Design of a Percutaneous Left Ventricular Assist Device

Shivam Gupta

1

, K. R. Balakrishnan

2

and R. Krishna Kumar

1

1

Department of Engineering Design, Indian Institute of Technology Madras, Chennai, India

2

MGM Hospitals, Chennai, India

Keywords: Percutaneous Left Ventricular Assist Device (PVAD), Computational Fluid Dynamics (CFD), Systemic Mock

Circulation Loop (SMCL), Particle Image Velocimetry (PIV).

Abstract: Percutaneous Left Ventricular Assist Device is used for short (1-2 weeks) of cardiac support and have

strenuous design methodology as compared to conventional Left Ventricular Assist Device (LVAD). The aim

of this study is (i) to design a micro-axial blood pump (ii) valídate the design using Computational Fluid

Dynamics (CFD) and Systemic Mock Circulation Loop (SMCL), and (iii) flow visualization using Particle

Image Velocimetry (PIV). The diameter of the impeller is 7.6 mm and length is 15 mm. One of the most

important aspect of the design was the elimination of the bearing. The optimum parameters ascertained

includes a wrap angle of 250

0

,

blade thickness of 0.5 mm and shroud clearance of 0.25 mm. The straightener

and diffusor were eliminated to reduce the net surface area exposed to blood. The pump characteristics were

obtained using a Systemic Mock Circulation Loop (SMCL), developed in-house. The dynamic response was

recorded by varying arterial compliance from 0.5 mL/mm Hg to 2 mL/mm Hg in SMCL. The design showed

a consistent pump characteristics over a range of arterial compliance and an optimum flow rate of 2.5L/min

at 60mm Hg, whereas the maximum flow rate of 2.8L/min at 80 mm Hg. The flow characteristics obtained

using PIV were in good agreement with the CFD results.

1 INTRODUCTION

Every year 17.9 million deaths are reported

worldwide from Cardiovascular Disease (CVD),

which is 31% of all deaths worldwide (Benjamin et

al., 2019). The number of Heart Transplants

performed worldwide in 2018 is approximately 3500

(Cook et al., 2015). Percutaneous Left Ventricular

Assist Device (henceforth called PVAD) is used to

support a failing heart. Unlike conventional Left

Ventricular Assist Device (LVAD), the PVAD, is

transplanted and used for a duration of only 6 to 14

days allowing the heart to recover (Casassus et al.,

2015). Currently available PVAD’s includes,

Impella (2.5/CP/5.0) by Abiomed Corporations and

HeartMate PHP by Thoratec Corporation. The

Impella 2.5 (size 12 Fr) delivers a maximum flow

rate of 2.5 L/min at 50,000 rpm whereas Impella 5.0

(size 21 Fr) delivers maximum flow rate of 5L/min

at 33,000 rpm (Lima et al., 2016). The HeartMate

PHP (size 21 Fr) delivers a maximum flow rate of

5L/min at 21,000 rpm (Van et al., 2016).

Three criteria are generally used for the design of

the PVAD. They are: a) Flow rate and pressure head,

which in this case is 2.5 L/min at 60 mm Hg b)

reduction of the exposure time of the blood in the

high shear regions, c) reduction of high shear region.

PVAD design is an iterative process where authors

have used conventional pump design theories to

develop the initial design (Gregory et al., 2017),

(Song et al., 2004) and (Yu H., 2015). Nevertheless

these theories and calculations requires

modifications to design PVAD, especially at various

regions between hub and shroud, wrap angle of

blades, shroud clearance, and changes in pump

parameters when the diffusor is not used. The wrap

angle, which governs the exposure time, clearance

gap which governs the wall shear stress, and changes

in design parameters to avoid high shear zones by

eliminating the diffusor, are critical aspects to be

considered while designing the PVAD.

The development of PVAD requires in vitro

performance test to analyse flow rates, pressure

variations, dynamic response with respect to

conditions like preload and after-load. Identifying

these parameters helps to validate the PVAD’s initial

design. Mock circulation loops (MCL) have been

developed for a simple non-pulsatile prototypes as

well as for a more complex pulsatile prototypes

(Gregory et al., 2009). Though mock circulation loop

298

Gupta, S., Balakrishnan, K. and Kumar, R.

Design of a Percutaneous Left Ventr icular Assist Device.

DOI: 10.5220/0009190702980305

In Proceedings of the 13th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2020) - Volume 1: BIODEVICES, pages 298-305

ISBN: 978-989-758-398-8; ISSN: 2184-4305

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

represents the human arterial system, consisting of

both pulmonary and systemic circulations, in this

work only systemic circuit has been used to validate

the PVAD (Vilchez et al., 2016). Gregory et al. has

developed a Mock Circulation Loop (MCL) which

has been widely used as a benchmark design, which

includes peripheral resistance, compliance,

inertance, systemic and pulmonary circuits, VAD

connections and adjustable cardiac connections

(Gregory et al., 2011). Pantalos et al. used MCL to

mimic the Frank-Starling response under normal

heart, diseased heart, and cardiac recovery conditions

(Pantalos et. al., 2004). Timms et al. developed a

MCL which represents pulsatile left and right

ventricles (Timms et al., 2005)

In order to visualize the flow field in the pump

region, for miniaturized rotary centrifugal (Day et al.,

2004) and axial blood pumps (Apel et al., 2001),

particle image velocimetry (PIV) has been widely

used. Flow visualization can either be done using a

single camera (in two dimensions), or using two

cameras for a three dimensional visualization. Due to

the small size of the percutaneous pumps, a region to

provide an optical access has always been a

challenge. Moreover the velocity gradients

resolution in the clearance space between tip and the

shroud requires a high resolution CCD camera,

which is not covered in this study.

2 MATERIALS AND METHODS

2.1 Pump Design Theory

PVADs are micro axial pumps of less than 8 mm and

their speed is inversely proportional to their size. Red

blood cells which are 10 microns in size are the most

affected part of the blood due to the high rotational

speed of these pumps (Lund et al., 2016). Another

major design parameter which affects the shear stress

on RBCs is the clearance gap between the shroud and

the impeller tip (Yu H., 2015). Moreover regions of

vortices and stagnation in the pump can cause

hemolysis and thrombosis (Gregory et al., 2017).

Considering these major criteria, design of the PVAD

is a cumbersome process compared to a conventional

axial flow pump. The impeller geometry includes

impeller hub and shroud diameter, inlet and outlet

blade angles, wrap angle, clearance gap and blade

profiles. The Design condition imposed for current

PVAD is 2.5 L/min at a pressure head of 60 mm Hg.

Cordier Diagram being the most common starting

point for the selection of any pump in the

conventional design theory was used, after which

Table 1: Initial design parameters.

Location Hub T1 T2

T3 Shroud

24.3

0

22.8

0

21.4

0

20.2

0

19.1

0

36.2

0

32.1

0

28.9

0

26.3

0

24.1

0

Calculated parameters: De Haller Ratio (HR)= 0.75,

Hub diameter (d)= 6 mm, Chord length (c)= 8 mm.

Assumed parameters : Number of blades (Z), Wrap

angle (), Clearance gap (c), Blade thickness (t).

velocity triangles were used to calculate the blade

angles at various locations of hub, shroud and points

between them (Song et al., 2004), Since there lies

infinite points between the hub and the shroud, we

have selected a total three points at a span (T) of 0.25,

0.5, 0.75, thus making it a total five points to calculate

the inlet and the outlet blade angles.

=

. @

. @

(1)

= { − }

(2)

The de Haller ratio (HR) and angle of deflection ()

provides an insight on the loading of the blades. A

smaller de Haller ratio results in more blade loading.

Normally, the de Haller ratio should be larger than 0.7

to avoid stalling of flow, where flow separation

occurs on the suction side of the blade (Gregory et al.,

2017). On the other hand, angle of deflection is

directly proportional to the work done by the

impeller. Table 1 shows the initial design parameters

calculated from the conventional designed

methodology. These design calculations does not

give number of blades, wrap angle, clearance gap,

blade thickness and the effect of variable hub

diameter on the flow characteristics of impeller. So

these initial design parameters were assumed as listed

in Table 1 which is later optimized with an iterative

design process using CFD results. The impeller of

PVAD was modelled using BladeGen (ANSYS®

Academic Research Mechanical, Release 18.1), the

blade profile at the leading edge and trailing edge was

estimated as an ellipse for smooth entry and exit.

2.2 CFD Study

Computational Fluid Dynamics study has proven to

be an efficient method to get good insights of impeller

designs and also for initial validation of the design

(Song et al., 2004).

The study used Ansys TurboGrid

for meshing and Ansys CFX for solving the RANS

Design of a Percutaneous Left Ventricular Assist Device

299

Table 2: Study for optimum wrap angle.

Wrap

angle ()

Head (m) Power (W) O= H/P (m/W)

90

0

0.95 m 0.83 W 1.140 m/W

150

0

0.79 m 0.76 W 1.048 m/W

250

0

0.73 m 0.64 W 1.137 m/W

360

0

0.41 m 0.39 W 1.050 m/W

equations, which are commercial available software.

(ANSYS Inc., Canonsburg, PA, USA). TurboGrid is

an interactive hexahedral grid generation system,

specifically designed for turbo machinery. It is

preprogrammed with several templates tailored to the

complex curvatures of various types of turbines,

compressors and pumps. BladeGen files were

imported to TurboGrid, which generates the flow

domain for the impeller geometry. Tip clearance at

shroud was directly given in TurboGrid which was

varied from 0.1-0.25 mm, based on different models

at different iteration steps. The meshing was further

refined at trailing edge by keeping the trailing edge

cut- off factor at 3.

The meshed data of fluid domain was then

transferred to CFX, where the inlet boundary

condition was kept as

mass flow rate and the outlet

was kept open to let the pressure develop over time.

The flow domain was given a counterclockwise

rotation and a no-slip boundary condition was

applied to the walls. Rotational periodicity interface

was used to reduce the computational time.

A frequently used turbulence model in the field

of rotary blood pumps is the Shear Stress Transport

(SST) model, which is regarded as an industry

standard due to good validation results. K-Ɛ turbulent

models used in conventional VAD’s predicts fluid

flow outside the boundary layer, but fails to capture

near field flow regimes (Song et al., 2004) and (Demir

et al., 2011). Since PVAD is micro-axial entity with

high rotational speed, it is important to track the near

boundary phenomenon and hence SST turbulent

model has been used in our study.

Due to the very high rotational speed, N (nearly

12000 to 27000 rpm) and the small dimension of the

pump, the computational time step must be very

small in order to capture flow field adequately. Thus,

time required for 1 revolution (t) is given by

=

60

× 1000

(3)

Table 3: Study for optimum chord length.

Chord length

(mm)

Head (m) Power

(W)

O= H/P

(m/W)

8 mm 0.7336 m 0.645 W 1.137 m/W

12 mm 0.878 m 0.86 W 1.02 m/W

Moreover, if the number of blades is ‘z’ and hence for

a periodic fluid domain, time taken to spin one pitch

(

) is given by

=

(4)

To capture more information about the flow field, we

have further reduced the time step by a factor of 5,

which solely depends on the amount of information

needed and the computational power. So, the final

time step (T

F

) is given by

T

=

T

5

(5)

The total time taken is 0.8 sec. The streamlines are

shown in figure 1a.

2.3 Design Iterations

Based upon initial parameters adopted from

conventional design theory, a CFD model was

generated and an initial analysis was carried out.

Based on the CFD results, the design parameters were

altered, and the process was repeated. Four assumed

variable parameters which were not possible to be

calculated from conventional pump theories, namely

wrap angle (P1), clearance gap (P2), blade thickness

(P3), and the number of blades (P4), were fixed with

this approach. The number of blades is assumed to be

two. More blades were not considered, as the net

blood exposure surface area increases with number of

blades, along with drive power requirements. The

clearance gap is fixed to 0.25 mm due to the limitation

in manufacturing. The blade thickness, should be as

minimum as possible to increase the net flow area

between the blades. As per the current manufacturing

methods, a blade thickness of 0.5 mm has been

chosen, which results in a unit head loss of 0.1 m/W,

but an increase of 7.9 % of flow area was achieved.

Different wrap angles of 90

0

, 180

0

, 250

0

and 360

0

were analysed, as shown in Table 2.

Table 3 shows the effect of chord length for one

of the iterations on the pump characteristics.

BIODEVICES 2020 - 13th International Conference on Biomedical Electronics and Devices

300

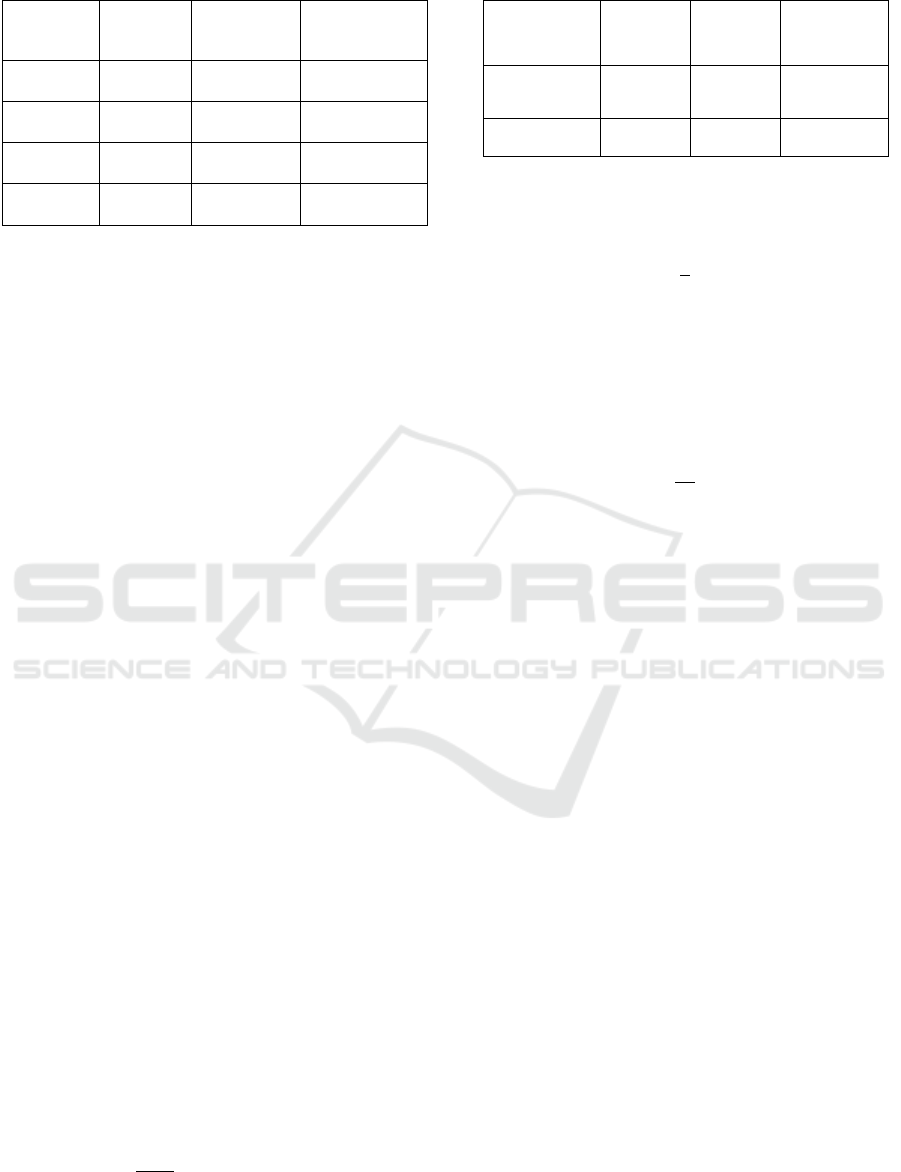

Figure 1: a) Vortices at trailing edge, b) shear stress distribution at leading edge, c) velocity vectors at 50% span, and d)

velocity vectors at 95% span.

Head per unit power obtained from CFD has been

used for comparisons. Maximum pressure rise

increases with blade length. However, blade length

affects the torque required to rotate the PVAD and an

increase in length increases the exposure time of the

RBC’s causing an increase in damage to these cells.

The blade length from the leading edge (LE) to

the trailing edge (TE) is fixed as 12mm to

accommodate motor shaft, which is 7 mm in length.

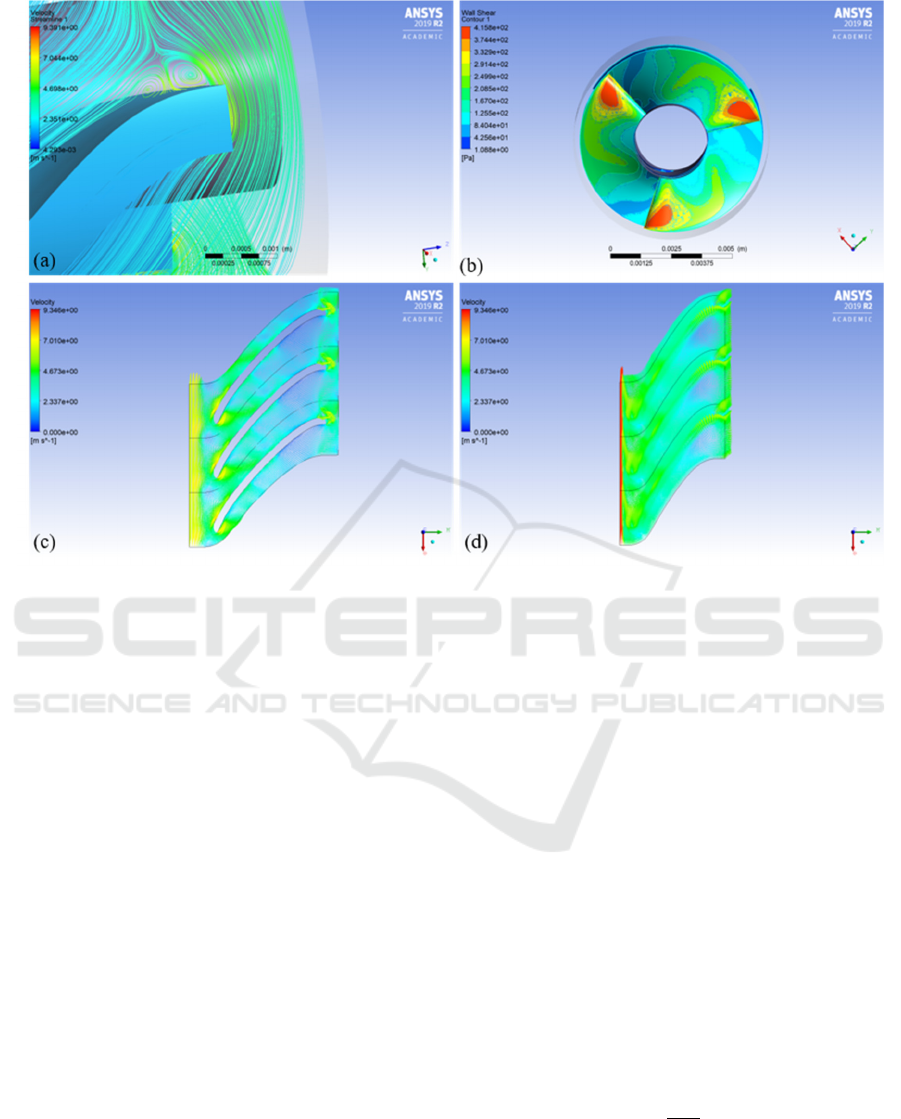

Figure 2c shows the geometry of the final design.

The configuration does not include flow straightener

or diffusor to reduce exposure time.

2.4 Prototyping and Assembly

The impeller illustrated in figure 2c is manufactured

using additive manufacturing technology of PolyJet

printer (Stratasys Systems, US), which has an

accuracy of 16 microns. VeroClear material is used

for the prototyping. A BLDC motor of 8 mm in

diameter with 7mm shaft length (Faulhaber GmbH,

Germany) was tight fitted with the impeller. The

casing for the pump with 0.25 mm clearance was

initially 3D printed and later on manufactured with

glass for PIV experiment.

3

SYSTEMIC MOCK

CIRCULATION LOOP

A mock circulation loop was designed and

constructed as shown in figure 2b. A two-element

Windkessel model is used to model the MCL

(Catanho et al., 2012). Two compliance chambers to

mimic aortic compliance and venous compliance

were used. Aortic compliance (AoC) of 1.65 mL/mm

Hg and a Venous Compliance (VoC) of 10 mL/mm

Hg have been used (Timms et al., 2005). The

compliance chamber is made of an acrylic cylinder,

filled with air and sealed at the top at a desired

pressure to produce the desired value of compliance.

Table 4 shows the designed MCL parameters. The

compliance is given by

=

(6)

Where

are the volume of air and

pressure of air above water column in the chamber.

From expression (6), it can be seen that the

Design of a Percutaneous Left Ventricular Assist Device

301

Figure 2: a) Pump Assembly inside rectangular acrylic casing, b) Systemic Mock Circulation Loop. (VoC: Venous

Compliance Chamber) (AoC: Arterial Compliance Chamber) (LA: Left Atrium), and c) Impeller with motor

compliance can be varied either by varying volume of

air or by varying the pressure exerted by air in the

compliance chamber. The resistance of the blood

vessels is modelled as a lumped parameter, adjusted

by a flow control valve. To prevent interference with

the pressure flow rate response of the MCL due to

connecting tubes, the resistance of all the tubes

combined is set at 0.06 mm Hg.s/mL (Gregory et al.,

2017). Clear acrylic tubes of internal diameter of 20

mm were used for the arteries and veins to lower the

frictional losses.

Table 4: Design parameters for systemic mock circulation

loop.

Parameter

AoC VoC LA

Compliance 1.65

mL/mm Hg

10

mL/mm Hg

-

Diameter 100 mm 150 mm 40 mm

Height 250 mm 600 mm 400 mm

Pressure Variable Variable atmosph

eric

An Arduino Uno is used to link the sensors with the

workstation. Two MPX-5100 AP pressure sensors

(NXP Semiconductors, Netherlands), are used, along

with a non-invasive ultrasonic flow sensor -

UF08B100 (Cynergy 3, UK).

4

PARTICLE IMAGE

VELOCIMETRY

Particle Image Velocimetry was used as a flow

visualization methodology. Due to the small size of

the pump, there were several constraints, namely a)

the observational area should be optically accessible,

which was achieved by making a glass casing, b) the

seeding particles should follow the flow field and

should reflect the laser light in sufficient amount to

be captured by the camera, for which hollow glass

particles, coated with silver, of 10 micron diameter

were used. In order to avoid the effect of the

curvature, of pump casing, a rectangular acrylic

casing was made to enclose the pump and was filled

with a mixture of water-glycerol (35% glycerol and

65% water) to match the refractive index. The study

was conducted in two parts, (i) the laser was

illuminated in the vertical plane and the camera was

placed in the front (figure 3a) and (ii) the laser was

illuminated in the horizontal plane and the camera

was placed at the top (figure (3b, 3c and 3d)).

Image acquisition is accomplished with a

commercial available PIV system (Dantec Dynamics,

BIODEVICES 2020 - 13th International Conference on Biomedical Electronics and Devices

302

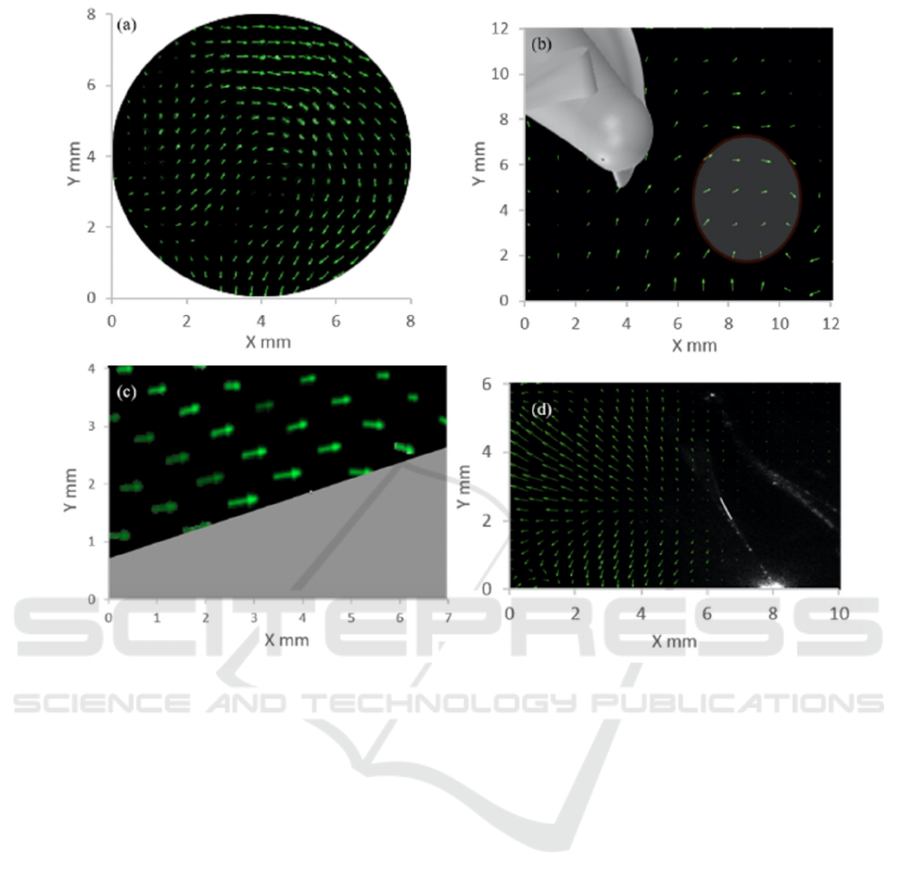

Figure 3: a) Inlet flow regimes, b) flow vortices at Leading edge, c) no vortices or stagnation at middle of the impeller, and

f) bifurcation zone at the outlet.

GmbH, Germany) using a 400 mJ Nd:YAG laser at

532 nm. A CCD camera along with Navitar zoom

6000 lens was used to capture the flow field. Single

frame double-pulse laser mode was used to arrest the

motion of the impeller at high speed. PIVlabs toolbox

in Matlab (The Mathworks, Inc., Natick, MA, USA)

was used to analyse the flow fields (Thielicke et al.,

2014). The impeller was painted black to minimise

the pseudo reflections from impeller surface. Figure

3 explains the flow fields in various regions of the

pump.

5

RESULTS AND DISCUSSIONS

A PVAD with diameter 7.6 mm and impeller length

15 mm has been successfully prototyped to achieve

an optimum flow rate of 2.5 L/min at 60 mm Hg.

There was a trade-off between pressure rise, power

requirement and net blood exposed area when wrap

angle and chord length is varied (Table 2 and Table

3). The increase in wrap angle from 90

0

to 250

0

have

shown an increase in flow rate. The final prototype

has a wrap angle of 250

0

, to achieve 2.5 L/min of flow

rate and chord length of 12 mm, to accommodate 7

mm of shaft length. The reduction in constant hub

diameter of 5.8 mm to variable hub diameter of 3 mm

at the leading edge and 5.8 mm at the trailing edge

has increased the net flow rate at the same pump

speed. Moreover, reducing the blade thickness from 1

mm to 0.5 mm has increased the flow area for the

same size of PVAD. Figure 1a represents regions of

vortices at the trailing edge possibly caused to the

absence of the diffusor. The trailing edge angle of the

impeller can further be modified to eliminate this

recirculation region. Figure 1b shows that the shear

stress distribution at the entry is below 400 Pa, which

is within the acceptable limits (Song et al., 2004) and

(Yu H., 2015). The highest shear stress regions were

at the leading edge of the impeller when the fluid is

expected to make its first contact.

Figure 1c represents the velocity vectors at 50%

Design of a Percutaneous Left Ventricular Assist Device

303

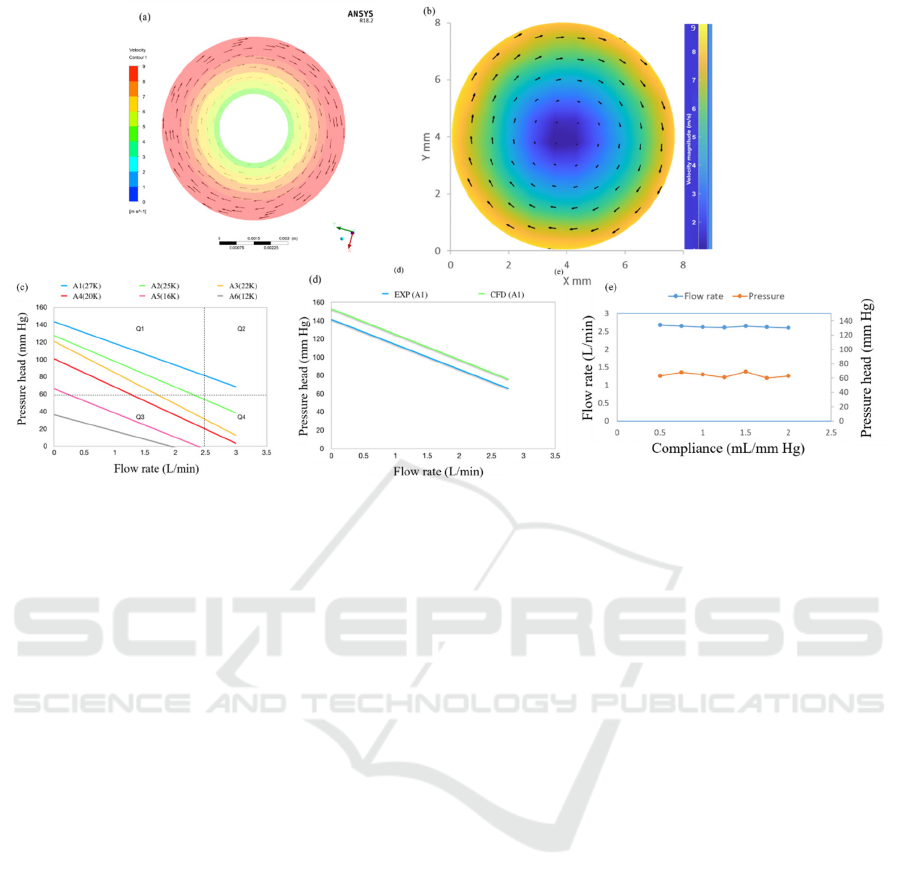

Figure 4: a) CFD results at inlet, b) PIV results at inlet, c) H-Q curve of designed PVAD at various speeds, d) Comparison of

CFD and Experimental HQ curve, and e) Pump performance at different Arterial compliance value.

span, with a maximum velocity of 9.3 m/sec and

figure 1d represents the leakage losses in the pump

due to the clearance gap which are not accounted for

in the conventional pump design theory being used.

Figure 3a and 3b illustrates the flow regime at the

inlet to impeller under front and top view

respectively, and shows recirculation at inlet as

expected, due to the elimination of flow straightener.

Figure 3c shows straight flow fields without any

vortices at the middle section of the impeller. Figure

3d shows a bifurcation region at the outlet of impeller

possibly due to sudden increase in flow area. The

spatial resolution is 16 pixels which corresponds to

approximately 0.125 mm.

Figure 4a illustrates the CFD velocity contour

and vectors for the optimum design and figure 4b

illustrates the experimental PIV contour and vectors.

The maximum velocity is near the shroud and it

decreases towards the centre. The difference between

the CFD and the experimental results is less than

10%.

Figure 4c represents the H-Q curve for various

conditions ranging from 27000 rpm (A1) to 12000

rpm (A6). It can be seen that the designed point is

achieved with A1 condition. The region Q1

represents points at which pressure difference above

60 mm Hg can be achieved. Region Q2 refers to the

extreme working region of the PVAD mainly during

the condition of multiple organ failure. Region Q3

represents the working region under recovering heart

condition and region Q4 refers to high flow rate

conditions under low pressure.

Figure 4d is a comparison between experimental

and CFD results. It can be seen that CFD has

marginally over predicted the PVAD’s performance.

Figure 4e shows the pump performance by varying

the Aortic Compliance, from (2 mL/mm Hg to 0.5

mL/mm Hg). The designed PVAD showed a

consistent performance with less than 6% variation

under diseased heart condition.

The results shown agree with the defined

problem, that is, the PVAD developed is capable to

deliver 2.5 L/min at 60 mm of Hg. These

characteristics very well matches with the state of the

art devices available as of now (Lima et al., 2016)

and (Van et al., 2016). Moreover the size of the

PVAD is within anatomical space constraint. Current

limitation of this PVAD, due to unavailability of low

power high rpm motors, is to deliver higher flow

rates, upto 5 L/min, with same dimensions. The

future work will be focused on a) testing the

prototype with blood to measure Normalised Index

of Hemolysis (NIH), to better interpret the trade-off

between wrap angle and chord length and b) to insert

the motor impeller assembly into a catheter and

check dynamic response of PVAD with blood in

SMCL.

BIODEVICES 2020 - 13th International Conference on Biomedical Electronics and Devices

304

6 CONCLUSION

In this study a Percutaneous Left Ventricular Assist

Device (PVAD) is designed and validated via

Systemic Mock Circulation Loop (SMCL), and

Computational Fluid Dynamics (CFD). The flow

field was visualized using Particle Image

Velocimetry (PIV). The iterative design procedure

successfully eliminates the variables one by one to

reach an optimum design parameter using

conventional pump theory. SMCL and PIV turns out

to be insightful in an early stage development of

PVAD to predict pump performance under varied

arterial compliance and visualizing regions of

vortices at various regions of the impeller. The PVAD

showed consistent performance under diseased heart

condition with a reduced arterial compliance.

REFERENCES

Benjamin, E. J., Muntner, P., & Bittencourt, M. S. (2019).

Heart disease and stroke statistics-2019 update: a report

From American Heart Association. Circulation,

139(10), doi:10.1161/CIR.0000000000000659.

Cook, J. A., Shah, K. B., Quader, M. A., Cooke, R. H.,

Kasirajan, V., Rao, K. K., & Tang, D. G. (2015). The

total artificial heart. Journal of thoracic disease, 7(12),

2172.

Casassus, F., Corre, J., Leroux, L., Chevalereau, P.,

Fresselinat, A., Seguy, B., & Barandon, L. (2015). The

use of Impella 2.5 in severe refractory cardiogenic

shock complicating an acute myocardial

infarction. Journal of interventional cardiology, 28(1),

41-50.

Lima, B., Kale, P., Gonzalez-Stawinski, G. V., Kuiper, J.

J., Carey, S., & Hall, S. A. (2016). Effectiveness and

safety of the Impella 5.0 as a bridge to cardiac

transplantation or durable left ventricular assist

device. The American journal of cardiology, 117(10),

1622-1628.

Van Mieghem, N. M., Daemen, J., Den Uil, C., Dur, O.,

Joziasse, L., Maugenest, A., & van Geuns, R. J.

(2016). Design and Principle of Operation -HeartMate

PHPTM(Percutaneous (Vol. 74, p. 9). EIJ-‐ D-‐ 15-‐

00467.

Gregory, S., Stevens, M., & Fraser, J. F. (Eds.).

(2017). Mechanical Circulatory and Respiratory

Support. Academic Press.

Song, X., Untaroiu, A., Wood, H. G., Allaire, P. E.,

Throckmorton, A. L., Day, S. W., & Olsen, D. B.

(2004). Design and transient computational fluid

dynamics study of a continuous axial flow ventricular

assist device. ASAIO journal, 50(3), 215-224.

Yu, H. (2015). Flow design optimization of blood pumps

considering hemolysis (Doctoral dissertation, Otto von

Guericke Universität Magdeburg).

Gregory, S. D. (2009). Simulation and development of a

mock circulation loop with variable

compliance (Doctoral dissertation, Queensland

University of Technology).

Vilchez-Monge, M., Truque-Barrantes, A., & Ortiz-Leon,

G. (2016, November). Design and construction of a

hydro-pneumatic mock circulation loop that emulates

the systemic circuit of the circulatory system. In 2016

IEEE 36th Central American and Panama Convention

(CONCAPAN XXXVI) (pp. 1-6). IEEE.

Gregory, S. D., Stevens, M., Timms, D., & Pearcy, M.

(2011, January). Replication of the Frank-Starling

response in a mock circulation loop. In 2011 Annual

International Conference of the IEEE Engineering in

Medicine and Biology Society (pp. 6825-6828). IEEE.

Pantalos, G. M., Koenig, S. C., Gillars, K. J., Giridharan,

G. A., & Ewert, D. L. (2004). Characterization of an

adult mock circulation for testing cardiac support

devices. ASAIO journal, 50(1), 37-46.

Timms, D., Hayne, M., McNeil, K., & Galbraith, A. (2005).

A complete mock circulation loop for the evaluation of

left, right, and biventricular assist devices. Artificial

organs, 29(7), 564-572.

Day, S. W., & McDaniel, J. C. (2004). PIV measurements

of flow in a centrifugal blood pump: steady flow.

Apel, J., Neudel, F., & Reul, H. (2001). Computational fluid

dynamics and experimental validation of a microaxial

blood pump. ASAIO journal, 47(5), 552-558.

Lund, L. H., Edwards, L. B., Dipchand, A. I., Goldfarb, S.,

Kucheryavaya, A. Y., Levvey, B. J., & Stehlik, J.

(2016). The registry of the International Society for

Heart and Lung Transplantation: thirty-third adult heart

transplantation report—2016; focus theme: primary

diagnostic indications for transplant. The Journal of

Heart and Lung Transplantation, 35(10), 1158-1169.

Demir, O., Biyikli, E., Lazoglu, I., & Kucukaksu, S.

(2011). Design of a centrifugal blood pump: Heart

Turcica Centrifugal. Artificial organs, 35(7).

Catanho, M., Sinha, M., & Vijayan, V. (2012). Model of

aortic blood flow using the windkessel

effect. University of California of San Diago, San

Diago.

Thielicke, W., & Stamhuis, E. (2014). PIVlab–towards

user-friendly, affordable and accurate digital particle

image velocimetry in MATLAB. Journal of Open

Research Software, 2(1).

Design of a Percutaneous Left Ventricular Assist Device

305