Constraints and Challenges in Designing Applications for Industry 4.0:

A Functional Approach

Mateus Coelho Silva

a

, Frederico Luiz Martins de Sousa

b

, D

´

ebora Lage Moreira Barbosa

c

and Ricardo Augusto Rabelo Oliveira

d

Departamento de Computac¸

˜

ao, Instituto de Ci

ˆ

encias Exatas e Biol

´

ogicas, Universidade Federal de Ouro Preto,

Rua Diogo Vasconcelos - 128 - Bauxita, 35400-000, Ouro Preto, MG, Brazil

Keywords:

Industry 4.0, IoT, Machine-to-Machine Communication, Sensor Fusion.

Abstract:

The Industry 4.0 concept relies on the integration of its composing elements using modern tools. These mod-

ern industrial plants must consider concepts like the Internet of Things, Cyber-Physical Systems and Smart

Devices. The main features involved in these architectures are the local control, machine-to-machine infor-

mation exchange, and human-to-machine interface through virtualization. The integration of these elements

to create a connected environment presents a challenge to developers and engineers. In this text, we perform

a theoretical analysis of the main constraints and challenges in designing and implementing novel applica-

tions using digital twins, robots, wearable devices, and other control interfaces. To evaluate the theoretical

approach, we performed a series of tests in prototype environments.

1 INTRODUCTION

Industrial environments are evolving to Cyber-

Physical Production Systems (CPPS) through the

concepts of Industry 4.0 and the Internet of Things

(IoT) (Vogel-Heuser and Hess, 2016). Applications in

this context allow researchers to do engineering steps

towards the comprehension of the concepts related to

this topic (Zezulka et al., 2016). This kind of envi-

ronment bases on network connections, decentraliza-

tion and virtualization, allowing the human-machine

interaction, as well as machine-to-machine communi-

cation (Brettel et al., 2014).

Robots and Smart Actuators have an extensive

role in Industry 4.0, as instruments to automate mul-

tiple industrial processes. They are tools that offer

safety, flexibility and the possibility of collaboration

with other devices in modern environments (Bahrin

et al., 2016). Thus, they are not only a replacement

for humans performing repetitive tasks but also col-

laborative components linked by smart sensors and

human-to-machine interfaces.

Many times, industrial processes present hazards

a

https://orcid.org/0000-0003-3717-1906

b

https://orcid.org/0000-0002-8522-6345

c

https://orcid.org/0000-0002-8119-4964

d

https://orcid.org/0000-0001-5167-1523

to the involved workers (Saleh and Cummings, 2011;

Shaikh et al., 2018). Within this topic, the prospect

of operating and controlling industrial processes away

from their hazards is a possible solution for this mat-

ter. Therefore, another important topic is human inter-

action through data virtualization and digitalization.

All this interaction requires a network-based en-

vironment in which the devices can communicate

with each other and generate insights and decisions.

Thus, this integration uses the paradigm of the Inter-

net of Things (IoT) as a basis for the development of

novel applications. The IoT is a modern paradigm in

which devices communicate through network connec-

tions, especially using wireless technologies (Hozdi

´

c,

2015).

As mentioned, multiple connections compose an

Industry 4.0 application environment. Furthermore,

the virtualization aspect is relevant to create this kind

of system. Also, the integration of elements such as

robots and smart sensors have a significant role in

industrial applications. Finally, this appliance must

have elements that allow machine-to-machine com-

munication and human-to-machine interfaces.

Although there is a comprehension from the im-

portance of Industry 4.0 and its elements, the liter-

ature lacks discussions of functional constraints for

designing such applications. Furthermore, the litera-

ture lacks on works that test these constraints in pro-

Silva, M., Martins de Sousa, F., Barbosa, D. and Oliveira, R.

Constraints and Challenges in Designing Applications for Industry 4.0: A Functional Approach.

DOI: 10.5220/0009570307670774

In Proceedings of the 22nd International Conference on Enterprise Information Systems (ICEIS 2020) - Volume 1, pages 767-774

ISBN: 978-989-758-423-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

767

totype environments. Thus, in this work, we provide

both a theoretical and practical analysis of the main

constraints and challenges of developing applications

based on elements of Industry 4.0. As these are the

minimal conditions for the design of appliances, it

configures this as a functional approach. Hence, the

main objective of this work is:

• Establish the theoretical main functional con-

straints and challenges in the development of In-

dustry 4.0 applications and test them in controlled

prototype environments;

At first, we organize and understand what are the main

constraints in the design of Industry 4.0 applications

through a theoretical approach, discussed in Section

2. We analyze the elements which compose these

systems, as well as their single constraints and in-

tegration challenges. Furthermore, we created pro-

totype environments in which we test some of these

constraints to create model applications and perform

tests, presented in Section 3. Finally, we discussed

the results in Section 4.

2 THEORETICAL ANALYSIS

In this section, we introduce the theoretical view of

the aspects covered in this work. Our objective here is

to establish the main functional constraints and chal-

lenges concerning the design of novel applications for

Industry 4.0 from a theoretical approach. Our further

tests will validate the restrictions gathered in this sur-

vey.

2.1 Industry 4.0 and the IoT

Lasi et al. (Lasi et al., 2014) present the most mod-

ern industrial paradigm as the fourth industrial revo-

lution, henceforth called “Industry 4.0”. In this new

paradigm, industrial plants will require decentralized,

modular and efficient manufacturing units. Saldivar

et al. (Saldivar et al., 2015) presents some of the main

design principles regarding Industry 4.0:

• Interoperability;

• Virtualization;

• Decentralization;

• Real-Time Capability;

• Service Orientation;

• Modularity;

There are some key concepts and technologies to en-

hance the functioning of these systems, such as Big

Data, Machine Learning, and IoT. According to At-

zori et al. (Atzori et al., 2010), the Internet of Things

(IoT) is a novel paradigm in modern telecommuni-

cation. The main techniques to enhance communi-

cation between devices are wireless network proto-

cols. Taneja and Davy (Taneja and Davy, 2017) en-

force that a typical IoT application bears several mod-

ules running together. Beyond smartphones, tablets

and personal computers, novel computer-based de-

vices can also compose these networks. Some exam-

ples of IoT devices are:

• Robots (Ashokkumar and Thirumurugan, 2018);

• Gloves (K

¨

oseoglu et al., 2018; Farahani et al.,

2018);

• Helmets (Roja and Srihari, 2018);

• Smart Sensors and Cameras (Iba

˜

nez et al., 2018;

Jang et al., 2018);

Each module can combine in multiple ways to build

and integrate several IoT appliances. This feature is

enforced by the modularity of the device network, as

stated previously.

2.2 Constraints and Requirements for

Industry 4.0 Applications

The works found in the literature do not present a for-

mal approach to the basic functional constraints and

requirements for the Industry 4.0 application design

process. Thus, in this section, we create a theoreti-

cal basis for the main restraints for designing novel

solutions.

Initially, we look at the constraints from the

ground theoretical perceptions from Industry 4.0. As

presented previously, the main concepts around this

topic are the Cyber-Physical Systems (CPS) (Vogel-

Heuser and Hess, 2016) and the Internet of Things

(IoT) (Hozdi

´

c, 2015). Therefore, we formalize the

constraints combining three main sources: The main

restraints of CPS, the main requirements from the IoT

and the Industry 4.0 design principles (Saldivar et al.,

2015).

At first, we evaluate the Cyber-Physical Systems.

Abad et al. (Abad et al., 2016) enforce that these

systems must remain fully operational throughout the

task execution time. This constraint creates a need

for software safety protocols to observe soft and hard

real-time requirements. Furthermore, this requires

hardware robustness and reliability, which is a basic

embedded systems constraint (Hansen, 2017). These

restraints represent a reliability aspect in the produced

data, which is hardware- and software-dependant. Xie

et al. (Xie et al., 2018) reinforce the reliability as a

ICEIS 2020 - 22nd International Conference on Enterprise Information Systems

768

constraint for CPSs, and its direct relation with real-

time requirements.

Also, we analyze the Internet of Things’ main

constraints. Samie et al. (Samie et al., 2016) en-

force that the Internet of Things goal is the ubiquity

of network-based decentralized devices. As much as

information is the most important value, the network

communication capability is the main constraint in

developing IoT applications (Gravalos et al., 2018).

Tuyishmere et al. (Tuyishimire et al., 2016) state that

Wireless Sensor Networks are the main theoretical

base for IoT applications. From these applications,

we learn that these networking constraints affect the

data reliability.

Therefore, we present two main issues as the most

important constraints in the design of Industry 4.0 ap-

plications:

• Software and Hardware Reliability. As a CPS,

the application must present reliable hardware and

software elements to provide the environment to

develop the proposal;

• Networking and Communication. As an IoT ap-

plication, the devices must provide services with

minimal quality restraints to enable fully opera-

tional applications in the context of Industry 4.0

with data reliability.

From the design principles presented by Saldivar et al.

(Saldivar et al., 2015), the reliability constraint from

the CPS analysis serves mostly the interoperability,

real-time capability, and modularity of the proposed

application. The networking constraint affects, for the

most part, the interoperability, virtualization, decen-

tralization and service orientation aspects.

3 PROTOTYPE ENVIRONMENTS

In the previous section, we introduced the main

constraints, challenges, and elements employed in

the creation of advanced network-integrated environ-

ments based on the IoT and CPS concepts. In this

section, we present prototype environments based on

Industry 4.0, created to experiment and validate the

gathered information.

As stated, Industry 4.0 applications have two main

constraints: Software and Hardware Reliability and

Networking and Communication. Through this con-

jecture, we created two different environmental tests

to validate both these constraints.

3.1 First Environment - Digital Twin

Wearable-based Teleoperation

The first prototype environment evaluates the Hard-

ware and Software reliability aspect. In our proposed

appliance, we use a digital twin virtual environment

and tactile feedback from a data glove as Human-

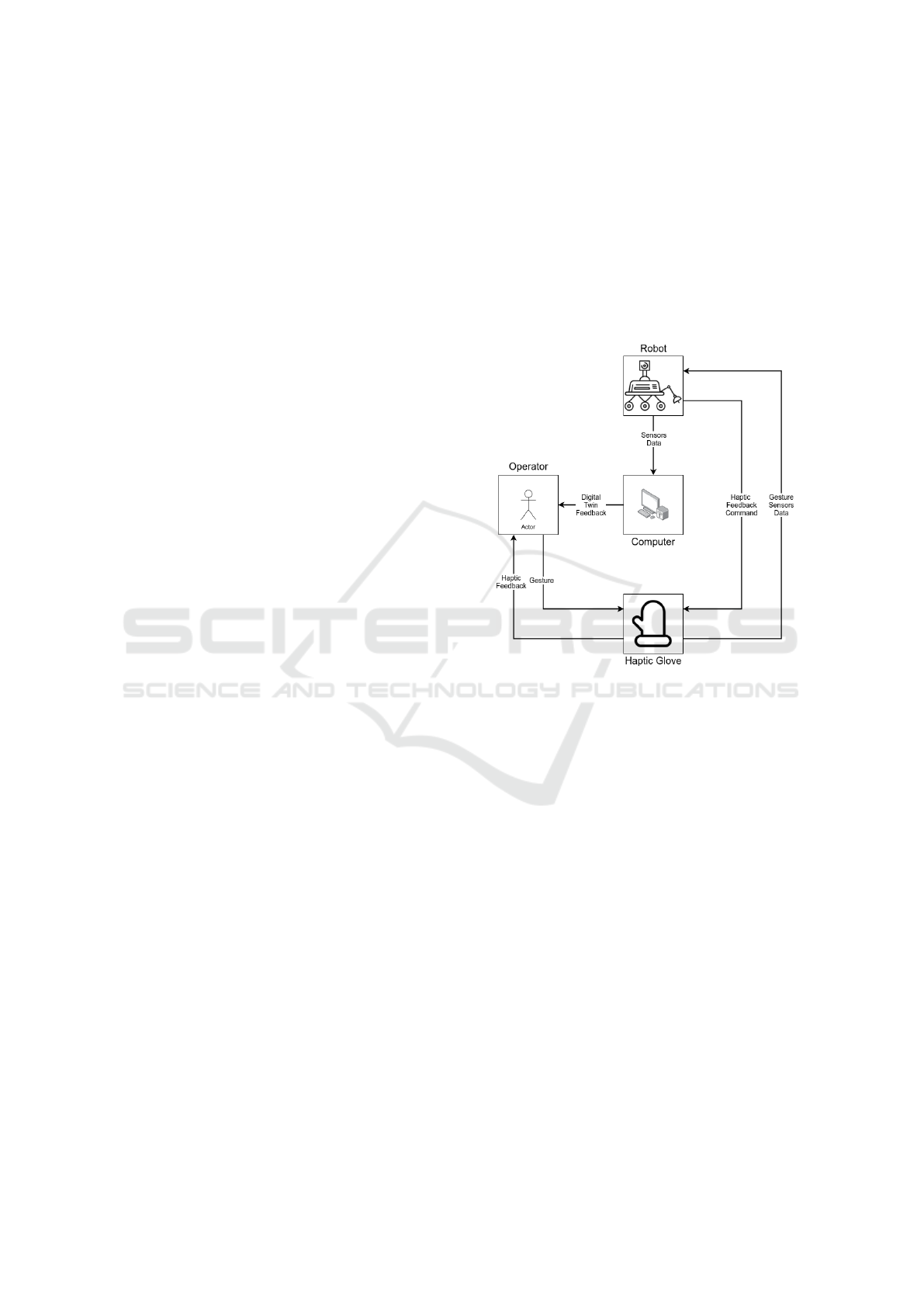

Robot Communication interfaces. Figure 1 displays

the proposed environmental architecture.

Figure 1: IoT-based operation environment architecture.

As stated before, the operator receives information

from the robot through the digital twin application

and the tactile feedback from the glove. He uses the

haptic glove as a communication interface with the

system. The glove embedded computer node actively

sends the gesture sensors information to the robot for

interpretation and acting. It produces haptic feedback

using an embedded vibration motor.

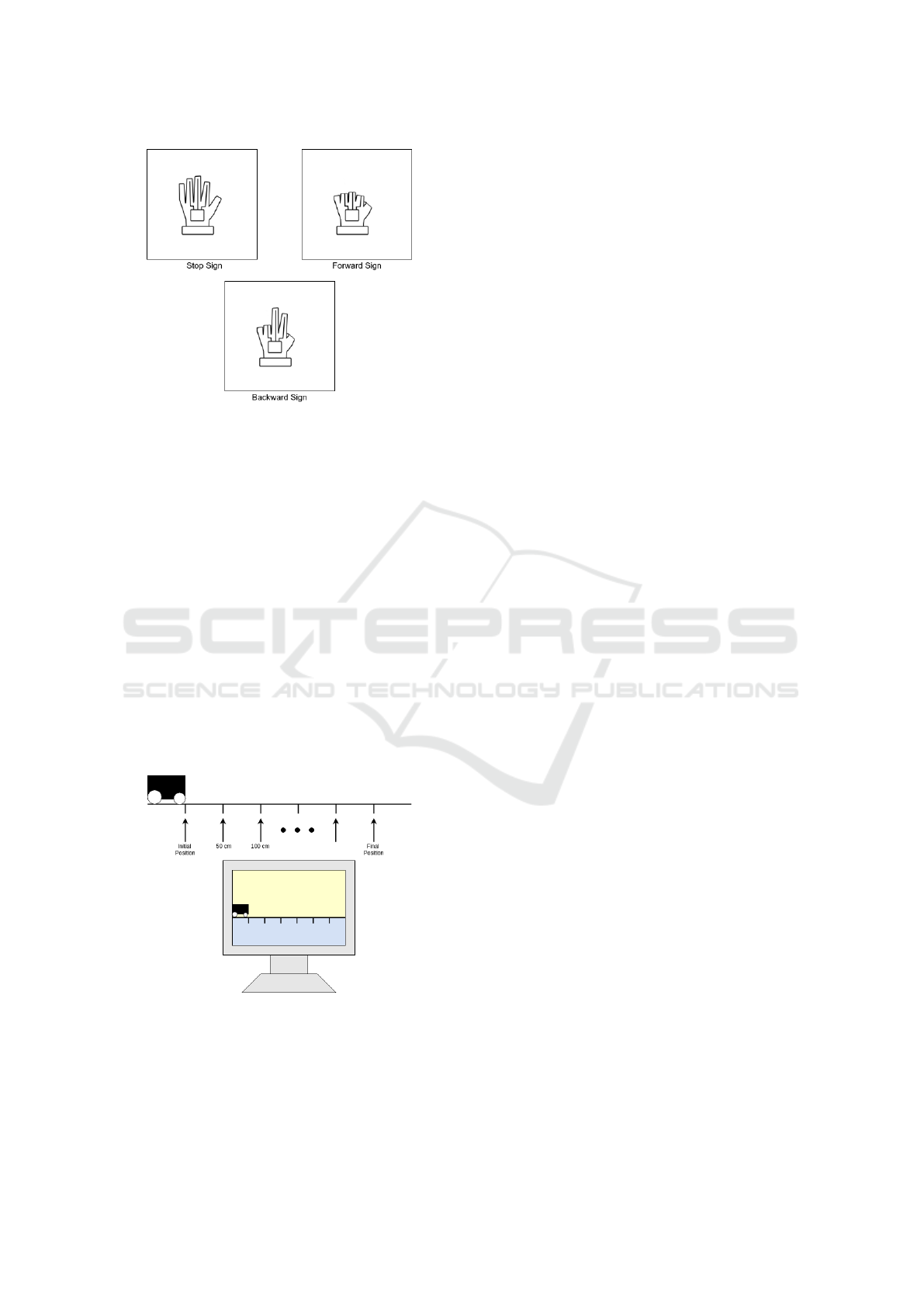

In this appliance, the robot receives the fingers

data and turns it into a hand signal command. There

are three main basic hand signs. If the user keeps his

hand open, the robot should stay stopped. If the hand

is closed, the robot should travel forwards at a con-

trolled speed. Finally, there’s another special sign to

make the robot travel backward, with only the two

first fingers open. Figure 2 displays these hand signs.

The robot receives the information from the glove,

interprets the gesture and acts accordingly, sending

the position encoders and obstacle detection sensors

data to the digital twin application. In case the robot

detects an obstacle, it sends a signal to the digital twin

application and the haptic glove to generate a feed-

back response. Finally, the computer application tries

Constraints and Challenges in Designing Applications for Industry 4.0: A Functional Approach

769

Figure 2: Robot Control Hand Signs.

to reproduce the robot condition from its transmitted

sensor data.

The communication means used by these proto-

types is a Wireless Local Area Network. The applica-

tions running on each device send and receive data us-

ing UDP protocols to avoid delays in the data stream.

3.1.1 Validation Test

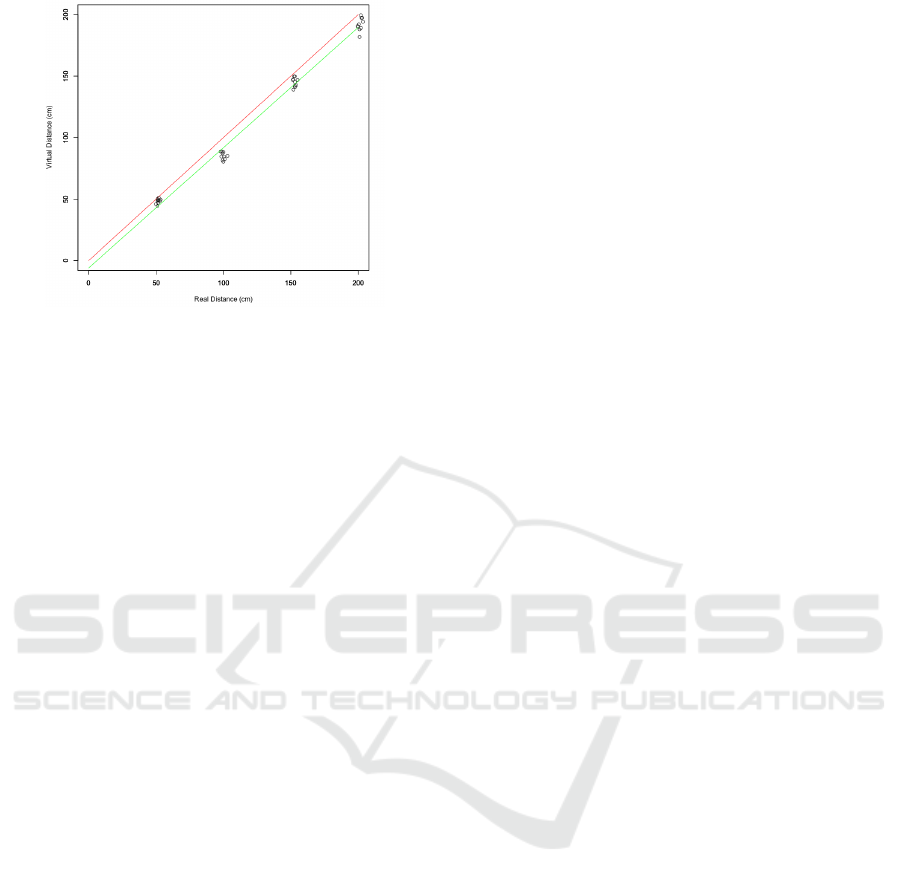

In order to test and validate the proposed architecture

using the presented prototypes, we arranged a setting

containing elements to examine the system proposed

features. With this environment, we tested the preci-

sion of the digital twin.

For the digital twin validation, we proposed a test

to compare the longitudinal distance from the robot

against the reproduction in the virtual environment.

Figure 3 illustrates the test set.

Figure 3: Digital Twin Validation Test Illustration.

To evaluate the reproduction of the digital twin envi-

ronment, we obtained values of real distances and the

correspondent value on the digital twin environment

for various measures. In an ideal circumstance, the

regression function obtained from these points should

approximate from a function as the represented on

equation 1, where d

vi

(d

r

) is the ideal value of the

robot position in the virtual representation as a func-

tion of the actual real position value d

r

.

d

vi

(d

r

) = d

r

(1)

From the point cloud obtained from the tests, we ap-

plied a linear regression model to represent the same

function with the actual obtained values. This func-

tion is represented in equation 2, where d

v

(d

r

) is the

value obtained from the linear regression of the scat-

ter plot, represented as a function of the real position

value d

r

.

d

v

(d

r

) = α.d

r

+ β (2)

Where α and β are the regression parameters. The

next step is to evaluate the quality of this function.

Thus, we represent the error function between the

ideal and the obtained functions. This E(d

r

) function

is represented in the equation 3.

E(d

r

) = d

v

(d

r

) − d

vi

(d

r

)

E(d

r

) = α.d

r

+ β − d

r

E(d

r

) = (α − 1).d

r

+ β

(3)

In this equation, the term α − 1 represents the angu-

lar coefficient error, which represents how good is the

position measurement. Also, the angular coefficient

error indicates the percentage error of the representa-

tion when the offset is corrected. The β term repre-

sents the offset error, which is a calibration term.

3.2 First Environment - Validation Test

Results

In this test, we needed to obtain the data that will cor-

relate the distances of the digital twin and the real dis-

tances. Therefore, we manually measured the robot’s

traveled distance and compared it to the value ob-

tained using the embedded encoder sensor.

We have measured these values 40 times, using

distances from 50 to 200 cm. From this data, we ap-

plied the method described in Section 3.1.1 to obtain

the α − 1 and beta values that represent the quality

factors of this representation. Figure 4 displays the

results obtained from this test.

In Figure 4, the red line represents the ideal rela-

tion, represented by the d

vi

(d

r

) = d

r

function. From

the obtained points, represented as black spots in the

figure, we have obtained the line that represents the

actual behavior of the system given its real data. The

ICEIS 2020 - 22nd International Conference on Enterprise Information Systems

770

Figure 4: Validation Test Results.

green line displays the function that represents this

behavior, represented by the equation:

d

v

(d

r

) = 0.977.d

r

− 6.01

The resulting angular coefficient is α = 0.977 and the

linear coefficient is β = −6.008. The angular error

factor is α − 1 = −0.022. These results indicate that

the behavior of the virtual environment based on the

provided sensor data has a percentage error of approx-

imately -2.3%. Also, there’s an approximate offset of

6.01 cm, which can be easily solved by adding a bias

to the obtained sensor value.

3.3 Second Environment - Digital Twin

Inspection of Autonomous Robot

Routine

The second prototype environment is designed to

evaluate the Network and Communication constraint.

Through this architecture, we expect to assess the

real-time constraints of this system. For this task,

the robot performed an autonomous routine through

the ground, providing the sensor information through

network queries as an IoT node.

To test the network capability, multiple devices

persistently query the embedded sensors data. For

this matter, they must open the connection, retrieve

the data and close the connection. The robot connec-

tion node accepts one request at a time. As part of the

prototype environment, the devices generate a repro-

duction of the device position in a grid.

The robot runs two threads. One of them controls

its movements and data acquisition. The second one

controls the network connections. The devices will

have an active 50 ms sleep time, and then persistently

attempt to acquire the data from the sensor. To un-

derstand how the network affects the quality of the

provided data, we tested the time required for each

device to complete the following cycle:

1. Establish connection with the node;

2. Acquire data;

3. Produce digital twin frame;

4. Sleep (50ms);

The evaluation of the real-time constraint in the net-

work environment requires a test formalization. We

consider this scenario as a soft real-time system,

as the deadline violation decreases the quality of

the provided information without catastrophic conse-

quences. Thus, we designed this experiment strictly

as a Quality-of-Service (QoS) test, based on other

similar analyses in the context of Wireless Sensor

Networks and IoT (Silva and Oliveira, 2019; Bouk-

erche and Samarah, 2008; Silva et al., 2019). In

the existing perspectives, the examination considers

one or multiple devices consuming data from multi-

ple sensors. Thus, we created a proper formalization

for a scenario with various devices consuming data

from a single node.

At first, we evaluate the time as discrete intervals,

as the set T = t

i

, i = 0, 1, 2, 3, ..., following the rule

that t

i+1

−t

i

= θ, where θ is a constant sampling time.

The soft real-time deadline will be represented by φ,

where φ = k.θ, k ∈ N

∗

. In other words, the deadline

is represented as an integer number of sampling time

intervals. Given this start point, we establish the fol-

lowing definitions:

Definition 1. Let D = d

i

be the finite set of devices

consuming the data from the IoT node, where i ∈ N;

Definition 2. Let E = e

i

be the finite set of events that

each device performs, where i ∈ N;

Definition 3. Let L = l

d,e

be the length of time in-

terval that the device d takes to perform an event e,

where d ∈ D and e ∈ E;

Definition 4. Let P = p

i

be the set of patterns of

events to be observed in the devices, where p

i

= E

i

,

E

i

⊂ E and i ∈ N;

Definition 5. Let O = o

i

be the finite set of observa-

tions of a certain pattern p

i

∈ P on the devices, where

p

i

= E

i

, E

i

⊂ E and i ∈ N;

The equation that represents the elapsed time λ to ob-

serve a certain pattern p

i

∈ P is:

λ

p

i

=

∑

l

d,e

k

|∀e

k

∈ E

i

, E

i

= p

i

(4)

Given the equation above, let

ˆ

O be a subset of O,

where λ

p

i

≤ φ, ∀o

i

∈

ˆ

O. Finally, given the sets O and

ˆ

O:

Constraints and Challenges in Designing Applications for Industry 4.0: A Functional Approach

771

Definition 6. Let N be the number of elements on the

subset O;

Definition 7. Let N

h

be the number of elements on

the subset

ˆ

O

The quality factor Q

f

will be represented by the

following equation:

Q

f

=

N

h

N

(.100%) (5)

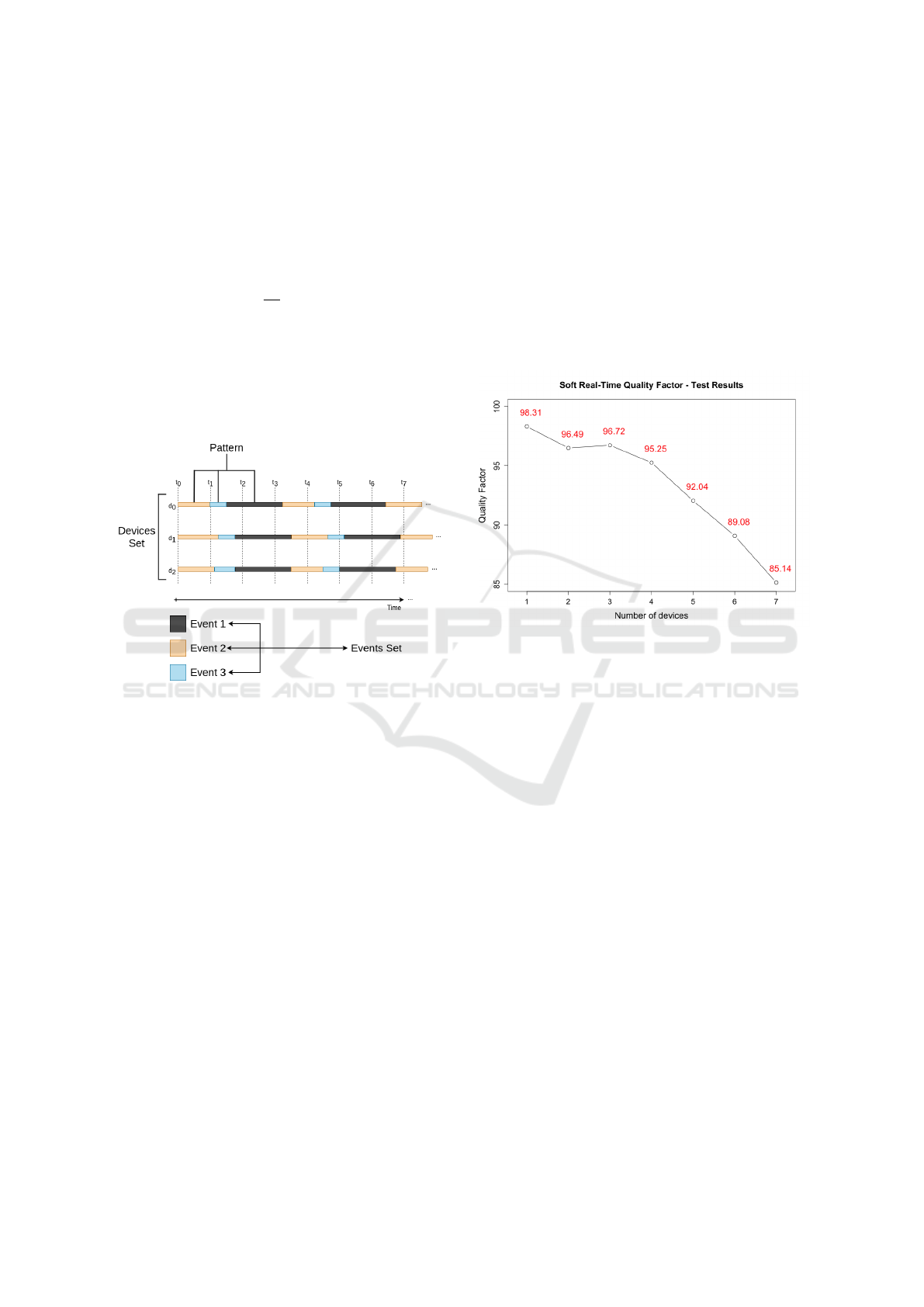

In other words, the quality factor observes how many

times the devices perform a pattern of events without

violating its soft real-time constraint. As presented

before, all devices will try to acquire the data and pro-

cess it in parallel and asynchronously. Figure 5 repre-

sents how this test works.

Figure 5: Illustration of the Observed Test Variables.

In this test, we experiment on how increasing the

number of querying devices affects the network qual-

ity factor.

3.4 Second Environment - Validation

Test Results

In the previous subsection, we demonstrated how to

evaluate the quality of a soft real-time constraint in

the context of a distributed IoT architecture. For this

matter, we evaluate and quantify how increasing the

number of devices consuming data affects the qual-

ity factor of the soft real-time system, following the

notation created. In this section, we present the orga-

nization and results of the employed tests.

At first, we established the following set of events

to evaluate:

• e1: Establish connection with the IoT node;

• e2: Acquire the node sensor data;

• e3: Process data and generate the frame of the

digital twin;

• e4: Sleep and idle time.

For testing aspects, we divided our time slots into

intervals of θ = 10ms. Furthermore, we established

a soft real-time deadline of φ = 10.θ = 100ms. We

tested this aspect for a system having from one to

seven devices as clients. These clients operate asyn-

chronously, and must persistently query the IoT de-

vice to acquire the sensors data. We used various

sets of devices, containing from one to seven clients.

The time length observations from the events were

recorded by each client.

Figure 6: Results of the Soft Real-Time Quality Factor Test.

From the quality test value, the expected behavior is a

loss of quality due to concurrency in the soft real-time

constraint. Figure 6 displays the results of the test for

each number of client devices. Typically, there is a

quality factor loss of 1% to 4% for each extra client

consuming the data. From qualitative analysis, this

quality loss reflects in the real-time precision in the

digital twin during the execution.

In further investigation, we also examined how

each step contributed to quality loss. For this mat-

ter, we analyzed the average period length for each

described event. From the data logs, we observed

that the main impairment in quality comes in the first

phase, which is the connection establishment. This

happens as the network concurrency increases and the

device answers one connection at a time.

4 DISCUSSION

In this work, we presented the main concepts, con-

straints, and challenges in designing Industry 4.0 ap-

plications. To understand how these constraints ap-

ply to design applications, we developed two different

architectures to simulate modern network-integrated

ICEIS 2020 - 22nd International Conference on Enterprise Information Systems

772

environments based on IoT and CPS concepts. From

those, it was able to test the two main aspects iden-

tified in the theoretical analysis: Software and Hard-

ware reliability, and Networking and Communication.

The first proposed architecture is a robot and dig-

ital twin virtual environment, with a data glove as a

Human-Robot Communication interface with tactile

feedback. For this matter, we created a local appli-

ance based on prototypes and providing a digital twin

virtual feedback environment.

Our validation test set consisted of comparing real

distances and their correspondence on the digital twin

environment for different measurements. The result

obtained for the digital twin shows that although its

percentage error of approximately -2.2% and an ap-

proximate offset of 6.01 cm.

This simulation displays relevant aspects that can

happen in the environment of an Industry 4.0, regard-

ing the uncertainties of the representation of digital

twins and possible uncertainty sources. With this

appliance, it was able to observe many uncertainty

sources, vital for designing an Industry 4.0 applica-

tion. Network traffic, sensor uncertainty, mechanical

flaws, hardware limitations, and configurations add

difficulties to the implementation of such an environ-

ment.

Nevertheless, the test allowed us to understand

how capable did the appliance perform all the pro-

posed tasks with adequate approximation. Therefore,

these tests are suitable tools to validate the proposed

architecture with the challenges of the element’s reli-

ability. Finally, it also helps to indicate possible prob-

lems associated with the communication of the nodes,

such as network traffic and latency, which were ana-

lyzed in the following tests.

The second proposed environment uses the evolu-

tion of the robot used in the previous section. How-

ever, the objective of this test is not to define the qual-

ity of the data produced by the hardware, but the in-

fluence of the network requests overload in the soft

real-time requirements. For this matter, we proposed

a test which interprets this constraint as a Quality-of-

Service issue.

The results of our test display that there is an

expected quality loss of 2% to 4% for each extra

node persistently consuming data from the device. At

first, only 1.69% of the requests violated the soft-

real time constraint with only one consuming device.

When running the same process with seven consum-

ing devices, the real-time constraint violation ratio in-

creased to 14.76%. Moreover, our further analysis

displays that networking overload is responsible for

this loss. This result indicates how the overload of

network requests in this environment impairs the real-

time constraints in distributed IoT networks in the In-

dustry 4.0.

In the papers found in the literature, no author for-

malized the main functional constraints for the Indus-

try 4.0 design process. Thus, we proposed two main

restrictions based on the ground concepts of these ap-

plications. Our tests in the prototype environments

display how the main constraints identified in the the-

oretical analysis affect a designed application.

ACKNOWLEDGMENTS

The authors would like to thank Renato Avilez for

developing the Data Glove. The authors would like

to thank CAPES, CNPq and the Federal Univer-

sity of Ouro Preto for supporting this work. This

study was financed in part by the Coordenac¸

˜

ao de

Aperfeic¸oamento de Pessoal de N

´

ıvel Superior -

Brasil (CAPES) - Finance Code 001.

REFERENCES

Abad, F. A. T., Mancuso, R., Bak, S., Dantsker, O., and

Caccamo, M. (2016). Reset-based recovery for real-

time cyber-physical systems with temporal safety con-

straints. In 2016 IEEE 21st International Conference

on Emerging Technologies and Factory Automation

(ETFA), pages 1–8. IEEE.

Ashokkumar, M. and Thirumurugan, T. (2018). Integrated

iot based design and android operated multi-purpose

field surveillance robot for military use. In Interna-

tional Conference for Phoenixes on Emerging Current

Trends in Engineering and Management (PECTEAM

2018). Atlantis Press.

Atzori, L., Iera, A., and Morabito, G. (2010). The internet of

things: A survey. Computer networks, 54(15):2787–

2805.

Bahrin, M. A. K., Othman, M. F., Azli, N. N., and Talib,

M. F. (2016). Industry 4.0: A review on indus-

trial automation and robotic. Jurnal Teknologi, 78(6-

13):137–143.

Boukerche, A. and Samarah, S. (2008). A novel algorithm

for mining association rules in wireless ad hoc sen-

sor networks. IEEE Transactions on Parallel and Dis-

tributed Systems, 19(7):865–877.

Brettel, M., Friederichsen, N., Keller, M., and Rosen-

berg, M. (2014). How virtualization, decentraliza-

tion and network building change the manufacturing

landscape: An industry 4.0 perspective. International

journal of mechanical, industrial science and engi-

neering, 8(1):37–44.

Farahani, B., Firouzi, F., Chang, V., Badaroglu, M., Con-

stant, N., and Mankodiya, K. (2018). Towards fog-

driven iot ehealth: Promises and challenges of iot in

medicine and healthcare. Future Generation Com-

puter Systems, 78:659–676.

Constraints and Challenges in Designing Applications for Industry 4.0: A Functional Approach

773

Gravalos, I., Makris, P., Christodoulopoulos, K., and Var-

varigos, E. A. (2018). Efficient network planning for

internet of things with qos constraints. IEEE Internet

of Things Journal, 5(5):3823–3836.

Hansen, F. O. (2017). Energy-aware model-driven devel-

opment of a wearable healthcare device. In Software

Engineering in Health Care: 4th International Sym-

posium, FHIES 2014, and 6th International Work-

shop, SEHC 2014, Washington, DC, USA, July 17-18,

2014, Revised Selected Papers, volume 9062, page 44.

Springer.

Hozdi

´

c, E. (2015). Smart factory for industry 4.0: A review.

International Journal of Modern Manufacturing Tech-

nologies, 7(1):28–35.

Iba

˜

nez, J. F., Casta

˜

neda, J. E. S., and Santos, J. C. M.

(2018). An iot camera system for the collection of data

using qr code as object recognition algorithm. In 2018

Congreso Internacional de Innovaci

´

on y Tendencias

en Ingenier

´

ıa (CONIITI), pages 1–6. IEEE.

Jang, S. Y., Lee, Y., Shin, B., and Lee, D. (2018).

Application-aware iot camera virtualization for video

analytics edge computing. In 2018 IEEE/ACM Sym-

posium on Edge Computing (SEC), pages 132–144.

IEEE.

K

¨

oseoglu, M., Celik, O. M., and Pektas, O. (2018). De-

sign of a smart glove for monitoring finger injury re-

habilitation process via mqtt server. In 2018 2nd Inter-

national Symposium on Multidisciplinary Studies and

Innovative Technologies (ISMSIT), pages 1–6. IEEE.

Lasi, H., Fettke, P., Kemper, H.-G., Feld, T., and Hoffmann,

M. (2014). Industry 4.0. Business & information sys-

tems engineering, 6(4):239–242.

Roja, P. and Srihari, D. (2018). Iot based smart helmet for

air quality used for the mining industry.

Saldivar, A. A. F., Li, Y., Chen, W.-n., Zhan, Z.-h., Zhang,

J., and Chen, L. Y. (2015). Industry 4.0 with cyber-

physical integration: A design and manufacture per-

spective. In 2015 21st international conference on

automation and computing (ICAC), pages 1–6. IEEE.

Saleh, J. H. and Cummings, A. M. (2011). Safety in the

mining industry and the unfinished legacy of mining

accidents: safety levers and defense-in-depth for ad-

dressing mining hazards. Safety science, 49(6):764–

777.

Samie, F., Tsoutsouras, V., Xydis, S., Bauer, L., Soudris,

D., and Henkel, J. (2016). Distributed qos manage-

ment for internet of things under resource constraints.

In Proceedings of the Eleventh IEEE/ACM/IFIP Inter-

national Conference on Hardware/Software Codesign

and System Synthesis, pages 1–10.

Shaikh, M. A., Weiguo, S., Shahid, M. U., Ayaz, H., and

Ali, M. (2018). An assessment of hazards and occu-

pational health & safety practices for workers in the

textile industry: A case study. Journal of Academic

Research in Business and Social Sciences, 8(12):333–

347.

Silva, M. and Oliveira, R. (2019). Analyzing the effect

of increased distribution on a wearable appliance. In

2019 IEEE 43rd Annual Computer Software and Ap-

plications Conference (COMPSAC), volume 2, pages

13–18. IEEE.

Silva, M. C., Amorim, V. J., Ribeiro, S. P., and Oliveira,

R. A. (2019). Field research cooperative wearable sys-

tems: Challenges in requirements, design and valida-

tion. Sensors, 19(20):4417.

Taneja, M. and Davy, A. (2017). Resource aware place-

ment of iot application modules in fog-cloud comput-

ing paradigm. In 2017 IFIP/IEEE Symposium on Inte-

grated Network and Service Management (IM), pages

1222–1228. IEEE.

Tuyishimire, E., Adiel, I., Rekhis, S., Bagula, B. A.,

and Boudriga, N. (2016). Internet of things in

motion: A cooperative data muling model under

revisit constraints. In 2016 Intl IEEE Conferences

on Ubiquitous Intelligence & Computing, Advanced

and Trusted Computing, Scalable Computing and

Communications, Cloud and Big Data Computing,

Internet of People, and Smart World Congress

(UIC/ATC/ScalCom/CBDCom/IoP/SmartWorld),

pages 1123–1130. IEEE.

Vogel-Heuser, B. and Hess, D. (2016). Guest edito-

rial industry 4.0–prerequisites and visions. IEEE

Transactions on Automation Science and Engineer-

ing, 13(2):411–413.

Xie, G., Peng, H., Li, Z., Song, J., Xie, Y., Li, R., and

Li, K. (2018). Reliability enhancement toward func-

tional safety goal assurance in energy-aware automo-

tive cyber-physical systems. IEEE Transactions on In-

dustrial Informatics, 14(12):5447–5462.

Zezulka, F., Marcon, P., Vesely, I., and Sajdl, O. (2016). In-

dustry 4.0–an introduction in the phenomenon. IFAC-

PapersOnLine, 49(25):8–12.

ICEIS 2020 - 22nd International Conference on Enterprise Information Systems

774