Investigating the Influence of Emotional Intelligence on the Supplier

Selection Decisions with Fuzzy Cognitive Maps

Maria Drakaki

1

, Panagiotis Tzionas

2

and Kuanysh Abeshev

3

1

Department of Science and Technology, University Center of International Programmes of Studies,

International Hellenic University, 14th km Thessaloniki -N.Moudania, GR-57001, Thermi, Greece

2

Department of Industrial Engineering and Management, International Hellenic University,

P.O. Box 141, GR-57400, Thessaloniki, Greece

3

School of Engineering Management, Almaty Management University,

Rozybakiyeva st., 227, 050060, Almaty, Kazakhstan

Keywords: Supplier Selection, Sustainability, Fuzzy Cognitive Maps, Supply Chain Risks, Emotional İntelligence.

Abstract: Supplier selection holds a strategic role in supply chain management. Multi-criteria decision making

methods combined with fuzzy and intelligent approaches have been primarily used to solve supplier

selection problems considering sustainability and risk factors. Yet sustainability criteria as well as risk

factors proposed in the literature vary, as well as the assigned weight values that measure the relative

importance of the various criteria and risks. Moreover, human decisions involve emotions. Therefore, it

would be useful to identify potential causal relationships between criteria and risk factors and emotional

intelligence of decision makers, in order to identify potential biases in the decision making process. In

particular, trust and relationship building with the suppliers may affect the emotional intelligence of

decision makers. For this purpose, in this paper a methodology which uses Fuzzy Cognitive Maps is

presented, in order to investigate by simulation, different scenarios that could identify the influence of

emotional intelligence of the decision makers regarding the supplier selection problem.

1 INTRODUCTION

Globalisation and sustainability have contributed to

the strategic role of the supplier selection in the

supply chain. Long-term relationships between firms

and their suppliers as well as finding eligible

suppliers are key aspects for the enhancement of the

strategic position of the firms in the supply chain

(Ho et al., 2010; Ghadimi et al., 2018).

Traditional supplier selection criteria include

quality, cost, delivery and service (Songhori et al.,

2011). However, sustainability has shifted the focus

of supplier selection criteria from economic criteria

to the Triple Bottom Line dimensions, which include

besides the economic dimension, environmental and

social ones (Chen et. al., 2006; Kuo et al., 2010;

Govindan et al., 2015; Gören, 2017; Ghadimi, 2018;

Drakaki et al., 2019a).

Besides, sustainability requirements apply to the

selection of appropriate suppliers, whereas peer-to-

peer governance relationships based on cooperation

between buyers and their suppliers contribute

positively to this end (Jiang, 2009). Thus, both

sustainability and risks should be considered for the

supplier selection problem (Alikhani et al., 2019;

Drakaki et al., 2019a).

However, global supply chains are exposed to

supply risks categorised into operational risks and

disruptions (Tang, 2006). Disruptions are

unexpected events which disrupt the normal supply

of goods within a supply chain, whereas operational

risks relate to supply problems such as quality, cost

or production technology. Moreover, supply chain

members are interconnected and therefore risks

occuring at one member propagate to the other

supply chain members. Yet integration of

sustainability can contribute to the management of

supply chain risks (Giannakis and Papadopoulos,

2016). Yet only a few studies exist that have

considered both sustainability and risk factors for the

supplier selection problem (Awasthi et al., 2018;

Alikhani et al., 2019; Mokhtar et al., 2019; Drakaki

et al., 2019a). Alikhani et al. (2019) considered risks

as the outcome of supplier selection decisions,

whereas some criteria and risk factors were

Drakaki, M., Tzionas, P. and Abeshev, K.

Investigating the Influence of Emotional Intelligence on the Supplier Selection Decisions with Fuzzy Cognitive Maps.

DOI: 10.5220/0009856306810686

In Proceedings of the 6th International Conference on Vehicle Technology and Intelligent Transport Systems (VEHITS 2020), pages 681-686

ISBN: 978-989-758-419-0

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

681

interrelated and therefore cosidered dependent

factors. Drakaki et al. (2019b) have not considered

risks as independent factors and integrated risks in

the decision making methodology. Hamdi et al.

(2018) have presented a literature review on supplier

selection under supply chain risk management.

Mokhtar et al. (2019) considered financial and

production stability, quality and cost as supply chain

risk indicators for the operational disturbances

which affect suppliers. The authors argued that

feedback actions taken by manufacturers in order to

reduce risk exposure can become the source of

further risks for the suppliers.

Relationships with suppliers have been of

primary importance for the supply chain

performance. Das and Teng (2001) investigated the

relationship between trust and risk within a

company. The authors argued that the structural

preferences of decision makers were made under the

overall goal of risk minimisation and based on their

perceptions of relational risk and performance risk.

The relational risk was related to the level of

partners’ cooperation and commitment and the

associated consequences. Therefore, relational risk

was mostly related to trust between partners and

decision makers’ risk perceptions were influenced

by psychological factors including trust propensity.

Beneficial links between collaboration and

partnership performance have been found in Zybell

(2013). Rao and Goldsby (2009) categorised supply

chain risks into environmental, industry,

organisational, problem-specific and decision

making risks. The authors argued that decision

making risks were partially due to knowledge, skills,

and bias of decision makers. Guertler and Spinler

(2015) limited the set of risks and corresponding risk

indicators for risk monitoring due to their

interrelatedness. The authors proposed that the

availability and continuity of contact persons could

be considered a risk indicator for the risk of unstable

communication with the suppliers. Manello and

Calabrese (2019) argued that traditional supplier

selection criteria such as price and delivery have

similar importance with reputational factors for the

supplier selection in the automotive industry. The

authors argued that there is scarce literature related

to how buyers actually select suppliers, in contrast to

a plethora of literature related to how they should

select suppliers. The authors argued that long-term

cooperation is based on trust and information

sharing.

The supplier selection problem has been

investigated using Fuzzy Cognitive Maps (FCMs)

(Xiao et al., 2012; Drakaki et al., 2019b). FCMs

originate from cognitive maps and use fuzzy logic in

order to include vague and qualitative information.

An FCM is a signed weighted graph consisting of

nodes and arcs where nodes represent the concepts

of the system under consideration and the arcs

represent the causal relationships between nodes.

FCMs can be constructed by groups of experts and

the causal relationships between nodes can be

expressed with linguistic variables taking values in

the term set T(influence)={ negatively very strong,

negatively strong, negatively medium, negatively

weak, negatively very weak, zero, positively very

weak, positively weak, positively medium,

positively strong} (Groumpos, 2010). The Center of

Gravity method is used to calculate the numerical

weights which take values in [-1, 1].

Timed evolution of FCMs is performed for a

number of iterations until the FCM either stabilizes

to a stable state or shows a cyclic behavior or does

not converge. For an FCM with N concepts, C

i

,

i=1,…,N, the concept values are updated for a

number of iterations. At iteration k+1, concept C

i

is

updated as follows

𝐶

𝑓𝐶

∑

𝐶

∙𝑤

(1)

The weight value, w

ji

, shows the degree of influence

of concept j on concept i. The sigmoid function can

be used as the threshold function f when the concept

values are in [0, 1], and the tangent function is used

when the values are in [-1, 1]. Numerous

applications of FCMs exist for modeling and control

of complex systems as well as to provide decision

support tools [Hunter et al., 2004; Li and Lin, 2006;

Chen and Paulraj, 2004; Xiao et al., 2012;

Kontogianni et al., 2012; Papageorgiou et al., 2017;

Drakaki et al., 2019b; Drakaki et al., 2019c).

In this paper the sustainable supplier selection

problem with risk factors is considered, with focus

on how the emotional intelligence of decision

makers can influence their supplier selection

decisions. Therefore, an FCM based methodology is

proposed in order to identify the impact of causal

relationships between concepts such as relationships

of decision makers with suppliers and supplier

selection criteria and risk factors which are included

in the objective decision making process.

The proposed methodology is presented next.

Conclusions include future directions.

2 THE METHODOLOGY

In the context of the supplier selection problem, the

purpose of the this paper is to present a methodology

iMLTrans 2020 - Special Session on Intelligent Mobility, Logistics and Transport

682

which can identify the influence of the emotional

intelligence of the decision makers on supplier

selection criteria and risk factors.

The methodology consists of the following steps:

1. Identification of all concepts that are relevant to

the aims of this paper in order to be included as

FCM concepts.

2. Identification of the causal relationships between

concepts and their signs.

3. Calculation of the weight matrix.

4. Simulations with scenario building in order to

explore the influence of the emotional intelligence

concepts on the values of supplier selection criteria

and risk factors.

Identification of the FCM Concepts

The system concepts that are used in the FCM

include decision makers’ concepts related to

emotional intelligence, supplier selection risk factors

and supplier selection criteria. They have been

chosen based on the presented literature. The FCM

concepts related to emotional intelligence include

trust, relationship building, relationship

commitment, and bias (Das and Teng, 2001; Zybell,

2013; Ghadimi et al., 2018; Rao and Goldsby,

2009). The risk factors include quality, service, cost,

long-term cooperation, supplier’s profile, continuity,

opportunism (Drakaki et al., 2019b; Alikhani et al.,

2019). The sustainable supplier criteria include

price, productivity, capacity, long-term relationship,

lead time, quality, production technology,

responsiveness, reputation, environmental

management system, environmental competencies,

occupational health and safety management system,

employees’ supportive activities (Gören, 2017;

Drakaki et al., 2019a; Alikhani et al., 2019; Paul,

2015). Tables 1, 2 and 3 show the concepts related

to emotional intelligence, risk factors and

sustainable supplier selection criteria, respectively.

Table 1: FCM concepts related to emotional intelligence.

Emotional

intelligence

concepts

Description

Trust (C

1

) Mutual trust in the relationship.

Relationship

b

uilding (C

2

)

Cooperation, collaboration,

communication, information sharing.

Relationship

commitment

(

C

3

)

Collaboration, information sharing,

trust.

Bias (C

4

) Limitation of decision makers related

to their knowledge and skills.

Table 2: Risk factors for sustainable supplier selection (as

well as FCM concepts).

Risk factors Description

Quality risk

(

C

5

)

Risks related to the quality of the

p

roduct.

Service risk

(C

6

)

Risks related to the capacity,

production technology and

res

p

osiveness of the su

pp

lier.

Cost (C

7

) Risks related to product price of the

su

pp

lier.

Long-term

cooperation

(

C

8

)

Risks arising from trust and

relationship commitment with the

su

pp

lier.

Supplier’s

p

rofile

(

C

9

)

Risks related to past performance of

the su

pp

lier.

Continuity

(C

10

)

Risks related to dispuptions such as

natural disasters.

Opportunism

(

C

11

)

Risks related to opportunistic behavior

of the su

pp

lier.

Table 3: Criteria for sustainable supplier selection (as well

as FCM concepts).

Sustainability

dimensions

Criteria

Economic

dimension

Price (C

12

)

Productivity (C

13

)

Capacity (C

14

)

Long-term relationship (C

15

)

Continuity (C

16

)

Lead Time (C

17

)

Quality (C

18

)

Production technology (C

19

)

Responsiveness (C

20

)

Reputation (C

21

)

Environmental

dimension

Environmental management system

(C

22

)

Environmental competences (C

23

)

Social

dimension

Occupational health and safety

management system (C

24

)

Supportive activities (C

25

)

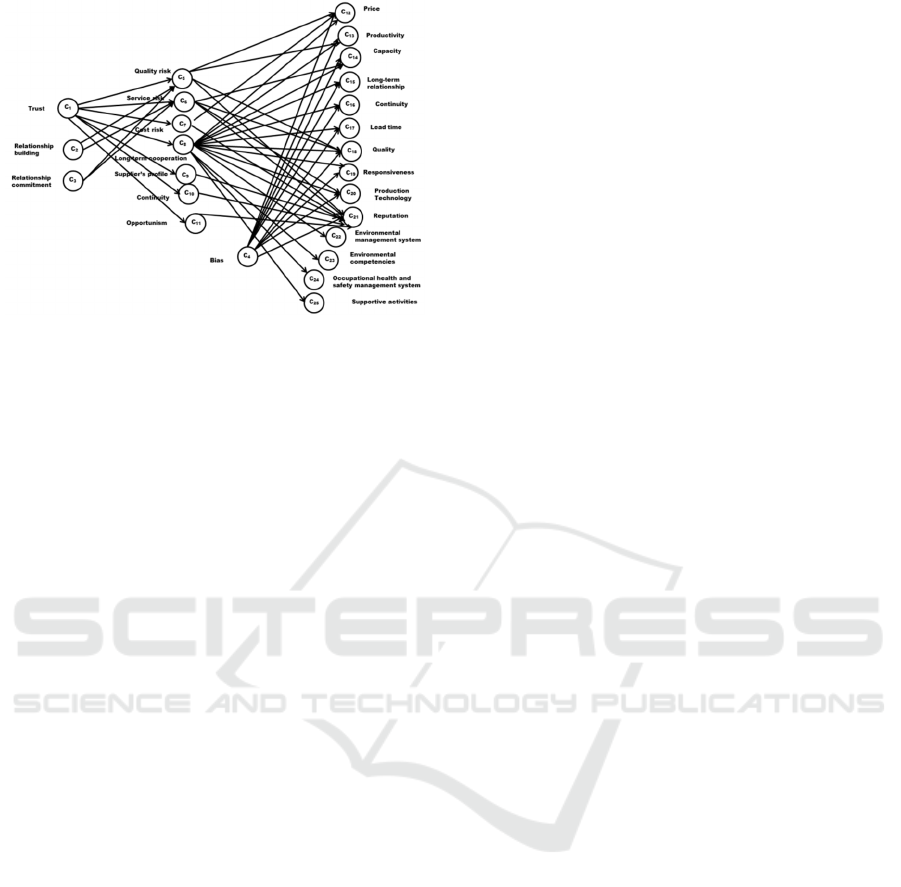

Identification of the Causal Relationships

between Concepts and Their Signs

Figure 1 shows the constructed FCM. The direction

of arcs in Figure 1 shows the direction of causality

between the nodes (concepts). The weight values,

w

ij

, of the connections show the degree of influence

of the causality between nodes. In this paper, it is

assumed that there is no influence among FCM

concepts representing the emotional intelligence

related concepts, among the supplier selection

criteria, as well as among FCM concepts

representing the risk factors.

Investigating the Influence of Emotional Intelligence on the Supplier Selection Decisions with Fuzzy Cognitive Maps

683

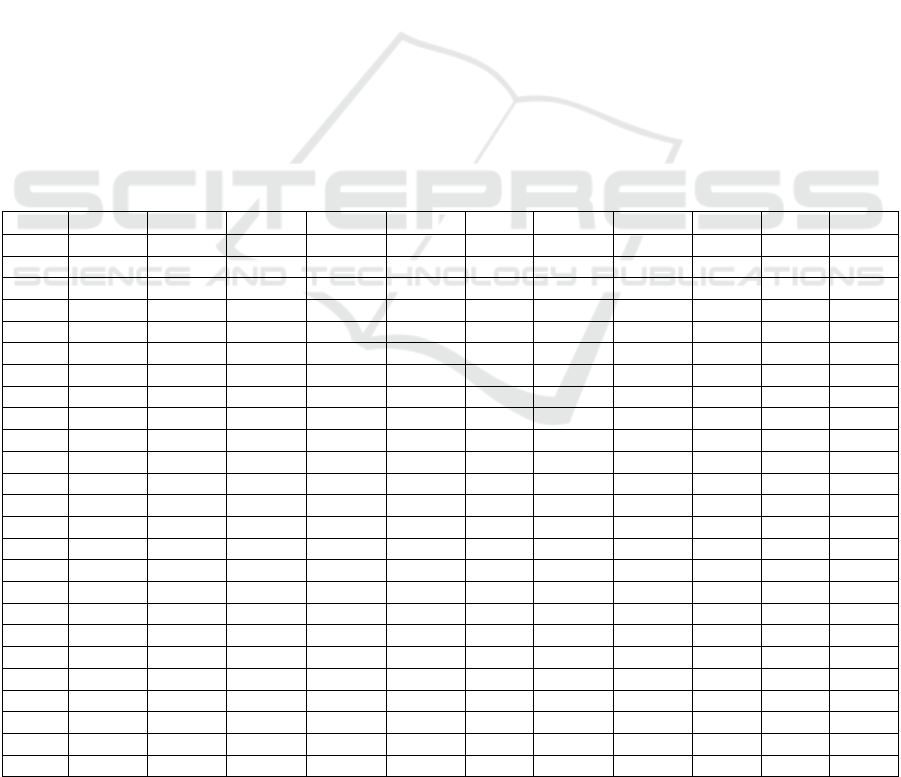

Calculation of the Weight Matrix

Table 4 shows the weight matrix expressed in

linguistic terms (Groumpos, 2010). Positive weight

value between concepts C

i

and C

j

means that an

increase in C

i

will cause an increase in C

j

, negative

weight value means that an increase of C

i

will cause

a decrease in C

j

, whereas a value of 0 indicates that

there is no influence of C

i

on C

j

. The values of the

linguistic terms will be determined based on the

Center of Gravity method.

In this paper, it is assumed that concepts

representing trust, relationship building and

relationship commitment will negatively influence

the values of the concepts representing risk factors.

Therefore, an increase in the level of trust between

decion makers and suppliers will lead to a decrease

in the value of all risk factors used in the

formulation of the supplier selection problem.

Simulations with Scenario Building

Simulation allows investigation of different “what

if” scenarios. FCM concepts are assigned initial

values and the behavior of the modeled system is

observed as it evolves in time according to Equation

(1). It is, therefore, possible to observe whether the

system will reach in the future, after a number of

iterations, a stable state or it will become unstable or

will show a cyclic behavior. Therefore, simulations

with scenario building provide decision support to

decision makers by making predictions of future

system states (Kontogianni et al., 2012). Therefore,

three scenarios have been proposed.

1. The FCM concept values will be assigned initial

values equal to 0. In this scenario all concepts are

de-activated initially.The simulation results will

show an upper bound for the performance of the

system.

2. The FCM concept values will be assigned initial

values equal to 1. In this scenario all concepts are

fully activated initially.The simulation results will

show a lower bound for the performance of the

system.

3. The FCM concept values related to emotional

intelligence will be assigned values equal to 0,

whereas all other concepts will be assigned values

equal to 0.5. The simulation results will show the

impact of the emotional intelligence related concepts

on risk factors and criteria values.

Table 4: The FCM weight matrix expressed in linguistic terms. The weight value w

ij

shows the influence of concept C

i

(represented by the columns) on the concept C

j

(represented by the rows).

C

j

\

C

i

C

1

C

2

C

3

C

4

C

5

C

6

C

7

C

8

C

9

C

10

C

11

C

1

zero zero zero zero zero zero zero zero zero zero zero

C

2

zero zero zero zero zero zero zero zero zero zero zero

C

3

zero zero zero zero zero zero zero zero zero zero zero

C

4

zero zero zero zero zero zero zero zero zero zero zero

C

5

nw nw nw zero zero zero zero zero zero zero zero

C

6

nw nw nw zero zero zero zero zero zero zero zero

C

7

nw nw nw zero zero zero ze

r

o zero zero zero zero

C

8

nw nw nw zero zero zero zero zero zero zero zero

C

9

nw nw nw zero zero zero zero zero zero zero zero

C

10

nw nw nw zero zero zero zero zero zero zero zero

C

11

nw nw nw zero zero zero zero zero zero zero zero

C

12

zero zero zero

p

w nw zero nw nw zero zero zero

C

13

zero zero zero

p

w nw zero zero nw zero zero zero

C

14

zero zero zero

p

w zero nw zero nw zero zero zero

C

15

zero zero zero

p

w zero zero zero nw zero zero zero

C

16

zero zero zero

p

w zero zero zero nw zero zero zero

C

17

zero zero zero

p

w zero zero zero nw zero zero zero

C

18

zero zero zero

p

w nw nw zero nw zero zero zero

C

19

zero zero zero

p

w zero zero zero nw zero zero zero

C

20

zero zero zero

p

w zero nw zero nw zero zero zero

C

21

zero zero zero

p

w nw nw nw nw nw nw nw

C

22

zero zero zero zero zero zero zero nw zero zero zero

C

23

zero zero zero zero zero zero zero nw zero zero zero

C

24

zero zero zero zero zero zero zero nw zero zero zero

C

25

zero zero zero zero zero zero zero nw zero zero zero

nw: negatively weak; pw: positively weak.

The concepts corresponding to the supplier selection criteria (C

12

-C

25

) have zero influence to each other/ Therefore, the corresponding

columns have been omitted for simplicity, however the corresponding weight values are equal to zero.

iMLTrans 2020 - Special Session on Intelligent Mobility, Logistics and Transport

684

Figure 1: The FCM for the investigated system.

3 CONCLUSIONS

Supplier selection is of strategic importance for

supply chain performance. In this paper, a

methodology has been proposed, in order to study

the influence of emotional intelligence of the

decision makers regarding the supplier selection

problem decisions. Supplier selection depends on

the criteria and risk factors taken into account in the

multi-criteria decision making methods. Yet both

criteria and risk factors vary, as well as their

assigned weight values. Decision makers may

choose a different set of the above variables,

influenced by their emotional intelligence. Concepts

related to trust, relationship building, relationship

commitment and bias have been linked to the

emotional intelligence of the decision makers. A

methodology which uses Fuzzy Cognitive Maps has

been proposed in order to investigate by using

simulations and building of different scenarios the

causal relationships between the involved concepts.

The FCM concepts are related to the emotional

intelligence of the decision makers, risk factors and

sustainability criteria for the supplier selection

problem. Future research will apply the proposed

method to a case study.

REFERENCES

Alikhani R., Torab S.A., Altay N. (2019). Strategic

supplier selection under sustainability and risk criteria.

International Journal of Production Economics, 208,

69–82.

Awasthi, A., Govindan, K., Gold, S. (2018). Multi-tier

sustainable global supplier selection using a fuzzy

AHP-VIKOR based approach. International Journal

of Production Economics, 195, 106–117.

Chen, I. and Paulraj, A. (2004). Towards a theory of

supply chain management: the constructs and

measurements. Journal of Operations Management,

vol. 22 (2), 119-150.

Chen C., Lin C., Huang S. (2006). A fuzzy approach for

supplier evaluation and selection, International

Journal of Production Economics, 102, 289–301.

Drakaki, M. Gören, H. G., Tzionas, P. (2019a). A multi-

agent based decision framework for sustainable

supplier selection, order allocation and routing

problem, Proceedings of the 5th International

Conference on Vehicle Technology and Intelligent

Transport Systems, VEHITS, Heraklion, Greece.

Drakaki, M. Gören, H. G., Tzionas, P. (2019b). Supplier

Selection Problem in Fuzzy Environment Considering

Risk Factors, Proceedings of the 12th International

Conference on the Developments in eSystems

Engineering, DeSE, Kazan, Russia.

Drakaki, M. Gören, H. G., Tzionas, P. (2019c) Fuzzy

Cognitive Maps as a Tool to Forecast Emotions in

Refugee and Migrant Communities for Site

Management, Lecture Notes in Business Information

Processing LNBIP, Springer.

Ghadimi, P., Toosi, F. G. and Heavey, C. (2018). A multi-

agent systems approach for sustainable supplier

selection and order allocation in a partnership supply

chain. European Journal of Operational Research,

269, 286–301.

Giannakis, M., Papadopoulos, T. (2016). Supply chain

sustainability: a risk management approach.

International Journal Production Economics, 171,

455-470.

Gören Güner, H. (2018). A decision framework for

sustainable supplier selection and order allocation with

lost sales. Journal of Cleaner Production, 183, 1156-

1169.

Govindan, K., Jafarian, A. and Nourbakhsh, V. (2015). Bi-

objective integrating sustainable order allocation and

sustainable supply chain network strategic design with

stochastic demand using a novel robust hybrid multi-

objective metaheuristic. Computers and Operations

Research, 62, 112-130.

Groumpos, P. P. (2010). Fuzzy cognitive maps: Basic

theories and their application to complex systems, in

M. Glykas (ed.), Fuzzy Cognitive Maps, Vol. 247 of

Studies in Fuzziness and Soft Computing, Springer,

pp. 1–23.

Guertler, B., Spinler, S. (2015). Supply risk

interrelationships and the derivation of key supply risk

indicators. Technological Forecasting & Social

Change, 92, 224–236.

Hamdi, F., Ghorbel, A., Masmoudi, F., Dupont, L. (2018).

Optimization of a supply portfolio in the context of

supply chain risk management: literature review.

Journal of Intelligent Manufacturing, 29 (4), 763–788.

Hunter, L. M., Kasouf, C. J., Celuchc, K. G., Curry, K. A.

(2004). A classification of business-to-business buying

decisions: risk importance and probability as a

Investigating the Influence of Emotional Intelligence on the Supplier Selection Decisions with Fuzzy Cognitive Maps

685

Framework for e-business benefits. Industrial

Marketing Management, 33(2), 145–154.

Ho, W., Xu, X., Dey, P.K., (2009). Multi-criteria Decision

making approaches for supplier evaluation and

selection: a literature Review. European Journal of

Operational Research, 202, 16-24.

Kontogianni, A.D., Papageorgiou, E.I., Tourkolias, C.

(2012). How do you perceive environmental change?

Fuzzy Cognitive Mapping informing stakeholder

analysis for environmental policy making and non-

market valuation. Applied Soft Computing, 12, 3725–

3735.

Kuo, R.J., Lee, L.Y., & Hu, T.-L. (2010). Developing a

supplier selection system through integrating fuzzy

AHP and fuzzy DEA: a case study on an auto lighting

system company in Taiwan. Production Planning and

Control, 21 (5), 468-484.

Jiang, B. (2009). The effects of interorganizational

governance on supplier's compliance with SCC: an

empirical examination of compliant and non-

compliant suppliers. Journal of Operations

Management, 27 (4), 267–280.

Li, S. and Lin, B. (2006). Accessing information sharing

and information quality in supply chain management.

Decision Support Systems, 42 (3), 1641-1656.

Manello, A., Calabrese, G. (2019). The influence of

reputation on supplier selection: An empirical study of

the European automotive industry. Journal of

Purchasing and Supply Management., 25(1), 69-77.

Mokhtar, S., Bahri, P.A., Moayer, S., James, A. (2019).

Supplier portfolio selection based on the monitoring of

supply risk indicators. Simulation Modelling Practice

and Theory, 97, 101955.

Papageorgiou, E. I., Hatwágnerb, M. F., Buruzsc, A.,

Kóczy, L. T. (2017). A concept reduction approach for

fuzzy cognitive map models in decision making and

management. Neurocomputing, 232, 16-33.

Paul, S.K. (2015). Supplier selection for managing supply

risks in supply chain: a fuzzy approach. International

Journal of Advanced Manufacturing Technology, 79,

657–664.

Rao, S., Goldsby, T.J. (2009). Supply chain risks: a review

and typology. International Journal of Logistics

Management 20, 97–123.

Songhori, J.M., Tavana, M., Azadeh, A., & Khakbaz,

M.H. (2011). A supplier selection and order allocation

model with multiple transportation alternatives.

International Journal of Advanced Manufacturing

Technology, 52, 365-376.

Tang, C. S. (2006). Perspectives in supply chain risk

management. . International Journal of Production

Economics, 103 (2), 451–488.

Xiao, Z., Chen, W. and Li, L. (2012). An integrated FCM

and fuzzy soft set for supplier selection problem based

on risk evaluation. Applied Mathematical Modelling,

36, 1444–1454.

Zybell, U. (2013). Partner management – managing

service partnerships in the supply chain – a systemic

perspective. International Journal of Physical

Distribution and Logistics Management, 43, 231–261.

iMLTrans 2020 - Special Session on Intelligent Mobility, Logistics and Transport

686