Case Study: Regulation of Noise Produced by a Rotary-screw

Propulsion Unit in an All-terrain Vehicle

Umar Vahidov, Alexander Belyaev, Vladimir Makarov

a

, Dmitriy Mokerov and Yuri Molev

Nizhny Novgorod State Technical University n.a. R.E. Alekseev, Minin St., 24, Nizhny Novgorod, Russian Federation

Keywords: Rotary-screw Propulsion Unit, Ice, Interaction, Noise Level.

Abstract: The study presents methods developed to calculate permissible level of acoustic radiation produced by a

rotary-screw propulsion unit on ice. The study is based on the papers of the researchers who studied acoustic

waves generated by construction and road vehicles. The authors of the study applied the aforementioned

theories to the case of interaction between a rotary-screw propulsion unit and ice. The paper provides general

measuring methods and evaluates how every type of interaction between propulsion unit components and ice

affects overall level of generated acoustic pressure. The results and conclusions obtained during the research

can be used to help manufacturers select the parameters of the rotary-screw propulsion unit which contribute

to reduction of noise inside the cabin of an all-terrain vehicle.

1 INTRODUCTION

One way to increase population mobility and

transport accessibility in less-populated regions is to

develop all-terrain vehicles. However, there is one

issue that remains unresolved, and challenges the

development of such vehicles: poor ride comfort due

to high noise and vibration levels [Shashurin, 2010].

Multiple research papers studying technical

condition of all-terrain vehicles have established that

acoustic impact on vehicle drivers considerably

exceeds permissible values reducing efficiency of all-

terrain vehicles and affecting the occupants [SanPiN

2.2.4.3359-16, SN 2.2.4/2.1.8.562-96, SP

51.13330.2011].

2 THEORETICAL RESEARCH

Noise generated by all-terrain vehicles has three main

sources: engine and transmission, vibration

fluctuations caused by uneven road surface, and a

rotary-screw propulsion unit. Design of most all-

terrain vehicles is currently based on wheeled

vehicles permitted to participate in road traffic,

suggesting that cabin, engine, transmission units and

assemblies comply with enforceable requirements to

a

https://orcid.org/0000-0002-4423-5042

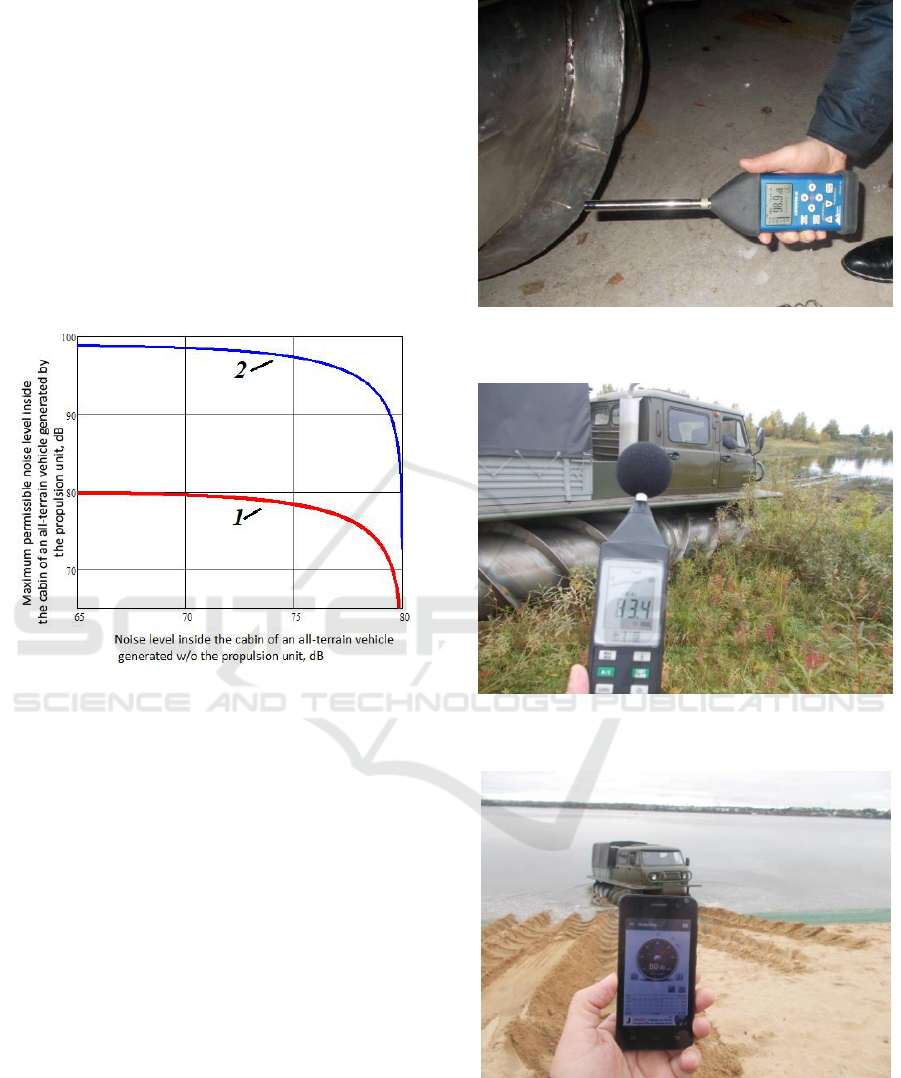

Figure 1: Noise level measured in the cabin of snow and

swamp-going vehicle “Uzola” manufactured by LLC “All-

Terrain Vehicles Plant” in Zavolzhye. [https://zvm-nn.ru].

548

Vahidov, U., Belyaev, A., Makarov, V., Mokerov, D. and Molev, Y.

Case Study: Regulation of Noise Produced by a Rotary-screw Propulsion Unit in an All-terrain Vehicle.

DOI: 10.5220/0009570605480551

In Proceedings of the 6th International Conference on Vehicle Technology and Intelligent Transport Systems (VEHITS 2020), pages 548-551

ISBN: 978-989-758-419-0

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Figure 2: Noise level measured in the cabin of a multi-

functional rescue vehicle with a rotary-screw propulsion

unit produced by Research and Education Centre

“Transport”, Nizhny Novgorod State Technical University

n.a. R.E. Alekseev.

noise level on the road. Also, perfectly smooth ice

rules out noise caused by deformation, and bending

of body and rotary-screw propulsion unit components

[Nikitin, 2004, Abramova, 2018, Erasov, et al. 2019].

Considering the abovementioned, overall level of

noise generated by the rotary-screw propulsion unit in

an all-terrain vehicle cabin can be calculated from the

following overall noise level equation [SN

2.2.4/2.1.8.562-96]:

)

1,0

10

0,1

lg(1010

n

1i

1,0

10 lg10

K P

i

LL

L

L

L

+=

=

=

(1)

where L

K

is overall noise level in the all-terrain

vehicle cabin with rotary-screw propulsion unit

switched off, and LP is the sought-for noise level

produced by the rotary-screw propulsion unit. From

which we obtain the following:

−

+=−

)(1,0

101lg10

PK

LL

K

LL

(2)

or:

−

=−

−

)(1,0

101

)(1,0

10

КРK

LLLL

)LL(,)

КР

)LL(,

K

−=−

−

10110lg(

10

K

)LL(,

Р

L)L

K

+−=

−

11010lg(

10

(3)

In his paper “Measurement of noise in the cabins

of construction and road vehicles” [Shashurin, 2010],

A.E. Shashurin states that equation for cabin noise

level generated by a linear source of acoustic

vibrations, i.e. by a rotary-screw propulsion unit, can

be sought from the following equation:

,2lg10)1lg(10

0

lg10lg10

2

lg10

++−+

++−+

+−=

K

r

r

A

S

r

L

arctg

Р

L

D

L

(4)

where L/2r – ratio of the noise source length to the

distance from the source to the cabin (for rotary-

screw propulsion units, this ratio equals to 3), -

diffuse field approximation factor, r

0

– distance from

the cabin floor to the ground surface (r/r

0

ratio for

rotary-screw propulsion unit vehicles is 1, because

noise is generated at the point where rotary-screw

propulsion unit has contact with the ground surface)

S – total area of the all-terrain vehicle cabin, which

can vary from 10 to 50 square meters depending on

the design; A – equivalent sound absorption surface

of the cabin, which equals to the total area of the cabin

multiplied by sound absorption factor (0,3 [11] for

low-frequency acoustic vibrations produced by a

propulsion unit), – cabin sound insulation factor,

when critical sound insulation frequency for the walls

(f

gr

), equal to 100-200 Hz, is lower than the sound

frequency f (up to 500Hz) calculated from the

following equation:

dB

gr

f

ffM

3015325,0lg

136

500

lg5

0,1*2,1

01,0*1000*500*14,3

lg20

3lglg5

r

lg20

−=++

++=

=+++

=

(5)

where М is a factor equal to the ratio of the acoustic

blanket weight (blanket density multiplied by its

thickness) to the air weight between the driver and the

cabin walls (air density multiplied by the distance

from the driver to the cabin wall), and - loss factor

equal to 0,25 [Shashurin, 2010];

According to [Shashurin, 2010] 10lg(S/A) ratio

varies from 20 to 12dB, 10lg(1-

К

) ratio from 0 to 4

dB varies from 20 to 12dB. Therefore, maximum

sound level generated by a propulsion unit in the

Case Study: Regulation of Noise Produced by a Rotary-screw Propulsion Unit in an All-terrain Vehicle

549

ground surface contact area shall be calculated

according to the following formula:

,L)L

K

)LL(,

D

K

1911010lg(

10

++−=

−

(6)

Minimum sound level shall be as follows:

K

)LL(,

Р

L)L

K

+−=

−

11010lg(

10

(7)

The 19 dB difference indicates that current cabins

reduce sound level generated by propulsions units of

all-terrain vehicles approximately by 19 dB.

Solution of these equations is presented in Figure

3.

Figure 3: Relationship between the maximum permissible

sound level produced by a propulsion unit and the sound

level inside the all-terrain vehicle generated w/o the

propulsion unit with no sound insulation of the cabin (1)

and with standard sound insulation (2).

3 EXPERIMENTAL RESEARCH

Research conducted on various propulsion units of

all-terrain vehicles shows that current design of the

propulsion units does not always keep the generated

sound within the acceptable limits.

4 CONCLUSIONS

The results show that propulsion units with acoustic

radiation under 70dB have almost no effect on the

sound level in the cabin. Propulsion units with

acoustic radiation of 90-100dB produce the noise

which considerably influences acoustic comfort in the

cabin, and those with radiation level over 105 dB

become the only source of noise around the driver.

Figure 4: Sound level generated by a rotary-screw

propulsion unit on the concrete.

Figure 5: Sound level produced by a rotary-screw

propulsion unit on marsh.

Figure 6: Sound level generated by a rotary-screw

propulsion unit on water and sand.

Since the technical regulations in force [GOST

23941-79, GOST 27408-87, GOST Р 51401-99]

stipulate a 80 dB limit for the permissible noise level

in the cabin. We can use the obtained data to develop

VEHITS 2020 - 6th International Conference on Vehicle Technology and Intelligent Transport Systems

550

requirements to a rotary-screw propulsion unit

installed in various types of vehicles.

ACKNOWLEDGEMENTS

This study was conducted in continuation of the

research conducted in the "Nizhny Novgorod

scientific and practical school of transport snow" in

the framework of cooperation between the Nizhny

Novgorod state technical University. R. E. Alekseeva

and LLC All-Terrain Vehicles Plant.

REFERENCES

Abramova, E., Mashorin, G., Molev, Y. and Sogin, A.,

2018 The simulations of helical blade interaction with

ice. MATEC Web of Conferences 245, 17002

GOST 23941-79 Noise. Methods for determination of noise

characteristics. General requirements.

GOST 27408-87 Methods for statistical processing of data

in determination and control of machine emitted noise

level.

GOST Р 51401-99 Noise of machines. Determination of

sound power levels of noise sources using sound

pressure. Engineering method in an essentially free

field over a reflecting plane.

Erasov, I., Kuklina, I., Mokerov, D. and Molev, Yu, 2019.

Simulation of noise generated by a rotary-screw mover

as a result of friction. IOP: Conference Series Earth and

Environmental Science 695, 012027.

Lipin, A., Molev, Y., Mokerov, D., Strizhak, A. and

Khudyakov, V., 2019 Ways of decreasing noise impact

on operator by changing rotary-screw propulsion units

natural frequency of vibration. IOP: Journal of

Physics: Conference Series 1177: 012040

Nikitin, S.A., 2004 Snowblower with optimized vibration

and sound characteristics. PhD thesis. Voronezh, 159 p.

SanPiN 2.2.4.3359-16 "Sanitary-epidemiological

requirements to physical factors in the workplaces"

SN 2.2.4/2.1.8.562-96 "Noise at Workplaces, in Residential

and Public Spaces, and in Areas of Residential

Development"

SP 51.13330.2011 Sound Protection. Updated SNiP version

dd. 23-03-2003

Shashurin, A.E., 2010. Case study: Interior noise reduction

with sound-insulating cabins in construction vehicles:

PhD thesis. Baltic State Technical University

"Voenmeh" D.F. Ustinov. St. Petersburg, 178 p.

Case Study: Regulation of Noise Produced by a Rotary-screw Propulsion Unit in an All-terrain Vehicle

551