Inducing the Learning of Ergonomics and

Anthropometric Design using Motion Capture and

Virtual Simulation in an Industrial Context

Donovan Esqueda

1a

, Luis Enrique Villagómez

1b

, Yuliana Tónix

2c

and Ailin Velilla

3d

1

Tecnologico de Monterrey, Escuela de Ingeniería y Ciencias, Mexico

2

Tecnologico de Monterrey, Escuela de Arquitectura, Arte y Diseño, Mexico

3

Engineering Department, BOCAR Group, Mexico

Keywords: Educational Innovation, Higher Education, Ergonomics & Anthropometric Design, Engineering Education.

Abstract: Through this paper, we present an approach that simplifies the understanding of ergonomics and

anthropometric design to Mechatronics Engineering students at Tecnológico de Monterrey by presenting both

the theory behind those topics and a practical approach using specialized software and hardware. The latter,

carried out in an industrial context to avoid musculoskeletal diseases at work, assisted the sensitization of

engineering students into designing products and workstations that would account for the needs of their users.

1 INTRODUCTION

A central and important concept in human factors is

“the system”, an entity that exists to carry out some

purpose and is composed of humans, machines, and

other elements that, in many ways, work together.

The elements of a system interact to accomplish some

goal which could not be produced independently by

their components.

Therefore, we can consider a man-machine

system as a combination of one or more human beings

interacting with one or more physical components, in

which certainly given inputs produce some desired

outputs. In this approach of the man-machine systems

is where the ergonomics was born.

Ergonomics works as a multidisciplinary subject

and in order for it to be applied in a consistent and

coherent way, a model or framework is required

which specifies its areas of application, boundaries,

and limitations (Bridger, R.S., et al 1995). We cannot

get this framework to be derived from the study of

anatomy, psychology, or physiology alone since these

sciences are focused at the level of the human

component rather than as part of the work systems.

a

https://orcid.org/0000-0001-9277-8554

b

https://orcid.org/0000-0003-3583-9167

c

https://orcid.org/0000-0002-6216-6140

d

https://orcid.org/0000-0001-8711-1077

Ergonomics studies the human component in the

context of different activities. Particular emphasis is

placed on the design of human-machine interfaces

(HMI) to ensure increased safety and usability of

equipment and the removal of harmful stressors

decreasing risks.

Hence, the basic objectives that are pursued with

ergonomics when analysing and treating this type of

systems, are mainly related to the improvement of the

person-machine interrelation and control, the

environment of the workplace, and staying under the

limits of action of the person, helping us to detect and

correct risks of physical and/or psychological fatigue.

This requires to create databases that possess enough

knowledge about the limitations which are

comprehensive enough for different populations.

We can think about ergonomics as a research and

practice field regarding the projects of a conception

of jobs and leisure, and the functional attributes of the

products and services (Mondelo et al., 2001). Thus,

the importance of understanding ergonomics and its

relation to product design, by both designers and

engineers, is significant in order to avoid tasks that

may lead to injuries.

74

Esqueda, D., Villagómez, L., Tónix, Y. and Velilla, A.

Inducing the Learning of Ergonomics and Anthropometric Design using Motion Capture and Virtual Simulation in an Industrial Context.

DOI: 10.5220/0009368000740083

In Proceedings of the 12th International Conference on Computer Supported Education (CSEDU 2020) - Volume 2, pages 74-83

ISBN: 978-989-758-417-6

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

There are several risk factors to be mindful at

workstations either office or factories where we can

find systems of human-machine interaction for long

hours of work shifts. This way, taking no importance

on ergonomics can derive to several problems and

injuries on users, such as Musculoskeletal disorders

(MSD) which are injuries or disorders of the muscles,

nerves, tendons, joints, cartilage, and spinal discs.

Work-related musculoskeletal disorders (WMSD) are

conditions in which the work environment and

performance of work contribute significantly to that

condition.

Just in Mexico, WMSD has been reported as the

third cause for years lived in disability, and the

seventeenth cause of years of life lost (Clark et al.,

2018). Additionally, good ergonomics can improve

safety and comfort, and so they can lead to increasing

the productivity of workers (Zagloel et al., 2015).

Ergonomics aims to ensure that human needs for

safe and efficient working are met in the design of

work systems, this ability of people to do their jobs is

influenced by both physical design and job content.

Design students usually underestimate the needs of

good ergonomics and anthropometric design until

they create their first physical prototype, as they care

more about aesthetics and functionality (Dias et al.,

2015). Engineering students are even less likely to

think about these topics. Through this paper, we

present an innovative way to present Ergonomics and

Anthropometric Design to engineering students, with

a theoretical approach supported by a practical

approach in an industrial context and involving

technologies.

This article is organized as follows: Section 2

presents a background in the study of ergonomics and

anthropometric design as it is taught to Industrial

Designers at the faculty and some proposals from

different authors that involve the use of technology.

Section 3 introduces the context of teaching these

topics for Mechatronic Engineers and details the

learning experience that was designed. Section 4

presents the validation of this instructional design

learning strategy and Section 5 opens the

conversation for future work.

2 BACKGROUND

Human has been aware of the relation between their

body and the objects around them since prehistoric

times. For example, the length of the first arrows was

designed for maximum reach in the drawing of the

bow. Egyptians built chairs, ventilated beds and

seaworthy boats just by referencing it multiple times

to the cubit (i.e. elbow to the tip of the middle finger).

The arrival of the machines during the past 200

years brought an early modern period in which the

operator’s needs come last. The first machine designs

were thought to be used by a certain population size.

When operators of those specific dimensions became

scarce, the concept of human engineering (a term

coined by the United States Army) began by

analyzing the workspace to accept a variable

population.

Before World War II, engineers and architects had

some physical guidelines based on the average man.

The Department of Agriculture was in charge of

taking these measurements but this was not always

accurate for human engineering. It was until World

War II, under the statement that machines win wars

and the fact that they were becoming more complex,

that the relation between human-machine acquired

importance.

In Britain, the field of ergonomics was born after

World War II, and the name was invented by Murrell

in 1949, despite objections that people would confuse

it with economics. The emphasis was on equipment

and workspace design and the relevant subjects were

held to be anatomy, physiology, industrial medicine,

design, architecture, and illumination engineering. In

the United States, a similar discipline emerged,

known as human factors, but its scientific roots were

grounded in psychology (Mondelo et al., 2001).

The word “anthropometry” comes from the Greek

words Anthropos (man) and metron (measure).

Anthropometric data is used in ergonomics to specify

the physical dimensions of workspaces, equipment,

furniture, and clothing so as to “fit the task to the

man” (Grandjean, 1973) and to avoid physical

mismatches between the dimensions of equipment

and products, and the corresponding user dimensions.

According to Pheasant (1996), anthropometry

historical antecedents date back to the Renaissance.

However is well known that this discipline emerged

during the nineteenth century and, among other

aspects, focuses on physical differences between

people of different ethnics origins (Tilley & Henry

Dreyfuss Associates, 2002). In order to perform such

comparisons, it was essential to develop measurement

techniques to obtain data from individuals, and

statistical methods to process that data. The data can

be used only to assess individuals from the same

population from which they were sampled, and can be

categorized in different ways:

Structural anthropometric data contains all

measurements of the bodily dimensions of subject in

static positions. Measurements are made from one

Inducing the Learning of Ergonomics and Anthropometric Design using Motion Capture and Virtual Simulation in an Industrial Context

75

clearly identifiable anatomical landmark to another or

to a fixed point in space (e.g. the height of the

knuckles above the floor). Many structural variables

are important in the design of vehicles, products,

workspaces, and clothing (Bridger, 1995). Any

person involved in a process design should be advised

to study the anthropometry tables and differences in

body proportion between different groups (e.g. there

is an approximately 10 cm height difference between

the U.S. and Japanese males in the standing position

which might imply differences in product design).

The second type of anthropometric data is the one

collected to describe the movement of a body part

with respect to a fixed reference point. For example,

to account for the maximum forward reaches of

standing subjects, the area swept out by the

movement of the leg can be used to describe

workspace envelopes (i.e. zones of easy or maximum

reach around an operator). The size of the workspace

envelope increases with the number of unconstrained

joints (Bridger, R.S., et al. 1995).

Ergonomic evaluations in workplaces can help

identify the levels of risk that are within the permitted

range, in order to increase efficiency both for

operators and owners of the business. Modern

ergonomics contributes to the evaluation of work

systems and products with multidisciplinary teams

that include them at different stages of design and

manufacturing. Therefore, it is highly important to

practice and develop these abilities in students,

whether engineers or designers.

At Universities, ergonomics evaluation has for the

main purpose to detect the risk levels for the operators

that are present in a workplace and to consider health

problems due to bad ergonomics or by the lack of

anthropometric data. As expressed by Davies and

Bingham, 2015, design and engineering students and

lecturers have recognized the importance of applying

ergonomic principles within the design process but

the amount and of this teaching varies even within the

same university due to time constraints and the ability

of students to assimilate information.

As presented in Jellema et al. (2019), the use of

software can raise awareness in students about the

benefits of 3D anthropometry in Ergonomic Product

Design. Moreover, the use of 3D human models with

software such as NX (Baier et al., 2014) and its

human modelling tool or DhaibaWorks (Endo et al.,

2014) might improve design decisions to optimize

specific purposes. Tecnomatix Jack, for example, is

used in a case study of hospital bed design using

OWAS and RULA posture analysis (Gunther and

Quintero-Durán, 2015) and along with a Kinect to

identify correct postures in a supermarket (Colombo

et al., 2013). The latter was the main inspiration for

the Instructional Design strategy presented here,

which enhances the learning experience of the

ergonomics and anthropometrics topics for

engineering students.

The strategy was carried out as part of an optative

course, in which a motion-capture camera was used

along an academic license of commercially available

software to evaluate postures. The description of the

activity is detailed in the following sections.

3 VIRTUAL ERGONOMICS AND

ANTHROPOMETRICS

Mechatronics Engineering students at Tecnológico de

Monterrey who started their major between 2007 and

2018 take two mandatory courses related to

Engineering Product Design: Mechatronic Design

and Mechatronics Laboratory.

In these courses, some basic concepts on

Anthropometry and Ergonomics are introduced,

being this the only common approach of the students

to such concepts through their major:

Introduction to ergonomics.

Consequences of bad ergonomics.

Visual ergonomics.

Methods to assess posture ergonomics such as

Ovako Working Analysis System (OWAS),

Rapid Upper Limb Assessment (RULA) and

Rapid Entire Body Assessment (REBA).

International standards on ergonomics.

Virtual tools and commercially available

mechatronic sensors for ergonomics in

different contexts (sports, work, driving car).

Introduction to anthropometric design and

procedure to account for the 5-95 percentiles in

the design of products and workstations.

Examples of measurements in different

positions and the relation to the design

parameters.

Video of research carried out by a university to

improve crash dummies for changing

populations.

The approach is theoretical and limited to a 1-hour

session, and students usually don’t ask questions

regarding this part. However, once they are requested

to apply those concepts to their own product, they

struggle to develop them. The main proposals of this

article is to make use of a simple task that, with the

help of technology, can help Mechatronic

Engineering students understand better the concepts

of Ergonomics and Anthropometrics.

CSEDU 2020 - 12th International Conference on Computer Supported Education

76

3.1 Advanced Industrial Automation

The bachelor in mechatronics engineering has

specialized topics in the last semesters, such as the

Advanced Industrial Automation (AIA) course that is

taught on a yearly basis. AIA requires that students

have completed at least one basic automation course,

two control engineering courses, and two

intermediate courses on industrial networks and

Programmable Logic Controllers (PLC). Due to the

speciality of the course and the infrastructure capacity

of the laboratory, only a maximum of fifteen students

per course is accepted.

AIA course focuses on designing, evaluating,

validating and optimizing production processes

through the application of product lifecycle

management solutions together with industrial

automation technologies such as PLC, industrial

networks and human-machine interfaces. The topics,

oriented towards manufacturing processes and not in

product design, include methodologies for process

modeling, digitization and information gathering,

facility design and simulation, virtual commissioning

and digital twins, PLC Programming and start and

stop modes guide (GEMMA), offline Robot

Programming, cyber-physical systems, virtual

ergonomics, and mixed reality (Villagomez et al.,

2019).

3.2 A Workshop in the Context of an

Optative Course

Every module of the course has practices related to

one of the topics mentioned above. These activities

are divided in a brief presentation of the theoretical

concepts, exercises solved by students through the

guidance of the lecturer, and an online training course

given at learning advantage platform by Siemens

Digital Industries Software (Siemens DIS, 2019).

At the end of each module, a comprehensive

practice is assigned to the students, allowing them to

practice the knowledge acquired during the module.

Short exams are applied to evaluate the quality of

their learning. Finally, a high percentage of the final

grade is assessed with a final project. The project

includes all of the topics of the course and requires

the application of the knowledge and skills that have

been developed since the first semester of their major.

The final project is divided into several

subprojects: PLC programming of a modular

assembly line, the deployment of an algorithm to

diagnose communication failures between PLC’s, the

creation of a digital twin of the assembly line, the

connection of the digital twin with the PLC’s

program, and the virtual ergonomics analysis which

will be detailed in the next subsections.

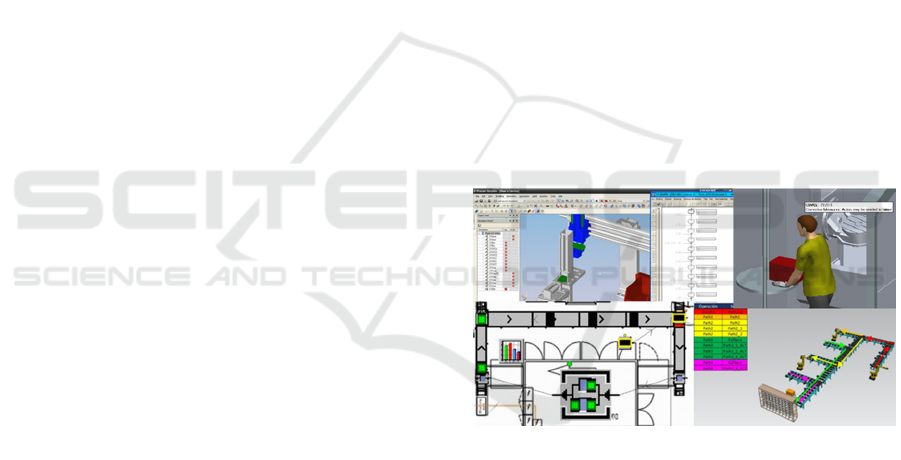

3.3 Tecnomatix Portfolio

Students learn several software tools to create digital

twins of automated processes, including the modeling

of workstations and workers’ interactions. All the

software used in the course was developed by

Siemens Digital Industries Software.

Siemens DIS includes around 250 software

solutions to support the development of products and

process life cycle. In the case of the project, two main

suites were used: NX, a platform that allows

performing computer-aided design, engineering and

manufacturing; and the Tecnomatix portfolio, for

digital manufacturing.

Within the Tecnomatix portfolio there is software

that helps us to model and simulate industrial plants

through discrete event simulation (Plant Simulation),

the design of bill of process (Process Designer),

robots’ offline programming (RobotXpert), design of

virtual environments and virtual commissioning

(Process Simulate), and for the design of operations

that require operators (Jack). Some simulations and

modeling examples are presented in Figure 1.

Figure 1: Example of 3D models made in NX and

simulations made in Tecnomatix portfolio.

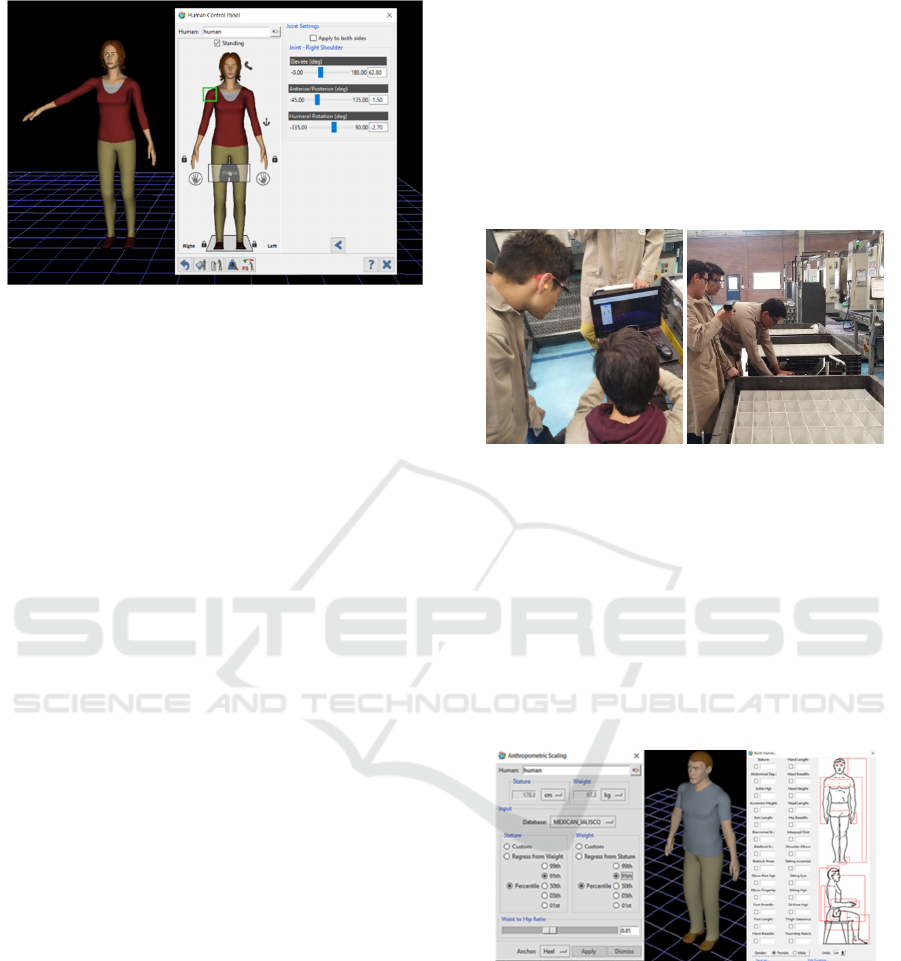

The software Jack allows creating virtual

dummies (a male: Jack, and a female: Jane, depicted

in Figure 2) with anthropometric characteristics of a

human body. With the information of the joints of the

human body, the software allows creating postures

that a human would perform in the real world.

Additional information from the objects or

environments with which you would be interacting

(size of the objects, the weight of the objects) and the

activities that would be performed (pushing or pulling

objects, walking, changing postures) simplify the

analysis of postures at work to avoid a possible

musculoskeletal injury in an individual.

Inducing the Learning of Ergonomics and Anthropometric Design using Motion Capture and Virtual Simulation in an Industrial Context

77

Figure 2: Shoulder Joint Settings for Jane.

3.4 Case Scenario: Industrial Partner

Bocar Group is a German – Mexican group that

started its operation in Mexico City in 1958. Their

first products were fuel pumps and carburetors.

Nowadays, Bocar Group is a product developer and a

full-service supplier of aluminum and plastic parts

products for the automotive industry. Bocar Group

employs 6,000 workers in 11 facilities for production

in Mexico and 5 engineering and commercial offices

around the globe.

The group is divided into three primary divisions:

a) Bocar focus in plastic and aluminum

manufacturing parts and complex assemblies for

automotive applications, b) Auma develops and

produces aluminum die-cast products and c) Plasti

Tec produces plastic injection-moulded parts. Bocar

Group has a collaborative network with the

institution, which allows students to make practices

in their facilities.

3.4.1 Problem Identification

Among the practices carried out by undergraduate

students, it was included the ergonomics study of the

operators of a line of machining processes for

aluminum parts at Bocar Group. The students would

observe the different production processes in the

company and analyze different operations to

determine the ergonomic implications existing in said

operation.

An issue detected was that the machines were

designed for a percentile with anthropometry other

than the machinery and it was necessary to identify if

this might arise a possibility of generating some long-

term musculoskeletal injury. To this end, the students

measured the workers at each station and used the

ergonomics modules of Jack to analyze the workers’

postures during operations.

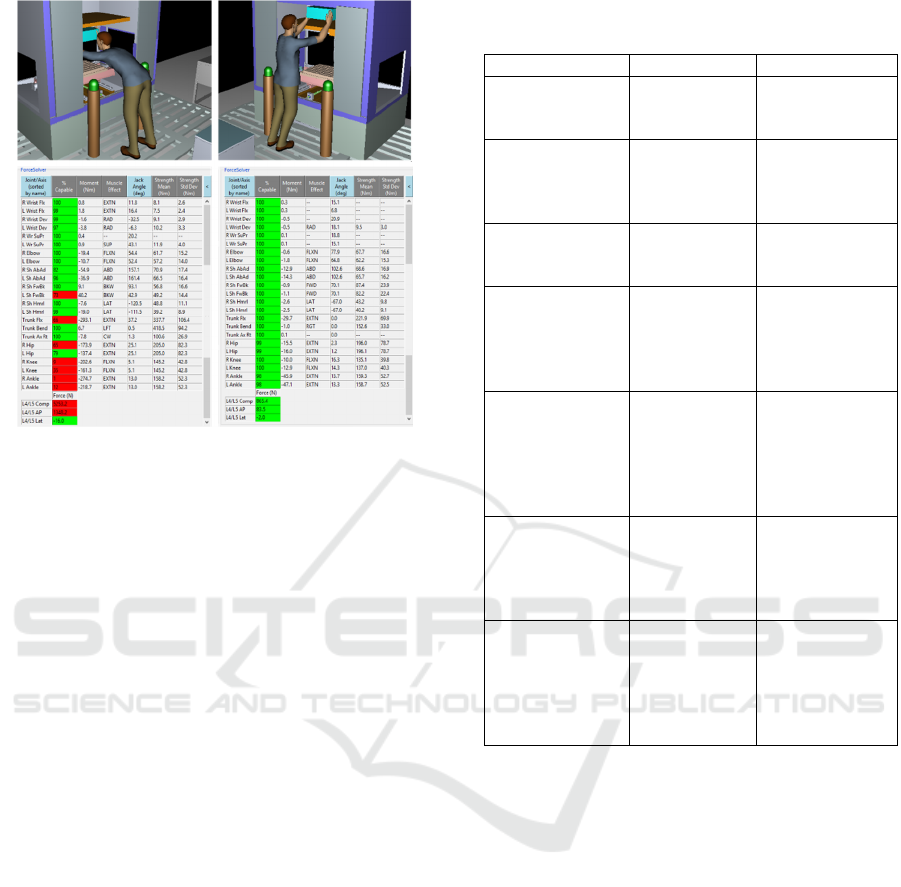

3.4.2 Data Gathering and Data Capture

Students were divided into teams of 3 or 4 members

to analyze the processes of loading and unloading

material on the company's machines. They used a

first-generation Microsoft Kinect sensor as an

infrared camera to detect the movements of the

operators and the software Jack allowed to record the

postures immediately (Figure 3).

Figure 3: Left: The measurements of the workers is

parametrized in the software. Right: the students capture the

movements and positions of the workers with a Kinect.

Within the software, the operator must be

parametrized, entering data such as weight and

height. A feature of Tecnomatix Jack is that it has a

database of anthropometric characteristics from

different countries and regions of the world, but if the

operator characteristics do not match with the models

in the databases, a custom profile can be created

(Figure 4).

Figure 4: Anthropometric measurements in Jack.

3.4.3 Data Analysis and Results

The students analysed the data collected and observed

the ergonomic implications of performing different

operations. The OWAS analysis of the postures

captured was made and the results were presented, as

part of the final project for AIA. The analysis from

the students shows that some postures can be

performed by the operator to see if there is discomfort

or not (Figure 5).

CSEDU 2020 - 12th International Conference on Computer Supported Education

78

Figure 5: Example of a non-ergonomically appropriate

position (left) versus an ergonomically appropriate position

(right) validated with the help of the software. The red

indicators on the right side indicate posture issues.

The students identified some repetitive operations

that generate stress in body joints while (hip, knee,

ankle) due to a non-skid element that was placed on

the floor. The proposed solution was to adjust the

height of the worktable according to the thickness of

the non-skid element or to replace it.

4 ASSESSMENT IN PRODUCT

DESIGN

Mechatronic Design and Mechatronics Laboratory

are project-oriented courses in which students must

develop an engineering product and the processes

associated with its design and manufacture (Esqueda

et al., 2019). To this mean, they identify a need within

a target population and carry out several design

iterations around their needs.

Regarding anthropometric and ergonomic

considerations, they were given liberty to include

what they feel adequate, without any particular

requirements. The degree of development of this

activity had no influence in the grade of the students

since the objective was just to validate their

understanding of the topics. Yet, we defined the

following score to assess their understanding:

Table 1: Score table to assess ergonomics and

anthropometrics degree of development.

1 point 2 points

A. Association

of design and

target population

They included

one kind of

user

They considered

more than one

kind of users

B. Dimensions

of the target

population

Got data from

a book or

digital source

Gathered

experimental

data

C. Weight of

their target

population

Got data from

a book or

digital source

Gathered

experimental

data.

D. Their design

was created by

percentiles:

An average

user (50%) or

fitting a large

person

(100%)

Design can

adapt to diverse

percentiles

(usually 5%-

95%)

E. Weight limits

of the device,

ergonomic

handles or

adequate

position to lift it

One of the

past elements

was taken into

account in

their design

Two of the past

elements were

taken into

account in their

design

F. Ergonomic

fitting and/or

easy reaching to

certain parts

One of the

past elements

was taken into

account in

their design

Two of the past

elements were

taken into

account in their

design

G. Design

iterations with

anthropometric

data or

ergonomics

They iterated

their design

taking one

parameter of

their target

population.

They iterated

their design

taking several

parameters of

their target

population

4.1 Example Projects

The following two examples are given to present the

work carried out by the students.

4.1.1 Earthquake Detection System

The students of this team proposed a system to detect

earthquakes, a phenomenon that is very common in

Mexico City. The problem they had identified was

that, in several seismic communities, there was no

anticipated public alert as there is in Mexico City.

They also identified that even in Mexico City, there

were a vulnerable group of people: those with hearing

impairment.

Their device would then be composed of two

components: one docking station that would be

responsible for getting earthquake alerts (either by an

internet connection to Mexico’s Seismological

Service or by an accelerometer’s response whenever

there was no connection available) and a bracelet

Inducing the Learning of Ergonomics and Anthropometric Design using Motion Capture and Virtual Simulation in an Industrial Context

79

connected via Arduino’s Bluetooth Shields HC-05

and HC-06.

If an earthquake was detected, the docking station

would turn on some flashy LED lights and a sound

alert for the people in the house without the hearing

impairment. Likewise, it would send an alert to the

bracelet so it would vibrate, letting the person with

the hearing impairment be aware of the danger. The

docking station would also serve to charge the battery

of the bracelet.

For their anthropometric analysis, they researched

the 5-95 percentiles of the wrist circumferences for

two groups of population: kids between 5 and 12

years, and teens/adults over 12 years. They also

considered an ergonomic aspect: the fact that certain

people wear their wrist straps with different levels of

tightness (see Figure 6).

To validate this, they measured experimentally

the wrists of 10 kids and 10 adults at different

positions. This information allowed them to define

the placement for the holes in the strap for both the

kids and the adult version (see Figure 7).

.

Figure 6: Positions of the strap for the wrist (top) and

experimental measures to complement their data (bottom).

Figure 7: Part of the Technical Drawing for one version of

their straps. Units in mm.

Some insights obtained from asking their target

markets were that the bracelet should be lightweight

and both devices should be safe. This motivated them

to take out a screen they have previously considered

to reduce weight and redesign both of their devices

without sharp edges.

Figure 8: Final proposal of the docking station (left) along

with its compatible bracelet (right).

For the docking station, they would include two

big luminous buttons (one red and one green) to turn

on/off the alert manually if needed. The screen would

also display information regarding the earthquake.

Finally, they also considered that placing it in the

bureau next to the bed would be optimal for reaching

it either while standing up or while laying down in

bed, which would be advised in an instruction’s

manual to their end-users.

4.1.2 Smart Lunchbox

This project was a solution after detecting bad

nutrition habits of students and workers in Mexico.

To solve this, some students proposed a lunchbox that

would interact with an app to promote healthy dietary

habits. (Figure 9).

Figure 9: Render of the smart lunchbox.

The app would register information regarding

their nutrition and exercise habits, as well as

information about their weight, height and other

factors that could let nutritionists identify a healthy

diet for them. The app would then propose what to fill

the lunchbox compartments with, and control the

unlocking of those compartments at the right time for

eating to reduce the chance of people cheating in their

diet.

CSEDU 2020 - 12th International Conference on Computer Supported Education

80

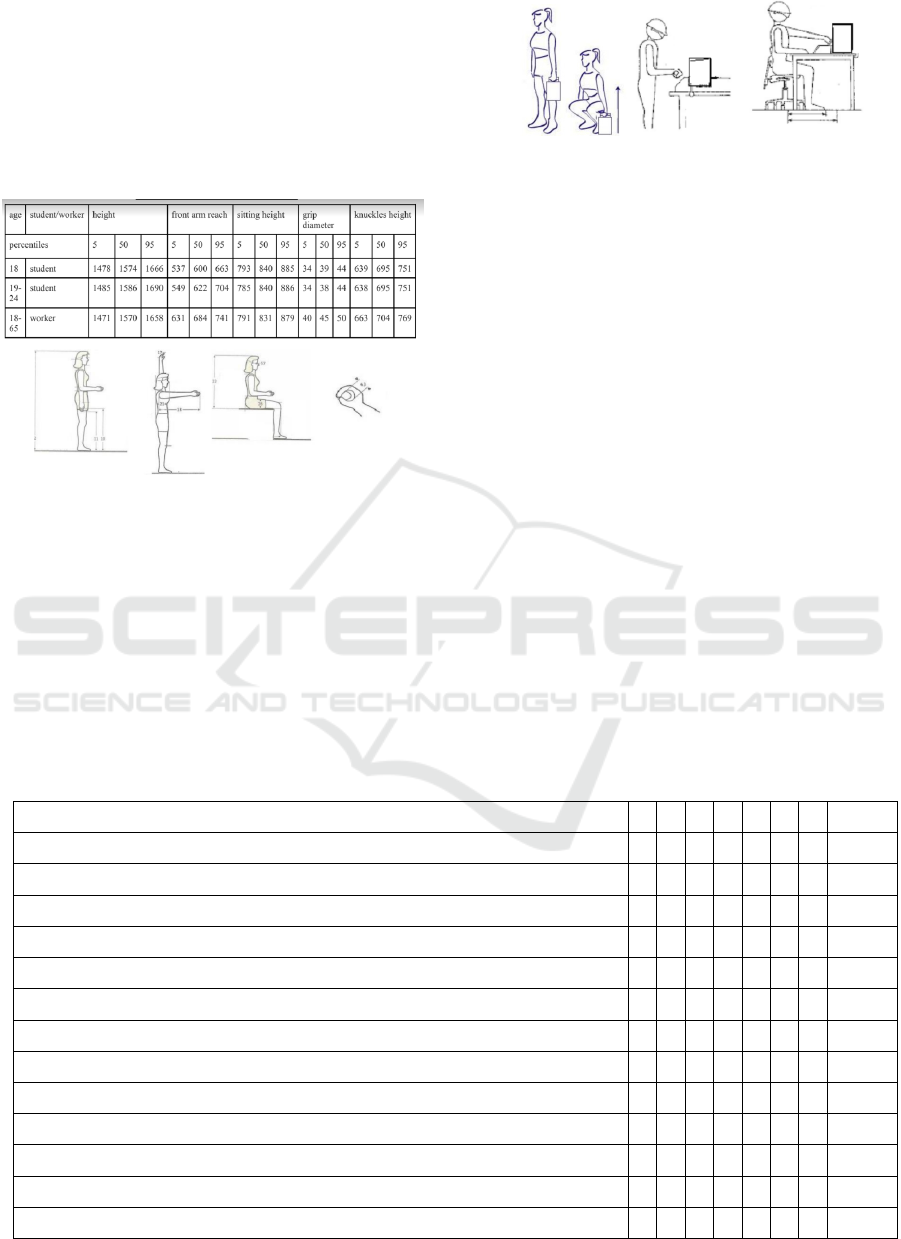

Their ergonomic analysis would focus on people

ranging the ages of 18 to 45 years old. With data

obtained from Avila et al. (2007), summarized for

women in Figure 10, they obtained the data of the

5-50-95 percentiles for different dimensions they

found useful for their design (height, the front reach

of the arm, sitting height, grip diameter and knuckles

height).

Figure 10: Summarized anthropometrics information for

the female population between 18-65 years old as obtained

from Avila et al. (2007).

With that information, the students identified the

positions in which their target markets would use and

lift their device (Figure 11), in order to define the

dimensions for optimal use, as well as a weight limit

when empty (500 g) to reduce the effort of lifting it.

They grip diameter and knuckles height data was used

to define the length and diameter of the handle.

Figure 11: Recommended positions for lifting or using the

device.

4.2 Scores

Table 2 shows the scores assigned for the projects

presented during 3 consecutive periods of 2019: the

semester going from January to May had 6 teams, an

intensive summer period in June-July with 4 teams,

and another semester going from August to December

with 3 more teams. All teams were composed of 4 to

6 students. The score of each column relates to the

categories given in Table 1, where a 0 means no

consideration at all was made by the team.

To validate if there was a meaningful connection

between the activity of the optative course of

Advanced Industrial Automation and their

understanding in a different context (i.e. product

design instead of machine design), several projects

were compared, shown in Figure 12. The x-axis

represents the number of students enrolled in the

optative course independently of the semester in

which they were enrolled in the mandatory courses

(which had a total of 62 students), while the y-axis

shows the score obtained in their ergonomics and

anthropometrics assessment presented in Table 2.

Table 2: Score table to assess ergonomics and anthropometrics degree of development.

Project A B C D E F G Score

Coffee-Delivery guided robot 2 1 0 0 0 0 0 3

Autonomous inventory robot for supermarket warehouses 2 1 0 1 0 1 1 6

Tennis-ball picker guided robot 0 0 0 0 2 0 1 3

Wrist wearable to avoid truckers from getting sleepy 1 1 0 2 1 1 1 7

Baby cradle with automatic rocking system 2 1 0 1 0 0 1 5

Closet that scans the available clothes and proposes combinations through an app 0 0 0 0 0 1 1 2

Intelligent modular power strip 0 0 0 0 0 0 0 0

Earthquake detection docking station and compatible wrist wearable 2 2 0 2 0 2 2 10

Airbag vest for motorcycle riders 2 1 0 2 0 2 1 8

Marking device for home burglars 1 1 0 1 0 1 1 5

Smart lunchbox with nutritional follow-up 2 1 1 1 2 2 2 11

Plastic bottles melting machine to generate 3D printing filament 0 0 0 0 0 0 0 0

Interactive braille book with compatible toy 1 1 1 1 1 0 1 6

Inducing the Learning of Ergonomics and Anthropometric Design using Motion Capture and Virtual Simulation in an Industrial Context

81

While more information is required in order to

statistically validate this result, we can observe that

there seems to be a correlation between the number of

students taking the AIA course, and the degree of

development of ergonomics and anthropometric

design.

Figure 12: A comparison of the % of students in a team

enrolled in the optative course versus the score obtained. A

smaller circle indicates a single team having that score and

percentage of participants a bigger circle indicates two

teams shared the same situation.

5 DISCUSSION & FUTURE

WORK

Even if the sample is small, it can be observed that

teams with 0-1 person enrolled in the AIA course

developed fewer concepts than teams with 3-4

members enrolled in such a course. Having no impact

on their grade confirms that the better the concepts

were understood, the better the analysis they did.

However, even if it simplified learning of the

concepts, none of the student teams did a virtual

ergonomic analysis, possibly due to time restrictions

with the graded deliverables on the project and the

unavailability of the hardware/software combination

in their own computers. Moreover, it would be

interesting to see their degree of development when

certain restrictions are set as graded.

The next step of this research considers doing a

small workshop as part of the mandatory courses, in

which the students can use Kinect and Jack to

evaluate postures using the OWAS assessment while

they are assembling their prototype. Moreover, we

might plan an experience with a company having a

high rate of musculoskeletal disorders to propose

simple product design solutions to mitigate those

risks.

Another step that needs to be implemented is the

design of a grading tool that assesses the

understanding of Ergonomics, Anthropometrics, and

the use of simulation software to anticipate WMSD.

ACKNOWLEDGEMENTS

The authors would like to acknowledge the financial

support of Writing Lab, TecLabs, Tecnologico de

Monterrey, Mexico, in the production of this work.

We would like to acknowledge as well the support

of Grupo Bocar to allow students to do the workshop

at their facilities. Finally, we would like to thank the

students of the Earthquake Detection System (Lissete

Martínez, Mario Lizárraga, Rodrigo Pérez, Daniel

Hernández and Angel Vega) and the Smart Lunchbox

(Jorge Ramos, Adrián Morfín, Alejandro Olivares,

Andrés Morán and Erik Hernández) for sharing their

designs, as well as the students of AIA 2019 course

who developed an accurate process simulation.

REFERENCES

Avila, R., Prado, L., González, E. 2007. Dimensiones

antropométricas de población latinoamericana,

Univ.de Guadalajara. Guadalajara, Mexico, 2nd ed.

Baier, A., Baier, M., Dusik, D., Grabowski, Ł., Miera, A.,

Papaj, P., Sobek, M. Computer-Aided Process of

Designing the Mechatronic Silesian Greenpower

Electric Car. In Selected Engineering Problems, No. 4,

Institute of Engineering Process Automation and

Integrated Manufacturing Systems. October 2014.

https://doi.org/10.4028/www.scientific.net/AMR.1036

.674

Bridger, R.S., 1995. Introduction to Ergonomics,

International Editions.

Colombo, G., Regazzoni, D., Rizzi, C., De Vecchi, G.,

Preliminary Analysis of Low-cost Motion Capture

Techniques to Support Virtual Ergonomics. In

International Conference on Research into Design,

Chennai, India, January 7

th

-9

th

2013.

Clark, P., Denova-Gutierrez, E., Razo, C., Rios-Blancas,

M.J., Lozano, R., The burden of musculoskeletal

disorders in Mexico at national and state level, 1990-

2016: estimates from the global burden of disease study

2016. In Osteoporosis International (2018) 29: 2745.

https://doi.org/10.1007/s00198-018-4698-z

Davies, P., Bingham, G., The importance of common sense:

Ergonomics in Design Education. In Proceedings of the

15

th

International Conference on Engineering and

Product Design Education (E&PDE 2013), Dublin,

Institute of Technology. 5

th

-6

th

September 2013.

Dias, A. C., Almendra, R., Moreira da Silva, F., The

application of ergonomic knowledge by undergraduate

product design students: FAULisbon as a case study. In

Score obtained

CSEDU 2020 - 12th International Conference on Computer Supported Education

82

Procedia Manufacturing, Volume 3, 2015, Pages 5851-

5858: 6

th

International Conference on Applied Human

Factors and Ergonomics (AHFE 2015) and the

Affiliated Conferences AHFE 2015.

https://doi.org/10.1016/j.promfg.2015.07.888

Endo, Y., Tada,. M., Mochimaru, M. 2014, Development of

Virtual Ergonomic Assessment with Human Models. In

3

rd

International Digital Human Modeling Symposium.

Tokyo, Japan, 7

th

-10

th

December 2010.

https://doi.org/10.1109/IEEM.2010.5674380

Esqueda, D., Delgado, F., Morano, H., García, A. 2019.

Engineering Product Design Education with a Mixed

Design-Thinking and Lean Start-up Approach. In

Proceedings of the 21

st

International Conference on

Engineering and Product Design Education (E&PDE

2019), University of Strathclyde, Glasgow. 12

th

-13

th

September 2019. https://doi.org/10.35199/epde2019.45

Grandjean E. 1973, Ergonomics in Computerized Offices.

Taylor and Francis, London.

Gunther, P., Quintero-Durán, M., Ergonomic assessment of

hospital bed moving using DHM Siemens Jack. In

Proceedings 19th Triennial Congress of the IEA,

Melbourne 9-14 August 2015.

Jellema, A., Gallouin, E., Massé, B., Ruiter, I., Molenbroek,

J., Huysmans, T., 3D Anthropometry in Ergonomic

Product Design Education. In Proceedings of the 21

st

International Conference on Engineering and Product

Design Education (E&PDE 2019), University of

Strathclyde, Glasgow. 12

th

-13

th

September 2019.

https://doi.org/10.35199/epde2019.2

Mondelo, P. R., Gregori, E., Blasco, J., Barrau, P.,

Ergonomía 3, Diseño de puestos de trabajo, 2a.

Edición, Alfaomega Grupo Editor 2001

Pheasant, S., 1996, Bodyspace: Anthropometry,

Ergonomics And The Design Of Work:

Anthropometry, Ergonomics And The Design Of

Work, Taylor and Francis Tilley, A. R, Henry Dreyfuss

Associates, Human Factors in Design, The Measure of

Man and Woman, John Wiley & Sons, Inc, 2002

Siemens Digital Industries Software, (2019). Customer

Success Stories. Retrieved from:;

https://www.plm.automation.siemens.com/global/en/o

ur-story/customers/#?productKeywords=tecnomatix

Tilley, A. R, Henry Dreyfuss Associates, Human Factors in

Design, The Measure of Man and Woman, John Wiley

& Sons, Inc, 2002

Villagomez, L. E., Solis-Cordova, J., Vasquez, V., Batres,

R., Molina, A., Velilla, A., Amaro, J., Esparza, G.,

Laboratory of Intelligent Operational Decisions: A

Proposal for Learning Digital and Smart Manufacturing

Concepts. In 2019 IEEE 11th Int. Conference on Eng.

Ed. (ICEED), Kanazawa, Japan, 2019, pp. 153-158.

https://doi.org/10.1109/ICEED47294.2019.8994936

Zagloel, T. Y. M., Hakim, I. M., Syarafi, A. M., Pre-

eliminary Design Adjustable Workstation for Piston

Assembly Line Considering Anthropometric for

Indonesian People. 2015.

https://doi.org/10.5281/zenodo.1110688

Inducing the Learning of Ergonomics and Anthropometric Design using Motion Capture and Virtual Simulation in an Industrial Context

83