Optimization of Graphene Oxide Layer-by-Layer Films to Be Used as

an Enhancer Coating of Optical Fibers Sensors

Carlota Xavier

a

, Paulo Zagalo, Paulo A. Ribeiro

b

and Maria Raposo

c

CEFITEC, Departamento de Física, Faculdade de Ciências e Tecnologia, UNL, Campus de Caparica,

2829-516, Caparica, Portugal

Keywords: Optical Fiber Sensors, Graphene Oxide, Layer-by-Layer Films, Adsorption, Desorption.

Abstract: The stability of Graphene oxide (GO) layers obtained by the layer-by-layer (LbL) films was investigated

having in view the development of tunnable surfaces for optical fibre sensors in aqueous environments. For

this purpose layer-by-layer (LbL) films based polyethylenimine (PEI) and GO, were prepared and

characterized. The kinetics of adsorption of PEI/GO LBL films revealed that the adsorbed amount per bilayer

increases linearly with the number of bilayers as expected. Furthermore adsorbed amount per bilayer for short

adsorption times tends to a constant value revealing that GO layer growth also follows the adsorption

behaviour expected polyelectrolytes in which electrostatic interaction is ruling the process. Finally desorption

studies carried out to infer about GO layer stability revealed that GO layers are more stable at higher solutions

pHs and if the adsorption time for each layer is short. These results/conclusions allowed to infer on the

possible range of applications of PEI/GO LbL films.

1 INTRODUCTION

Graphene oxide thin films, prepared by the layer-by-

layer (LbL) technique (Oliveira, 2001), have been

used as sensing layers for different kind of sensors

namely for detection of triclosan in water (Marques,

2017) and wastewater (Magro, 2019) using the

electronic tongue concept (Magro et al, 2019a),

(Magro et al, 2019b) and by measuring the impedance

spectra. However, studies on the contribution of pH

of wastewater matrices for the stability of the GO thin

films revealed to be strongly influenced by

pH((Magro et al, 2019a; Magro et al, 2019b).

Recently, it was demonstrated the possibility of using

GO as a coating material for enhancing sensing

properties of fiber sensors (Monteiro, 2019).

Moreover, GO LbL deposited on optical fibers

revealed to work as temperature sensors of aqueous

solutions (Costa, 2018). It should be also referred that

the optical fiber devices are widely explored in

literature for hydrostatic pressure (Xu, 1993), lateral

load (Novais, 2017), and strain (Liu, 2015; Monteiro,

a

https://orcid.org/0000-0003-3970-4155

b

https://orcid.org/0000-0001-9665-7610

c

https://orcid.org/0000-0003-4710-0693

2017) sensing, having therefore general application as

optical sensing devices.

In this work, LbL films prepared from

polyethylenimine (PEI) and GO, were prepared and

characterized in order to optimize its stability on

different pHs.

2 MATERIALS AND METHODS

Thin films were prepared by the LbL technique

(Oliveira et al., 2001) using the polyelectrolyte

polyethyleneimine (PEI) and graphene oxide (GO).

These compounds were acquired from Sigma-Aldrich

(St Louis, MO, USA). These films were adsorbed

onto quartz supports by adsorbing alternate layers of

PEI and GO at solid/liquid interface. PEI aqueous

solutions with a monomeric concentration of 2x10

-2

M and GO solution with a concentration of 2mg/mL

were prepared by diluting these compounds in ultra-

pure water, produced with a Millipore system

(Bedford, MA, USA). The adsorption times for each

layer were of 5, 15 and 30 s, and after adsorption of

192

Xavier, C., Zagalo, P., Ribeiro, P. and Raposo, M.

Optimization of Graphene Oxide Layer-by-Layer Films to Be Used as an Enhancer Coating of Optical Fibers Sensors.

DOI: 10.5220/0009380701920195

In Proceedings of the 8th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2020), pages 192-195

ISBN: 978-989-758-401-5; ISSN: 2184-4364

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

each layer the solid support was washed with

ultrapure water to remove the molecules which are

not completely adsorbed on the adsorbed layer. After

the adsorption of each layer, the thin-film was dried

using a flux of nitrogen gas. Films of PEI/GO were

prepared with different number of bilayers. To

analyse the effect of pH of PEI/GO LbL films

prepared with 12 bilayers, (PEI/GO)

12

were

immersed in aqueous solutions with different pHs to

characterize the desorption as a function of time. The

adsorbed/desorbed amounts were characterized by

ultra-violet spectroscopy using a double beam

spectrophotometer UV-2101PC (Shimadzu).

3 RESULTS AND DISCUSSION

3.1 Buildup of PEI/GO LbL Films

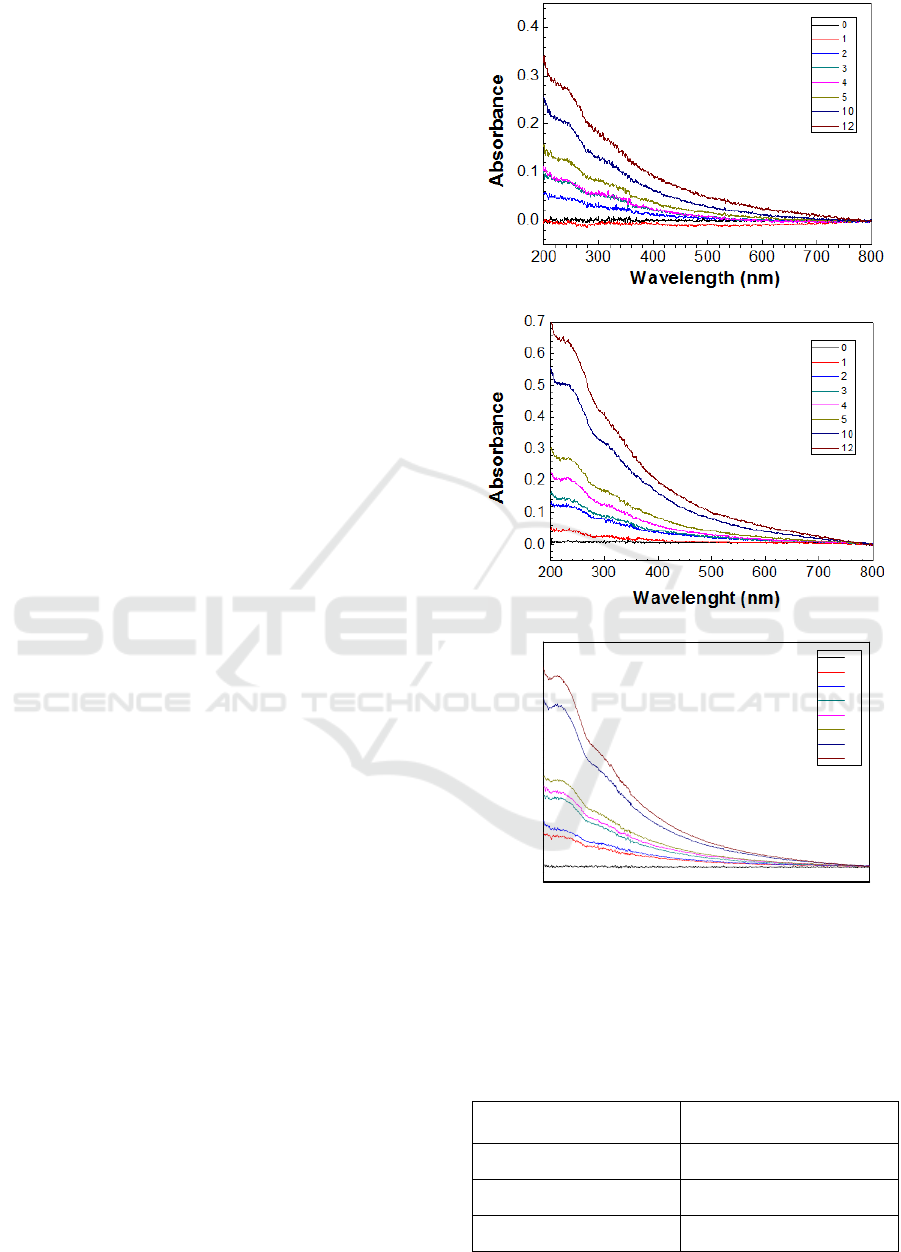

Figures 1 a), b), and c) show the obtained UV-Vis

spectra of PEI/GO LbL films, prepared with 5, 15 and

30s adsorption times.

The obtained spectra bands shown in figure 1 are

essentially associated to the electronic transitions of

GO, namely, the peak located at 230 nm is associated

with π-π* transitions of the aromatic ring (phenol)

and to n-π* transition of the group carboxylic acid.

The maximum absorption band located at 247 nm can

be associated with transitions of π-π* type of the

benzene aromatic ring. The band at 299 nm

correspond to n-π* transitions of the carbonyl group

(Silverstein et al, 1991). These curves also reveal that

the PEI/GO layers grow linearly with the number of

bilayers as demonstrated in graph of Figure 2 where

the absorbance at 230 nm is plotted versus the number

of bilayers. The slopes of obtained from these curves,

displayed in table 1, reveal that the adsorbed amount

per unit of area and per bilayer increases with

adsorption time up to a constant value. This indicates

that the adsorption kinetics curve of GO onto PEI

layer at lower adsorption times presents a first short

characteristic time, in accordance with what is

normally observed in polyelectrolyte adsorption,

followed of a second adsorption process associated to

diffusion process (Raposo, 1997; Ferreira, 2013), as

observed in the adsorption of GO onto optical fibers

measured by reflectance (Monteiro, 2019).

The decrease of adsorption time also lead to

increased films the uniformity as observed by optical

microscopy, data not shown here, result which is

crucial for optical applications.

a)

b)

c)

Figure 1: Absorbance spectra of PEI/GO LbL films with

different number of bilayers prepared with: a) 5s, b) 15 and

c) 30s of adsorption of each layer.

Table 1: Calculated values of absorbance at 230 nm per

bilayer, i.e, the slope of data of figure 2.

Adsorption Time per

Layer (s)

Absorbance @ 230 nm per

Bilaye

r

5

0.0226 ±0.0009

15

0.0510 ±0.0008

30

0.052 ±0.002

200 300 400 500 600 700 800

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

Absorbance

Wavelength (nm)

0

1

2

3

4

5

10

12

Optimization of Graphene Oxide Layer-by-Layer Films to Be Used as an Enhancer Coating of Optical Fibers Sensors

193

Figure 2: Absorbance at 230 nm as a function of the number

of bilayers of PEI/GO LbL films prepared at different

adsorption period of time, namely, 5, 15 and 30 s.

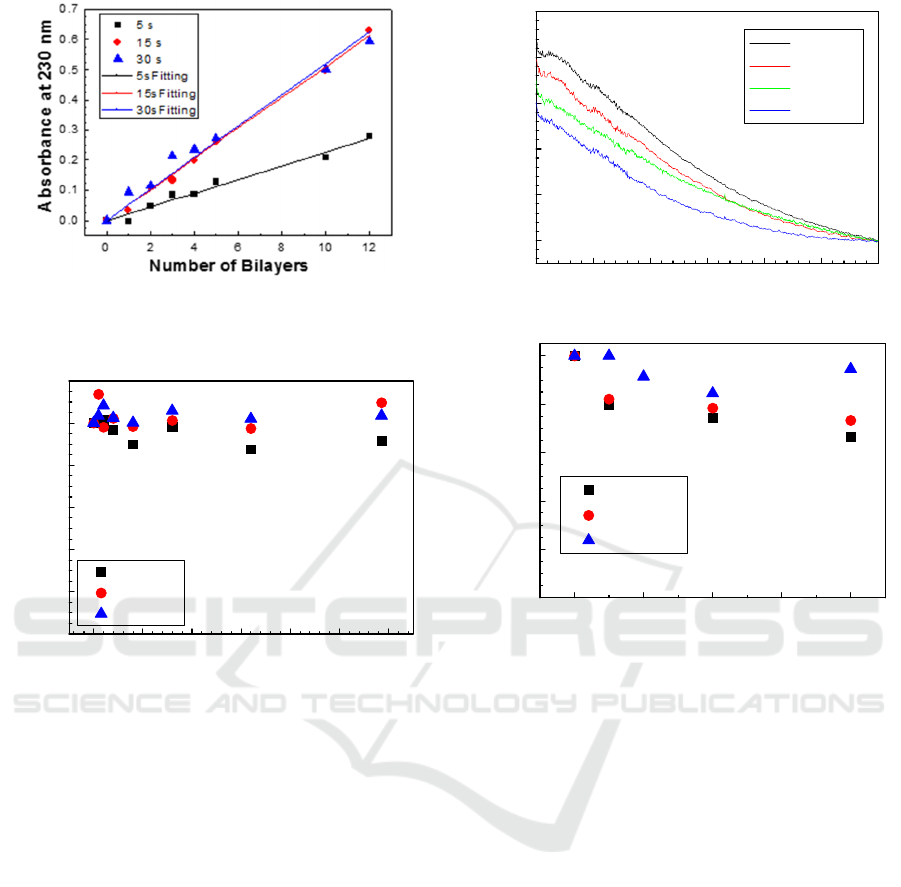

Figure 3: Evolution of the normalized absorbance at 230 nm

of the (PEI/GO)

12

LbL films prepared with an adsorption

time of each layer 30s as a function of immersion in

aqueous solutions with different pHs.

3.2 GO Desorption Kinetics

To analyse the stability of the PEI/PSS LbL films,

films with 12 bilayers were immersed in aqueous

solutions with different pH, namely, 5.5, 7 and 9, and

the UV –visible spectra were measured after different

immersion times. The obtained desorption kinetics

obtained for films prepared with an adsorption period

of time of 30s are shown in Figure 3. These

adsorption kinetics were obtained by plotting the

absorbance at 230 nm after normalization with

respect to the value of this absorbance before

immersing the films in the aqueous solutions a

different pHs. Similar curves are obtained for short

adsorption times. Although the obtained curves reveal

that pH does not have a strong effect in the GO

desorption, when films are prepared with short

adsorption times, a small desorption takes place at

smaller pHs.

a)

b)

Figure 4: a) Absorbance spectra of a (PEI/GO)

12

LbL film

prepared with 60s of adsorption of each layer after to be

immersed in an pH=7 aqueous solution. b) Evolution of the

normalized absorbance at 230 nm of the (PEI/GO)

12

LbL

films prepared with an adsorption time of each layer 60s as

a function of immersion in aqueous solutions with different

pHs.

However, films prepared with higher adsorption

times revealed to desorb in a large amount as

demonstrated in Figure 4 a) in which the normalized

absorbance of a (PEI/GO)

12

LbL film, prepared with

60s of adsorption of each layer after to be immersed

in an pH=7 aqueous solution during several periods

of time is seen to decrease. In fact a similar trend but

more intense to that observed in desorption kinetics

of Figure 3, is attained, when the normalized

absorbance at 230 nm of the (PEI/GO)

12

LbL films,

prepared with 60s adsorption time of each layer, are

plotted as a function of immersion time in aqueous

solutions with different pHs. This result demonstrates

that the molecules which are strongly adsorbed by

ionic interactions are less affected than the ones

adsorbed as a result of the process.

0 50 100 150 200 250 300

0.0

0.2

0.4

0.6

0.8

1.0

1.2

pH=5.5

pH=7

pH=9

Abs. Normalized

Desorption Time (min)

200 300 400 500 600 700 800

0.0

0.1

0.2

0.3

0.4

0.5

5 min

20 min

160 min

300 min

Absorbance

Wavelenght (nm)

0 10203040

0.0

0.2

0.4

0.6

0.8

1.0

pH=5.5

ph=7

ph=9

Normalized Absorbance

Desorption Time (min)

PHOTOPTICS 2020 - 8th International Conference on Photonics, Optics and Laser Technology

194

4 CONCLUSIONS

This study allowed to conclude that the adsorption of

a GO layer on PEI/GO LbL films follows the general

two stages adsorption processes found

polyelectrolytes. The first adsorption stage takes

place within the first seconds, the adsorption is

dominated by the adsorption of molecules which are

bound to the last layer of polyelectrolyte by ionic

interactions. At a given adsorption time these

adsorbed molecules somehow prevent more

molecules to be adsorbed and for larger adsorption

times, the presence of counterions and diffusion

process enable that more GO molecules to be

adsorbed. As a results these last molecules are not so

strongly bound to the last polyelectrolyte layer and

can be removed more easily by desorption. Therefore

the layers with smaller adsorption times are more

stable than for higher adsorption times. This study

also revealed that these films are more stable at higher

pHs allowing choose the adequate solutions for

sensor applications where these LbL films are stable.

ACKNOWLEDGEMENTS

The authors acknowledge the financial support from

FEDER, through Programa Operacional Factores de

Competitividade COMPETE and Fundação to

Fundação para a Ciência e Tecnologia, Portugal,

through projects “Development of Nanostrutures for

Detection of Triclosan Traces on Aquatic

Environments” (PTDC/FIS-NAN/0909/2014) and

the UID/FIS/00068/2019. PM Zagalo acknowledges

to Fundação para a Ciência e a Tecnologia for his PhD

fellowship (PD/BD/142768/2018) from RABBIT

Doctoral Programme.

REFERENCES

Costa, H.F.C. 2018. Desenvolvimento de dispositivos

sensores de fibras ópticas revestidas de filmes finos de

óxido de grafeno, Master Degree Thesis, Faculdade de

Ciências e Tecnologia, Universidade Nova de Lisboa,

Portugal.

Ferreira, Q., Ribeiro, P.A., Raposo, M. 2013.Villain's

fractal growth of poly[1-[4-(3-carboxy-4-

hydroxyphenylazo) benzenesulfonamido]-1,2-

ethanediyl, sodium salt] J-aggregates onto layer-by-

layer films and its effect on film absorbance spectrum

Journal of Applied Physics, 113, 243508.

Liu, S.; Yang, K.; Wang, Y.; Qu, J.; Liao, C.; He, J.; Li, Z.;

Yin, G.; Sun, B.; Zhou, J.; Wang, G.; Tang, J.; Zhao, J.

2015. High-sensitivity strain sensor based on in-fiber

rectangular air bubble. Sci. Rep., 5, 7624.

Magro, C., 2019. Advances in applied electrokinetics:

Treatment, by-productics reuse and sensors´system,

PhD Thesis, Faculdade de Ciências e Tecnologia,

Universidade Nova de Lisboa, Portugal.

Magro, C., Mateus, E., Raposo,M., Ribeiro, A. B, 2019

Overview of electronic tongue sensing in

environmental aqueous matrices: Potential for

monitoring emerging organic contaminants”,

Environmental Reviews, 27(2),202-214

Magro, C., Zagalo, P.M., Pereira-da-Silva, J., Mateus, E.P.,

Ribeiro, A.B., Ribeiro, P.A., Raposo, M. 2019b.

Triclosan detection in aqueous environmental matrices

by thin-films sensors: impedantiometric electronic

tongue. Proceedings 2019, 15, 24, 2019, https://doi.org/

10.3390/proceedings2019015024 .

Marques, I., Magalhães-Mota, G., Pires, F., Sério, S.,

Ribeiro, P.A., Raposo, M. 2017. Detection of Traces of

Triclosan in Water”, Applied Surface Science, 421,

142–147.

Monteiro, C. S., Raposo,M., Ribeiro, P.A., Silva, S.,

Frazão, O. 2019. Graphene oxide as a tunable platform

for microsphere-based optical fiber sensors, Proc. SPIE

11207, Fourth International Conference on

Applications of Optics and Photonics, 112070X;

https://doi.org/10.1117/12.2527267.

Monteiro, C.; Silva, S.; Frazao, O. 2017. Hollow

Microsphere Fabry–Perot Cavity for Sensing

Applications. IEEE Photonics Technol. Lett. 29, 1229–

1232

Novais, S., Ferreira, M. S., Pinto, J. L. 2017. Lateral Load

Sensing with an Optical Fiber Inline Microcavity. IEEE

Photonics Technol. Lett., 29, 1502–1505.

Oliveira, O.N., Raposo, M., Dhanabalan, A., 2001. In

Langmuir-Blodgett (LB) and Self-assembled (SA)

polymeric films, in: Nalwa, H.S.B.T.-H. of S. and I. of

M. (Ed.), Handbook of Surfaces and Interfaces of

Materials. Academic Press, Burlington, pp. 1–63.

Raposo, M., Pontes, R. S., Mattoso L. H. C., Oliveira Jr., O.

N. 1997. Kinetics of Adsorption of Poly (o-

methoxyaniline) Self-assembled films,

Macromolecules, 30, 6095-6101.

Silverstein, R. M., Bassler, G. C. & Morrill, T. C.

1991.Spectrometric Identification of Organic

Compounds.

Xu, M. G., Dakin, J. P. 1993. Novel hollow-glass

microsphere sensor for monitoring high hydrostatic

pressure. In Fiber Optic and Laser Sensors X, Vol.

1795, pp. 2–7.

Zagalo, P.M., Magro, C., Pereira-da-Silva, J., Bouchikhi,

B., el Bari, N., Ribeiro, P.A., Raposo, M. (2019).

Detection of Triclosan in tuned solutions by pH and

ionic strength using PAH/PAZO thin films.

Proceedings 2019, 15, 25, https://doi.org/10.3390/

proceedings2019015025 .

Optimization of Graphene Oxide Layer-by-Layer Films to Be Used as an Enhancer Coating of Optical Fibers Sensors

195