A Decision Support System for a Multi-trip Vehicle Routing Problem

with Trucks and Drivers Scheduling

Nilson F. M. Mendes and Manuel Iori

Departament of Sciences and Methods of Engineering, Universit

`

a degli Studi di Modena e Reggio Emilia,

Reggio Emilia, Italy

Keywords:

Decision Support System, Optimization, Vehicle Routing, Scheduling.

Abstract:

Many real-world transportation problems can be modeled as variants of the well-known vehicle routing prob-

lem (VRP), where a fleet of vehicles based at a central depot is used to deliver freight to clients at a minimum

cost. Frequently, the problems defined in the VRP literature and the corresponding solution algorithms do not

catch all the problem features incurred by the companies in their every-day activity, and further flexibility is

needed during the decision process to make adjustments on the fly. In this paper, we present a decision support

system developed for an Italian pharmaceutical distribution company to deal with a Multi-Trip VRP character-

ized by additional constraints and Truck and Driver Scheduling. The problem is solved in the software with a

two-phase algorithm: the first phase consists of an Iterated Local Search metaheuristic that defines the vehicle

routes, whereas the second phase invokes a mathematical model to assign trucks and drivers to the routes.

The software allows, between the two phases, changes in the solution to better fit the company requirements.

Computational results prove the effectiveness of the proposed method.

1 INTRODUCTION

Vehicle Routing Problems (VRP) are a traditional and

well studied topic in Operations Research and Man-

agement Science. The process of defining efficient

and convenient routes is one of the main concerns for

a large number of companies, and it can lead to sig-

nificant losses when it is not performed accurately. In

such field, developing a good Decision Support Sys-

tem (DSS), capable of satisfying all requirements and

covering all relevant characteristics of the real prob-

lem at hand, is not an easy task. Despite the vast

literature dealing with different VRP types, finding

a variant that exactly describes the operations of a

company is also difficult. Most of the times, even

state-of-the-art algorithms are not satisfactory in de-

livering good real routes, due to unrealistic assump-

tions, lack of information, too optimistic or determin-

istic approaches or simply because they are not flexi-

ble enough to provide alternatives when the best solu-

tion is not approved by the decision maker. Conscious

of this situation, companies are always looking for al-

ternatives that could give them a better (or more ro-

bust) approximation, of even hiring professionals or

software houses to developed custom softwares that

exactly fit their needs.

In this paper, we describe a branch of a DSS that we

are developing for an Italian company specialized in

the storage and distribution of pharmaceutical prod-

ucts. This branch provides a routing plan and a driver

scheduling and assignment for each route. Further-

more, it provides a set of quantitative reports that al-

low one to better analyze the quality and fitness of the

solution obtained. The problem we solve is a Rich

Multi-Trip VRP with Driver and Vehicle Scheduling,

where the term “rich” implies that the problem con-

tains a number of additional constraints with respect

to the basic VRP. The problem derives indeed from

the union of a VRP with Time Windows (VRPTW),

see, .g., (Solomon, 1984), and a Multi-Trip Vehicle

Routing and Scheduling Problem (MTVRSP), see,

e.g., (Brandao and Mercer, 1997), but also includes

additional constraints defined by the distribution com-

pany. In short, the aim is to create a minimum-cost

one-week routing plan to deliver products to a set

of clients by using a heterogeneous fleet of vehicles

based at a central depot, while satisfying clients ser-

vice time windows, vehicle and drivers incompatibil-

ities, driving regulation, and presence of intermediate

depots.

The contributions of this work are multiple: we

clearly describe an optimization problem derived

Mendes, N. and Iori, M.

A Decision Support System for a Multi-trip Vehicle Routing Problem with Trucks and Drivers Scheduling.

DOI: 10.5220/0009364403390349

In Proceedings of the 22nd International Conference on Enterprise Information Systems (ICEIS 2020) - Volume 1, pages 339-349

ISBN: 978-989-758-423-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

339

from a real-world distribution activity; we solve the

problem by means of a two-phase algorithm; we

present a software architecture that allows for an intu-

itive and quick man-in-the-middle approach to make

the algorithm fully usable within a DSS; we present

a large computational evaluation on a set of realis-

tic instances; and we discuss how the approach can

be replicated to solve other difficult VRP with opera-

tional constraints.

The remainder of the paper is organized as fol-

lows. In Section 2, a short review of the related litera-

ture is provided. In Section 3, a formal description of

the problem and the company vision of it are given.

Next, in Section 4, we describe how the system works

and how the user participates to the solution process.

In Section 5, we describe the solution approach and

then, in Section 6, we computationally evaluate it on

a case study.

2 LITERATURE REVIEW

As aforementioned, the problem that we study in this

paper is a union of a VRPTW, see, e.g., (Solomon,

1984), and a MTVRSP, see, e.g., (Brandao and Mer-

cer, 1997). The VRPTW has a broad and well-studied

literature, and it is included in many MTVRSP prob-

lems. Consequently, we focus our short review on the

MTVRSP literature. We refer the reader interested

in VRPTW and other VRP variants to the books by

(Golden et al., 2008) and (Toth and Vigo, 2014).

Despite the fact that they well model scenar-

ios where short routes are common or desirable,

MTVRSP are relatively new in the literature. While

the traditional VRP was introduced sixty years ago

by (Dantzig and Ramser, 1959), the multi-trip ver-

sion appeared only thirty years after with (Fleis-

chmann, 1990). In such article, the term used was

not even“multi-trip”, but “VRP with multiple vehi-

cle uses”. Other well known characteristics were also

studied in that article, like time windows and hetero-

geneous fleet. The number of vehicles was also lim-

ited, making the use of the same vehicle several times

more desirable.

Six years later (Taillard et al., 1996) proposed a

three phase heuristic for the problem that started by

generating a pool of reasonable routes (first phase)

from which a subset was selected (second phase) and

then assigned to feasible workdays according to a bin

packing-like procedure (third phase).

The first explicit mention to the term “truck

drivers” as a part of the problem name occurred, to

the best of our knowledge, in (Brandao and Mercer,

1997). Such paper considered the driver maximum

working hours in a day as well the needed breaks

during a route. Other features, like unloading time,

vehicle incompatibilities with some clients and the

possibility to hire additional vehicles if the available

ones were not enough, were also taken into account.

To solve the resulting problem, they proposed a tabu

search heuristic. They found good results for in-

stances with approximately 20 vehicles, divided into

two types, and 70 clients. The work was then pursued

by the same authors in (Brandao and Mercer, 1998),

where they discussed a simplified version of an algo-

rithm used in a real-world application, and they re-

ported reductions of about 5% on the delivery costs.

(Campbell and Savelsbergh, 2004) proposed an

efficient insertion heuristic to the basic Vehicle Rout-

ing and Scheduling Problem (VRSP), a MTVRSP

without multi-trips, having polynomial complexity.

(Z

¨

apfel and B

¨

ogl, 2008) presented a heuristic method

to solve an MTVRSP with possibility of drivers out-

sourcing. (Cattaruzza et al., 2014a) proposed a

memetic algorithm and an adaptation of the split pro-

cedure, see, e.g., (Duhamel et al., 2011), to seg-

ment a chromosome into a MTVRP solutions. (Azi

et al., 2014) used an Adaptive Large Neighborhood

Search (ALNS) algorithm to solve a variant of the

MTVRSP problem where visits to some clients could

be avoided.

Just a few papers in the literature developed ex-

act methods to solve the MTVRSP. The first was (Azi

et al., 2010), that made use of a column generation

approach embedded with a branch-and-cut algorithm.

A similar approach was also employed by (Macedo

et al., 2011). A more robust method was provided by

(Mingozzi et al., 2013), where the authors presented

two set-partitioning formulations for the problem, one

having a binary variable for each route and the other a

binary variable for each schedule. Their solution pro-

cedure used bounding methods to reduced the orig-

inal set of routes and schedules. (Hernandez et al.,

2016) also used a similar strategy, but with less re-

finements in the space solution. In (Tang et al., 2015),

a pickup and delivery problem inside an airport was

modeled as a trip-chain-oriented set-partitioning, and

then solved directly using CPLEX.

In 2006, a new regulation about truck drivers was

created in Europe, aiming at giving better job con-

ditions to the workers and rising the safety on the

transportation activity. The EC N

o

561/2001 defined

a large set of rules about drivers work regime like

maximum duration of daily shifts, mandatory breaks,

overtimes, minimum rest time between two shifts and

weekly rests. Among the new rules we can highlight

the minimum rest of 45 minutes after 4.5 hours of

uninterrupted activity (that can be replaced by a 15

ICEIS 2020 - 22nd International Conference on Enterprise Information Systems

340

minutes break after a 30 minutes break within the 4.5

hours) , daily driving time of nine hours (that can be

extended to 10 hours two times per week), at least

11 hours of daily rest and a maximum of 56 hours of

weekly driving time. This regulation entered in force

in April 2007, and right after that digital tacographs

became mandatory in the European Union, allowing

the authorities to check, a posteriori, the drivers work-

ing times. This new scenario motivated several stud-

ies where the driver was individually considered.

The first study considering these new constraints

was presented, to the best of our knowledge, by (Goel,

2009). In this paper, a Large Neighborhood Search

(LNS) is used to create a weekly schedule where all

the rest and break rules are respected. To reduce the

explored solution space, the authors did not consid-

ered overtimes and the 15 minutes more 30 minutes

break possibility.

(Kok et al., 2010), on the other hand, was the

first to consider all the rules presented in the EC N

o

561/2001 regulation and in the Directive 2002/15/EC.

To solve an MTVRP incorporating such features, they

proposed a restricted dynamic programing framework

where clients were sequentially added to the end of

partial vehicle routes. Feasibility of such additions

was controlled by extra state dimensions.

A few years later, (Drexl et al., 2013) proposed a

two-stage method to solve a MTVRSP with the pres-

ence of relay stations where the drivers are allowed

to change a vehicle. The first stage consists in solv-

ing a pickup-and-delivery problem, see, e.g., (Bat-

tarra et al., 2014) and (Doerner and Salazar-Gonz

´

alez,

2014) with time windows and relay stations, whereas

the second consists in soling a VRPTW with multiple

depots.

Two papers deal with a multi-commodity

MTVRSP variant where some commodities cannot

be transported together. The former is by (Battarra

et al., 2009), who introduce the problem and proposes

an adaptive guidance heuristic to solve it, whereas the

latter is by (Cattaruzza et al., 2014b), who describe

an ILS heuristic.

Vehicle routing and scheduling problems are stud-

ied in the context of home healthcare planning by (Al-

gethami et al., 2017), that compares some operators

in a genetic algorithm. In the same path (Algethami

et al., 2019) proposes an adaptive multiple crossover

to the problem.

Some most recent studies in the MTVRSP area

are those by (Masmoudi et al., 2016) and (Benkebir

et al., 2019). The former tests a set of metaheuris-

tics to solve a multi-trip dial-a-ride problem, and the

second proposes a hybrid method composed by a ge-

netic algorithm and a local search for the MTVRSP.

Others relevant study are (He and Li, 2019), where

is described a two-echelon multi-trip VRP in a con-

text of crop harvesting and (Babaee Tirkolaee et al.,

2019) that describes a case study of a multi-trip VRP

applied to an urban waste collection. Further informa-

tion about the MTVRSP can be found in (Cattaruzza

et al., 2016). We also refer to (Lahyani et al., 2015)

as a recent review of the literature on rich VRP.

3 PROBLEM DESCRIPTION

The Multi-Trip Rich Vehicle Routing Problem with

Truck and Driver Scheduling, henceforth refereed to

as MTRVRPTDS, describes a one-week products de-

livery operation. In this problem, trucks and drivers

are individually assigned to each route, considering

driver regulation and operational constraints. The

routes are created trying to minimize the distances,

and must respect the client time windows. Deliveries

can be anticipated (changing from the required day

to the previous day) if it is allowed by the client and

useful to improve the costs of the overall plan.

Formally, let D be a set of days in a week, F a set

of storage facilities, C a set of clients, T a set of trucks

and W a set of drivers. Each client c ∈ C has a demand

of O

cd

pallets, on day d ∈ D, that must be delivered

inside a time window [α

c

,β

c

]. A service time of S

cd

minutes is required to unload the delivery to client c

in day d, independently of the truck internal organi-

zation of the cargo. Each vehicle t ∈ T is driven by a

unique driver w ∈ W . Vehicles are grouped in types,

on the basis of their speed V

t

and capacity Q

t

. Drivers

have different contracts and skills. They are allowed

to work at most h hours by day, at most h

week

hours

per week, and they may drive only a subset T

w

⊆ T of

the available vehicles, for each w ∈ W .

A unique depot is given. This is due to the fact that

the company centralizes all the deliveries of a region

to that depot. The depot is supplied of pharmaceu-

tical products by a regional entity, and it is expected

that all the products are available in the moment in

which they are required by the clients. Each route de-

parts from the unique depot, passes through a subset

of clients, and then returns to the depot. An agreement

between drivers and the company limits the maximum

duration of a route in 8 hours, less than the maximum

daily shift allowed by the ECD 56/2006 which is 9

hours. It is also imposed that the total weekly work-

ing time cannot exceed 40 hours, and that the daily

working extra time is limited to at most 20% of the

maximum daily shift.

Some vehicles cannot be sent to visit some clients

(because they are too big for the road or they do not

A Decision Support System for a Multi-trip Vehicle Routing Problem with Trucks and Drivers Scheduling

341

have enough power to climb a hill). This is taken into

account by considering a set R

t

of clients that can be

reached by vehicle t ∈ T .

Each vehicle and driver can be assigned to more

than one route per day. This is possible if the next

route starting time is after the first route ending time

plus the time required to reload the truck or the driver

have a break.

Additionally to the main depots there are, in some

regions, intermediate warehouses that can be supplied

by exclusive routes coming from the main depots.

Those intermediate warehouses receive loads that will

be delivered in the next day to the clients, working

like a buffer. The use of an intermediate warehouse

has a cost E

f

, with f ∈ F being an intermediate ware-

house and F being the set of all intermediate ware-

houses.

A missing point about driver regulation that is

not included in the problem definition concerns the

mandatory breaks that drivers should do during the

day and the rests between the days. They were

not considered in the software specification, because

they were considered too operational and quite unpre-

dictable. As reported by one of the employees, as de-

lays or changes in the routes can happen, it could be

hard to stop at the moment defined by the specific se-

quence provided by the DSS, because the driver could

be in a non-safe place. Beside this, it could trigger

some drivers resistance due to the fact that some of

them have already their preferences on where to stop

in each place they use to visit. In any case, we dis-

cuss how these constraints could be included in our

approach below. Regarding the rest between days,

no route should start before 5 AM. If a driver arrives

late at night, the responsible manager would change

the scheduling to avoid this driver to pick a too early

route in the next day. This type of on-the-fly changes

are usual when using DSS to solve optimization prob-

lems.

4 SOFTWARE DATA FLOW

The usability is a very important feature considered

by us to develop this software. It is commonly pointed

out as one of the main factors for the success of a soft-

ware in a company. A poor usability can make DSS

with advanced algorithms and analytic tools unused

due to the resistance of the decision makers to learn

and deal with the system complexity.

To ensure that our DSS is used by the company,

we decided to create a friendly web interface to deal

with the process of loading, visualizing and control

of optimization inputs. More than only providing an

easy-to-learn tool to run an algorithm, this interface

was thought to allow the decision maker to be part

of the solving process and have a clear overview of

solution quality. The application described in this pa-

per is a module inside a larger software belonging to

the same project. This module is divided into two

parts, following the strategy proposed by us to solve

the problem.

The flow starts with the rich VRP input load.

This input consists in three files, one describing the

clients, with all the information about time windows,

demands, service times and vehicle restrictions; the

second describing the type of vehicles available with

its respective average speeds, capacity and number of

units available, and finally the third with the parame-

ters.

The distances between the clients can be

informed by the user in the client file or

evaluated in the system using the LibOSM

(https://github.com/Marcussacapuces91/LibOsm/)

that is part of the Open Street Maps ecosystem and

Lemon (https://lemon.cs.elte.hu/trac/lemon), from

COIN-OR. These libraries together make possible

to calculate real road distance between any pair of

points that corresponds a valid address in a given

region using only a local geo-spatial database. In this

way, it is possible to get all the information needed

without the use of Internet or accessing external web

services.

After all the data are loaded (or calculated, if we

consider distances), the user can start the optimiza-

tion with a click. To solve this part of the problem we

invoke a heuristic algorithm that takes approximately

1 to 3 minutes to converge with instances involving

around 200 clients. Such heuristic is described in de-

tail in (Kramer et al., 2019), and is sketched below

in the next section. The results obtained are a set

of product transfers from a depot to an intermediate

warehouse and a set of delivery routes departing from

the main depot. Each route or transfer has a departure

time and receives a vehicle type assigned to it, but not

information about the driver.

Before proceeding to the next step, the decision

maker can adjust the solution obtained by changing

the departure time, the vehicle type assigned, the

clients in the route and the visit order. After each

change, a solution automatic validation is performed.

If a change leads to an infeasible solution, a rollback

procedure is done and the user is informed with a pop-

up.

To plan an individual driver and truck to each

route the user can proceed in two ways. The first way

is to load route information using Excel files like in

the previous phase. This method is useful when some

ICEIS 2020 - 22nd International Conference on Enterprise Information Systems

342

other persons or systems created the routes, so it is

possible to get some improvement by better using the

resources available. The second way is to load the

first phase solution as input to the second part, and

this can be done with just one click. Next, the user

just needs to insert the information about the drivers

and the details about each vehicle.

The driver and truck assignment is calculated by

solving a mathematical model using a Mixed Integer

Linear Programming (MILP) solver. As in the first

phase, changes in the solution provided by the system

are allowed and checked, as already described. Once

all these steps are finished, the solution remains stored

in the software database and can be visualized in a

dashboard or downloaded in an Excel file.

A last important point to highlight is the tolerance

of the DSS with respect to infeasible solutions. In real

problems, not satisfying all constraints is common.

However, it is not interesting for a decision maker to

simply have no answer after it called a solver. Con-

sidering this, we show any solution obtained at the

end of optimization, treating the typical sources of in-

feasibility as penalizations in the objective functions,

but warning the user about that. A typical situation

of this type occurs when not enough trucks or drivers

are available for the daily deliveries. In this case, the

model incurs in a penalty, the solution is however re-

turned, and the decision maker knows which routes

can be directly performed by the company and which

ones should be postponed to the next day or given to a

third-party logistic operator. The tolerance with infea-

sible solution is not extended to infeasibilities inserted

by the user through solution edition. As aforemen-

tioned, no valid modifications are undone to avoid de-

teriorate a feasible or almost feasible solution.

5 SOLUTION APPROACH

To solve the MTRVRPTDS, we use a two-phase ap-

proach. In the first phase, we use the Multi-Start Iter-

ated Local Search (MS-ILS) metaheuristic developed

by (Kramer et al., 2019). This MS-ILS was originally

developed to solve the same VRP we face in this pa-

per, but without considering multiple-trips neither the

presence of a limited umber of trucks and drivers. We

thus modified this algorithm in the way described be-

low in Section 5.1 to fit with the new characteristics.

In the second phase, the routes created in the previ-

ous phase are given in input to a new mathematical

model, described in Section 5.2, that assigns drivers

and trucks to the routes and defines the effective de-

parting time of each route.

5.1 Multi-start ILS Heuristic

The subproblem solved in the first phase of the

MTRVRPTDS defines a set of delivery routes and

product transfers from main depots to intermediate

warehouses. In this phase, trucks and drivers are not

individualized, but we just define how many vehicles

of each capacity and average speed are used. The

deliveries must be done by satisfying the client time

windows and some of them can be anticipated to the

previous day at the expenses of opening an auxiliary

depot. To solve this problem, we used an adapted ver-

sion of the MS-ILS by (Kramer et al., 2019), where

a penalty is added in the cost function whenever the

number of vehicles of a certain type used is greater

than the number of available vehicles.

The algorithm can be briefly described as follows.

At each iteration, a constructive method creates an

initial route connecting the depot to a hospital (that

are the clients with larger demands in our instances)

and associate the largest allowed vehicle to the route.

After this is done for all the hospitals, the remaining

clients are inserted in the routes created following a

lowest-cost-increase criterion. Time windows viola-

tions are accepted, but penalized.

After creating the initial solution, the algorithm

starts the ILS loop. In this loop, a Randomized Vari-

able Neighrborhood Descent (RVND) algorithm is

used as local search procedure. The RVND selects,

at each iteration, an inter-route neighborhood (from a

list of four) and executes it. If the solution is not im-

proved, then the neighborhood is removed from the

list and the algorithm tries another one. Otherwise,

the list is reinitialized and the algorithm tries to im-

prove the current solution using one of three possible

intra-route neighborhoods. When the list of available

inter-routes neighborhood becomes empty (i.e., after

four not improvement iterations) the method stops.

After the local search has been performed, a pertur-

bation phase is invoked. In this step, a local search

is chosen randomly (from a list of three) to randomly

modify the solution. The ILS method is iterated until

a given number of iterations without improvements is

reached (in our settings, 20 iterations). The multi-start

executes the ILS 20 times.

5.2 Mathematical Model

The subproblem solved in the second phase of the

MTRVRPTDS defines which truck and driver must

execute a route and defines the departure and arrival

times at each client, considering the truck average

speed, the service start time and the time windows. In

some cases, no truck and driver are assigned to a route

A Decision Support System for a Multi-trip Vehicle Routing Problem with Trucks and Drivers Scheduling

343

due to limited resources. In this case, a penalty is ap-

plied in the objective function. The penalty roughly

corresponds to the cost of assigning the route to an ex-

ternal distribution company. We also apply penalties

when a driver works more than her maximum daily

working hours or compatibilities are not satisfied. The

maximum overtime is modeled as a hard constraint, as

well the weekly maximum working hours.

The MILP model uses the following parameters:

• DC

w

- Cost of driver w ∈ W

• DOTC

w

- Overtime hour cost of driver w ∈ W

• PR - Penalty for route not assigned

• TT P - Total daily time (1440)

• CST

r

c

- Service time of client c ∈ C in the route

r ∈ R

• TD

r

ab

- Total distance between points a and b in

the route r ∈ R

• TD

r

- Total distance on route r ∈ R

• TST

r

- Total service time on route r ∈ R

• TAS

t

- Truck t ∈ T average speed

• (TW B

c

,TW E

c

) - Limits of time windows of

client c ∈ C

• E

r

- Set of routes segments in the route r ∈ R

• C

r

- Set of clients in the route r ∈ R

• D

r

- Day in which the route r ∈ R is executed

• LT - Truck loading time

• R

d

- Routes in the day d ∈ D

• DMH

w

- Daily maximum working hours of driver

w ∈ W

• W MH

w

- Weekly maximum working hours of

driver w ∈ W

• FWC

wc

- Equals to 1 if it is strictly forbidden to

assign the driver w ∈ W to routes containing the

client c, equals to 0 otherwise

• FTC

tc

- Equals to 1 if it is strictly forbidden to as-

sign the truck t ∈ T to routes containing the client

c, equals to 0 otherwise

• FTW

tw

- Equals to 1 if it is strictly forbidden to

assign the driver w ∈ W and the truck t ∈ T to the

same route, equals to 0 otherwise

• SOFT FWC

wc

- Equals to 1 if it is not desirable

to assign the driver w ∈ W to routes containing the

client c, equals to 0 otherwise

• SOFT FTC

tc

- Equals to 1 if it is not desirable

to assign the truck t ∈ T to routes containing the

client c, equals to 0 otherwise

• SOFT FTW

tw

- Equals to 1 if it is not desirable

to assign the driver w ∈ W and the truck t ∈ T to

the same route, equals to 0 otherwise

The equations (1) to (31) defines the model proposed.

All the variables that represents time instants or inter-

vals as well the temporal parameters are expressed in

minutes. Every time the characters f and l appear as a

client-index in the model, they represent the first and

last clients of the route.

Min

∑

w∈W

∑

d∈D

(sig

wd

∗ DC

w

+ DOTC

w

∗ pun

wd

)

+PR ∗ ncr

r

+ penComp

(1)

Subject to

∑

w∈W

x

wr

+ ncr

r

= 1 r ∈ R

(2)

∑

i∈T

y

ir

+ ncr

r

= 1 r ∈ R

(3)

max(TW B

c

,ac

cr

) ≤ bc

ir

∀r ∈ R c ∈ C

r

(4)

bc

cr

+CST

r

c

≤ dc

cr

+ ncr

r

∗ T T P

∀r ∈ R, c ∈ C

r

(5)

dc

cr

+

∑

i∈T

y

ir

∗ T D

r

c1,c2

/TAS

i

≤ ac

c2,r

∀r ∈ R, (c1,c2) ∈ E

r

(6)

dc

dep,r

− (bc

ls

+CST

s

l

+

∑

i∈T

y

is

∗ T D

s

l,dep

/TAS

i

)

≤ (ro

rs

− 1) ∗ T T P + LT ∀r, s ∈ R|D

r

6= D

s

(7)

x

wr

+ x

ws

≤ ro

rs

+ ro

sr

+ 1 ∀r, s ∈ R, w ∈ W

(8)

y

ir

+ y

i

s ≤ ro

rs

+ ro

sr

+ 1 ∀r, s ∈ R, i ∈ T

(9)

∑

r∈R

d

x

wr

≤ |R| ∗ sig

wd

∀w ∈ W, d ∈ D

(10)

Ua

wd

≤ dc

f r

+ T T P ∗ (1 − x

wr

)

∀w ∈ W, d ∈ D ,r ∈ R

d

(11)

Ca

wd

+ T T P ∗ (1 − x

wr

) ≥

dc

lr

+

∑

i∈T

y

ir

∗ T D

r

l,dep

/TAS

i

∀w ∈ W, ∀ d ∈ D ,r ∈ R

d

(12)

Ca

wd

−U a

wd

≤ DMH

w

+ pun

wd

∀w ∈ W, d ∈ D

(13)

ICEIS 2020 - 22nd International Conference on Enterprise Information Systems

344

∑

d∈D

(Ca

wd

−U a

wd

) ≤ W MH

w

∀w ∈ W

(14)

x

wr

≤ (1 − FWC

wc

)+

(1 − FWC

wc

) ∗ wcp

wc

− SOFT FWC

wc

∀w ∈ W, c ∈ C

r

(15)

y

ir

≤ (1 − FTC

ic

)+

(1 − FTC

ic

) ∗tcp

ic

− SOFT FTC

ic

∀i ∈ T ,c ∈ C

r

(16)

x

wr

+ y

ir

≤ (2 − FTW

iw

)+

(2 − FTW

iw

) ∗twp

iw

− 2 ∗ SOFT FTW

iw

∀w ∈ W, i ∈ T,r ∈ R

(17)

penComp = M ∗ (

∑

i∈T

∑

c∈C

tcp

ic

+

∑

w∈W

∑

c∈C

wcp

wc

+

∑

w∈W

∑

i∈T

twp

iw

)

(18)

dc

dep,r

+

∑

i∈T

y

ir

∗ (T D

r

− T D

r

l,dep

)/TAS

i

+T ST

r

≤ ac

lr

+CST

r

l

+ T T P ∗ ncr

r

∀r ∈ R

(19)

dc

dep,r

+

∑

i∈T

y

ir

∗ (T D

r

dep, f

)/TAS

r

≥ TW B

f

− T T P ∗ ncr

r

∀r ∈ R

(20)

x

wr

∈ 0, 1 ∀w ∈ W, r ∈ R

(21)

y

tr

∈ 0, 1 ∀t ∈ T,r ∈ R

(22)

ncr

r

∈ 0, 1 ∀r ∈ R

(23)

0 ≤ bc

cr

≤ TW E

c

−CST

r

c

∀r ∈ R, c ∈ C

r

(24)

0 ≤ ac

cr

≤ TW E

c

−CST

r

c

∀r ∈ R, c ∈ C

r

(25)

0 ≤ dc

cr

≤ TW E

c

∀r ∈ R, c ∈ C

r

(26)

Ua

wd

,Ca

wd

≥ 0 ∀w ∈ W, d ∈ D

(27)

0 ≤ pun

wd

≤ 0.2 ∗ DMH

w

∀w ∈ W, d ∈ D

(28)

wcp

wc

≥ 0 ∀w ∈ W, c ∈ C

(29)

tcp

tc

≥ 0 ∀t ∈ T,c ∈ C

(30)

twp

tw

≥ 0 ∀t ∈ T,w ∈ W

(31)

The binary variable x

wr

defines if the driver w ∈ W is

assigned to the route r ∈ R. Similarly, y

ir

is a binary

variable that defines if the truck i ∈ T is assigned to

the route r ∈ R. In the model implementation, no y

variable is created when the truck capacity is lower

than the total demand in the route. The variables ac

cr

,

bc

cr

and dc

cr

define, respectively, the arrival time, ser-

vice begin time and departure time for client c ∈ C and

route r ∈ R. The binary variable ro

rs

defines if the

routes r,s ∈ R can be assigned to the same driver and

truck. Routes in different days have no restrictions of

this kind. The variables Ua

wd

and Ca

wd

represent the

first departure and last arrival time for driver w ∈ W

in day d ∈ D.

Some variables are defined to describe situa-

tions where penalties must be applied. The vari-

able ncr

r

represents a non-executed route, pun

wd

represents instead the overtime of driver w ∈ W in

day d ∈ D. The variables, wcp

wc

, tcp

ic

and twp

tw

are, respectively, binary variables that represent non-

desirable driver/client, truck/client and truck/driver

assignments. Finally, penComp simply sums up all

the non-desirable assignment penalties.

Constraints (2) and (3) define that, in order to

execute a route, we should assign a driver and a

truck, otherwise the ncr

r

variable corresponding to

that route would be activated. Constraints (4) to (6)

define the minimum begin service time, client depar-

ture time and client arrival time, respectively. In (7),

we verify if it is possible to assign the same route to

the same pair driver/client. The two following con-

straints avoid or permit it, according to the value of

variables ro

rs

and ro

sr

. Constraints (10) check if a

driver is used in the day. In constraints (11) to (14),

the driver working hours (including eventual pauses)

are calculated and limited. Constraints (15) to (18)

check the assignment incompatibilities. Finally, (19)

defines a lower bound to arrive in the last client and

(20) defines an upper bound for the departure of a

route. The remaining constraints ensure variable do-

mains.

6 CASE STUDY

In this section, we present the computational results

that we obtained on a case study. The aim of the tests

we performed was to evaluate the DSS performance

in finding good solutions. We used a PC equipped

with a processor Intel Core i5-7200 with 2.5 GHz,

Windows 10 and 8GB of RAM. The heuristic was

implemented using C++ and the model using JuMP

A Decision Support System for a Multi-trip Vehicle Routing Problem with Trucks and Drivers Scheduling

345

library of Julia language. To solve the model, we used

the IBM MILP solver CPLEX 12.8.

The instances we used are taken from a realistic

scenario originating in the Italian region of Basilicata.

All the instances have some common characteristics,

such as 187 clients, 2 types of vehicles, truck aver-

age speeds (40 km/h for the larger vehicle type and

60 km/h for the smaller vehicle type), the daily de-

mands, the assignment resctrictions, 8 hours of maxi-

mum shift duration, and 60 minutes between two con-

secutive routes assigned to the same driver/truck. In

Table 1 we report some details on number of cus-

tomers and daily demands.

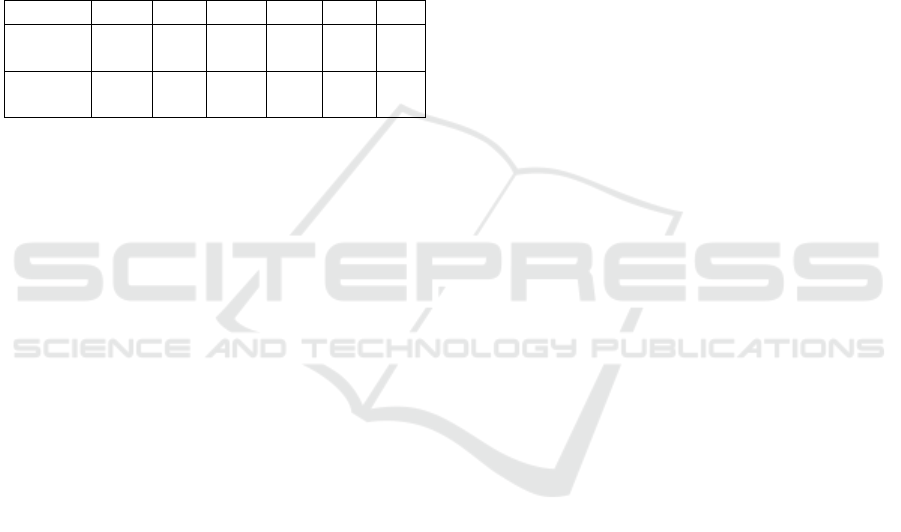

Table 1: Number of Clients and Total Demands per Day.

Day Mon Tue Wed Thu Fri Sat

N. of

clients

37 37 44 38 51 2

Total

demand

530 490 560 540 630 60

We created instances by attempting variations in the

number of vehicles of each type, capacity of vehicles,

time window size and maximum number of clients per

route. All those variations generated a total of 40 in-

stances, divided in 5 blocks of 8 instances each. All

tests were executed like in a standard use of the soft-

ware, as described in Section 4. To give a user per-

spective of the results we limited the maximum run

time of the MILP solver to 30 minutes.

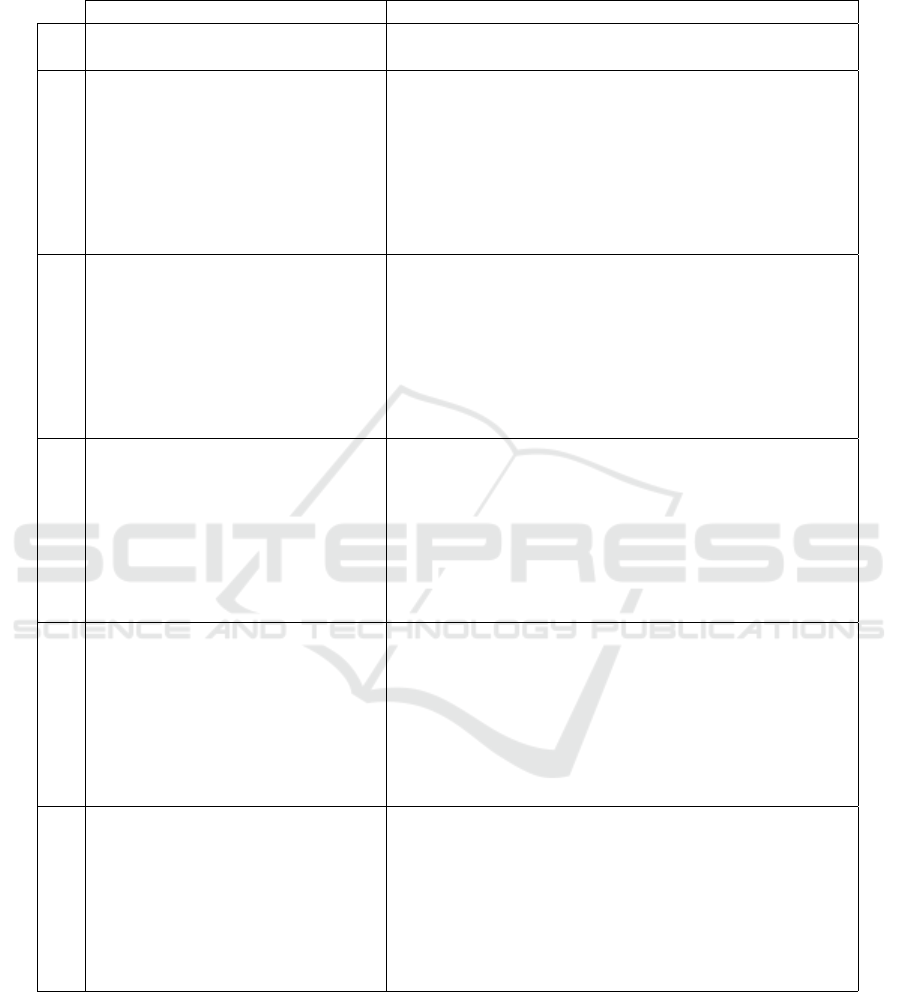

Table 2 summarizes the main results we obtained.

The table reports the identification number of each

instance (ID), the truck capacity (TC), the time win-

dow size (TW), the maximum number of clients per

route (MCR) and the number of trucks per type (N. of

trucks).

For what the concerns the results obtained by the

optimization method, we highlight in column NR the

number of routes generated by the MS-ILS heuristic

adopted in the first phase of our algorithm, and in col-

umn Km the total distance of such routes. The first

phase required between one and two minutes to solve

any of the instances in the table. We could not find a

clear correlation between instance configuration and

run time of the algorithm. Regarding the solution

quality, we observe that the number of routes gener-

ated by the first phase algorithm does not have a sig-

nificant correlation with number of vehicles used and

total distance (correlations −0.008 and 0.03, respec-

tively). Even in instances with a total of 10 trucks

the number of routes does not change significantly.

On the other hand, fleet total capacity creates a larger

variation on number of routes as well as the total

distance run (correlations −0.73 and −0.71, respec-

tively). As we can see, the number of routes and total

distance grow almost equally as the fleet capacity re-

duce.

Average distance by route is 156 km, with a small

standard deviation of only 4.7 km. This means all

routes can be traveled in less than four hours, even

with the slowest vehicle. This is an advantage in

small-sized time window scenarios and makes the

problem regarding breaks along the day less relevant.

In the second phase, the model was able to find as-

signments to all routes for about 30% of the instances.

In another 42% of instances, only one or two routes

were not assigned. In a real life operation this kind

of solutions is not a major concern if visualized in

advance. The decision maker can improve these so-

lutions by contacting an external truck and driver, or

delaying some deliveries.

However, cases where a higher number of non-

assigned routes (as for instances 1 and 2 in block E)

are more critical. Those cases could be caused by

problems like deliveries imbalance, non appropriated

fleet size or worse, a bad warehouse location. On the

other hand, it could represent a lack o efficiency of

the algorithm in building routes and schedules with

the available resources, which can be verified with a

deeper solution analysis.

Table 2 also highlights a low number of instances

solved to optimality (14 out of 40) and some large

gaps. The gap increases when the fleet capacity is re-

duced and the time windows get tighter. As the gaps

were not directly connected with the quality of the

solutions, we looked for another factors that could be

interfering in the convergence of model solving. To

investigate changes that could provide a better perfor-

mance in the proposed method, we tested a modified

version of the model in which variable sig

wd

as well

constraints 10 were removed.

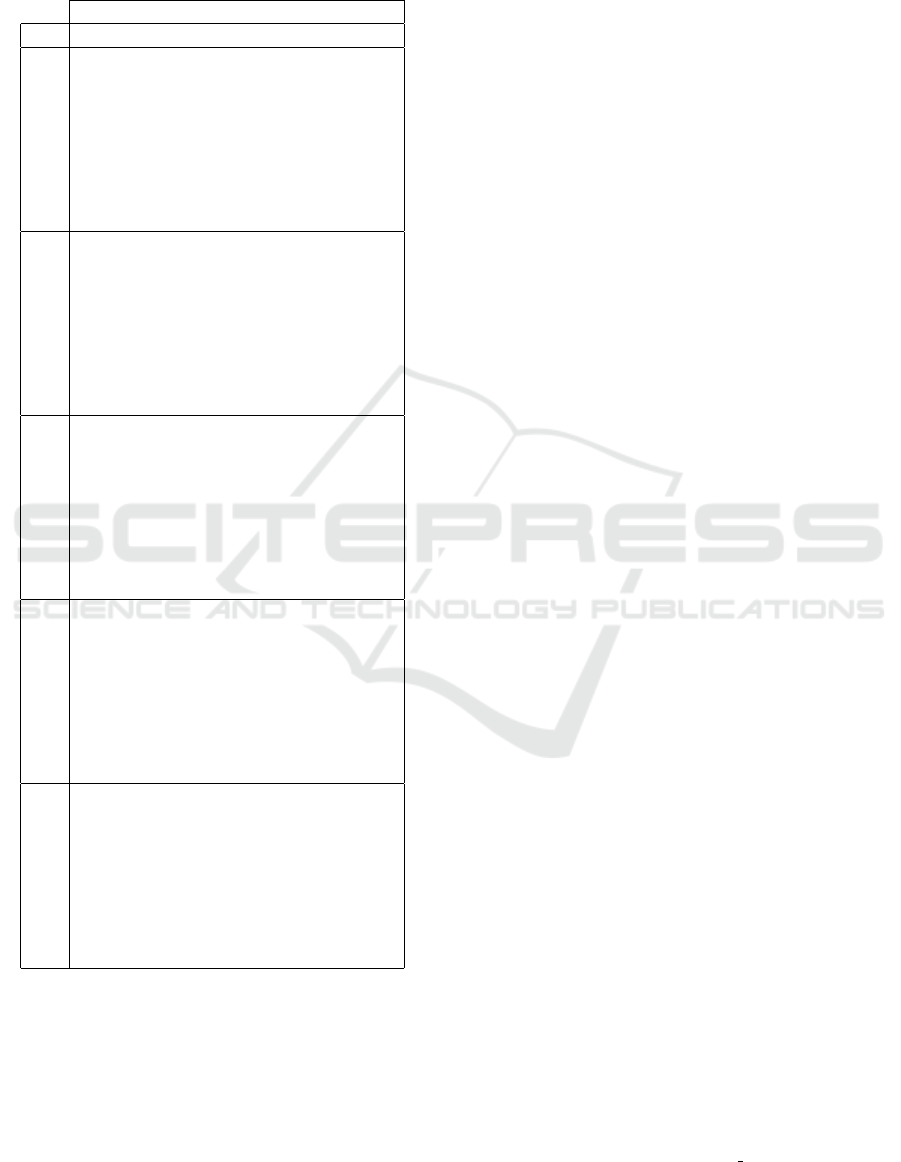

The results that we obtained with this simplified

model are shown in Table 3. The changes we made

on the model were useful in improving the solution

convergence, aa all the instances were solved to the

proven optimality. All but one of instances were

solved in less than one minute, and in many cases the

gap between the objective functions found on regu-

lar and modified versions were lower than 10%. The

numbers of non-assigned routes in this model version

were the same as those found with the original model.

This makes us conclude that the simplified model is

a good compromise between the representation of the

real-world problem and the need fo a quick and effec-

tive solution convergence.

ICEIS 2020 - 22nd International Conference on Enterprise Information Systems

346

Table 2: Instance Variable Parameters and Main Data about Obtained Solutions. Abbreviations : TC - Truck Capacity, TW -

Time Window, MCR - Maximum Clients per Route, NR - Number of Routes, Time - Model Solving Run Time, UB - Model

Objective Function, LB - Lower Bound, NAR - Non-Assigned Routes.

Parameters Results

ID TC TW MCR

N. of

trucks

NR Km Time UB LB Gap NAR

1A

70/60 6-18 6

3 - 5 48 7635 1845 15435 15084 2.32 3

2A 2 - 6 47 7610 1857 15469 15133 2.2 3

3A 4 - 4 48 7587 1837 15435 15084 2.3 3

4A 5 - 3 49 7699 1813 5522 5176 6.7 1

5A 6 - 2 49 7551 1857 10522 10084 4.3 2

6A 7 - 3 49 7615 1839 15380 15107 1.8 3

7A 3 - 7 49 7632 1901 10380 10084 2.9 2

8A 5 - 5 49 7632 1833 10380 10084 2.9 2

1B

70/40 6-18 6

3 - 5 58 9197 1834 1198 751 5.9 0

2B 2 - 6 60 9388 1907 11251 5684 97.9 2

3B 4 - 4 58 9282 1833 5618 5212 7.8 1

4B 5 - 3 59 9163 1831 5671 5196 9.1 1

5B 6 - 2 56 9109 1814 671 212 216.5 0

6B 7 - 3 58 9512 1849 476 210 126.6 0

7B 3 - 7 58 9167 1839 1676 1374 21.2 0

8B 5 - 5 58 9237 1832 5444 5105 6.6 1

1C

50/40 6-18 6

3 - 5 69 10179 1814 1337 814 64.2 0

2C 2 - 6 69 10254 1812 6337 684 826.4 1

3C 4 - 4 68 10131 1812 1241 127 87.7 0

4C 5 - 3 70 10365 1813 1337 120 101.4 0

5C 6 - 2 70 10365 1813 1390 117 108.8 0

6C 7 - 3 69 10239 1812 440 84 423.8 0

7C 3 - 7 69 10402 1813 551 110 441.0 0

8C 5 - 5 69 10383 1838 508 84 504.7 0

1D

70/60 7-17 8

5 - 3 46 7409 1848 11284 10748 5.0 2

2D 2 - 6 47 7314 1833 11284 10748 5.0 2

3D 4 - 4 47 7359 115 11284 11284 0 2

4D 5 - 3 46 7402 106 16251 16251 0 3

5D 6 - 2 47 7338 1840 16347 15148 7.9 3

6D 7 - 3 46 7442 355 10476 10476 0 2

7D 3 - 7 47 7466 133 11076 11076 0 2

8D 5 - 5 47 7454 194 5476 5476 0 1

1E

70/60

7 - 13

and

11 - 18

8

5 - 3 46 7307 48 31205 31205 0 6

2E 2 - 6 47 7456 54 36453 34653 0 7

3E 4 - 4 46 7336 54 16559 16559 0 3

4E 5 - 3 47 7520 56 16400 16400 0 2

5E 6 - 2 46 7476 67 11443 11443 0 2

6E 7 - 3 47 7465 67 15637 15637 0 3

7E 3 - 7 47 7444 70 21301 21301 0 4

8E 5 - 5 46 7635 69 733 733 0 0

7 CONCLUSIONS

In this paper, we presented a decision support system

to help decision makers in the solution of real cases

of a Multi-Trip Rich Vehicle Routing Problem with

Truck and Driver Scheduling, a problem where good

delivery routes need to be created and then matched

with the available trucks and drivers. We proposed

a two-phase heuristic procedure, in which the first

phase is an adaptation of a metaheuristic from the lit-

erature, and the second phase consists of a mathemat-

ical model.

A Decision Support System for a Multi-trip Vehicle Routing Problem with Trucks and Drivers Scheduling

347

Table 3: Results Obtained Solving the Model without

Drivers Fixed Costs. Abbreviations: Time - Model Solv-

ing Run Time in Seconds, UB - Model Objective Function,

LB - Lower Bound, NAR - Non-Assigned Routes.

Results

ID Time UB LB Gap NAR

A1 16 15000 15000 0 3

A2 15 15000 15000 0 3

A3 13 15000 15000 0 3

A4 15 5000 5000 0 1

A5 14 10000 10000 0 2

A6 15 15000 15000 0 3

A7 14 10000 10000 0 2

A8 15 10000 10000 0 2

B1 20 600 600 0 0

B2 20 10600 10600 0 2

B3 16 5000 5000 0 1

B4 23 5000 5000 0 1

B5 16 600 600 0 0

B6 22 0 0 0 0

B7 19 1200 1200 0 0

B8 14 5000 5000 0 1

C1 21 600 600 0 0

C2 35 5600 5600 0 1

C3 32 0 0 0 0

C4 32 0 0 0 0

C5 211 0 0 0 0

C6 18 0 0 0 0

C7 17 0 0 0 0

C8 22 0 0 0 0

D1 20 10600 10600 0 2

D2 17 10600 10600 0 2

D3 28 10600 10600 0 2

D4 37 15600 15600 0 3

D5 17 15600 15600 0 3

D6 16 10000 10000 0 2

D7 22 10600 10600 0 2

D8 25 5000 5000 0 1

E1 15 30600 30600 0 6

E2 25 35600 35000 0 7

E3 26 15600 15600 0 3

E4 27 15600 15600 0 2

E5 72 10600 10600 0 2

E6 18 15000 15000 0 3

E7 14 20600 20600 0 4

E8 15 0 0 0 0

Extensive computational experiments were per-

formed on realistic instances. We could observe that

the system had troubles in identifying good solutions

in very restricted scenarios, but it could consistently

produce good quality solutions in other reasonable

scenarios. For such scenarios, we could also note

that the algorithm had a regular performance behav-

ior, and this is an important feature to make the user

trust the software. The run time was most of mostly

low, satisfying the requirements of the system without

compromising the solution qualities.

Future research directions will be concentrated on

adapting and testing the current approach in more

flexible and general scenarios. For example, when

deliveries can be done in the next day, vehicles or

drivers are not available in some days of the week,

or when different truck average speeds must be used

depending on the fact that the vehicle is in an urban

area or not. Considering the user experience, we plan

to make visible to the decision maker data about road

blocks, tolls, and information on client satisfaction, to

help her in the evaluation of eventual route changes.

A synchronization with the warehouse operation soft-

ware is also being evaluated to improve the allocation

of workers to recover products and load trucks. We

also plan to replace the mathematical model with a

quick and effective metaheuristic, so as to be able to

provide in quick time good-quality problem solutions.

ACKNOWLEDGEMENTS

We thank the University of Modena and Reggio

Emilia (Italy) for the financial support to this work

provided with the grant FAR 2018 “Analysis and op-

timization of healthcare and pharmaceutical logistic

processes”.

REFERENCES

Algethami, H., Landa-Silva, D., and Martinez-Gavara, A.

(2017). Selecting genetic operators to maximise pref-

erence satisfaction in a workforce scheduling and

routing problem. In Proceedings of the 6th Interna-

tional Conference on Operations Research and Enter-

prise Systems, pages 416–423.

Algethami, H., Mart

´

ınez-Gavara, A., and Landa-Silva, D.

(2019). Adaptive multiple crossover genetic algorithm

to solve workforce scheduling and routing problem.

Journal of Heuristics, 25(4-5):753–792.

Azi, N., Gendreau, M., and Potvin, J.-Y. (2010). An ex-

act algorithm for a vehicle routing problem with time

windows and multiple use of vehicles. European Jour-

nal of Operational Research, 202(3):756–763.

Azi, N., Gendreau, M., and Potvin, J.-Y. (2014). An adap-

tive large neighborhood search for a vehicle routing

problem with multiple routes. Computers & Opera-

tions Research, 41:167–173.

Babaee Tirkolaee, E., Abbasian, P., Soltani, M., and Ghaf-

farian, S. A. (2019). Developing an applied algorithm

for multi-trip vehicle routing problem with time win-

dows in urban waste collection: A case study. Waste

Management & Research, 37(1

suppl):4–13.

ICEIS 2020 - 22nd International Conference on Enterprise Information Systems

348

Battarra, M., Cordeau, J.-F., and Iori, M. (2014). Pickup-

and-delivery problems for goods transportation. In

Toth, P. and Vigo, D., editors, The Vehicle Routing

Problem, Monographs on Discrete Mathematics and

Applications, pages 161–191. SIAM, Philadelphia.

Battarra, M., Monaci, M., and Vigo, D. (2009). An adap-

tive guidance approach for the heuristic solution of a

minimum multiple trip vehicle routing problem. Com-

puters & Operations Research, 36(11):3041 – 3050.

Benkebir, N., Pouliquen, M. L., Tr

´

evien, J.-F., Bounceur,

A., Euler, R., Pardiac, E., and Sevaux, M. (2019). On a

multi-trip vehicle routing problem with time windows

integrating european and french driver regulations.

Journal on Vehicle Routing Algorithms, 2(1):55–74.

Brandao, J. and Mercer, A. (1997). A tabu search algo-

rithm for the multi-trip vehicle routing and scheduling

problem. European journal of operational research,

100(1):180–191.

Brandao, J. and Mercer, A. (1998). The multi-trip vehicle

routing problem. Journal of the Operational research

society, 49(8):799–805.

Campbell, A. M. and Savelsbergh, M. (2004). Efficient in-

sertion heuristics for vehicle routing and scheduling

problems. Transportation science, 38(3):369–378.

Cattaruzza, D., Absi, N., and Feillet, D. (2016). Vehicle

routing problems with multiple trips. 4OR, 14(3):223–

259.

Cattaruzza, D., Absi, N., Feillet, D., and Vidal, T. (2014a).

A memetic algorithm for the multi trip vehicle routing

problem. European Journal of Operational Research,

236(3):833–848.

Cattaruzza, D., Absi, N., Feillet, D., and Vigo, D. (2014b).

An iterated local search for the multi-commodity

multi-trip vehicle routing problem with time windows.

Computers & Operations Research, 51:257 – 267.

Dantzig, G. B. and Ramser, J. H. (1959). The truck dis-

patching problem. Management science, 6(1):80–91.

Doerner, K. and Salazar-Gonz

´

alez, J. (2014). Pickup-and-

delivery problems for people transportation. In Toth,

P. and Vigo, D., editors, The Vehicle Routing Prob-

lem, Monographs on Discrete Mathematics and Ap-

plications, pages 161–191. SIAM, Philadelphia.

Drexl, M., Rieck, J., Sigl, T., and Press, B. (2013). Si-

multaneous vehicle and crew routing and scheduling

for partial- and full-load long-distance road transport.

Business Research, 6(2):242–264.

Duhamel, C., Lacomme, P., and Prodhon, C. (2011). Effi-

cient frameworks for greedy split and new depth first

search split procedures for routing problems. Comput-

ers & Operations Research, 38(4):723–739.

Fleischmann, B. (1990). The vehicle routing problem with

multiple use of vehicles. Fachbereich Wirtschaftswis-

senschaften, Universit

¨

at Hamburg.

Goel, A. (2009). Vehicle scheduling and routing with

drivers’ working hours. Transportation Science,

43(1):17–26.

Golden, B., Raghavan, S., and Wasil, E., editors (2008). The

Vehicle Routing Problem: Latest Advances and New

Challenges. Operations Research/Computer Science

Interfaces Series. Springer.

He, P. and Li, J. (2019). The two-echelon multi-trip vehicle

routing problem with dynamic satellites for crop har-

vesting and transportation. Applied Soft Computing,

77:387–398.

Hernandez, F., Feillet, D., Giroudeau, R., and Naud, O.

(2016). Branch-and-price algorithms for the solution

of the multi-trip vehicle routing problem with time

windows. European Journal of Operational Research,

249(2):551–559.

Kok, A. L., Meyer, C. M., Kopfer, H., and Schutten, J.

M. J. (2010). A dynamic programming heuristic for

the vehicle routing problem with time windows and

european community social legislation. Transporta-

tion Science, 44(4):442–454.

Kramer, R., Cordeau, J.-F., and Iori, M. (2019). Rich vehi-

cle routing with auxiliary depots and anticipated deliv-

eries: An application to pharmaceutical distribution.

Transportation Research Part E: Logistics and Trans-

portation Review, 129:162–174.

Lahyani, R., Khemakhem, M., and Semet, F. (2015). Rich

vehicle routing problems: From a taxonomy to a def-

inition. European Journal of Operational Research,

241(1):1–14.

Macedo, R., Alves, C., de Carvalho, J. V., Clautiaux, F., and

Hanafi, S. (2011). Solving the vehicle routing problem

with time windows and multiple routes exactly using a

pseudo-polynomial model. European Journal of Op-

erational Research, 214(3):536 – 545.

Masmoudi, M. A., Hosny, M., Braekers, K., and Dammak,

A. (2016). Three effective metaheuristics to solve the

multi-depot multi-trip heterogeneous dial-a-ride prob-

lem. Transportation Research Part E: Logistics and

Transportation Review, 96:60 – 80.

Mingozzi, A., Roberti, R., and Toth, P. (2013). An exact

algorithm for the multitrip vehicle routing problem.

INFORMS Journal on Computing, 25(2):193–207.

Solomon, M. M. (1984). Vehicle routing and scheduling

with time window constraints: Models and algorithms

(heuristics).

Taillard,

´

E. D., Laporte, G., and Gendreau, M. (1996). Vehi-

cle routeing with multiple use of vehicles. Journal of

the Operational research society, 47(8):1065–1070.

Tang, J., Yu, Y., and Li, J. (2015). An exact algorithm

for the multi-trip vehicle routing and scheduling prob-

lem of pickup and delivery of customers to the airport.

Transportation Research Part E: Logistics and Trans-

portation Review, 73:114–132.

Toth, P. and Vigo, D., editors (2014). Vehicle Rout-

ing: Problems, methods, and applications. SIAM,

Philadelphia, 2nd edition.

Z

¨

apfel, G. and B

¨

ogl, M. (2008). Multi-period vehicle

routing and crew scheduling with outsourcing op-

tions. International Journal of Production Economics,

113(2):980–996.

A Decision Support System for a Multi-trip Vehicle Routing Problem with Trucks and Drivers Scheduling

349