Mixed Pattern Recognition Methodology on Wafer Maps

with Pre-trained Convolutional Neural Networks

Yunseon Byun and Jun-Geol Baek

School of Industrial Management Engineering, Korea University, Seoul, South Korea

Keywords: Classification, Convolutional Neural Networks, Deep Learning, Smart Manufacturing.

Abstract: In the semiconductor industry, the defect patterns on wafer bin map are related to yield degradation. Most

companies control the manufacturing processes which occur to any critical defects by identifying the maps so

that it is important to classify the patterns accurately. The engineers inspect the maps directly. However, it is

difficult to check many wafers one by one because of the increasing demand for semiconductors. Although

many studies on automatic classification have been conducted, it is still hard to classify when two or more

patterns are mixed on the same map. In this study, we propose an automatic classifier that identifies whether

it is a single pattern or a mixed pattern and shows what types are mixed. Convolutional neural networks are

used for the classification model, and convolutional autoencoder is used for initializing the convolutional

neural networks. After trained with single-type defect map data, the model is tested on single-type or mixed-

type patterns. At this time, it is determined whether it is a mixed-type pattern by calculating the probability

that the model assigns to each class and the threshold. The proposed method is experimented using wafer bin

map data with eight defect patterns. The results show that single defect pattern maps and mixed-type defect

pattern maps are identified accurately without prior knowledge. The probability-based defect pattern classifier

can improve the overall classification performance. Also, it is expected to help control the root cause and

management the yield.

1 INTRODUCTION

The semiconductor manufacturing process is fine and

sophisticated. So, if a problem in any part of the

process occurs, it can be fatal on the yield. Yield

means the percentage of the actual number of good

chips produced, relative to the maximum number of

chips on a wafer. As the yield is the product quality

in the semiconductor industry, many engineers strive

to increase the yield.

One way to increase the yield is to check the

defect pattern on wafer bin maps and control the

causes of yield degradation. Wafer bin maps can be

obtained during the EDS(electrical die sorting) test.

EDS test is a step that checks the quality of each chip

on wafers. By testing various parameters such as

voltage, current, and temperature, the chips are

tagging good or bad. Then, engineers can identify

defect patterns that appear on the map. Defect

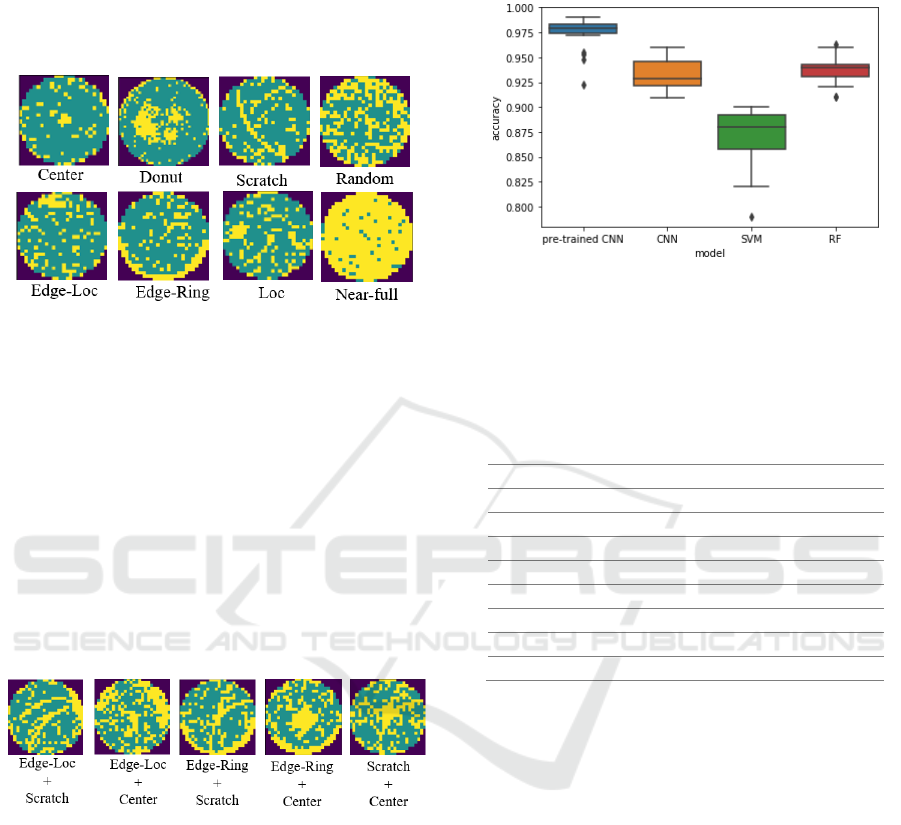

patterns contain various type such as center, donut,

scratch, and ring. Figure 1 shows the example of

pattern types on wafer bin maps. Each pattern is

related to the different causal factors. If the pattern is

exactly identified, it can be estimated what problem

occurs.

In fact, many engineers still check the map

visually (Park, J., Kim, J., Kim, H., Mo, K., and Kang,

P., 2018). So, it is difficult to identify many wafers

one by one as the demand for semiconductors

increases. Also, it is hard to classify the type,

especially when the patterns are mixed. Although

there are several studies for automatic classification,

more research on mixed patterns is still needed.

Figure 1: Various pattern types on wafer bin maps.

974

Byun, Y. and Baek, J.

Mixed Pattern Recognition Methodology on Wafer Maps with Pre-trained Convolutional Neural Networks.

DOI: 10.5220/0009177909740979

In Proceedings of the 12th International Conference on Agents and Artificial Intelligence (ICAART 2020) - Volume 2, pages 974-979

ISBN: 978-989-758-395-7; ISSN: 2184-433X

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

The real data contains the maps that are difficult

to distinguish any pattern or many patterns are mixed

on a wafer. If the mixed-type defects are incorrectly

determined as a single-type defect, the causal factors

cannot be identified properly. This may affect any

critical defects and cause yield degradation. So,

accurate pattern classification is needed.

In this paper, we propose a pattern classification

method with a pre-trained convolutional neural

network model. The automatic classification method

based on the probabilities increases the overall

classification accuracy. Also, it helps to identify the

exact causes of defects and improve the yield.

The paper is organized as follows. Section 2

presents the related algorithms, and the proposed

method is explained in section 3. Section 4 presents

the experimental results on the wafer map image data

to verify the performance of the model. Finally,

section 5 describes the conclusion.

2 RELATED ALGORITHMS

Generally, the convolutional neural networks are

good at image processing. So, we use the

convolutional neural networks as a classifier. Before

classifying, the weights are learned by convolutional

autoencoders. These are utilized on the convolutional

neural networks to increase performance. In this

section, the convolutional autoencoder and the

convolutional neural networks are described.

2.1 Convolutional Autoencoder

The convolutional autoencoder is an unsupervised

learning model that learns features from images

without label information (Guo, X., Liu, X., Zhu, E.,

and Yin, J., 2017). When the number of data is small,

it can be overfitted for the training data by using the

supervised learning model. Then, it is more effective to

use an unsupervised learning method such as

autoencoder (David, O. E., & Netanyahu, N. S., 2016).

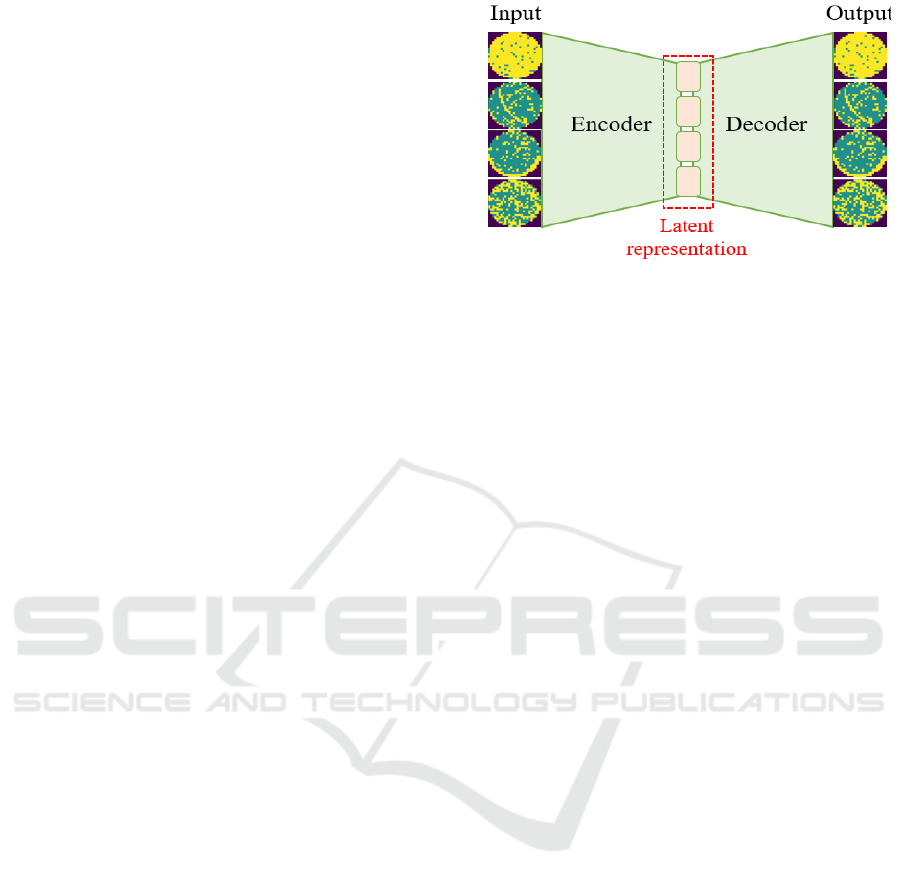

Autoencoder consists of an encoder and a

decoder, as shown in Figure 2. The key features are

trained in the hidden layer and the rest is lost in the

encoder. Then, the high dimensional data can be

reduced to the latent representations. A decoder

makes the approximation of the input as the output.

The output has to be close to the input as possible.

When as the number of nodes in the middle layer is

smaller than the number of nodes in the input layer,

the data can be compressed. The conventional

autoencoder represents high dimensional data as a

single vector.

Figure 2: The architecture of convolutional autoencoder.

The convolutional autoencoder, on the other

hand, compresses the data while maintaining the

coordinate space. So, it does not lose the space

information when the image data is used.

Convolutional autoencoder has the structure of

autoencoder using convolutional layers.

An encoder extracts the features from the

convolutional layers and pooling layers. The

convolutional layers find kernel patterns in the input

image. Kernels perform convolutional operations that

multiply the height and width of the images and

generate activation maps (Kumar, Sourabh, and R. K.

Aggarwal., 2018). And, the features are compressed

in the pooling layers. It helps to find important

patterns or reduce the number of computations (Park,

J., Kim, J., Kim, H., Mo, K., and Kang, P., 2018).

Max pooling is the most representative. An activation

map is divided by mn to extract the largest value.

Then, representative features can be extracted. After

the convolutional layers and pooling layers, the latent

representation

is generated in equation (1). is an

activation function for the input data . And, ∙ means

convolutional operation.

∙

(1)

A decoder reconstructs the data from the encoded

representation to be as close to the original input. The

reconstructed output value can be obtained from

equation (2).

means flip operation of weights and

c is biased.

∗

∈

(2)

The reconstruction loss measures how well the

decoder is performing and how close the output is to

the original data (Kumar, Sourabh, and R. K.

Aggarwal., 2018). The model is trained for

minimizing the reconstruction loss (Masci, J., Meier,

U., Ciresan, D., and Schmidhuber, J., 2011).

Mixed Pattern Recognition Methodology on Wafer Maps with Pre-trained Convolutional Neural Networks

975

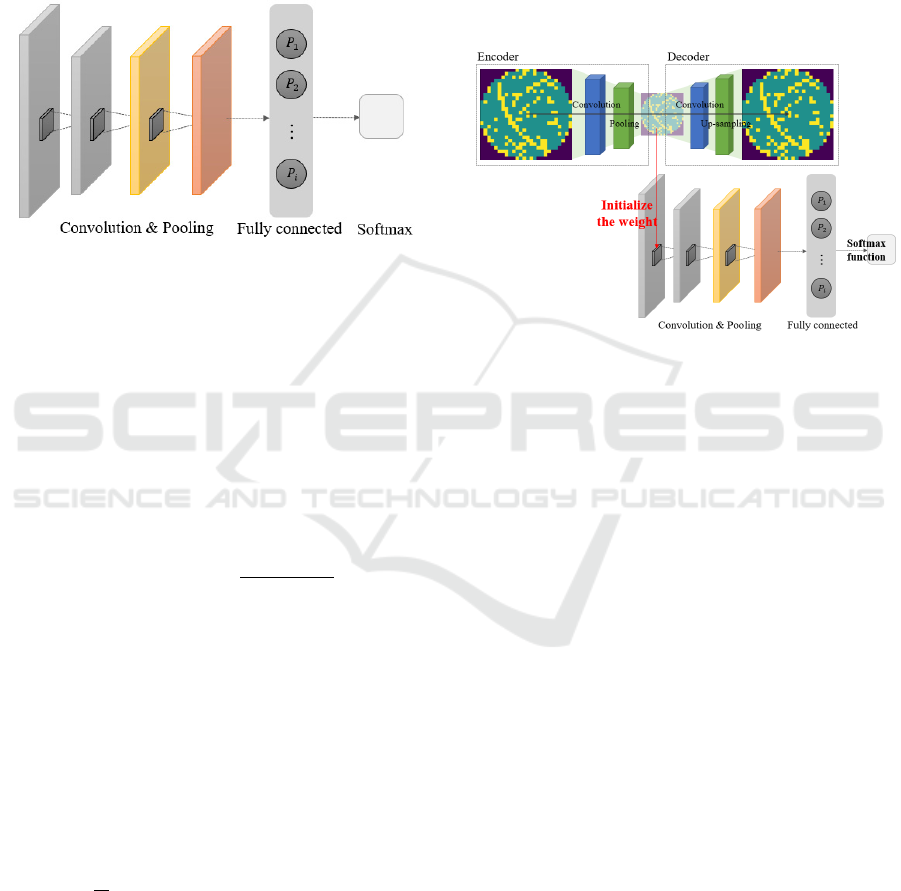

2.2 Convolutional Neural Networks

The convolutional neural networks are end-to-end

models that can be used on feature extraction and

classification. The hidden layers of CNNs consist of

convolutional layers, pooling layers, fully connected

layer, and output layer. The architecture is shown in

Figure 3.

Figure 3: The architecture of convolutional neural networks.

Features are extracted from convolutional layers

and pooling layers. After that, features are used for

classifying on a fully connected layer. Neurons in a

fully connected layer have full connections to all

activations in the previous layers. And, the number of

nodes in an output layer is the same as the number of

classes. On the output layer, the probabilities of classes

to be assigned are obtained using softmax function in

(3). The input data is .

means the weights of

node, and

means the bias of

node.

|,

,

∑

(3)

The loss function of the model in (4) can be

minimized using a backpropagation algorithm

(Cheon, S., Lee, H., Kim, C. O., and Lee, S. H., 2019).

The backpropagation algorithm looks for the

minimum error in weight space. The weights that

minimize the error is considered to be a solution to

the problem. is the number of data and is the

number of classes. And, 1

∈

is a function that has a

value of 1 when the actual class is .

1

1

∈

∈

(4)

The probabilities belonging to the

class are

obtained on the softmax function. And then, the node

with the highest probability value is classified into the

final class.

2.3 Pre-trained Convolutional Neural

Networks

The pre-trained convolutional neural networks is a

combination of convolutional autoencoder and

convolutional neural networks, as shown in Figure 4

(Masci, J., Meier, U., Ciresan, D., and Schmidhuber,

J., 2011). The weights of convolutional autoencoder

are used for initializing the weights of convolutional

neural networks.

Figure 4: The architecture of the pre-trained model.

The typical convolutional neural networks set the

initial weights randomly. On the other hand, using

weights of convolutional autoencoder make the data

be represented in low dimensional structures clearly.

It helps to create a classifier that reflects the features

more (Kumar, S., and Aggarwal, R. K., 2018).

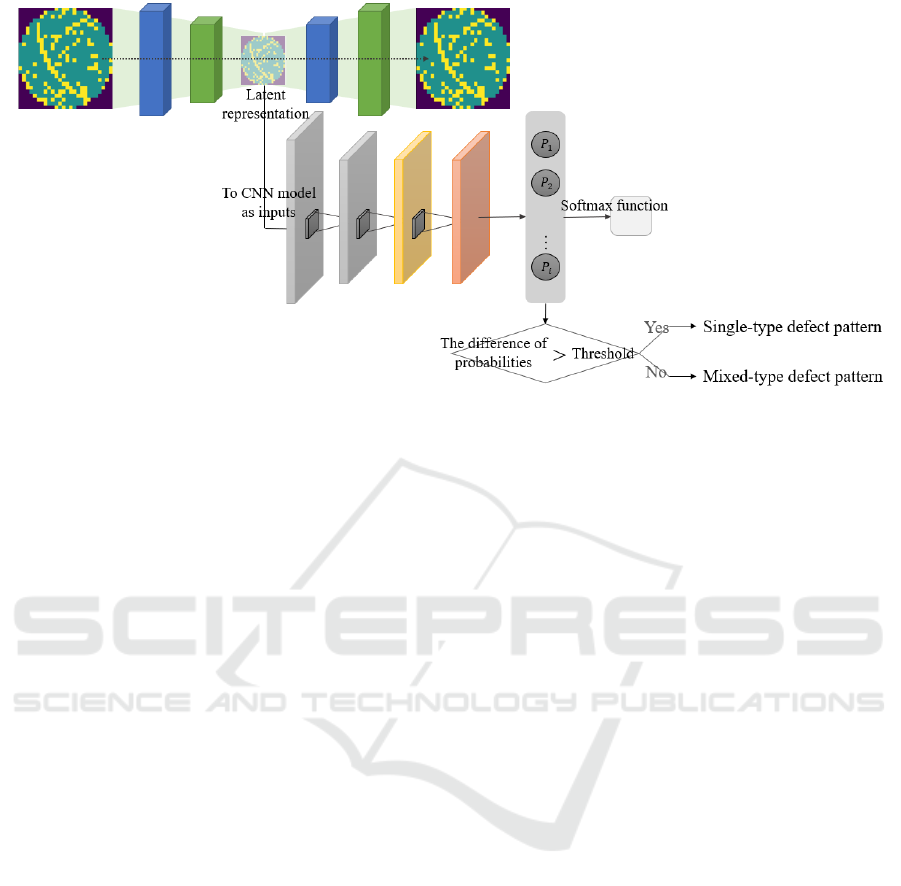

3 THE PROPOSED METHOD

In the paper, we propose the pattern classification

method based on probabilities on softmax function.

The method contains three steps to classify the defect

patterns of wafer maps. The first step is to initialize

the weights with the convolutional autoencoder. The

second step is to create pre-trained convolutional

neural networks for single-type pattern classification.

The final step is to determine whether the patterns on

wafer maps are mixed based probabilities on softmax

function. Figure 5 shows the proposed method with

the pre-trained model.

3.1 Initialization of Weights with

Convolutional Autoencoder

Image data contains the coordinate information in pixel

units. The coordinate information of a defective die is

important. As the convolutional autoencoder preserves

ICAART 2020 - 12th International Conference on Agents and Artificial Intelligence

976

Figure 5: The proposed method.

all coordinate information of the inputs, it can prevent

distortion in the feature space. So, training with the

convolutional autoencoder is effective for extracting

the features of images (Masci, J., Meier, U., Ciresan,

D., and Schmidhuber, J., 2011).

3.2 Pre-trained Convolutional Neural

Networks Training

The convolutional neural networks are known for the

classifier which has high performance on image data.

It uses the softmax function to classify classes.

Softmax is one of the activation functions. It takes

extracted features as inputs and calculates the

probabilities on each class. The sum of probabilities

is 1. And then, a class that has the highest probability

becomes the result of classification.

To get the probabilities of each class, we train the

convolutional neural networks with the single-type

pattern data. Then, the weights trained with the

convolutional autoencoder are set to the initialized

value of convolutional neural networks. It makes the

weights be finely adjusted and key information is

preserved. So, the features of the images are well-

reflected. Also, the pre-trained model is effective when

the number of labeled data is small (Kohlbrenner, M.,

Hofmann, R., Ahmmed, S., and Kashef, Y., 2017).

3.3 Probabilistic Mixed-type Pattern

Recognition on Wafer Maps

The model can obtain the probabilities on softmax

function. And, the class that the highest probability is

assigned becomes the result for classification. If there

are single-type defects, the probability of certain node

is prominent. However, for mixed-type patterns, there

are the several highest probabilities, so the difference

in maximum and next maximum is not large. The

calculation between the difference of probabilities

and a threshold in (5) is used for determining whether

the patterns are mixed or not. The prob

∈

means the probability that belongs on the class .

threshold

maximum

prob

∈

Nextmaximum

prob

∈

(5)

If the difference of probabilities is large, it means

that the pattern type of wafer map is clearly single.

And, if the difference is not large, it means that the

pattern type is mixed. The threshold value is specified

after checking the probability distribution of data.

4 THE EXPERIMENTAL RESULT

The dataset used in the experiment is WM-811K. It

contains 172,950 wafer map images. Each pixel in the

image represents a die on wafer maps. After testing, the

normal chip is represented as 1, and the defective chip

is represented as 2. Although the shape of the wafer is

a circle, the inputs of the convolutional neural network

have to be square. So, the empty pixel is represented as

0. The goal of the experiment is to classify the

defective patterns. So, we consider the only failure

types, not normal or no label. The number of usable

data is 25,519 but the size of all images is not the same.

Most of them are rectangular. Then, we resize the data

to the 2626 square images for the training of CNNs.

Mixed Pattern Recognition Methodology on Wafer Maps with Pre-trained Convolutional Neural Networks

977

Finally, we use only 7,915 to train the model, and the

data is divided into 7:3 and used for training and testing.

The inputs consist of eight single-type pattern

data, shown in Figure 6. There are center, donut,

scratch, random, edge-loc, edge-ring, loc, near-full.

Figure 6: The single-type defect pattern maps.

The data given contains only single-type defect

patterns. In this study, the recognition of mixed-type

defect patterns requires the mixed-type data on wafer

maps. We generated the mixed-type patterns through

the computation of single-type patterns. The target

patterns for generation are center, scratch, edge-loc,

and edge-ring patterns. We assume that only two

single-type patterns can be mixed. The generated

patterns are the mixture of edge-loc and scratch, the

mixture of edge-loc and center, the mixture of edge-

ring and scratch, the mixture of edge-ring and center,

and the mixture of scratch and center as shown in

Figure 7. The number of generated data is 580.

Figure 7: The mixed-type defect pattern maps.

4.1 The Result for Single-type Pattern

Classification

The pre-trained model is used for classifying the

single-type pattern maps to calculate the sigmoid

probability value. Figure 8 shows the 10-fold

classification performance of models. Compared with

the machine learning method like support vector

machine and random forest, the performance of the

pre-trained convolutional neural networks is excellent.

In particular, the proposed model outperformed the

original convolutional neural networks. This shows

that the setting of the initial weights, which reflect the

data characteristics using a convolutional autoencoder,

helps better classification of the patterns.

Figure 8: Classification performance of models.

The following Table 1 shows the result for

classification with the single-type test cases. Overall

classification accuracy is high, but the accuracy of

scratch, edge-loc, loc patterns is relatively low.

Table 1: Classification accuracy for the single-type data.

Pattern Type Accuracy

Center 97%

Donut 100%

Scratch 85.5%

Random 90%

Edge-Loc 87%

Edge-Ring 98.5%

Loc 85.4%

Near-full 100%

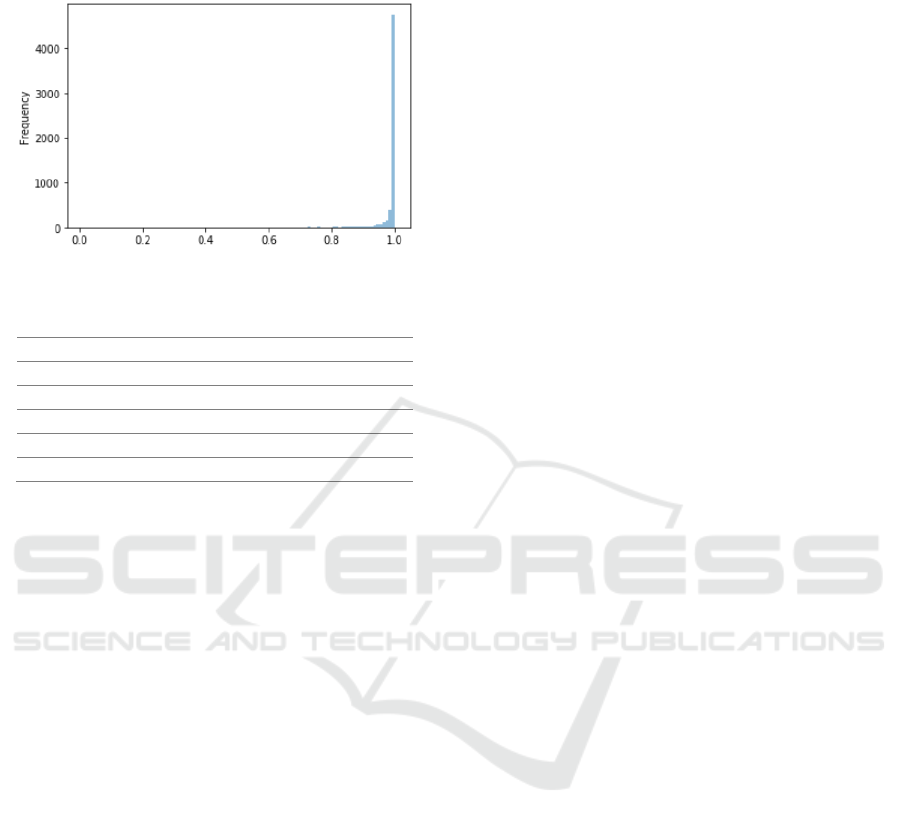

4.2 The Result for Mixed-type Pattern

Classification

The defect pattern maps can be determined whether

the patterns are mixed or not by calculating between

the threshold and the difference of probabilities on

softmax function. Then, the value of the threshold is

obtained from the distribution of probabilities on

softmax. Figure 9 describes the histogram of

probabilities. In the figure, the value is determined to

0.96 empirically.

By calculating the threshold and the difference of

probabilities, the mixed-type patterns can be

recognized. Table 2 shows the testing result of the

mixed-type data. In these results, we judge that the

model classified correctly only if it recognizes the

mixed-type pattern and accurately detects which one

is mixed. Although the model is well-determined for

mixing, it was not good for detecting a single-type

pattern that constitutes a mixed-type pattern. Among

ICAART 2020 - 12th International Conference on Agents and Artificial Intelligence

978

them, the accuracy is relatively low when an edge-

ring pattern is mixed.

Figure 9: The histogram for the difference of probabilities.

Table 2: Classification accuracy for the mixed-type data.

Pattern Type Accuracy

Center + Edge-Loc 59%

Scratch + Edge-Loc 41.6%

Center + Edge-Ring 69%

Scratch + Edge-Ring 64.4%

Center + Scratch 40%

5 CONCLUSIONS

This paper proposed the probabilistic method for

classifying defect patterns on wafer bin maps. We

construct the pre-trained model with the convolutional

autoencoder and convolutional neural networks. And,

we determine whether the patterns are mixed on wafer

maps, by calculating between the threshold and the

difference of probabilities. Experiments with WM-

811K data verifies the performance of the model. The

classification performance for the single-type pattern

of the model is excellent, but the performance for the

mixed-type pattern is relatively low. It is assumed that

the patterns of training data are not clearly

distinguished and that the threshold value is set to a

very high value due to the imbalance in the number of

single-type data and mixed-type data. So, it is

necessary to supplement such parts later. And, we

assume the only two patterns can be mixed, so the

study for more mixed-type patterns has to be conducted

to apply for the actual data.

ACKNOWLEDGEMENTS

This work was supported by the National Research

Foundation of Korea (NRF) grant funded by the Korea

government (MSIT) (NRF-2019R1A2C2005949).

This work was also supported by the BK21 Plus (Big

Data in Manufacturing and Logistics Systems, Korea

University) and by the Samsung Electronics Co., Ltd.

REFERENCES

Cheon, S., Lee, H., Kim, C. O., & Lee, S. H., 2019.

Convolutional Neural Network for Wafer Surface

Defect Classification and the Detection of Unknown

Defect Class. IEEE Transactions on Semiconductor

Manufacturing, 32(2), 163-170.

David, O. E., & Netanyahu, N. S., 2016. Deeppainter:

Painter classification using deep convolutional

autoencoders. In International conference on artificial

neural networks (pp. 20-28). Springer, Cham.

Guo, X., Liu, X., Zhu, E., & Yin, J., 2017. Deep clustering

with convolutional autoencoders. In International

Conference on Neural Information Processing (pp. 373-

382). Springer, Cham.

Kim, H., & Kyung, G., 2017. Wafer Map defects patterns

classification using neural networks. Korean Institute of

Industrial Engineers, 4319-4338.

Kohlbrenner, M., Hofmann, R., Ahmmed, S., & Kashef, Y.,

2017. Pre-Training CNNs Using Convolutional

Autoencoders.

Kumar, S., & Aggarwal, R. K., 2018. Augmented

Handwritten Devanagari Digit Recognition Using

Convolutional Autoencoder. In 2018 International

Conference on Inventive Research in Computing

Applications (ICIRCA) (pp. 574-580). IEEE.

Masci, J., Meier, U., Cireşan, D., & Schmidhuber, J., 2011.

Stacked convolutional auto-encoders for hierarchical

feature extraction. In International Conference on

Artificial Neural Networks (pp. 52-59). Springer,

Berlin, Heidelberg.

Nakazawa, T., & Kulkarni, D. V., 2018. Wafer map defect

pattern classification and image retrieval using

convolutional neural network. IEEE Transactions on

Semiconductor Manufacturing, 31(2), 309-314.

Park, J., Kim, J., Kim, H., Mo, K., & Kang, P., 2018. Wafer

Map-based Defect Detection Using Convolutional

Neural Networks. Journal of the Korean Institute of

Industrial Engineers, 44(4), 249-258.

Wu, M. J., Jang, J. S. R., & Chen, J. L., 2014. Wafer map

failure pattern recognition and similarity ranking for

large-scale data sets. IEEE Transactions on

Semiconductor Manufacturing, 28(1), 1-12.

Mixed Pattern Recognition Methodology on Wafer Maps with Pre-trained Convolutional Neural Networks

979