Capability Management in Resilient ICT Supply Chain Ecosystems

Jānis Grabis

1

, Janis Stirna

2

and Jelena Zdravkovic

2

1

Department of Management Information Technology, Riga Technical University, Kalku 1, Riga, Latvia

2

Department of Computer and Systems Sciences, Stockholm University, Borgarfjordsgatan 12, Stockholm, Sweden

Keywords: ICT Supply Chain, Capability, Digital Twin.

Abstract: An ICT system consists of multiple interrelated software and hardware components as well as related services.

They are often produced by a complex network of suppliers the control of which is hard, time consuming and

in many cases almost impossible for a single company. Hence, it is a common practice for malicious actors

to target the ICT product supply chain assuming that some members have lax security practices or lag behind

in terms of using the latest solutions and protocols. A single company cannot assure the security of complex

ICT systems and cannot evaluate risks and therefore, to be successful it needs to tap into a wider network of

ICT product developers and suppliers, which in essence leads to forming an ecosystem. We propose in this

study that such an ecosystem should be established and managed on the bases of its members capabilities,

which in this means capacity to meet desired goals, i.e., security and privacy requirements in a dynamic

business context. The proposal is illustrated on the case of the ICT product called IoTool, which is a

lightweight IoT gateway. The IoTool uses various third-party components such as sensors and actuators

supplied by different vendors.

1 INTRODUCTION

An ICT system consists of multiple interrelated

software and hardware components as well as related

services. These services are often produced by a

complex network of suppliers the control of which is

hard, time consuming and in many cases almost

impossible for a single company. Hence, it is a

common practice for malicious actors to target the

ICT product supply chain assuming that some of its

members have lax security practices or lag behind in

terms of using the latest solutions and protocols. From

the perspective of a product developer, onboarding of

new supply chain members is challenging, especially

in the case of decentralized supply chains and short

life-cycle products. Ongoing research suggests that

many procurement professionals do not consider

vendors’ cybersecurity capabilities to be an important

factor in selecting top-tier suppliers and calls for

action to address this (Rogers and Choi 2018). There

are many examples of supply-chain-induced

vulnerabilities. For example, 40 million Target credit

card data were stolen by exploring a security

shortcoming in HVAC devices used at the stores and

supplied by an external vendor or 40,000 U.K. users

were affected by a data leak in a third party customer

chat-bot (Kshetri and Voas 2019). Experts predict

that these problems will be amplified by a rush for

creating new devices and services relying on the 5G

mobile network (Madnick, 2019) which would open

the doors for malicious actors to exploit

vulnerabilities.

The position of this paper is that any member of

the ICT supply chain should have a capability to be

able to contribute to the development of secure and

trusted ICT systems (Zdravkovic et al., 2017). In this

regard capability is seen as an ability and capacity to

meet desired goals (i.e., security and privacy

requirements) in dynamic context (Sandkuhl and

Stirna, 2018).

A single company cannot assure the security of

complex ICT systems and cannot evaluate risks.

Therefore, the company needs to tap into a wider

network of ICT product developers and suppliers,

which leads to forming an ecosystem. Being a part of

a business ecosystem, provides a company with

abilities to leverage its technology, achieve

excellence in competences, as well as to collaborate

and compete with other companies of various sizes.

Making a company and its business offerings to fit to

a business ecosystem requires adjusting its goals,

capabilities and processes, which also leads to

improving the management of operations critical to

success. An ecosystem is seen as a network of

Grabis, J., Stirna, J. and Zdravkovic, J.

Capability Management in Resilient ICT Supply Chain Ecosystems.

DOI: 10.5220/0009573603930400

In Proceedings of the 22nd International Conference on Enterprise Information Systems (ICEIS 2020) - Volume 2, pages 393-400

ISBN: 978-989-758-423-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

393

organizations bound by both cooperation and

competition in their effort of delivering products and

services. Since today’s development and delivery of

ICT products and services is carried out digitally, in

this paper we are referring to Digital Business

Ecosystems (DBE). Members of such an ecosystem

have a joint interest to identify security threats and to

establish trust, while they might have vastly different

motivations in business terms. From the point of view

of an ecosystem, a key security related motivator is

the ability to ensure trust and resilience.

Evaluation of security concerns is an ongoing

activity as ICT product supply chain topology

continuously evolves in the dynamic context. A data-

driven digital twin resembling the ICT product

supply chain is used for continuous exploration and

prediction of arising threats. The digital twin explores

input and output data and limited knowledge of ICT

product supply chain’s internal structure to evaluate

threats. The evaluation and enactment of mitigation

actions require members’ collaboration across the

ecosystem. Hence, there is a need to develop methods

and business models for enabling this collaboration

and automated knowledge creation and application of

mitigation solutions. The knowledge in turn will

facilitate further design and auditing of ICT products

and their supply chains.

As a step towards the elaboration of such a digital

business ecosystem, the goal of this paper is to

conceptually outline a method framework and an

architecture of a software platform for efficient

development and management of resilient ICT supply

chains in dynamically evolving ICT product

ecosystems. The proposed approach employs the

principles of capability management and uses data-

driven digital twins for collaborative security and

trust evaluation.

The rest of the paper is structured as follows:

Section 2 outlines our ecosystem-based approach for

managing secure supply chains. Section 3 elaborates

the digital twin component, focal for enabling

security analysis in the chain. In section 4 a business

case is described as a proof-of-concept. A discussion

is given in section 5 including concluding remarks

and future work.

2 THE DBE-BASED APPROACH

ICT product Supply chains deal with creating specific

products or services, hence its ecosystem

encompasses different supply chain members and

other relevant business parties. The lead supply chain

member creates an ICT product supply chain

topology and the rest supply chain members

(partners) are selected according to their ability to

deliver trusted product capabilities.

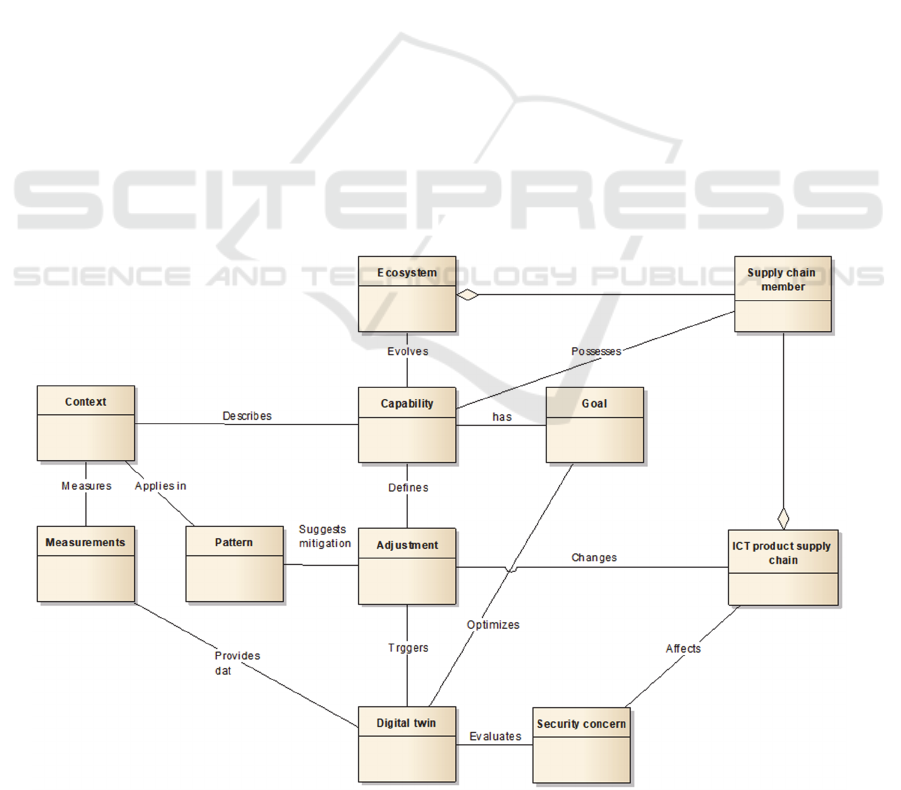

Figure 1: Conceptual model of the approach.

ICEIS 2020 - 22nd International Conference on Enterprise Information Systems

394

Our approach is based on the principle of a functioning

and evolving Digital Business Ecosystem. It consists

of the following core building blocks (1) the principle

of ecosystems of supply chains for ICT systems for

collaboration in terms of sharing knowledge for

solving threats and building trust, (2) the notion of

capability for configuring the supply chains with goal

and context awareness, (3) the need to develop and

manage digital twins to simulate and predict the

behaviour of the supply chain from the data of

executing capabilities, and (4) a collaboration-based

approach to the reconfiguration and adjustment of

supply chains to ensure needed security and optimal

trust. In Figure 1 the core conceptualisation for our

DBE-based approach is presented:

Capability defines a supply chain’s member’s

ability to provide secure and trusted products and

services. It serves as a protector for selecting supply

chain members, which are required to share common

goals, provide required contextual information, as

well as to share knowledge to a degree of trust

required in the supply chain. The elements of a

capability externally relevant are exposed through its

interface visible to any supply chain member being

involved in the ecosystem. Any context data of any

capability of the members is captured by measurable

properties (event logs, sensors) and streamed to the

digital twin of the supply chain. The twin is

responsible to detect any adverse security concern

related event, including trust and privacy violations

from the data received; it then acts, by relying on the

knowledge patterns available in the ecosystem, and

determine adjustments of related capabilities to stop

or diminish undesired behaviour measured by

capability’s KPI.

The capabilities are continuously developed in the

ecosystem by accumulating and formalizing secure

ICT product supply chain management knowledge

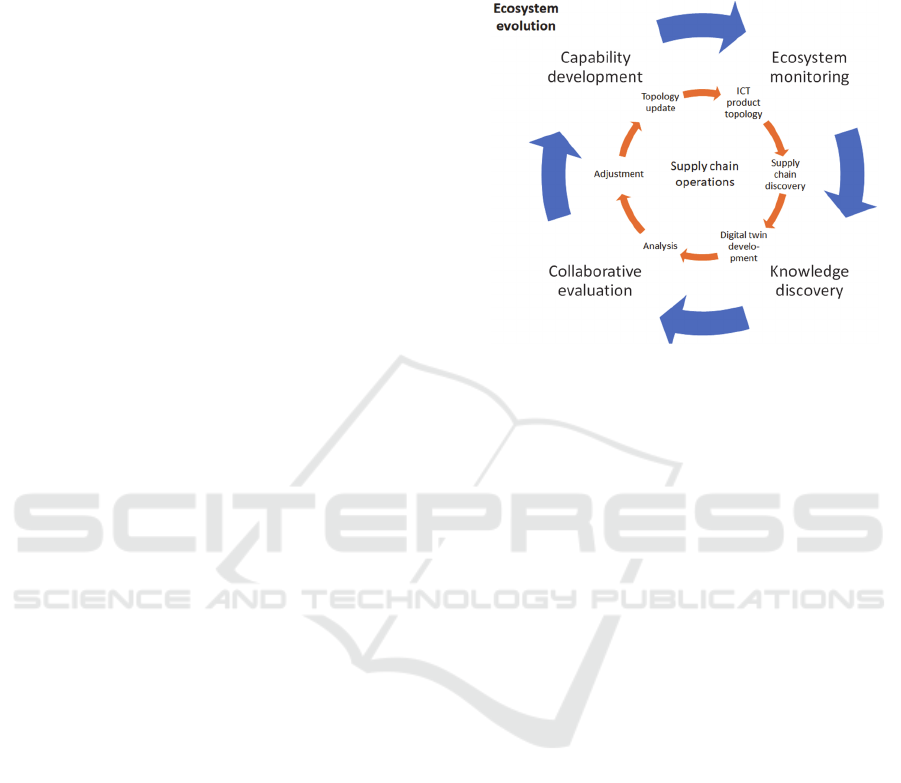

(Figure 2). The ICT product supply chain is dynamic

with hidden tiers, members, and connections, and live

supply chain and context data are analysed to uncover

these hidden aspects. A data-driven digital twin is

created to explore various supply chain operations

scenarios and for predicting the need for appropriate

adjustments. As the result, the supply chain topology

is updated. The topology reflects not only elements

defined in the initial design but also ones discovered

during supply chain operations.

Live ICT product supply chain analysis and

experimentation lead to knowledge discovery, i.e. to

eliciting the information relevant for dealing with

security concerns; which contextual information is

needed; and which data trends indicate security

threats. The knowledge is represented using patterns

that are subjected to collaborative evaluation in the

ecosystem. The patterns accepted by the chain

community contribute to further development for

secure supply chain management capabilities.

Figure 2: Dynamic interactions in the ICT product supply

chain and ecosystem.

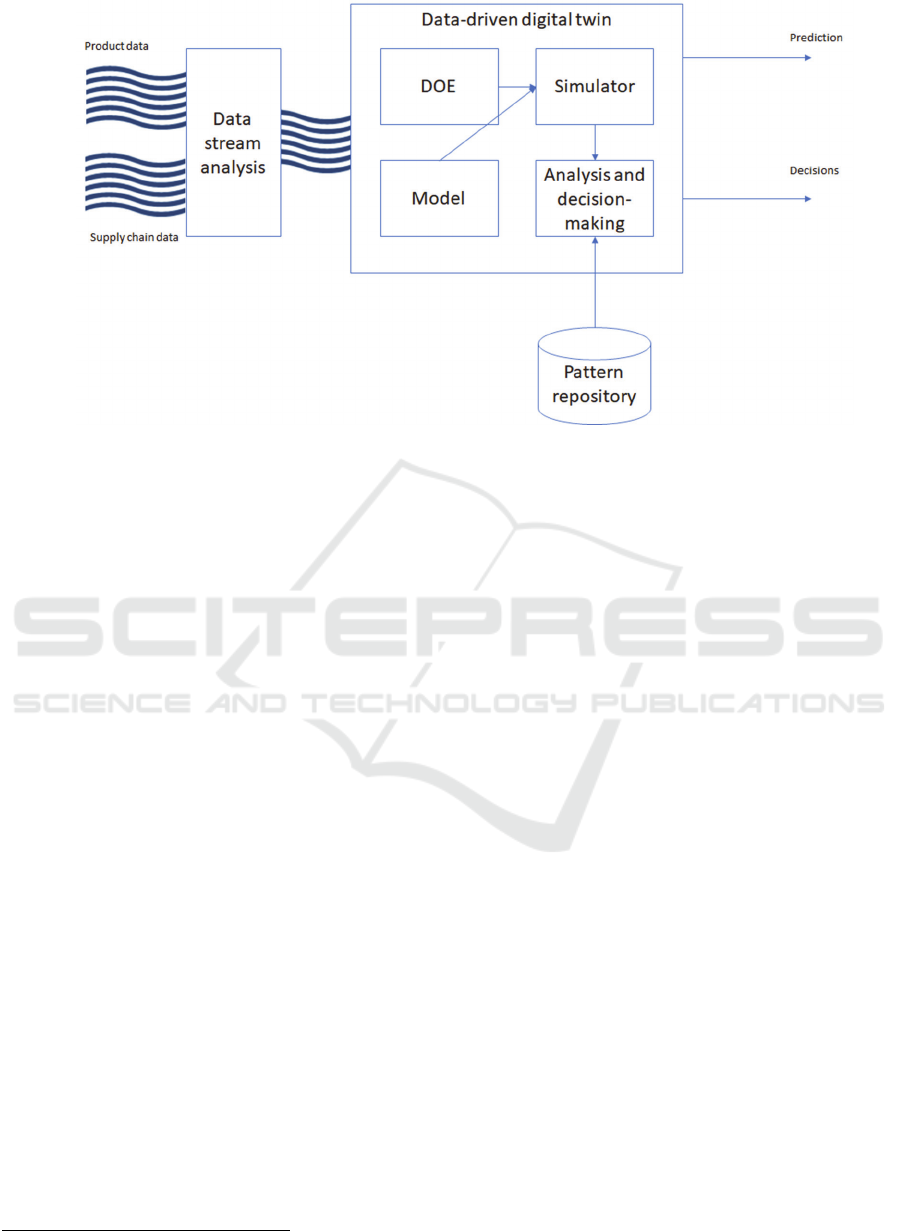

3 DATA-DRIVEN DIGITAL TWIN

A data-driven digital twin is a digital representation

of an ICT product supply chain on the basis of live

data streams for the purposes of analysis of security

concerns and experimentation (Figure 3). The ICT

product supply chain is only partially observable and

there is some level of uncertainty and missing data in

its representation. Therefore, it is referred as to data-

driven because of relaxed requirements in terms of

knowing the internal structure of the supply chain.

The digital twin receives data about a live ICT

product supply chain as specified in the Model

representing capabilities of the suppliers. The data

are representing the product and supply chain

perspectives. The data streams are analysed to

identify irregularities and to benchmark them against

the normal behaviour captured in the patterns. The

digital twin itself is used to predict the behaviour of

the ICT product supply chain and to propose

adjustments to cope with security concerns and to

reconfigure the supply chain. The digital twin uses a

learning based prediction model. The Design-of-

experiments (DOE) module is used to specify

manually or automatically scenarios to be explored to

identify weaknesses and potential threats. The

Simulator module is responsible for generating the

scenarios. The evaluation scenarios are visualized and

the prediction results are transferred to the portal and

the dashboard.

Capability Management in Resilient ICT Supply Chain Ecosystems

395

Figure 3: Components of the data driven digital twin.

4 PROOF-OF-CONCEPT

The example case considers an ICT product called

IoTool

1

, which is a lightweight IoT gateway. The

IoTool uses various third-party components such as

sensors and actuators supplied by different vendors.

The tool vendor needs to ensure that the components

are trusted, i.e. that they do not compromise IoTool

end-users. Currently, the IoTool design implements

fair-enough security, but it needs to face the

interoperation with additional untrustworthy IoT

devices and protocols which usually are black-boxes

in the sense that offer little information with regard to

which security and privacy protections they

implement.

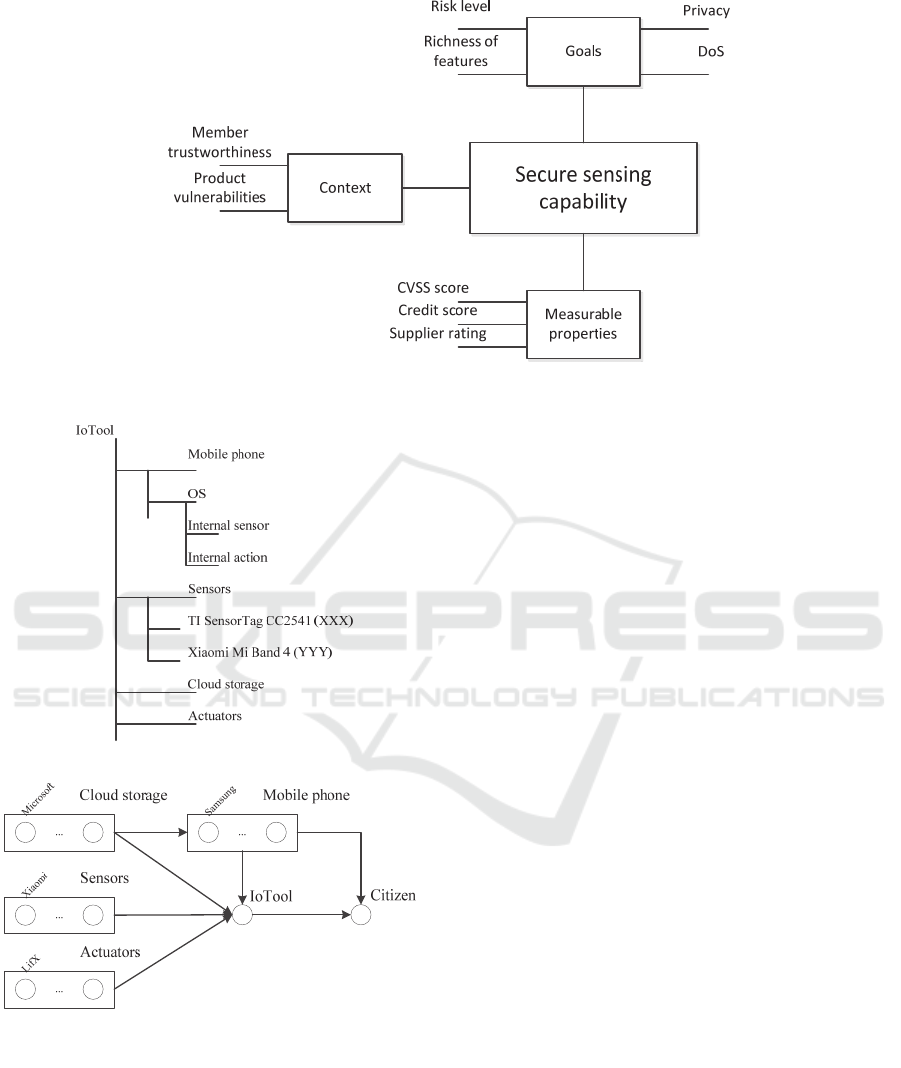

4.1 Capability Model

The IoTool solution uses some out-of-the-box

devices (e.g. smartphones) which are not 100%

secure; as well as the final users want to use them for

other purposes (e.g. as personal devices). It is

necessary therefore to ensure that the data transport

protocol is secured to keep data integrity and

confidentiality. By adopting the envisioned DBE-

based approach, the IoTool requires that vendors of

the connected devices provide the secure-sensing

capability (Figure 4). The goals of secure-sensing

capability are to preserve data privacy and to prevent

using sensing devices for DOS or similar malicious

activities as well as to have an appropriate risk level

and to provide the desired features requested from

customers. To ensure that the ICT product supply

chain is able to achieve these goals, the context is

defined, where the vendors and devices are

characterized by their trustworthiness and

vulnerabilities. Measurable properties (i.e., raw data)

are used to evaluate the context. Both internal and

external data sources are used.

The ICT product supply chain topology including

its product design and supply chain configuration is

developed (Figure 5). There is a choice between

various providers, for example, the IoTool can use

different cloud storage vendors, which could be also

selected according to their ability to support the

secure-sensing capability. Once the IT environment

supporting the digital twin for the supply chain is put

in place, the context is continuously evaluated on the

basis of the measurable property data and if

irregularities are observed the supply chain is

reconfigured. For example, in case external data

sources provide a report that one of the vendors has

supplied insecure devices and the Vendor

trustworthiness falls below a certain threshold set by

the IoTool vendor, the sensors provided by this

supplier are excluded from the offering.

1

https://iotool.io/

ICEIS 2020 - 22nd International Conference on Enterprise Information Systems

396

Figure 4: Secure sensing capability model.

Figure 5: Fragments of IoTool product design and supply

chain. The rectangles represent products; circles represent

vendors or supply chain members.

4.2 Supply Chain Configuration

ICT supply chain is continuously monitored for

security concerns. The digital twin employs various

models to represent and to analyse the supply chain.

A data driven supply chain configuration model

(Grabis et al. 2012) is one of these models. It uses the

current data to evaluate agreement of the established

supply chain typology with goals defined in the

capability. In the sample model provided, the supply

chain risk minimization is considered. The model

selects supply chain members (referenced using index

j) and products (references using index i) to minimize

the overall supply chain level of risk R (Eq. 1). The

risk is calculated by taking into account the context

factors, namely, the product vulnerability score a

i

and

supply chain member trustworthiness score b

j

. The

parameters w

i

indicate the relative importance of the

product item in the ICT product and

ij

is 1 if the ith

product is provided by the jth supply chain member

and 0 otherwise. The decision variable X

ij

is 1 if the

ith product provided by the jth supply chain member

is included in the ICT product supply chain and 0

otherwise.

11

min

MN

iijij ij

ij

RwabX

(1)

Eq. 2 requires the minimum set of features for the

ICT product stating that a function f of the selected

products should be larger than a specified threshold

F.

f

FX

(2)

Moreover, any selected supply chain member is

required to possess the secure sensing capability what

is represented by constraints in Eq. 3-5. The overall

trustworthiness risk contribution for any supplier

should not exceed the threshold T (Eq. 3). The

product item individual risk contribution should not

exceed the threshold U (Eq. 4). The supply chain

member trustworthiness score should be available

Capability Management in Resilient ICT Supply Chain Ecosystems

397

(Eq. 5), i.e. context data about the member should be

available.

1

,

M

i j ij ij

i

wb X T

j

(3)

,,

i j ij ij

ab X U i

j

(4)

,

j

b

j

(5)

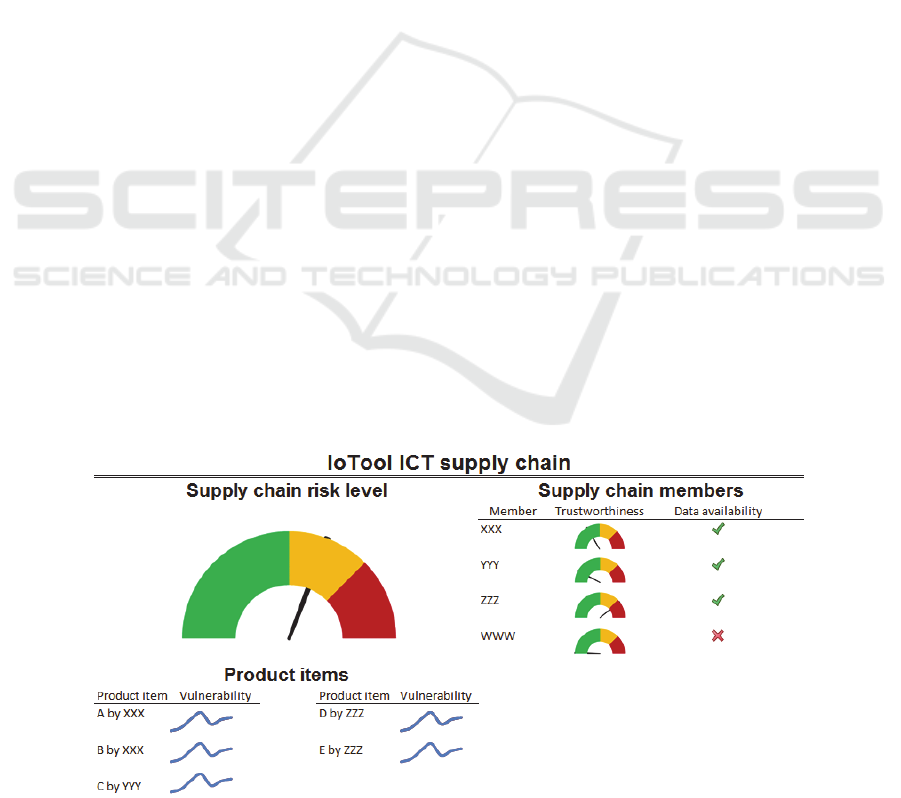

The ICT supply chain monitoring and

configuration results are represented using a

dashboard (Figure 6.) The dashboard shows the

current overall risk, the trustworthiness of individual

supply chain members and the vulnerability dynamics

of the product items. It is assumed that the

trustworthiness score is evaluated using data (i.e.,

measurable properties) provided from a credit scoring

agency (e.g., https://www.companyhouse.de/) and

the product vulnerability score is evaluated using data

from the Common Vulnerabilities and Exposures

database (https://cve.mitre.org/).

The example shows that the overall risk is below

the required threshold, however, the trustworthiness

of one of the supply chain members has declined.

Therefore, a supply chain configuration model

execution round should be triggered and

recommendations for supply chain reconfiguration

should be generated.

5 RELATED WORK

ICT products are ubiquitous and of major importance

in businesses and societies. These products are highly

modular and their components are sourced globally.

However, they often lack transparency and their

design evolves rapidly. Therefore, the supply chain

perspective of ICT products grows rapidly (Lu et al.,

2013). The concurrent product-supply chain design is

widely accepted in the supply chain management

theory and practice (Gran and Grunow, 2016).

However, the traditional supply chain configuration

methods (Chandra and Grabis, 2016) are not suitable

for secure ICT product supply chains because supply

chain topology is highly complex and rapidly

evolving. Traditional supplier on-boarding and

quality assurance techniques (Nikou et al., 2017) are

too time-consuming and require detailed product

design information. Data analytics help to uncover

complex supply chain topologies (Zhao et al., 2018),

though currently, the analysis is based on static data

structures. There are a number of developments on

secure supply chain management (Hasan et al., 2020)

as well as security concerns specifically from the ICT

perspective (Polatidis et al., 2017). However, these

methods are based on traditional security

management frameworks as well as they rely on static

analysis and periodic product and process inspection.

Lately, the principle of the DBE has received

attention for supporting and analysing networks of

companies and collaboration among them, cf., for

instance, (Conti et al., 2019; de Reuver et al., 2018;

Mäntymäki et al., 2018; Senyo et al,. 2017). The state

of the art in this area is mostly devoted to discussion

the viability of the ecosystem-based approach and to

proposing theoretical foundations.

Capability management (Sandkuhl and Stirna,

2018) is an approach to maintain viable DBEs. It

brings together organizations by sharing common

value, information and knowledge what can be

successfully applied also for security management

purposes. Lately, capability management has been

extended by open data processing for the purpose of

ensuring that business capabilities can be adjusted

Figure 6: Sample ICT supply chain dashboard.

ICEIS 2020 - 22nd International Conference on Enterprise Information Systems

398

and configured dynamically at run-time (Kampars et

al., 2019). Data stream processing is used to analyse

data needed for capability development and analytical

tools like digital twins can be used to evaluate the

required adjustment.

In the best and most advanced cases (Kritzinger et

al., 2018) digital models of supply chains are created

automatically (by analysing large sets of data

available in the existing ERP systems), which allows

speaking of digital shadows. These models are called

“shadows” because they do not provide automatic

mechanisms of intervention into the real world supply

chains for solving emerging business changes,

challenges, and disruptions. The proposal aims to

create true digital twins that will be created

automatically and provide means for automatic

configuration of the supply chain of ICT products.

The concept of digital twins just recently started to

get attention for application in the security

management domain. For instance, (Eckhart et al.

2019) propose to use digital twins to rise cyber

situational awareness for cyber-physical systems

through visualizations. Viability of using data

streams in digital twining has been recently

demonstrated by (Murphy et al. 2020).

6 DISCUSSION AND

CONCLUSIONS

This paper has presented a method framework and an

architecture of a software platform for efficient

development and management of resilient ICT supply

chains in dynamically evolving ICT product

ecosystems. The proposed approach is based on

capability management in digital business

ecosystems and it uses data-driven digital twins for

collaborative security and trust evaluation. The

specific novel contributions of the envisioned

approach are as follows. (1) A method bringing

together separate and diverse methods and tools

(capability management, digital twins, data stream

processing) to provide users with evidence-based

guidance to design and execute trusted and secure

ICT product supply chains. (2) Model-driven ICT

product supply chain optimization according to

business concerns such as goals and qualification

constraints. These are specified in the supply chain

capability model to account for reconfiguration

needs, supply chain partner selection, concurrent

product design, as well as for the fulfilment of trust

and security requirements. (3) The envisioned

approach allows including AI-based data streaming

solutions for graphs with changing structure, such as

dynamic ICT product supply chain topology and

variable data sources for identifying security

concerns and for discovering supply chain

management pain-points for further analysis using

digital twins and security services. (4) Data-driven

digital twin of combined physical and virtual entities

with limited knowledge of internal structure of ICT

product supply chain, for predicting the behaviour of

the chain, proposing the adjustments for coping with

identified security problems, and for reconfiguring

the supply chain. (5) Evidence-based collaborative

evaluation of security concerns using specialized

security management services and pattern discovery

that allow sharing supply chain knowledge to relevant

collaboration partners on mutually beneficial terms.

REFERENCES

Chandra, C., Grabis, J., 2016. Supply Chain Configuration,

Springer.

Conti, V., Ruffo, S.S., Vitabile, S. et al. 2019. BIAM: a new

bio-inspired analysis methodology for digital

ecosystems based on a scale-free architecture. Soft

Computing, Springer, pp 1133–1150.

de Reuver, M., Sørensen, C., Basole, R. C., 2018. The

Digital Platform: A Research Agenda. Journal of

Information Technology, 33(2), 124–135.

Eckhart, M., Ekelhart, A., Weippl, E., 2019. Enhancing

Cyber Situational Awareness for Cyber-Physical

Systems through Digital Twins, IEEE International

Conference on Emerging Technologies and Factory

Automation, 1222.

Grabis, J., Chandra, C., and Kampars, J., 2012. Use of

distributed data sources in facility location, Computers

and Industrial Engineering, vol. 63, no. 4, pp. 855-863.

Gran, T., Grunow, M., 2016. Concurrent product and

supply chain design: a literature review, an exploratory

research framework and a process for modularity

design, International Journal of Computer Integrated

Manufacturing, 29, 12, 1255-1271.

Hasan, M.M., Jiang, D., Ullah, A.M.M.S. Noor-E-Alam,

M., 2020. Resilient supplier selection in logistics 4.0

with heterogeneous information, Expert Systems with

Applications, vol. 139, 112799.

Kampars, J., Grabis, J. 2017. Near Real-Time Big-Data

Processing for Data Driven Applications. Innovate-

Data 2017: 35-42.

Kampars, J., Zdravkovic, J., Stirna, J., and Grabis, J., 2019.

Extending organizational capabilities with Open Data

to support sustainable and dynamic business

ecosystems. International Journal of Software and

Systems Modeling, 1-28.

Kritzinger, W., Karner, M., Traar, G., Henjes, J. & Sihn,

W., 2018. Digital Twin in manufacturing: A categorical

literature review and classification, IFAC-

PapersOnLine, vol. 51, no. 11, pp. 1016-1022.

Capability Management in Resilient ICT Supply Chain Ecosystems

399

Kshetri, N., Voas, J.M., 2019. Supply Chain Trust. IT

Professional 21(2): 6-10.

Lu, T., Guo, X., Xu, B., Zhao, L., Peng, Y. & Yang, H.,

2013. Next big thing in big data: The security of the ICT

supply chain, Proceedings - SocialCom/PASSAT/

BigData/EconCom/BioMedCom 2013, pp. 1066.

Madnick, S., 2019. 5G security concerns persist

with new research pointing to critical flaw,

https://www.itpro.co.uk/mobile/32893/

Mäntymäki M., Salmela H., Turunen M., 2018. Do

Business Ecosystems Differ from Other Business

Networks? The Case of an Emerging Business

Ecosystem for Digital Real-Estate and Facility

Services. In: Al-Sharhan S. et al. (eds) Challenges and

Opportunities in the Digital Era. LNCS 11195,

Springer.

Murphy, A., Taylor, C., Acheson, C., Butterfield, J., Jin, Y.,

Higgins, P., Collins, R. & Higgins, C., 2020.

Representing financial data streams in digital

simulations to support data flow design for a future

Digital Twin, Robotics and Computer-Integrated

Manufacturing, vol. 61.

Nikou, C., Moschuris, S.J., Filiopoulos, I., 2017. An

integrated model for supplier selection in the public

procurement sector of defence, International Review of

Administrative Sciences, vol. 83, pp. 78-98.

Polatidis, N., Pavlidis, M., Mouratidis, H., 2018. Cyber-

attack path discovery in a dynamic supply chain

maritime risk management system, Computer

Standards and Interfaces, vol. 56, pp. 74-82.

Rogers, Z., Choi, T.Y., 2018. Purchasing Managers Have a

Lead Role to Play in Cyber Defense, Harvard Business

Review.

Sandkuhl, K., Stirna, J., 2018. Capability Thinking, in

Capability Management in Digital Enterprises,

Springer.

Senyo P.K., Liu, K., Effah, J., 2017. Towards a

methodology for modelling interdependencies between

partners in digital business ecosystems, IEEE

international conference on logistics, informatics.

Zdravkovic, J., Stirna, J., Grabis, J., 2017. A Comparative

Analysis of Using the Capability Notion for Congruent

Business and Information Systems Engineering.

International Journal Complex Systems Informatics

and Modeling Quarterly 10, pp 1–20.

Zhao, K., Scheibe, K., Blackhurts, J., Kumar, A., 2018.

Supply Chain Network Robustness Against

Disruptions: Topological Analysis, Measurement, and

Optimization. IEEE Transactions on Engineering

Management, 66, 1, 127–139.

ICEIS 2020 - 22nd International Conference on Enterprise Information Systems

400