

with one industrial plant is investigated; it comprises

one buffer tank placed close to the industrial plant,

the sewer network from the buffer-tank to the WWTP

and one model for the entire household flow to the

WWTP.

ICINCO 2020 - 17th International Conference on Informatics in Control, Automation and Robotics

64

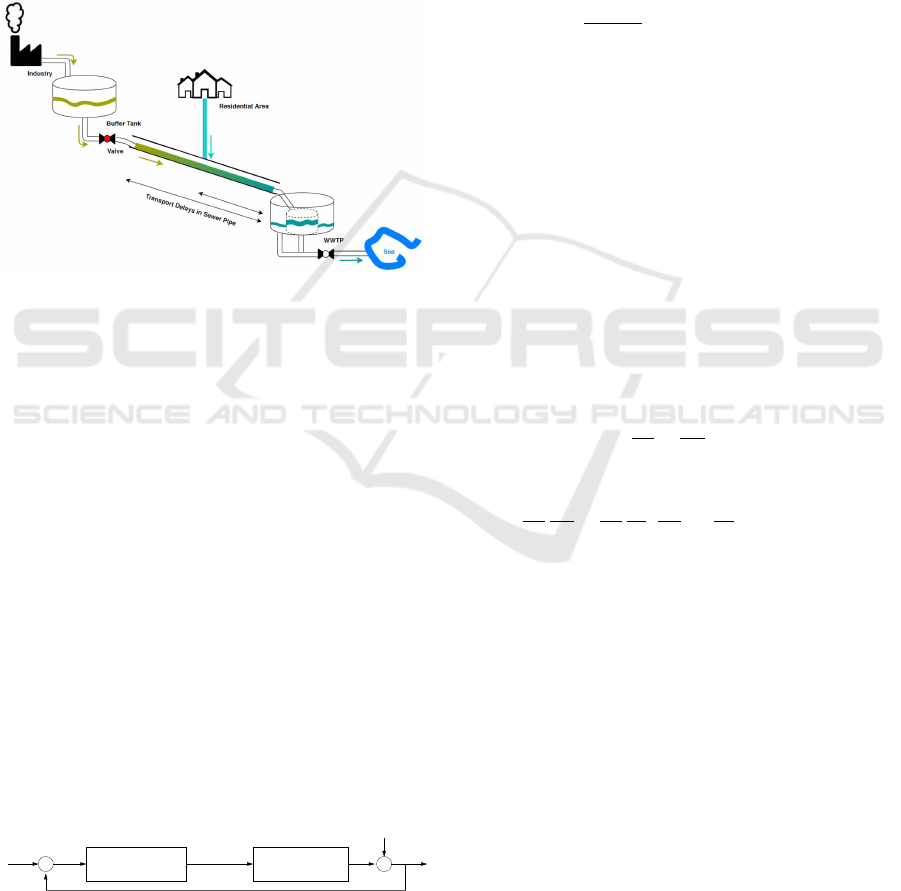

3 CONTROL CONCEPT

The main goal for the control system is to reduce the

fluctuations in the inlet flow, Y , to the WWTP. The as-

sumptions are that the only measurement is Y and the

only controllable variable is the outlet flow U from

the buffer tank. The inlet flow from industries to the

buffer tank is Q

i

. Y

re f

is the WWTP inlet flow refer-

ence. In this work, we look at one buffer tank. The

concept for controlling this may easily be extended to

more detention tanks. In Fig. 4 shows a sketch of the

simplified system.

Figure 4: Simplified sewer system with the main compo-

nents buffer tank, households, sewer pipe and WWTP.

A classical control concept is illustrated in Fig.

5. Q

h

is the total household flow disturbance and is

seen as a flow directly to the WWTP. The model of

the main pipe may include a transport delay; there-

fore, a classic controller will result in a low bandwidth

and poor disturbance rejection (Aastrom and Haeg-

glund, 2006), (Postlethwaite and Skogestad, 2005).

The disturbance is periodic, see Fig.3, this periodic-

ity is difficult to include in a classic control concept.

It is well known from the classical control theory that

cascading can improve the performance. More flow

measurements in the main pipe will make this pos-

sible and up-stream measurements of the household

flow could be used as feed forwards. Iterative learn-

ing control could be another way to improve a clas-

sic controller and a third concept is to use a neural

network. Model Predictive Control (MPC) relies on

predictions of future system behavior. In this case

household wastewater flow shows periodicity and the

delay times in the sewer net can be found, therefore

the MPC method is chosen.

+

ref

Q

h

U Y

Controller Main pipe

+

−

+

Y

Figure 5: Classical control concept for the problem showing

inputs, outputs and disturbances.

4 MODELLING THE SEWER

SYSTEM

The model for the MPC consists of a tank model, a

model of the sewer network, a household disturbance

model and a description of the industrial wastewater

flow.

The Tank Model

The tank is modelled as an integrating system

ρdV (t)

dt

= ρQ

i

(t) − ρU(t) (1)

Where V is the volume of wastewater in the tank

and ρ is the density. It is assumed that ρ is a constant.

The discrete version is:

V (k + 1) = V (k) + T

s

(Q

i

(k) −U (k)) (2)

Where T

s

is the sample time.

The Sewer Network Model

The pipes are generally not filled and considered as

open channels. The flow and the level in sewer net-

works are usually modelled by the Saint-Venant equa-

tions (Crossley, 1999), (frese.dk, 2018), (Andersen,

1977), (Michelsen, 1976). The general form of the

Saint-Venant equations are

∂A

∂t

+

∂Q

∂x

= 0 (3)

1

gA

∂Q

∂t

+

1

gA

∂

∂x

(

Q

2

A

) +

∂h

∂x

+ S

f

− S

b

= 0 (4)

where Q is the sewage flow [m

3

/s], A is the cross-

sectional area of the sewage flow [m

2

], h is the level

in the pipes [m], S

b

is the slope and S

f

is the fric-

tion. x is a spatial variable measured in the direction

of the flow [m], t is time [s] and g is gravitational ac-

celeration [m/s

2

]. If COD is included in the control a

supplementary equation is used to describe this.

These equations are not linear and thereby not

well suited for MPC. A simplified linear model is de-

rived.

The transport of fluids could also be seen as a

wave propagation. Since there is a net mass transfer

involved, the waves are translational. To understand

the wave phenomena in gravity and pressure driven

fluid mass flows, kinematic wave or dynamic wave

analysis is important. When the inertial and pressure

forces are minor in the momentum equation (4), kine-

matic waves govern the flow. Dynamic waves govern

Control of Sewer Flow using a Buffer Tank

65

flow when these forces are dominating. In a kine-

matic wave, the flow does not accelerate considerably

as the gravity and friction forces neutralize each other.

Disregarding the first three terms in equation (4),

the remaining two terms can be replaced by a flow

expression for a fully filled pipe; Mannings equation,

(R. Manning and Leveson, 1890) gives a relation be-

tween A, h and Q. Since cross sectional area is related

to water depth A = A(h) the following relation can be

given Q = Q(h) .

Using the chain-rule for the continuity equation

(3):

∂A

∂h

∂h

∂t

+

∂Q

∂h

∂h

∂x

= 0 (5)

The two terms

∂Q

∂h

and

∂A

∂h

can be expressed using

the Manning equation. These terms are non-linear.

Here we use a linearized version of this equation and

apply small fluctuations to the flow Q and thereby to

the water level h. This leads to the relation

c =

∂Q

∂A

=

∂Q

∂h

∂A

∂h

(6)

and the equation

∂h

∂t

+ c

∂h

∂x

= 0 (7)

close to the operating point

∂Q

∂h

is constant giving:

∂Q

∂t

+ c

∂Q

∂x

= 0 (8)

This equation describes waves propagating with

unchanged shape and speed c. Changes of flow at the

inlet of a pipe will appear at the outlet after a time

delay T

d

corresponding to the pipe length and propa-

gation speed c. This can be verified by assuming that

the flow in position x = 0 is Q(0,t) and is known as a

function of time t. The flow in an arbitrary position x

at time t −

x

c

is assumed to be

Q(x,t) = Q(0,t −

x

c

) (9)

To show that this is a solution to equation 8, the

partial derivatives with respect to t and x is

∂Q

∂t

=

∂Q(0,t −

x

c

)

∂(t −

x

c

)

∂(t −

x

c

)

∂t

=

∂Q(0,t −

x

c

)

∂(t −

x

c

)

(10)

∂Q

∂x

=

∂Q(0,t −

x

c

)

∂(t −

x

c

)

∂(t −

x

c

)

∂x

=

∂Q(0,t −

x

c

)

∂(t −

x

c

)

−1

c

(11)

inserting these two expressions into equation (8)

results in

∂Q(0,t −

x

c

)

∂(t −

x

c

)

+ c

∂Q(0,t −

x

c

)

∂(t −

x

c

)

−

1

c

= 0 (12)

which satisfies the equation.

These calculations show that the flows in the

sewer network can be modelled as delays under the

given assumptions.

The output flow from the buffer tank U is de-

layed by

L

c

where L is the length of the pipe from the

buffer tank to the WWTP. For control purposes the

discretized U can be expressed as U(k − τ) where τ is

the transport delay

The total flow to the WWTP Y is the household

flow and the delayed flow from the buffer tank, Y can

be described as:

Y (k) = Q

h

(k) +U (k − τ) (13)

where Q

h

(k) is the household flow at time k.

The Household Disturbance Model

The purpose of the model is to estimate the future

household flow. Investigations have shown a 24 hours

pattern where the flow is low during the night, Fig. 3.

A way to find the model of the flow is to use a large

number of measurements to find the frequency spec-

trum. Here the spectrum is found using a DFT and the

complex coefficients are used in an autonomous state

space model which describes average daily household

flow. This model supplemented with a stochastic in-

put will be used in a Kalman observer.

A continuous time sinusoidal in amplitude phase

form is described by (Kuo, 1966)

y(t) = a

0

+ a · cos(ωt + φ) (14)

where a

0

is the mean or zero frequency term, a is

the amplitude, ω is the frequency and φ is the phase

difference.

An autonomous state space model (SSM) can be de-

fined

˙x = Ax (15)

y = Cx (16)

whose state vector, system matrix, input and out-

put matrix are

x(t) =

a

0

a · cos(ωt + φ)

a · sin(ωt + φ)

(17)

and

ICINCO 2020 - 17th International Conference on Informatics in Control, Automation and Robotics

66

A =

0 0 0

0 0 −ω

0 ω 0

, C =

1 1 0

(18)

y(ω) is the Fourier transform of y(t). The real part

and the imaginary part of the Fourier transform coef-

ficients are used in C. The above SSM contains just

a single frequency. When there are multiple frequen-

cies, the sinusoidal signal and SSM is:

y(t) = a

0

+

N

∑

n=1

a

n

· cos(nωt + φ

n

) (19)

x(t) =

a

0

a

1

· cos(ω

1

t + φ

1

)

a

1

· sin(ω

1

t + φ

1

)

a

2

· cos(ω

2

t + φ

2

)

a

2

· sin(ω

2

t + φ

2

)

.

.

.

.

.

a

k

· cos(ω

k

t + φ

k

)

a

k

· sin(ω

k

t + φ

k

)

A =

0 0 0 0

0 A

1

0 ...

0 0 A

2

...

. . . A

k

where

A

i

=

0 −ω

i

ω

i

0

i = 1,2 ... k

C =

1 1 0 1 0 ... 1 0

The discrete-time equivalent of A in (18), with

sampling time T

s

is

Φ(T

s

) = e

AT

s

(20)

This matrix has block diagram structure,

Φ(T

s

) = diag(Φ

0

(T

s

),Φ

1

(T

s

),·· · ,Φ

k

(T

s

)) (21)

and can be split into

Φ

0

(T

s

) = 1 (22)

Φ

i

(T

s

) =

cos(ω

i

T

s

) −sin(ω

i

T

s

)

sin(ω

i

T

s

) cos(ω

i

T

s

))

(23)

Model for Industrial Waste Water

The industrial wastewater flow Q

i

is a significant part

of the total inlet to the WWTP. The flow is varying

and large COD pulses occur. Q

i

is measured several

times off-line one day per month.

Information on the industrial wastewater flow is

relevant for control purposes. The best-case scenario

is exact knowledge of flow and COD from the indus-

trial companies, alternatively a model for typical Q

i

variations can be of use. A third method is on-line

measurement of the COD and level in the buffer tank

inserted close to industry. To prove the concept Q

i

is

modelled as a constant flow combined with different

flow variations.

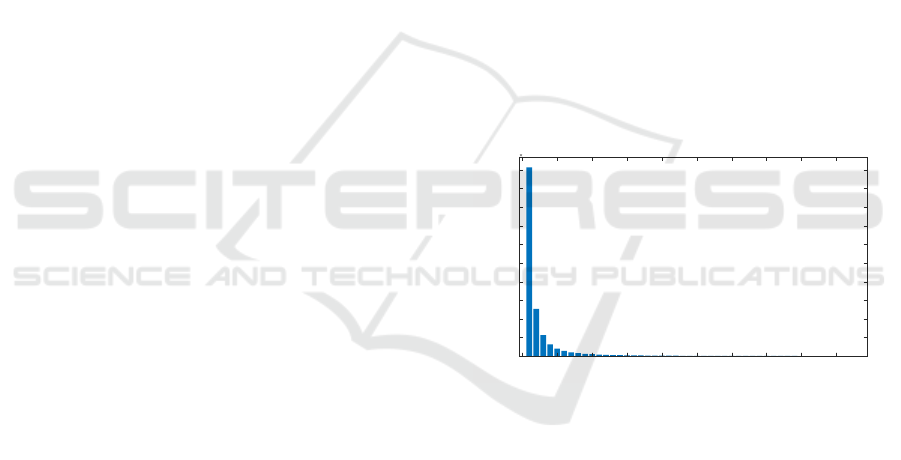

Model Parameters for Fredericia Sewer

System

The sewer network model from the buffer tank to the

WWTP is simplified to a time delay. This delay is

found using cross correlation of data from one day

from the heavy industry and data from the inflow to

the WWTP. It turns out that the strongest correlation

is at approximately 100 minutes. To find the param-

eters in the household disturbance model, measure-

ments of 30 days inflow to the WWTP are used. The

30 days measurement has been digital Fourier trans-

formed and the power spectrum is shown in Fig. 6.

Power Spectrum of Y(t)

0 0.005 0.01 0.015 0.02 0.025 0.03 0.035 0.04 0.045

Frequency (Hz)

0

1

2

3

4

5

6

7

8

9

10

|P(f)|

10

4

Figure 6: Bar plot of power spectrum which is the square of

DFT’s magnitude. At low frequencies, the magnitudes are

large.

The dominating frequencies are found by using a

threshold in the power spectrum. In Fig. 7 frequen-

cies from three different thresholds are simulated.

5 CONTROL OF THE BUFFER

TANK OUTPUT

The MPC (Maciejowski, 2002) aims to minimize the

variance of the input flow to WWTP. The following

performance function is used:

J =

H

p

∑

k=1

ˆ

Q

h

(k + τ) +U(k) − µ

2

R

+

H

p

∑

k=1

µ

S

(24)

Control of Sewer Flow using a Buffer Tank

67

Figure 7: Different model approximations of the original

flow data. The thresholds set for the model 1, 2 and 3 are

respectively 2500, 900 and 400. The purple curve consid-

ered 10 frequencies in the model. The blue curve considered

only 5 frequencies in the model. The latter model is used in

the subsequent section.

subject to system dynamics and constraints

V (k + i + 1) = V (k + i) + T

s

(

ˆ

Q

i

(k + i) −U(k + i))

Y (k + i + τ) =

ˆ

Q

h

(k + i + τ) +U(k + i)

V

min

≤ V ≤ V

max

U

min

≤ U ≤ U

max

(25)

The first equation is the model of the buffer tank,

where

ˆ

Q

i

is a prediction of the industrial outlet. In the

performance function the first term is the variance of

the total input to the WWTP, Y . µ is the mean value,

H

p

is the prediction horizon.

ˆ

Q

h

is the estimated out-

put of the household flow.

Estimation of

ˆ

Q

h

is based on a Kalman filter

(Kalman, 1960) assuming noise added to the au-

tonomous household flow model.

X(k + 1) = ΦX(k) + K(Q

h

(k) −CX(k)) (26)

where K is the Kalman-gain. The household flow

is predicted by

X(i + 1) = ΦX(i)

ˆ

Q

h

(i) = CX(i)

(27)

for

i = k..(k + H

p

+ τ) (28)

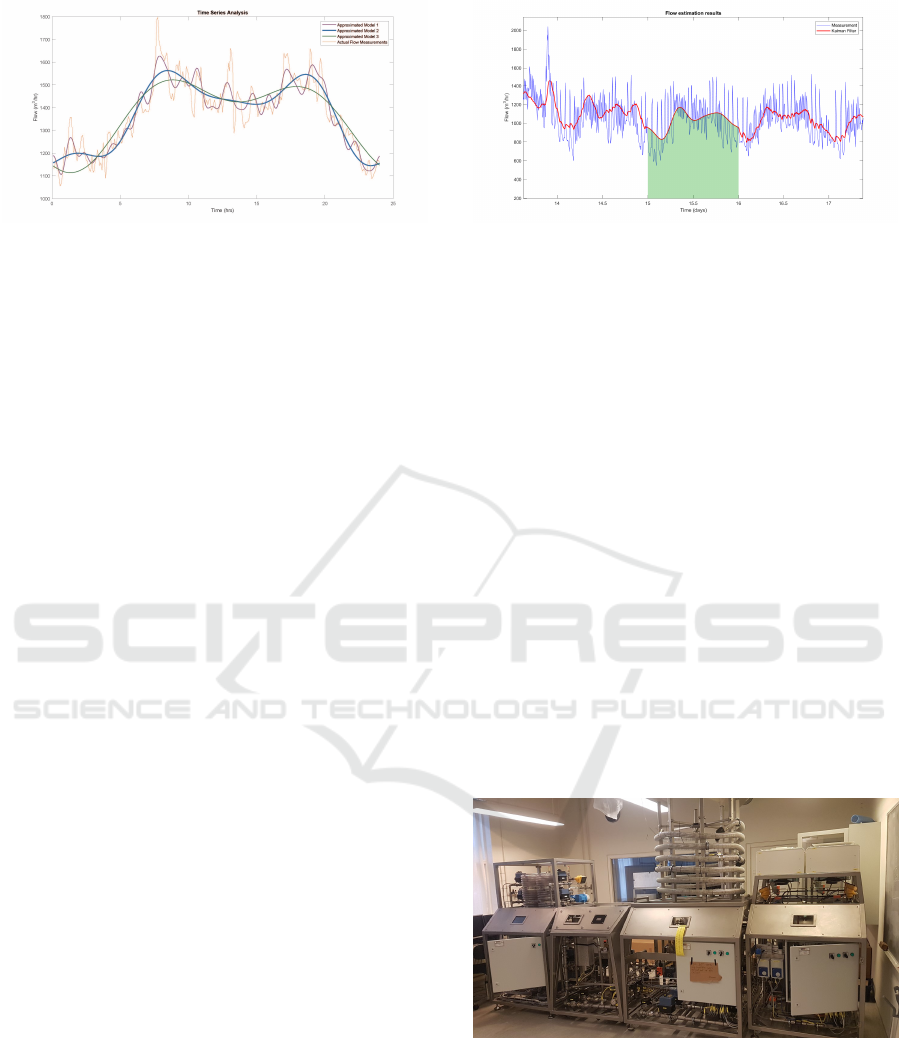

The Kalman filter approach is tested using mea-

sured data from Fredericia. In Fig. 8 the blue curve

represents measured data, the red curve is the Kalman

estimate. The Kalman filter is updated with measure-

ments at each sample except in the green region. In

the green section the Kalman filter estimates without

measurements. The results are good within the 24

hours estimate without measurements. The data rep-

resents a day without precipitation and the estimate

will be uncertain in rainy periods.

Figure 8: The Kalman filter estimation of

ˆ

Q

h

for day 15.

The process noise and measurement noise in the Kalman

filter had a variance of 0.01 and 25 respectively.

6 LABORATORY TEST OF THE

CONTROL CONCEPT

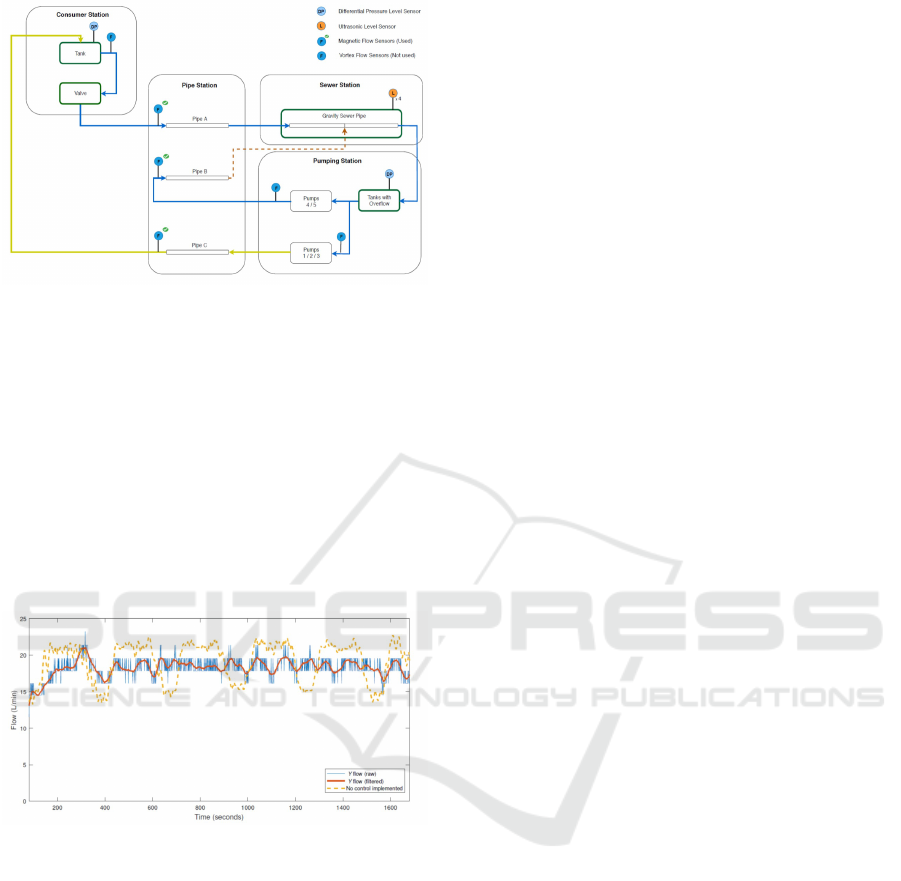

A buffer tank and on-line measurements are to be im-

plemented in Fredericia. To prove the concept the

control system is tested in Smart Water Lab at Aal-

borg University seen in Fig.9. Smart Water Lab has

components as tanks, pumps, valves, gravity pipes,

pressurized pipes etc. The modules of the Smart Wa-

ter Lab are configured to emulate the simplified sys-

tem as in Fig. 10. The consumer station is a buffer

tank from which appropriate household flow is emu-

lated. The blue arrows are pipes in the sewer system

and the sewer station is the WWTP. The purpose of

the pumping station is twofold, firstly it generates a

disturbance flow to the inlet of the Sewer Station emu-

lating the household flow and secondly it re-circulates

water to the consumer tank (yellow arrow).

Figure 9: Smart Water Lab at Aalborg University.

Deterministic (white-box) models are developed

to describe the dynamics of some key components of

the sewer network.

The laboratory set-up simulates the delay in the

gravity pipe and it is possible to introduce a distur-

bances illustrating the periodic household flow. The

disturbance can be seen as the yellow curve in Fig.

11. The flow from industry is implemented as a con-

ICINCO 2020 - 17th International Conference on Informatics in Control, Automation and Robotics

68

Figure 10: Circuit for the test set-up in Smart Water Lab

containing a consumer station, a pipe station, a sewer station

and a pumping station.

stant flow to the buffer tank. An MPC minimizing the

performance function equation 24 is implemented in

the laboratory by use of YALMIP (M.C. Grant and

Stephen, 2014), (Lofberg, 2014). It aims to minimize

the variations of the inlet flow to the sewer station.

The result can be seen in Fig. 11. The measurement

of the controlled flow (blue) has poor resolution, a fil-

tered version is the red curve. It is seen that the con-

trolled inlet flow has a lower variance than the original

uncontrolled flow (yellow).

Figure 11: Comparison of uncontrolled (yellow) and con-

trolled (blue and red) inlet to the sewer station.

The laboratory test shows that a buffer tank in

combination with an MPC algorithm can reduce the

variations in the inlet flow to the WWTP.

7 CONCLUSION

Typical inlet to a WWTP consists of periodic house-

hold flow and industrial flow. A control system for

minimization of flow variations to a WWTP using

a buffer tank for the industrial flow has been con-

structed. The controller is based on two models, one

model describing the flow variations from the buffer

tank to the WWTP and one describing the household

flow. The flow from the buffer tank to the WWTP is

described by the Saint-Venant equations. Under linear

assumptions it is shown that the flow model results in

a time delay. The model for the household flow uses

an autonomous description. The two models are in-

serted in a MPC with a performance that minimize

the flow variations. A lab set-up shows that the con-

trol concept is able to minimize the variance of the

mentioned flow.

REFERENCES

Aastrom, K. J. and Haegglund, T. (2006). Avanced PID

contro l. ISA.

Andersen, P. (1977). Optimering af driftsbetingelser for

spildevandsanlæg gennem automatisering. Aalborg

University, Denamrk.

Crossley, A. J. (1999). C, Accurate and efficient numeri-

cal solutions for the Saint Venant equations of open

channel flow. University of Nothingham.

DHI (2017). Wats-wastewater aeronoc/anaerobic transfor-

mation in sewers, mike eco lab template. In Scientific

Description. MIKE.

frese.dk (2018). https://www.frse.dk/Fredericia-

spildevand.aspx. urldate: 2018-10-03.

Kalman, R. E. (1960). A new approach to linear filtering

and prediction problems,Journal of basic Engineering

vol2, nr1, p 35-45. American Society of Mechanical

Engineers.

Kuo, F. F. (1966). Network analysis and synthesis. John

Wiley and Sons.

Lofberg, J. (2014). A toolbox for modeling and optimiza-

tion in MATLAB. CACSD Conference, vol.3, Taipei,

Taiwan.

Maciejowski, J. M. (2002). Predictive control: with con-

straints. Pearson education.

Marinaki, M. and Papageorgiou, M. (2005). Optimal real-

time control of sewer networks. Springer Science &

Business Media.

M.C. Grant, S. B. and Stephen, P. (2014). The

CVX Users Guide, Release 2.1. URL http://cvxr.

com/cvx/doc/CVX.

Mestre, L. S. and Murugesan, P. K. (2019). Laboratory Em-

ulation and Control of a Sewer System with Storage,

Master Thesis, Control and Automation, Aalborg Uni-

versity. Aalborg University, Denmark.

Michelsen, H. (1976). Ikke-stationær strømning i

delvis fyldte kloakledninger: en dimensioneringsme-

tode og en analysemetode. Afdelingen for Jord-

og Vandbygning, Den kgl. Veterinaer-og Landboho-

jskole,Denmark.

Ocampo-Martinez, C. (2005). Model predictive control of

wastewater systems. Springer Science & Business

Media, 2.

Overloop, P. J. V. (2006). Model predictive control on open

water systems. IOS Press.

Pilgaard, T. H. and Pedersen, J. N. (2018). Model Predictive

Control of a Sewer System, Master Thesis, Control

Control of Sewer Flow using a Buffer Tank

69

and Automation, Aalborg University. Aalborg Uni-

versity, Denmark.

Postlethwaite, I. and Skogestad, S. (2005). Multivariable

Feedback Control- Analysis and Design. Wiley and

Sons Ltd.

R. Manning, J. P. Griffith, T. P. V.-H. and Leveson, F.

(1890). On the flow of water in open channels and

pipes.

Schlutter, F. (1999). Numerical modelling of sediment

transport in combined sewer systems, The Hydraulics

and Coastal Engineering Group, Dept. of Civil Engi-

neering. Aalborg University.

T. Hvitved-Jacobsen, J. Vollertsen, and A. H. Nielsen

(2013). Sewer processes: microbial and chemical pro-

cess engineering of sewer networks. TCRC press.

ICINCO 2020 - 17th International Conference on Informatics in Control, Automation and Robotics

70