Visual Inspection of Collective Protection Equipment Conditions with

Mobile Deep Learning Models

Bruno Georgevich Ferreira, Bruno Gabriel Cavalcante Lima and Tiago Figueiredo Vieira

Institute of Computing, Federal University of Alagoas, Macei

´

o, Alagoas, Brazil

Keywords:

Deep Learning, Object Detection, Visual Inspection, Collective Protection Equipment.

Abstract:

Even though Deep Learning models are presenting increasing popularity in a variety of scenarios, there are

many demands to which they can be specifically tuned to. We present a real-time, embedded system capable

of performing the visual inspection of Collective Protection Equipment conditions such as fire extinguishers

(presence of rust or disconnected hose), emergency lamp (disconnected energy cable) and horizontal and ver-

tical signalization, among others. This demand was raised by a glass-manufacturing company which provides

devices for optical-fiber solutions. To tackle this specific necessity, we collected and annotated a database

with hundreds of in-factory images and assessed three different Deep Learning models aiming at evaluating

the trade-off between performance and processing time. A real-world application was developed with potential

to reduce time and costs of periodic inspections of the company’s security installations.

1 INTRODUCTION

Deep Learning (DL) has been presenting excellent

performances for the past decade in subjective tasks

due to its capability of adapting to large amounts

of data. This is particularly true in Computer Vi-

sion, given the high dimension and variability of im-

ages and videos. As a consequence, different Deep

Learning models have been applied to a wide range

of supervised learning tasks and its popularity is in-

creasing considerably (Dargan et al., 2019). Never-

theless, models can often be better tailored to tackle

highly specific demands (Aggarwal, 2018) from sev-

eral kinds of industries if an adequate partnership is

articulated between research lab and market.

In this context, we aim at solving a typical task

many companies rely on; the periodic visual inspec-

tion of Collective Protection Equipment (CPE). Un-

der a partnership firmed with a multinational com-

pany focused on manufacturing devices for installa-

tion of optical fiber systems, we tuned DL models to

inspect various specific conditions of fire extinguish-

ers, emergency lamps, horizontal and vertical signal-

ization, among others. An overview of the application

can be seen in the Figure 1. The solution can be ap-

plied remotely on the company’s surveillance system

or embedded on a tablet attached to a mobile robot

responsible for navigating the factory. It has the po-

tential of reducing costs and time associated with the

inspection of security systems.

More specifically, we present the following con-

tributions:

1. We collect and annotate a database containing

characteristics specifically aimed at tackling the

company’s demand. To the extent of our knowl-

edge, no database containing such features has

been presented so far.

2. We assess the performance of three DL models

and evaluate the trade-off between precision and

processing time. The system was embedded on a

tablet that can potentially be attached to a mobile

robot.

Figure 1: Overview of the application.

2 RELATED WORK

According to (Hocenski et al., 2016), using Computer

Vision in pottery can result in promising and satisfac-

tory results. Even though no deep learning algorithms

were used, they faced the necessity of automated as-

76

Ferreira, B., Lima, B. and Vieira, T.

Visual Inspection of Collective Protection Equipment Conditions with Mobile Deep Learning Models.

DOI: 10.5220/0009834600760083

In Proceedings of the 1st International Conference on Deep Learning Theory and Applications (DeLTA 2020), pages 76-83

ISBN: 978-989-758-441-1

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

sessment techniques for production analysis. Authors

used well traditional in image processing to create

three routines that detected problems in ceramic tiles

such as those related to surface, edge and corner. The

system worked in real time and was tested in a real

factory for validation with satisfactory results.

As stated in (Veeraraghavan et al., 2017), Battery

Management System (BMS) is a critical component

in electrical vehicles. Accurate detection of the actual

status of the battery is relevant, since this evaluation

has impact over the control of many stages of the car

functioning. Current models of battery estimation are

complex and unable to provide result information in

real time. Thus, authors applied deep learning tech-

niques to develop an less complex estimator which

would allow processing in real time. Complex bat-

tery model functionalities were simulated with using

neural networks and the models developed presented

high accuracy and real-time processing capabilities.

According to (Li et al., 2018), with the advance

of Internet of Things (IoT) have been largely incor-

porated into industry facilities. Allowing better mon-

itoring of their processes, sensors are now easier to

install on machinery and to be connected to local fog

via wireless networks. From sensors readings, often

with high sampling frequency, a big volume of data is

generated. From these data, authors proposed a clas-

sifier based on neural networks capable of detecting

faulty products. However, in order to be suitable for

industry, the classifier should be capable of running

inferences about all data in real time which could be

tackled using fog network.

Authors in (Rao and Frtunikj, 2018) elucidate dif-

ficulties that deep learning will find in automobile in-

dustry, bearing in mind the enormous effort that has

been applied in the production of autonomous vehi-

cles. One of the hardest difficulties is related to the

safety, since autonomous cars should not take deci-

sions harmful to passengers or people nearby.

For (Zhang et al., 2018), proposed the utilization

of a YOLOv2 for automated detection of oil facilities

to improve safety in extraction and production per-

formance. Results were compared to traditional tech-

niques with a combination of Haar features combined

AdaBoost classification. YOLOv2 presented higher

efficiency and accuracy.

As stated in (Choi et al., 2019), shipping indus-

try is one of the most dangerous and there are many

safety policies and techniques for decreasing the num-

ber of accidents. Besides the risk of not wearing

safety equipment appropriately, there exists the risk of

accidents due to unpredictable environment variables.

In this manner, authors proposed a model capable of

estimating the current risk of an environment, aiming

to evaluate which safety measures are more adequate

to make the workplace safer. A deep learning model

was trained and allowed the identification of danger-

ous zones, measuring risk automatically.

In (Chou et al., 2019), a detection scheme for

faulty coffee grains was proposed, together with a

Generative-Adversarial Network (GAN) which both

augmented the database and labeled new data. This

approach improved the generalization capability of

the model decreasing significantly the cost of creat-

ing the database, making it easier to train different DL

models for the task.

3 METODOLOGY

The steps that were followed in order to obtain our

results were;

1. building a database with labeled images for each

class;

2. designing deep network models considering ar-

chitectures more suited to the problem at hand;

3. testing the trained models.

3.1 Collecting the Database

The first stage of building the database was collect-

ing the images. For that, many photos of fire extin-

guishers were taken in diverse environments, such as,

the factory itself, the university facilities, many build-

ings, etc. One challenge was the difficulty in finding

fire extinguishers really rusty, or with noticeable de-

fects. This was due to safety laws that obligate near-

to-expire fire extinguishers to be replaced. Thus, im-

ages were also collected from the internet, with some

examples of faulty extinguishers. Another approach

was taking pictures of different rusty object while an-

notating only the rust. This strategy was aimed at

teaching the model characteristics of rust images in-

stead of teaching only what rusty extinguishers look

like.

After collecting fire extinguisher images and

emergency lamps, the annotation process begun. The

hose, the signaling plate, the rusty marks, the extin-

guisher body and the floor signaling were annotated

in extinguisher pictures. On the emergency lamp pho-

tos, the male socket plug, the female socket plug, the

status led and the body of the lamp were annotated.

These characteristics were chosen by considering the

demand presented by the company, which stated that

those are most common faults occurring on their fa-

cilities.

Visual Inspection of Collective Protection Equipment Conditions with Mobile Deep Learning Models

77

With respect to the extinguisher, only the hoses

in good conditions were annotated, considering that

the faulty hoses (including the ones placed inappro-

priately) were very different and, hence, should not

be detected by the model. Another reason for not an-

notating the situations where the hose was found in a

bad position was due to a proximity that the classes

would present in feature space, resulting in increased

difficulty for the classification. From the emergency

lamps, the power plug and the female socket on the

wall were annotated. If one of them was detected, we

assumed that the emergency lamp was not plugged

into the electrical power-line and, hence, was not be-

ing used.

Since the database was built from scratch, it did

not present many images per class, which led us to

apply some augmentation techniques to reduce over-

fitting. The first pre-processing technique was resiz-

ing all images to 300 × 300 pixels and the conversion

from PNG to JPEG. For data augmentation, the fol-

lowing techniques were used;

• vertical and horizontal mirroring;

• 90 degrees rotation;

• bright adjustment;

• resizing

• cropping

All augmentation techniques were applied ran-

domly during training. In the case of resizing and

cropping, the bounding boxes were taken into con-

sideration. When there were multiple objects of in-

terest in the same image, regions containing one or

more objects were extracted to generate a new sub-

image sample. This way, one image could generate

sub-images with combinations of its objects. At least

one object was visible for each sub-image.

3.2 Topologies

Three neural network topologies with very distinct

characteristics were chosen aiming to assess the pros

and cons of each one, in different circumstances. The

first was the MobileNet V2 SSDLite, proposed by

(Sandler et al., 2018). The second was FPN Resnet-

50 SSD, presented by (Lin et al., 2017). The third was

the Inception Resnet V2 Faster R-CNN with Atrous

Convolution, adapted from (Szegedy et al., 2017). All

architectures were trained using the same database,

for unbiased comparison.

3.2.1 MobileNet V2 SSDLite

The MobileNet V2 SSDLite (MV2) was chosen as the

first topology to be tested by the fact that it was de-

signed to run in mobile devices, which makes it faster

than other topologies. According to (Sandler et al.,

2018), the most important contribution presented in

MV2 was the new layers known as Inverted Residual

with Linear Bottleneck. This new layer presents an in-

put with reduced dimension, that is first expanded to

an increased dimension and filtered with depth-wise

separable convolutions. Next, filtered features have

their dimension reduced through linear convolutions.

The author also proposes a SSDLite that is a varia-

tion of the SSD, proposed by (Liu et al., 2016), with

the convolutional layers being replaced by depth wise

separable convolutions.

Despite the new layers Inverted Residual with Lin-

ear Bottleneck being the most important contribution

of MV2, they still inherit some very important charac-

teristics from its predecessor: the MobileNet V1. The

main inherited features are the depth-wise separable

convolutions, which decrease the necessary number

of mathematical operations in one inference, making

the topology faster to train and test. Depth-wise sep-

arable convolutions consist of replacing conventional

convolution by a factored version with two separated

layers. The first layer is the depth-wise convolution,

which executes a low-cost convolution applying only

one filter per input layer. The second layer is a 1 × 1

convolution, which is called point-wise convolution,

used to compute new features from the linear com-

bination of input layers. This is how the depth wise

separable convolutions is done. First, it applies only

one convolutional filter per each input layer. Then, it

summarizes the features generated on previous layer

with a 1 × 1 linear convolution.

3.2.2 FPN Resnet-50 SSD

The FPN Resnet-50 SSD (FPN50) has the follow-

ing characteristics: presents feature pyramid network

(FPN) as a generic extractor of features; has 50 resid-

ual layers; uses SSD as a multi-box detector.

The FPN is important by the fact that it aggregates

invariance to scale for the model. With respect to the

Resnet-50, its incorporation on the chosen model was

relevant since residual layers allow for more deep net-

works while preventing over-fitting. This is possible

because residual layers only apply convolutions when

strictly necessary. If not necessary, the layer will re-

produce the input on the output.

The FPN Resnet-50, proposed by (Lin et al., 2017)

was modified by replacing the Faster-RCNN by the

SSD. The FPN50 was chosen due to its capability of

detecting more complex features.

DeLTA 2020 - 1st International Conference on Deep Learning Theory and Applications

78

3.2.3 Inception Resnet V2 Faster R-CNN with

Atrous Convolution

Choosing the Inception Resnet v2 Faster R-CNN with

Atrous Convolution (IRV2) was due to the fact that it

presents, currently, one of the best results in object de-

tection according to (Huang et al., 2017). This topol-

ogy has a slower inference time than the previously

cited ones, since it is large, but also comes with larger

learning capabilities.

The IRV2 is a combination of the Inception Resnet

v2, proposed by (Szegedy et al., 2017), with the

Atrous Convolution, proposed by (Chen et al., 2017).

A model trained with this topology is not able to

compete with MV2 and FPN50, since the region pro-

posal architecture from it is the Faster-RCNN. Faster-

RCNN presents a bigger inference time when com-

pared to SSD, as showed by (Huang et al., 2017).

Thus, the main objective of using this topology

was to evaluate the performance of a model well

known by its high generalization capabilities and high

quality of bounding box prediction and classification.

This would bring a best case scenario in order to com-

pare previous models with it.

3.3 Training and Tests

For training and testing, it was defined which tech-

niques of database augmentation would be used, tak-

ing into consideration the low number of images per

class. Variables such as split ratio between training

and test sets, as well as evaluation metrics for the

model performance are chosen here. Training time

was also recorded for each model.

3.3.1 Data Augmentation

Chosen techniques for the augmentation were: ver-

tical and horizontal mirroring; 90 degrees rotation;

bright adjustment; resizing; and cropping.

Mirroring and rotations were made aiming at gen-

eralizing shapes of objects that were present on the

training base. However, using this kind of manipula-

tion excessively may produce the inverse effect, mak-

ing the model filters account more for color and tex-

ture.

Resizing and cropping had as objective the ag-

gregation invariance to scale for the models that do

not present this characteristic inherently, such as the

MV2.

With respect to the bright manipulation on the im-

age, this technique was aimed at making the model

less sensible to color, accounting more for contour

patterns and shapes.

3.3.2 Hardware and Software Infrastructure

A video-graphics card RTX 2080 Ti, with 11 GB of

RAM GDDR6, was used along with Object Detection

API from TensorFlow V1. The choice of a GPU of

family 20XX from Nvidia for training the models was

due to the presence of special cores in it, called Ten-

sorcores, which decrease training time significantly.

Tensorflow API for object detection provides all

topologies that were discussed previously, among oth-

ers. It allows for rapid prototyping, including easy ad-

justments in the parameters. This API also provides

pre-trained models with well known data-sets, allow-

ing for techniques such as transfer learning. It is ex-

tremely useful for limited custom databases.

In the adopted training process, pre-trained mod-

els were used for the three topologies on the

MSCOCO dataset, developed by (Lin et al., 2014).

We used 75% and 25% of the database for training

and testing ratio, respectively. Tests were carried out

over an Android smartphone, with a Snapdragon 845

processor.

3.3.3 Performance Metrics

In order to evaluate models at training and testing

time, the following metrics were defined: loss in

training set; loss in test set; Average Recall (AR) and

mean Average Precision (mAP) in test set; AR Across

Scales and mAP Across Scales in test set; frame rate

per second (FPS) on a mobile device and on RTX

2080 Ti.

Analysis of loss, both on training and test set, fo-

cused on evaluating if the models were generalizing

well or if they presented some over-fitting characteris-

tics. The AR metric calculation has three main config-

urations: (1) using one detection per image (AR@1);

(2) using ten detections per image (AR@10); and (3)

using 100 detections per image (AR@100). AR re-

sults using more detections tend to be better.

Similar to the AR, mAP calculations have three

main variants: (1) the mean of the Average Preci-

sion (AP) over the limits of Intersection over Union

(IoU), with values between 50% and 95% and step

of 5%; (2) the mean AP with IoU limits set to 50%

(mAP@0.5IoU); (3) the mean AP with IoU limits set

to 75% (mAP@0.75IoU).

With respect to Across Scales metrics, they are

calculated for three sets of objects: (1) small size

objects, with area less than 32

2

pixels; (2) medium

size objects, with area values between 32

2

e 96

2

pix-

els; and (3) large size objects, with dimensions larger

than 96

2

pixels. Thus, the AR Across Scales is cal-

culated for images with 100 detections for small ob-

Visual Inspection of Collective Protection Equipment Conditions with Mobile Deep Learning Models

79

jects (AR@100 small), medium objects (AR@100

medium) and large objects (AR@100 large).

By the other hand, mAP Across Scales is calcu-

lated using mAP’s first configuration for small im-

ages (mAP small), medium images (mAP medium)

and large images (mAP large). The analysis over the

FPS indicator, which consists of the number of im-

ages per second that the model able to analyze, is also

used for speed and efficiency analyses.

4 RESULTS AND DISCUSSION

As the training and testing activities were being ex-

ecuted, results were collected and evaluated, assess-

ing whether it was necessary to modify any configu-

rations. Thus, in this section, obtained results from

each methodology section will be presented.

4.1 Database

Collected database resulted in 137 photos of emer-

gency lamps, 147 photos of rusty objects and 256

photos of fire extinguishers. Even though we col-

lected photos from emergency lamps, models were

trained without this class of objects. This was due to

the fact that some of the objects from lamp emergency

class did not appear very clearly, which was the same

problem for the status led class. Trained models were

not able to find the power socket from the emergency

lamps either, explained by the lack of sufficient im-

ages for the proper generalization. Therefore, we de-

cided to train the models only for the classes strictly

related to fire extinguishers. Some examples from the

tailored dataset can be seen at Figure 2.

4.2 Models Performance

Performance for each of the trained models will be

analyzed in this section considering the metrics dis-

cussed in Section 3.

4.2.1 Losses

Losses for each model for both training and testing

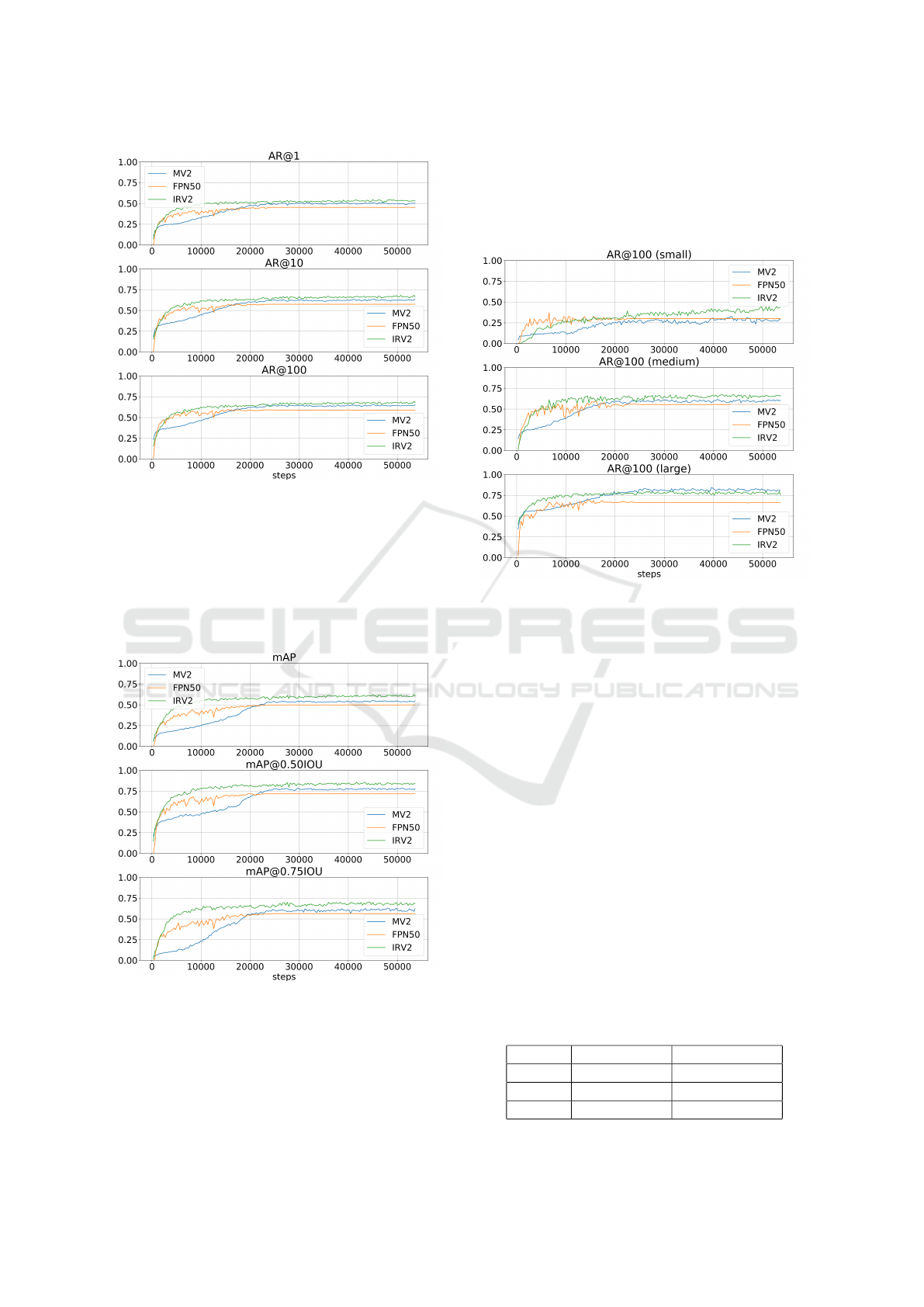

sets can be seen on Figure 3. Results show that losses

for FPN50 and IRV2 are significantly smaller than

MV2.

4.2.2 Average Recall

Here it is shown the AR results using all discussed

configurations : AR@1, AR@10 e AR@100. They

Figure 2: Database containing fire extinguishers (top cou-

ple of rows), vertical (red signs pointing out where extin-

guishers are) and horizontal (yellow stripes) signalization

and emergency lamps (bottom two rows).

Figure 3: Training and evaluation losses for the three mod-

els.

can be seen at Figure 4. It shows that MV2 had sim-

ilar results from IRV2, although it took more time to

reach its value. With respect to FPN50, it showed bet-

ter results considering the initial steps of training, but

had worse performance when compared to other two

models at the end of training. IRV2 kept better than

other models during all the training, no matter what

configurations was used.

4.2.3 Mean Average Precision

Regarding the mAP metric, shown in Figure 5, better

results were obtained from mAP@0.5IoU configura-

DeLTA 2020 - 1st International Conference on Deep Learning Theory and Applications

80

Figure 4: Average Recall for the three models.

tion. In a broader perspective, MV2 model was able

to approach the IRV2 for all configurations consid-

ering the last steps of training. FPN50, once again,

presented the best results at the training start, but did

not manage to maintain its lead until the end. During

all the training, IRV2 kept itself as the best model no

matter what configuration.

Figure 5: Mean Average Precision calculated for the three

models.

4.2.4 Average Recall across Scales

Results for the metric AR Across Scales are showed

in Figure 6. All models presented better results for

larger objects, when compared to medium and small

objects. MV2 presented a better result than IRV2 for

large objects. It is also shown that IRV2 presented

significantly better results for small objects. FPN50

results stabilizes quicker for all configurations, and

shows slightly better results for small objects.

Figure 6: Average Recall Across Scales for the three mod-

els.

4.2.5 Mean Average Precision across Scales

Results showed, as illustrated in Figure 7, that MV2

did not present good results for small objects. How-

ever, for medium and large objects, results are im-

proved for this topology, being closer to IRV2 per-

formance. FPN50 model presented to be better than

MV2, for small objects, but did not reach results as

good for medium and large objects.

4.2.6 Frames per Second Ratio

As listed in Table 1, it is shown that MV2 reaches

much better results than the other two models with

respect to Frames per Second (FPS). MV2 is the only

one that is able to run in a mobile device appropri-

ately. FPN50 is the second fastest, which presents a

good performance when running in a RTX 2080 Ti

graphics card. IRV2, at last, is not able to achieve a

good performance, running on average of 3 FPS.

Table 1: FPS rate for the three models in RTX 2080 Ti and

mobile device.

Models RTX 2080 Ti Mobile Device

MV2 42 5

FPN50 12 -

IRV2 3 -

Visual Inspection of Collective Protection Equipment Conditions with Mobile Deep Learning Models

81

Figure 7: Mean Average Precision Across Scales for the

three models.

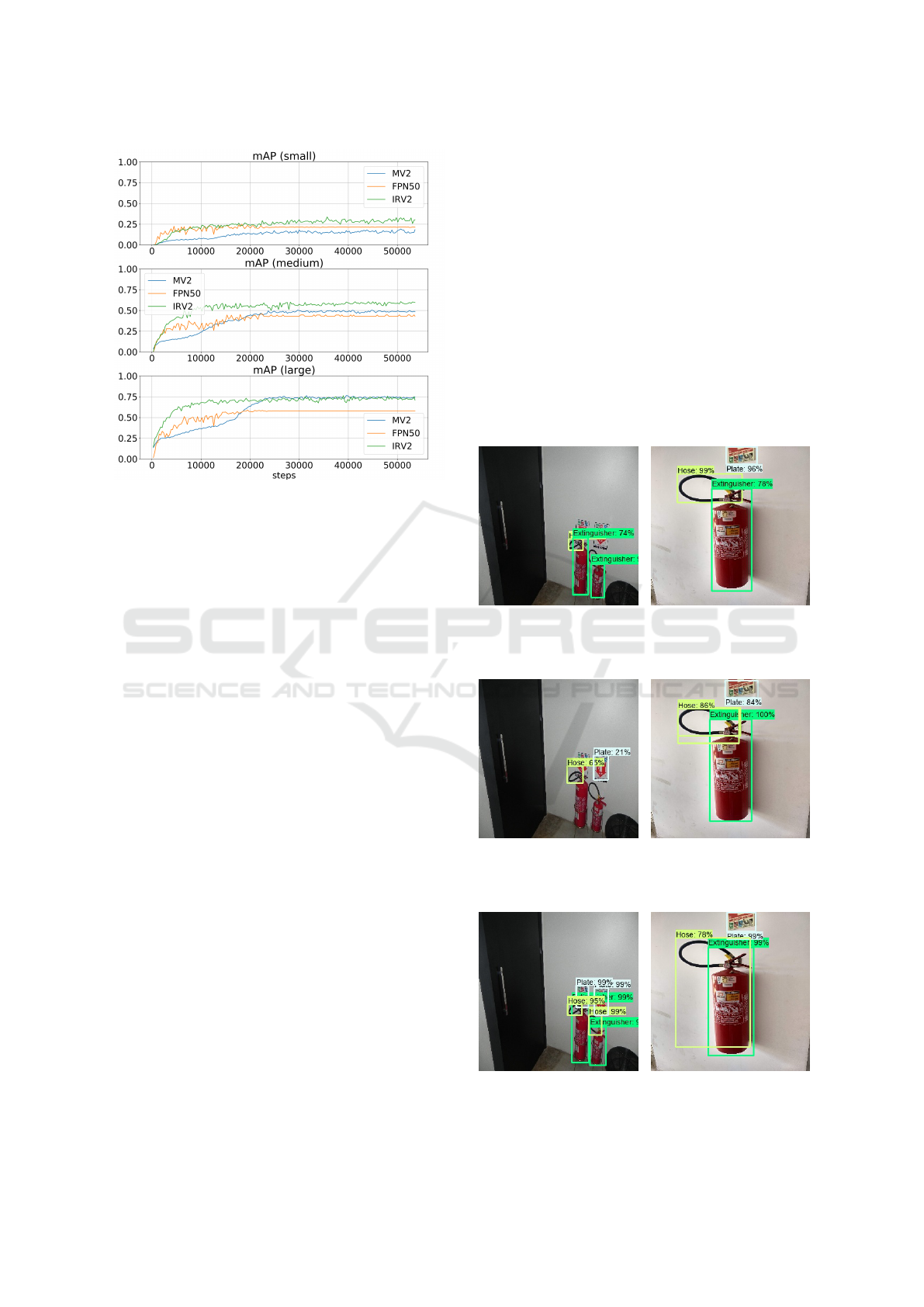

4.2.7 Comments about Models Performance

MV2 showed to be very versatile, achieving good

results to medium and large objects. Along with

FPN50, they were faster than IRV2. Despite achiev-

ing good results, MV2 and FPN50 did not perform

as good when the input image contained objects in a

more complex environment. Analyzing images pre-

sented at the Figures 8a, 9a and 10a, it’s possible

to notice that IRV2 managed to capture more com-

plex patterns from the image and carry out the detec-

tion successfully even in not so well behaved images.

Nonetheless, cases where images are ofter well be-

haved, models are able to reach similar results, as it is

shown in the Figures 8b, 9b and 10b.

5 CONCLUSION AND FUTURE

WORKS

Three models capable of detecting faults in fire extin-

guishers were detected. Used methodology may be

applied to other objects within industry environment

and developed models are adequate to different kinds

of auditing. A specific database was built using dif-

ferent sources and data augmentation. It was used to

train and test the models.

Results have shown that the MV2 allows for the

execution of an auditing in real time, by using the

model on a mobile device, or even on a computer if

better efficiency is need. FPN50 is an in-between for

the two other models, since it is able to detect small,

medium and big defects in the fire extinguishers and

allows for execution in real time, but cannot be ex-

ecuted in a mobile device. IRV2 provides the capa-

bility of detecting more complex patterns, being able

to better detect the flaws in the extinguishers and sig-

nificantly reducing the number of false-positives and

false-negatives. On the other hand, IRV2 requires

more robust computing power in order to be carried

out. Using networks pre-trained on large datasets al-

lowed for the models to converge easier when trained

on smaller datasets. This kind of approach is suitable

for deep learning applications.

As future works, more images will be fed into the

dataset and more classes will be created. With respect

to emergency lamps, more images will be collected so

that their audit can be executed along with extinguish-

(a) Unfavorable (b) Normal

Figure 8: Performances of FPN50’s topology when submit-

ted to unfavorable and normal scenarios.

(a) Unfavorable (b) Normal

Figure 9: Performances of MV2’s topology when submitted

to unfavorable and normal scenarios.

(a) Unfavorable (b) Normal

Figure 10: Performances of IRV2’s topology when submit-

ted to unfavorable and normal scenarios.

DeLTA 2020 - 1st International Conference on Deep Learning Theory and Applications

82

ers and other objects that will be incorporated on the

database.

We also intend to address other industry problems,

such as the verification of the load from the extin-

guisher, and if its labeling panel is preserved and read-

able. More up-to-date topologies will also be tested,

aiming to obtain better results for mobile devices.

Further results will be reported eventually.

ACKNOWLEDGEMENTS

The authors would like to thank the Edge laboratory

1

at the Federal University of Alagoas

2

which funded

this research through an agreement regulated by the

Information Technology Law.

REFERENCES

Aggarwal, C. C. (2018). Neural Networks and Deep Learn-

ing. Springer International Publishing, 1 edition. 1

Chen, L.-C., Papandreou, G., Kokkinos, I., Murphy, K., and

Yuille, A. L. (2017). Deeplab: Semantic image seg-

mentation with deep convolutional nets, atrous convo-

lution, and fully connected crfs. IEEE transactions on

pattern analysis and machine intelligence, 40(4):834–

848. 4

Choi, Y., Park, J.-H., and Jang, B. (2019). A risk estima-

tion approach based on deep learning in shipbuilding

industry. In 2019 International Conference on Infor-

mation and Communication Technology Convergence

(ICTC), pages 1438–1441. IEEE. 2

Chou, Y.-C., Kuo, C.-J., Chen, T.-T., Horng, G.-J., Pai, M.-

Y., Wu, M.-E., Lin, Y.-C., Hung, M.-H., Su, W.-T.,

Chen, Y.-C., et al. (2019). Deep-learning-based de-

fective bean inspection with gan-structured automated

labeled data augmentation in coffee industry. Applied

Sciences, 9(19):4166. 2

Dargan, S., Kumar, M., Ayyagari, M. R., and Kumar, G.

(2019). A Survey of Deep Learning and Its Ap-

plications: A New Paradigm to Machine Learning.

Archives of Computational Methods in Engineering.

1

Hocenski,

ˇ

Z., Mati

´

c, T., and Vidovi

´

c, I. (2016). Technol-

ogy transfer of computer vision defect detection to ce-

ramic tiles industry. In 2016 International Conference

on Smart Systems and Technologies (SST), pages 301–

305. IEEE. 1

Huang, J., Rathod, V., Sun, C., Zhu, M., Korattikara, A.,

Fathi, A., Fischer, I., Wojna, Z., Song, Y., Guadar-

rama, S., et al. (2017). Speed/accuracy trade-offs for

modern convolutional object detectors. In Proceed-

ings of the IEEE conference on computer vision and

pattern recognition, pages 7310–7311. 4

1

http://edgebr.org/

2

https://ufal.br/

Li, L., Ota, K., and Dong, M. (2018). Deep learning for

smart industry: Efficient manufacture inspection sys-

tem with fog computing. IEEE Transactions on In-

dustrial Informatics, 14(10):4665–4673. 2

Lin, T.-Y., Doll

´

ar, P., Girshick, R., He, K., Hariharan, B.,

and Belongie, S. (2017). Feature pyramid networks

for object detection. In Proceedings of the IEEE con-

ference on computer vision and pattern recognition,

pages 2117–2125. 3

Lin, T.-Y., Maire, M., Belongie, S., Hays, J., Perona, P.,

Ramanan, D., Doll

´

ar, P., and Zitnick, C. L. (2014).

Microsoft coco: Common objects in context. In Euro-

pean conference on computer vision, pages 740–755.

Springer. 4

Liu, W., Anguelov, D., Erhan, D., Szegedy, C., Reed, S.,

Fu, C.-Y., and Berg, A. C. (2016). Ssd: Single shot

multibox detector. In European conference on com-

puter vision, pages 21–37. Springer. 3

Rao, Q. and Frtunikj, J. (2018). Deep learning for self-

driving cars: chances and challenges. In Proceedings

of the 1st International Workshop on Software Engi-

neering for AI in Autonomous Systems, pages 35–38.

2

Sandler, M., Howard, A., Zhu, M., Zhmoginov, A., and

Chen, L.-C. (2018). Mobilenetv2: Inverted residu-

als and linear bottlenecks. In Proceedings of the IEEE

conference on computer vision and pattern recogni-

tion, pages 4510–4520. 3

Szegedy, C., Ioffe, S., Vanhoucke, V., and Alemi, A. A.

(2017). Inception-v4, inception-resnet and the impact

of residual connections on learning. In Thirty-first

AAAI conference on artificial intelligence. 3, 4

Veeraraghavan, A., Adithya, V., Bhave, A., and Akella, S.

(2017). Battery aging estimation with deep learning.

In 2017 IEEE Transportation Electrification Confer-

ence (ITEC-India), pages 1–4. IEEE. 2

Zhang, N., Liu, Y., Zou, L., Zhao, H., Dong, W., Zhou, H.,

Zhou, H., and Huang, M. (2018). Automatic recog-

nition of oil industry facilities based on deep learning.

In IGARSS 2018-2018 IEEE International Geoscience

and Remote Sensing Symposium, pages 2519–2522.

IEEE. 2

Visual Inspection of Collective Protection Equipment Conditions with Mobile Deep Learning Models

83