Microchannels Fabricated by Laser: From the Nanosecond to the

Femtosecond Pulse Duration

María Aymerich

1

, Javier R. Vázquez de Aldana

2

, David Canteli

3

, Carlos Molpeceres

3

and M. Teresa Flores-Arias

1a

1

Photonics4Life Research Group, Departamento de Física Aplicada, Facultade de Físicas,

Universidade de Santiago de Compostela, 15782, Santiago de Compostela, Spain

2

Aplicaciones del Láser y de la Fotónica Research Group, Departamento de Fïsica Aplicada, Facultad de Ciencias,

Universidad de Salamanca, 37008, Salamanca, Spain

3

Centro Láser UPM, Universidad Politécnica de Madrid, Crta. de Valencia km 3.7, 28031, Madrid, Spain

Keywords: Pulsed Laser, Laser Ablation, Laser Microstructuring, Microchannels, Laser-matter Interaction.

Abstract: Laser technologies are used to fabricate microchannels over glass substrates. A comparison among the results

obtained when these microchannels are fabricated with pulsed lasers in the three more important regime in

terms of pulse duration is made. A roadmap for obtaining a similar device when different pulsed lasers are

used is presented. The control on the surface roughness, a very important parameter to be taken into account

when biological applications are the possible ones, is also analysed.

1 INTRODUCTION

The last decades the fabrication of microchannels has

presented a huge interest. There are several

techniques used to fabricate these channels like

embossing; injection moulding or other

thermoforming techniques (Tsao, 2009); lithography

techniques (Fu, 2006); electron beam lithography

(Mali, 2006); photolithography (Stroock, 2002) and

soft-lithography (Xia, 1998) among others. Each of

these techniques is more suitable and it is chosen

depending on the substrate where the microchannels

want to be fabricated. Regarding the substrates, the

more commonly materials used for channel

fabrication are polymers (Xu, 2000), silicon

(Dwivedi, 2000) and glasses. The last one presents

numerous advantages such us their hardness, it is

chemically robust and has good electrical and thermal

properties. It has a low autofluorescence and is

transparent in the range of optical inspections

(Carlen, 2009).

Regarding the fabrication techniques, the laser

has outstand when using glass substrates, due to the

speediness of the process, the no contact nature,

versatility, precision and so on (Liao, 2012).

Although laser ablation is more common using

a

https://orcid.org/0000-0002-8036-9654

ultraviolet wavelengths when processing transparent

material in the visible range, IR range has also been

used for this aim (Nieto, 2014), (Nieto, 2010)

Physical phenomena involved in the ablation of

dielectric materials are different depending on the

laser pulse duration. (Liu, 1997), (Chichkov, 1996),

(Weck, 2008)

There are a huge number of application fields of

the glass microchannels, being one of them the

microfluidic studies. This field aroused a big interest

due to its numerous and promising biomedical

applications (Whitesides, 2006), (Sackmann, 2014).

Drug delivery (Metz, 2004), lab-on-a-chip analysis

(Stone, 2004), cell trapping or imitation of vessels for

in-vitro bioassays (Aymerich, 2017). The advantages

of using microchannel is, mainly, the small volumes

of liquid that are needed for the different analysis.

In this work, we present a roadmap for fabricating

microchannels on glass substrates by laser ablation

using pulsed laser in three pulse duration regimes

(nanosecond, picosecond and femtosecond). All the

lasers have their fundamental wavelength in the

infrared spectral range. In particular, it will be

analysed the different irradiances and parameters

should be used when microchannels with a fixed ratio

64

Aymerich, M., Vázquez de Aldana, J., Canteli, D., Molpeceres, C. and Flores-Arias, M.

Microchannels Fabricated by Laser: From the Nanosecond to the Femtosecond Pulse Duration.

DOI: 10.5220/0009179100640067

In Proceedings of the 8th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2020), pages 64-67

ISBN: 978-989-758-401-5; ISSN: 2184-4364

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

wants to be fabricated. These microchannels will be

characterised and compared.

Section 2 presents materials and methods. Main

results and discussions are presented in Section 3.

Section 4 summarizes the conclusions.

2 MATERIALS AND METHODS

The lasers used in the development of this works are,

a Rofin Nd:YVO

4

laser, a Lumera Super Rapid-HE

(Nd:YVO

4

) and one Spitfire from Spectra Physics.

The Rofin laser operates in Q-switch regime with 20

ns pulse duration and 1064 nm fundamental

wavelength. The laser setup was combined with a

galvanometer system that addressed the output beam

on the target. The lens used for focusing the laser over

the substrate is a flat field lens with a 100mm focal

length, that allows to operate with the same energy in

an area of 80x80 mm

2

. The Lumera Super Rapid-HE

(Nd:YVO

4

) has a fixed pulse duration of 12 ps and a

fundamental wavelength of 1064 nm. The system had

a motorized table and a processing head with a fix

lens providing a beam radius in focus of 16 µm. The

Spitfire of Spectra Physics emits pulses in the

femtosecond regime, with a fixed pulse duration of

100 fs and it works at its central wavelength of 800

nm. In this case, the beam is focused with an

achromatic lens of 200 mm. For fabricating

microchannels with this laser a computer-controlled

3-axes motorized stage is used. Beam radii for this

system was around 11 µm.

The substrate for fabricating the microchannels

are chosen to be a cheap soda-lime glass obtained

from a local supplier. The chemical composition of

both surfaces of the material is shown in table 1.

Table 1: Chemical composition of the used glass in both

sides of the piece.

Element Weight (%)

O 50.25

Si 33.06

Na 9.08

Ca 4.87

Mg 2.19

Al 0.54

Element Weight (%)

O 48.97

Si 32.34

Na 9.14

Ca 4.91

Mg 2.24

Al 0.49

Sn 1.90

Silicon dioxide (SiO

2

) is the main component in

both surfaces of soda-lime glass, followed by sodium

oxide (Na

2

O) and calcium oxide (CaO). However due

to the process used in the fabrication of these glasses,

in one side of the piece appears tin that play a key role

in laser ablation of the material (Nieto, 2014), (Nieto,

2015).

3 RESULTS

As a first step, we procced to determine the

parameters for each laser system that assure the

homogeneous ablation of the soda-lime substrate.

This is a very important step in order to be sure that

the microchannel fabricated will be homogeneous in

its final form.

We found that in the case of working with the

nanosecond laser we need a pulse energy of 700 µJ, a

repetition rate of 10kHz, a scan speed of the

galvanometer system of 50 mm/s and a pulse

overlapping of 73%. In the case of the laser with

pulses in the picosecond range, the pulse energy was

80 µJ pulse energy, the repetition rate 10 kHz, the

scan speed 20 mm/s and the pulse overlapping 96%.

Finally, for the laser with pulses in the femtosecond

regime, the pulse energy needed is 40 µJ, the

repetition rate is 1 kHz, the scan speed of the 3-axes

motorized stage is 0.6 mm/s and the pulse

overlapping 97%. Scanning speed and repetition rate

were determined to assure the overlapping needed

between two consecutive pulses for obtaining a

homogeneous channel.

All these parameters allow us to determine the

threshold mean fluences. As it is well known there is

several ways to define the threshold mean fluences.

Authors determine it experimentally as the minimum

fluence value that generates ablation in the material

with no overlapped pulses. For the nanosecond case,

it was found to be 138 J/cm

2

, 49 J/cm

2

for the

picosecond regime and 5 J/cm

2

for the femtosecond

one. In order to assure the quality and homogeneity

of the final microchannels, we decide to use an energy

per pulse equal to the double of the threshold energy.

In this way we assure the quality of the final device.

It can be observed that the value of the fluence needed

for ablating the material decrease as the pulse

duration decreases, as predicted in the literature. (Liu,

1997), (Chichkov, 1996), (Weck, 2008).

For comparing the channels obtained with the

three different lasers we propose the fabrication of a

channels with and aspect ratio 2:1 diameter:depth.

We carried out a previous study of the number of laser

scans we need to make, in order to achieve channels

Microchannels Fabricated by Laser: From the Nanosecond to the Femtosecond Pulse Duration

65

with this ratio. As expected, it is different for each

laser. In particular nine scans for the nanosecond

laser, one laser scan for the picosencond laser and one

laser scan for the femtosecond one are used. For these

numbers of laser scans, we obtain a channel of 8.7 µm

depth and 23.9µm diameter fabricated with the

nanosecond laser; a microchannel 8.4 µm depth x

17.8 µm diameter with the picosecond laser and a

channel with 10.1 µm depth and 20.7 µm diameter in

the femtosecond regime.

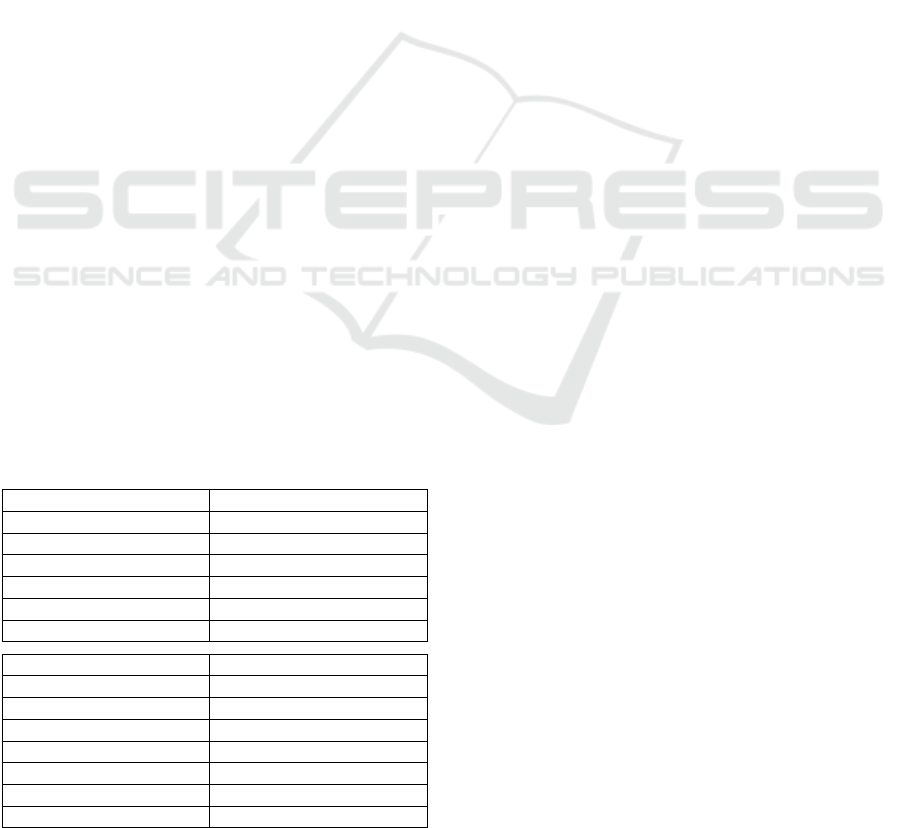

Figure 1: 3D confocal images of the microchannels

fabricated with: a) nanosecond, b) picosecond and c)

femtosecond pulse durations.

Figure 1 shows confocal images of channels

fabricated with the different pulsed lasers. We can see

that the channels fabricated with the three lasers have

the same aspect ratio. However, the surface roughness

of the channel was not equal at all. That is due to the

difference in the processes involved in the ablation

process when the three different temporal regimes are

considered. For the nanosecond case, the material is

expelled by heat deposition, melted and vaporized. In

the femtosecond pulse regime, the nature of the

process is more explosive, inducing a direct

vaporization of the material. In this case almost nor

thermal effect nor melting mechanics occur, so the

final channel has a high roughness value in contrast

with the smooth surface obtained in the channels

fabricated with the nanosecond pulses. In the

picosecond situation, a combination of both effects

occurs, resulting in a process where part of the

material is directly vaporized but also has a

significant transfer of heat to the lattice and,

therefore, melted material may appear.

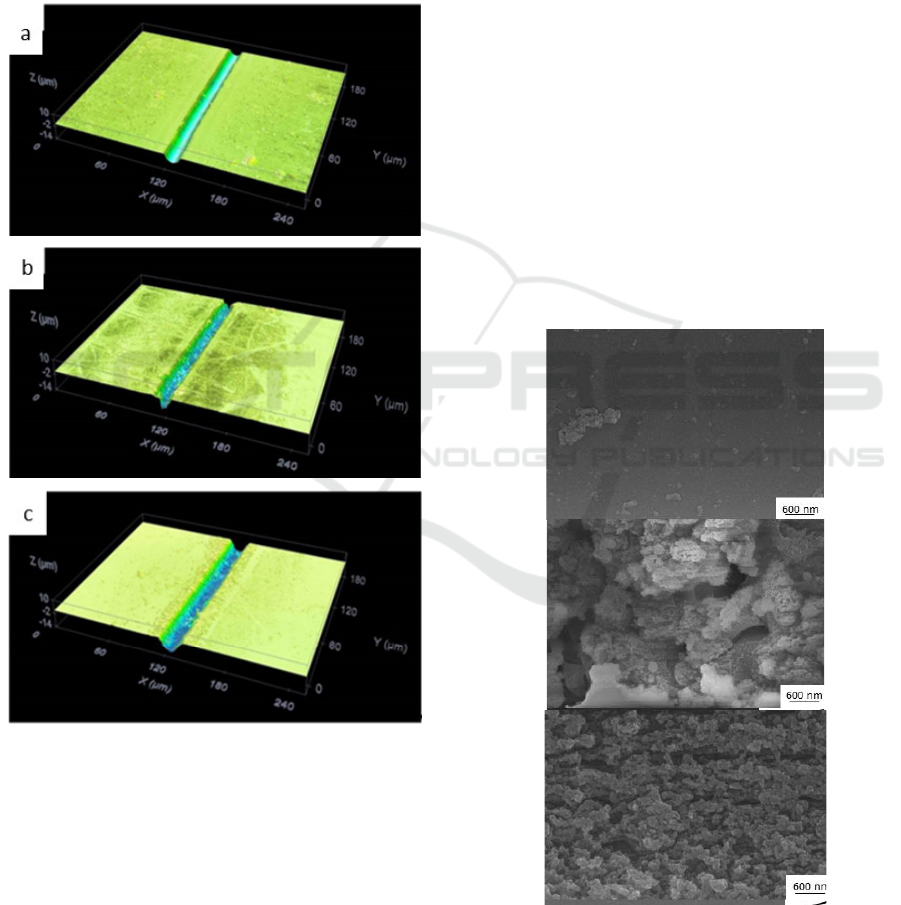

Arithmetical mean roughness of the surface (Sa)

was measured according to ISO 25178. Values for the

channels fabricated with the nanosecond pulse

duration were 178.7 nm, 1028.3 nm for the

picosecond and 1016.3 nm for the femtosecond

situation. As it can be observed, the surface roughness

of the picosecond and femtosecond channels is higher

than the ones manufactured with nanosecond pulse

duration (see Figure 2). This is due to the more

explosive nature of ablation with ultra-short pulses,

where material is directly vaporised.

Figure 2: SEM images of the surface of the microchannels

fabricated with a) nanosecond, b) picosecond and c)

femtosecond pulse duration.

a

b

c

PHOTOPTICS 2020 - 8th International Conference on Photonics, Optics and Laser Technology

66

4 CONCLUSIONS

In this work, we presented a roadmap for fabricating

microchannels with a same aspect ratio by direct laser

writing techniques. In particular, there were used

pulsed lasers working at the nanosecond, picosecond

and femtosecond regime. The microchannels were

fabricated on a soda-lima glass substrate. They were

characterized in terms of height and width as well as

in terms of their vale of the surface roughness. Laser

direct writing is shown as a fast, accurate, versatile

and non-contact technique for the manufacturing of

microchannels over soda-lime glass, advantageous

material due to its robustness and competitive cost. It

has been shown that channel with the same aspect

ratio can be obtained with lasers working in the three

temporal regimes. However, the roughness obtained

are very different due to the physical mechanism

involved in each ablative process. Depending on the

application the roughness of the wall of the channel

can be more appropriated. In particular a higher

roughness is more suitable for applications in the

biological area since the cell attachment is higher as

the roughness increases.

ACKNOWLEDGEMENTS

This work has been supported under contracts

RTI2018-097063-B-100, AEI/FEDER, UE,

FIS2017-87970-R Ministerio de Economía y

Competitividad, ED431E 2018/08, Xunta de

Galicia/FEDER, SA046U16, Junta de Castilla y León

and FIS2015-71933-REDT Ministerio de

Competitividad, Spain.

REFERENCES

Moore, R., Lopes, J., 1999. Paper templates. In

TEMPLATE’06, 1st International Conference on

Template Production. SCITEPRESS.

Smith, J., 1998. The book, The publishing company.

London, 2

nd

edition.

Tsao, C., Wand De Voe, D.L., 2009 Bonding of

thermoplastic polymer microfluidics in Microfluid.

Nanofluid.

Fu, C., Hung, C., H. Huang, C., 2006. A novel and simple

fabrication method of embedded SU-8 micro channels

by direct UV lithography, J. Phys. Conf. Ser

Mali, P., Sarkar, A., Lal, R., 2006. Facile fabrication of

microfluidic systems using electron beam lithography,

Lab Chip.

Stroock, A.D., Dertinger, S. K., Ajdari, A., Mezić, I., Stone,

H.A., Whitesides, G.M., 2002. Chaotic mixer for

microchannels, Science.

Xia, Y., Whitesides, G.M., 1998 Soft lithography, Annu.

Rev. Mater. Sci.

Xu, J., Locascio, L., Gaitan, M., Lee, C.S., 2000. Room-

temperature imprinting method for plastic

microchannel fabrication. Anal. Chem.

Dwivedi, V.K., Gopal, R., Ahmad, S., 2000. Fabrication of

very smooth walls and bottoms of silicon

microchannels for heat dissipation of semiconductor

devices. Microelectron. J.

Carlen, E.T., Bomer, J.G., van Nieuwkasteele, J.W., van

den Berg, A., 2009. Silicon and Glass Micromachining,

in Lab-on-a-Chip Technology for Biomedical and

Biological Applications: Fabrication and Microfluidics,

Caister Academic Press, Norfolk.

Liao, Y., Song, J., Li, E., Luo, Y., Shen, Y., Chen, D.,

Cheng, Y., Xu, Z., Sugioka, K., Midorikawa, K., 2012.

Rapid prototyping of three-dimensional microfluidic

mixers in glass by femtosecond laser direct writing, Lab

Chip.

Nieto, D., Delgado, T., Flores-Arias, M.T., 2014.

Fabrication of microchannels on soda-lime glass

substrates with a Nd: YVO 4 laser. Opt. Lasers Eng.

Nieto, D., Delgado, T., Flores-Arias, M.T., 2014.

Fabrication of microchannels on soda-lime glass

substrates with a Nd: YVO 4 laser. Opt. Lasers Eng.

Liu, X., Du, D., Mourou, G., 1997. Laser ablation and

micromachining with ultrashort laser pulses in IEEE J.

Quantum Electron.

Chichkov, B.N., Momma, C., Nolte, S., Von Alvensleben,

F., Tünnermann, A., 1996. Femtosecond, picosecond

and nanosecond laser ablation of solids. Appl. Phys. A

Weck, A., Crawford, T.H.R., Wilkinson, D.S., Haugen,

H.K., Preston, J.S., 2008. Laser drilling of high aspect

ratio holes in copper with femtosecond, picosecond and

nanosecond pulses. Appl. Phys. A

Whitesides, G.M., 2006. The origins and the future of

microfluidics, Nature.

Sackmann, E.K., Fulton, A.L., Beebe, D.J., 2014. The

present and future role of microfluidics in biomedical

research. Nature.

Metz, S., Bertsch, A., Bertrand, D., Renaud, P., 2004.

Flexible polyimide probes with microelectrodes and

embedded microfluidic channels for simultaneous drug

delivery and multi-channel monitoring of bioelectric

activity. Biosens. Bioelectron.

Stone, H.A., Stroock, A.D., Ajdari, A., 2004. Engineering

flows in small devices: microfluidics toward a lab-on-

a-chip. Annu. Rev. Fluid Mech.

Aymerich, M., Álvarez, E., Bao-Varela, C., Moscoso, I.,

González-Juanatey, J.R., Flores-Arias, M.T., 2017.

Laser technique for the fabrication of blood vessels-like

models for preclinical studies of pathologies under flow

conditions. Biofabrication.

Nieto, D., Arines, J., Flores-Arias, M.T., 2014. Fluence

ablation threshold dependence on tin impurities in

commercial soda-lime glass. Appl. Opt.

Nieto, D., Arines, J., O’Connor, G.M., Flores-Arias, M.T.,

2015. Single-pulse laser ablation threshold of

borosilicate, fused silica, sapphire, and soda-lime glass

for pulse widths of 500 fs, 10 ps, 20 ns.

Microchannels Fabricated by Laser: From the Nanosecond to the Femtosecond Pulse Duration

67