Determination of ISO 22400 Key Performance Indicators

using Simulation Models: The Concept and Methodology

Mateusz Kikolski

a

Faculty of Engineering Management, Bialystok University of Technology, Bialystok, Poland

Keywords: ISO 22400, Key Performance Indicators, Plant Simulation, Manufacturing Simulation.

Abstract: The study focuses on developing an approach to determining production key performance indicators (KPIs).

Different types of KPIs have been defined and their distribution has been determined. The article deals with

the problem of how to determine indicators. A review of KPIs and ISO 22400 was carried out. The author's

own methodology for simulation determination of indicators was proposed. The conducted case studies were

prepared on the basis of sample processes in order to indicate the mechanism of proceeding in the author's

methodology. The research used one of the available systems for designing and optimizing virtual models of

production processes and showed the possibilities of its use in the analysis of production processes.

1 INTRODUCTION

In today's highly competitive and dynamic business

environment, manufacturing industry faces new

challenges that require a broader view of the four

main classes of production attributes, i.e. cost, time,

quality and flexibility, as well as the need to increase

productivity.

The problem with a reliable and unambiguous

assessment of production efficiency is the lack of

ability to use comprehensive indicators to determine

it. Productivity is analyzed at the level of workstation,

individual operation, as well as the entire production

process and production lines. There are difficulties in

understanding and selecting specific indicators for

research, and there is a growing need for quick and

clear key performance indicators for sustainable

production (Kibira, Brundage, Feng, Morris, 2018).

Depending on the specifications of the production

process and the industry in which the company

operates, production lines can vary considerably in

design and configuration (Zwierzyński, 2018), which

can also affect how these processes are measured.

The performance indicators are a reference point

for employees, reflect current process characteristics,

facilitate collaboration rules that are defined, clear

and acceptable to all parties. At the operational level,

the indicators are used to solve current problems in a

dynamic way, while when planning and setting

a

https://orcid.org/0000-0003-1875-2625

strategies, they are used to analyze and build

objectives based on results. KPIs include a set of

individually selected indicators, which can be either

financial or non-financial (Rydzewska-Włodarczyk,

Sobieraj, 2015).

The aim of introducing KPIs into the production

process is to provide support to managers and to

enable them to quickly, easily and transparently

review the overall state of production processes in all

segments in a sustainable way. When a section fails

to meet predefined requirements, the manager is

quickly informed to find the cause and take further

action. In this way, potential damage can be avoided

or minimized (Rakar, Zorzut, Jovan, 2004).

2 ISO 22400 KEY

PERFORMANCE INDICATORS

According to ISO 22400, KPIs are defined as

quantifiable and strategic measurements that reflect

the critical success factors of an organization. Key

performance indicators are very important for

understanding and improving production efficiency.

ISO 22400 is a standard defined by the International

Organization for Standardization that defines how to

define, compose, exchange and use Key Performance

Indicators (KPIs) to support the management of

92

Kikolski, M.

Determination of ISO 22400 Key Performance Indicators using Simulation Models: The Concept and Methodology.

DOI: 10.5220/0009175800920099

In Proceedings of the 8th International Conference on Model-Driven Engineering and Software Development (MODELSWARD 2020), pages 92-99

ISBN: 978-989-758-400-8; ISSN: 2184-4348

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

production operations. ISO 22400 defines these

principles in a way that is as independent as possible

of the industry in which the manufacturing company

operates. It is defined by two catalogues: ISO 22400-

1:2014 (ISO 22400-1:2014) and ISO 22400-2:2014

(ISO 22400-2:2014).

ISO 22400 specifies an industry-neutral

framework for defining, composing, exchanging, and

using key performance indicators (KPIs) for

manufacturing operations management (MOM), as

defined in IEC 62264‑1 for batch, continuous and

discrete industries. ISO 22400-1:2014 provides an

overview of what a KPI is, presents concepts of

relevance for working with KPIs including criteria for

constructing KPIs, specifies terminology related to

KPIs, and describes how a KPI can be used (ISO

22400-1:2014).

ISO 22400-2:2014 specifies a selected number of

KPIs in current practice. The KPIs are presented by

means of their formula and corresponding elements,

their time behaviour, their unit/dimension and other

characteristics. ISO 22400-2:2014 also indicates the

user group where the KPIs are used, and the

production methodology to which they correspond

(ISO 22400-2:2014). With reference to equipment,

the KPIs in ISO 22400-2:2014 relate to work units, as

specified in IEC 62264 (IEC 62264).

In the literature, a constant upward trend can be

observed in the context of the number of studies

related to KPIs, and a steady increase in the number

of studies on this problem can be observed (Kikolski,

2019).

The indicators describing the operation of the

production system and being an object of the ISO

22400 standard, are characterized by a structured

structure and interrelationships. In ISO-22400-2 all of

the 34 KPIs are divided into four groups in production

systems. These four types are production,

maintenance, quality and inventory operations

management.

The production operations management KPIs deal

with production line activities. These KPIs are mostly

related to product managers and workers that work

close to the production lines.

The maintenance operations management KPIs

are regarding the maintenance of all the

manufacturing resources.

The quality operations management KPIs are of

importance in any manufacturing system, they ensure

that all products produced are of best quality. These

KPIs indicate the performance of whole production

line in terms of quality perspective.

Inventory operations KPIs deal with activities

such as transportation of raw material from

warehouse to production lines and picking up finished

products for storage.

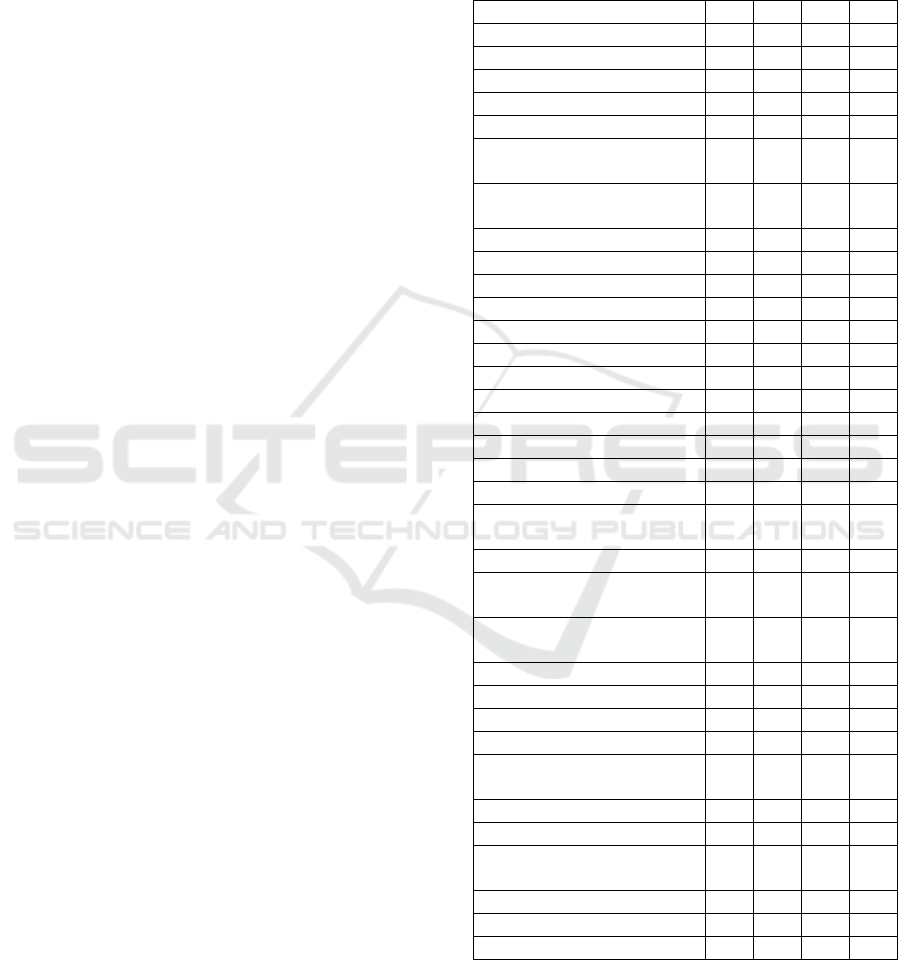

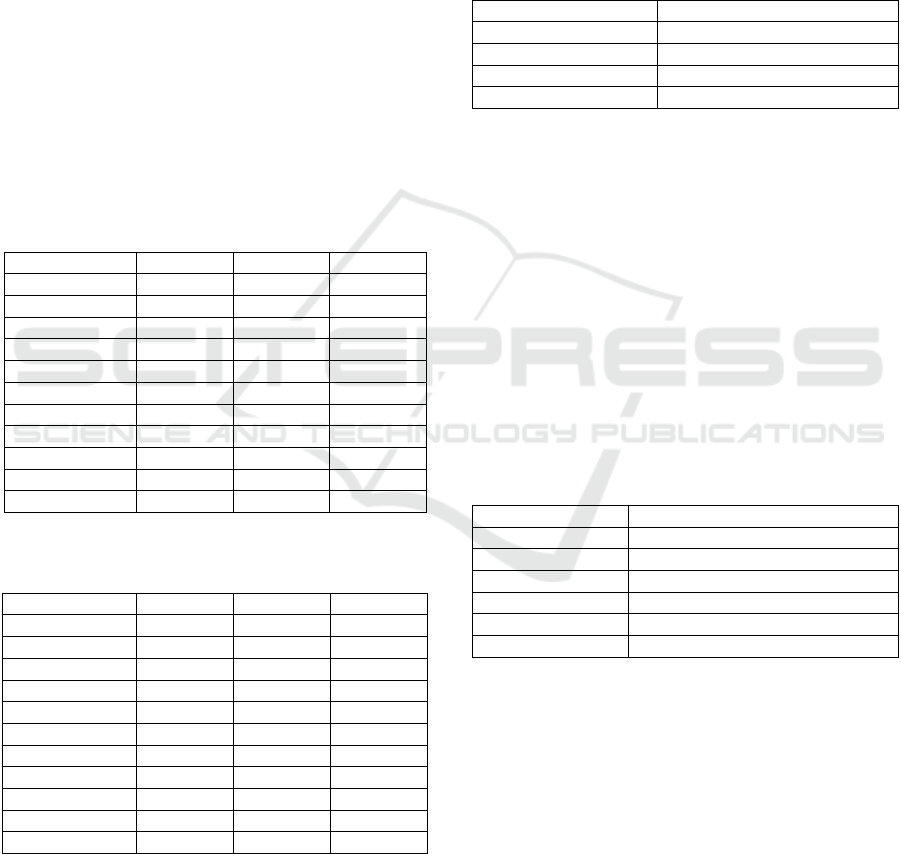

Table 1 presents a set of KPIs of the ISO 22400

standard (P – production, M – maintenance, I –

inventory, Q – quality).

Table 1: ISO 22400 key performance indicators.

KPIs P M I Q

Worker efficiency X

Allocation ratio X

Throughput rate X

Allocation efficiency X

Utilization efficiency X

Overall equipment

effectiveness index

X

Net equipment effectiveness

index

X

Availability X

Effectiveness X

Quality ratio X

Setup ratio X

Technical efficiency X

Production process ratio X

Actual to planned scrap ratio X

First pass yield X

Scrap ratio X

Rework ratio X

Fall off ratio X

Machine capability index X

Critical machine capability

index

X

Process capability index X

Critical process capability

index

X

Comprehensive energy

consumption

X

Inventory turns X

Finished goods ratio X

Integrated goods ratio X

Production loss ratio X

Storage and transportation

loss ratio

X

Other loss ratio X

Equipment load ratio X

Mean operating time

between failures

X

Mean time to failure X

Mean time to repair X

Corrective maintenance ratio X

Source: Usman, 2018.

The values achieved by the KPIs are very helpful

in the decision-making process, enabling the

identification of problems and the undertaking of

Determination of ISO 22400 Key Performance Indicators using Simulation Models: The Concept and Methodology

93

corrective or improvement actions. Proper use of

information from the KPI measurement should

contribute to more effective management of the

organisation's resources (Antczak, Gębczyńska,

2016).

3 RESEARCH METHODOLOGY

KPIs are used to focus on the expectations and needs

of users including the results of production

operations. The purpose of the ISO standards is to

enable the highest possible use of the KPI definition

in a wide variety of industrial sectors and regional

markets. According to ISO 22400, the following steps

are used to select and use KPIs in manufacturing

companies (ISO 22400-1:2014):

• identification of operations and elements of

operations assessed,

• setting targets to be achieved using performance

indicators,

• description of operational activities when

performance indicators are used to meet

expectations,

• definition of criteria for evaluation and

measurement of performance indicators,

• choice of performance indicators,

• evaluation of the results in relation to the

objectives of the performance indicators,

• execution of actions in order to achieve the

objectives set.

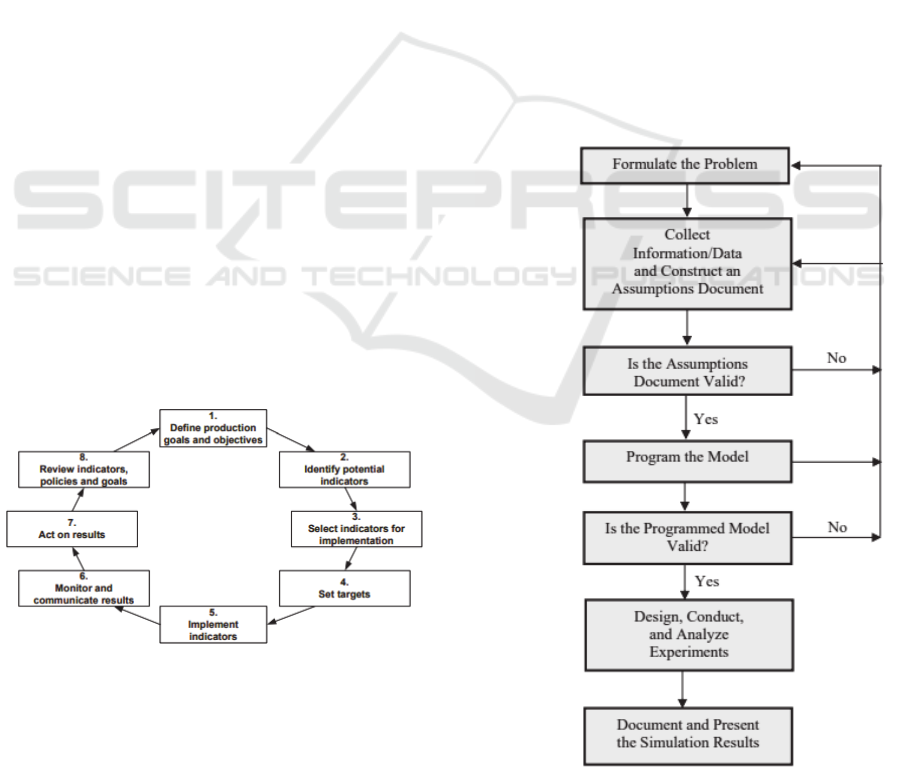

A similar approach (Figure 1) was presented by

Rakar, Zorzut and Jovan. They proposed an 8-step

model of KPI introduction in the form of a loop.

Figure 1: Closed-loop model for defining and measuring

production key performance indicators (Rakar, Zorzut,

Jovan, 2004).

The first step in identifying KPIs is to define

production targets that reflect the organisation's

mission. The next step is to identify potential

indicators showing performance and production

targets. The third step is to select the indicator to be

implemented, the next step is to select the objectives.

The fifth stage involves the implementation of

indicators, contains a set of data, their calculation,

evaluation and interpretation of results. This step is

the most labour-intensive and therefore requires the

participation of staff, especially middle management

of the company. The next step is related to monitoring

the results. In order to continuously improve the

processes, the results of the use of indicators should

be periodically evaluated. The seventh step consists

of actions based on results, which are considered a

critical step in the application of the indicator. The

last step is the review of indicators, principles and

objectives. This is an important step as it is assumed

to be the basis for setting new targets and indicators.

In this step, a possible elimination and selection of

new indicators is carried out.

Approach consists of using simulation models to

research. The creation of a simulation model of a

process is a multi-stage task (Law, 2008). Figure 2

presents the seven-step approach to conducting a

successful simulation study.

Figure 2: A seven-step approach for conducting

a successful simulation study (Law, 2008).

MODELSWARD 2020 - 8th International Conference on Model-Driven Engineering and Software Development

94

The simulation of production processes is a

technique used for solving problems occurring during

the manufacturing process. As a method, a computer

simulation is a system of research activities, i.e. a

structure of stage activities aimed at achieving a

research objective.

Modelling the production process involves the

creation of a virtual manufacturing process that

allows conducting a simulation and collecting

statistics. Statistics facilitate conducting reports and

comparing selected settings of the parameters that

characterise workstations. Computer models can be

freely improved, and further simulations can be

applied to various variants and settings anticipated by

the user (Kikolski, 2016).

Simulation studies are applied to and are used in

many scientific fields (Halicka, 2016). The

application of a simulation in production processes

constitutes a form of experimenting with a computer

model. Its objective is to provide an answer to the

question on how the production system will react to

various situations, according to arranged scenarios.

The application of simulation models allows for a

more effective selection of manufacturing strategies

by enterprises.

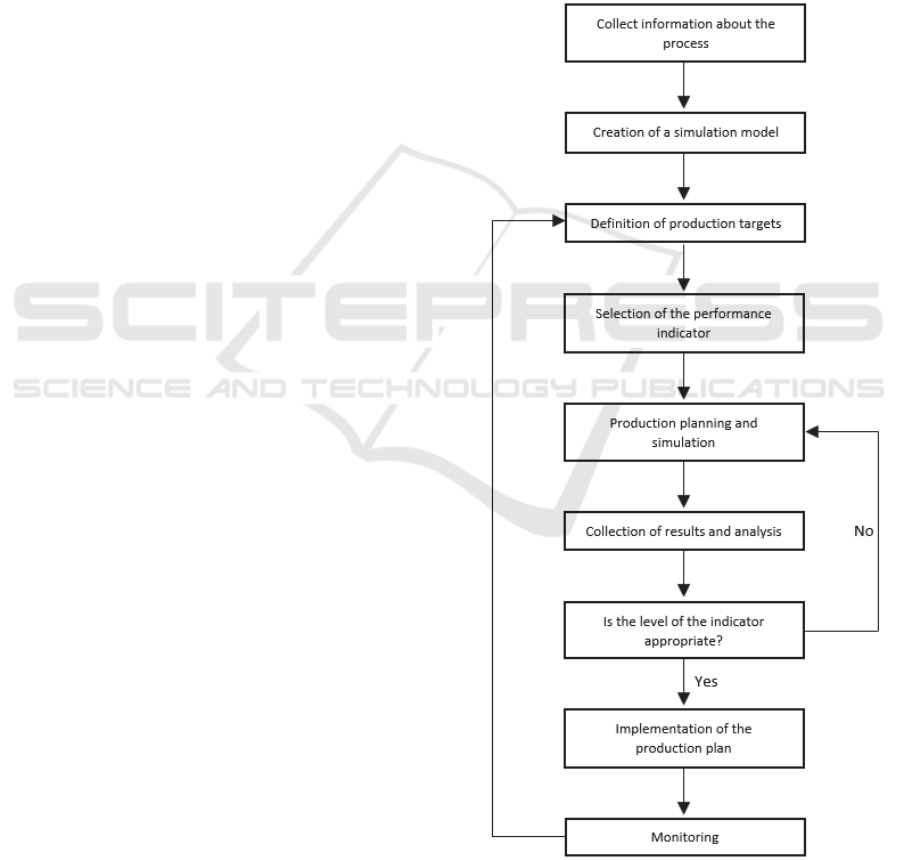

On the basis of studies on the creation of

simulation models and the determination of key

performance indicators, the author's own

methodology for the determination of KPIs with

using simulation models has been developed

(Figure 3).

The proposed methodology consists of nine steps.

The first stage is to collect information about the

process that is needed to create a simulation model -

its course, number of workstations, connections

between them and machine parameters.

The second stage is to create a virtual model of the

production process. This is one of the most important

stages, because errors in the project implementation

will cause incorrect results in the KPIs determination.

It is very important to develop a model at the

appropriate level of detail of the simulated model.

Many model designers, supported by powerful

simulation tools, tend to model everything regardless

of the project goals.

In the third stage, production targets are

formulated, to which the results of simulation variants

will refer.

The fourth step is to select a key performance

indicator that will be analysed. It should be noted that

it is possible to determine the selected indicator in a

created virtual production environment. If some

parameters are missing in the model, it becomes

impossible to determine which indicators use the

selected data (e.g. cost or energy consumption).

In the fifth stage, the results are collected and

analysed, which leads to the sixth stage - determining

whether the level of the chosen indicator is

satisfactory. If so, we move on to stage seven. If the

measurement of the indicator in the planned

production plan is too low, you should go back to

stage five and correct the production assumptions.

Stages seven and eight are the implementation of

the selected production plan and continuous

monitoring of performance, which may lead to further

production targets.

Figure 3: Proposal of methodology for the determination of

KPIs with using simulation models.

Determination of ISO 22400 Key Performance Indicators using Simulation Models: The Concept and Methodology

95

Simulation of performance indicators is part of the

original methodology for the facility layout design

methodology, which will consist of two sections: a part

supporting the design of a new layout of workstations

and a part focused on the reconstruction of the existing

layout of workstations. Regardless of the approach to

the problem with the production systems, the

measurement of production efficiency is a key element

of the manufacturing systems (Kikolski, Ko, 2018).

4 CASE STUDY

Knowledge of phenomena and processes is the goal of

many research programmes. Different methods are

used for this purpose, ranging from practical actions

involving observation to theoretical analyses, often

with the use of a mathematical apparatus. Nowadays,

computer simulation is a very important and effective

research method. Computer simulations are also

indicated as the most frequently chosen tools for

analysing the possibilities of process optimization in

production engineering (Kikolski, 2017). Building a

simulation model of a production process is a multi-

stage task. Modeling consists of creating a virtual

production process, which enables simulation and

collecting statistics. Statistics make it possible to

prepare reports and compare selected settings of

workstation parameters. Computer models can be

freely improved and subsequent simulations can be

performed for various variants and settings provided

by the user (Kikolski, 2016).

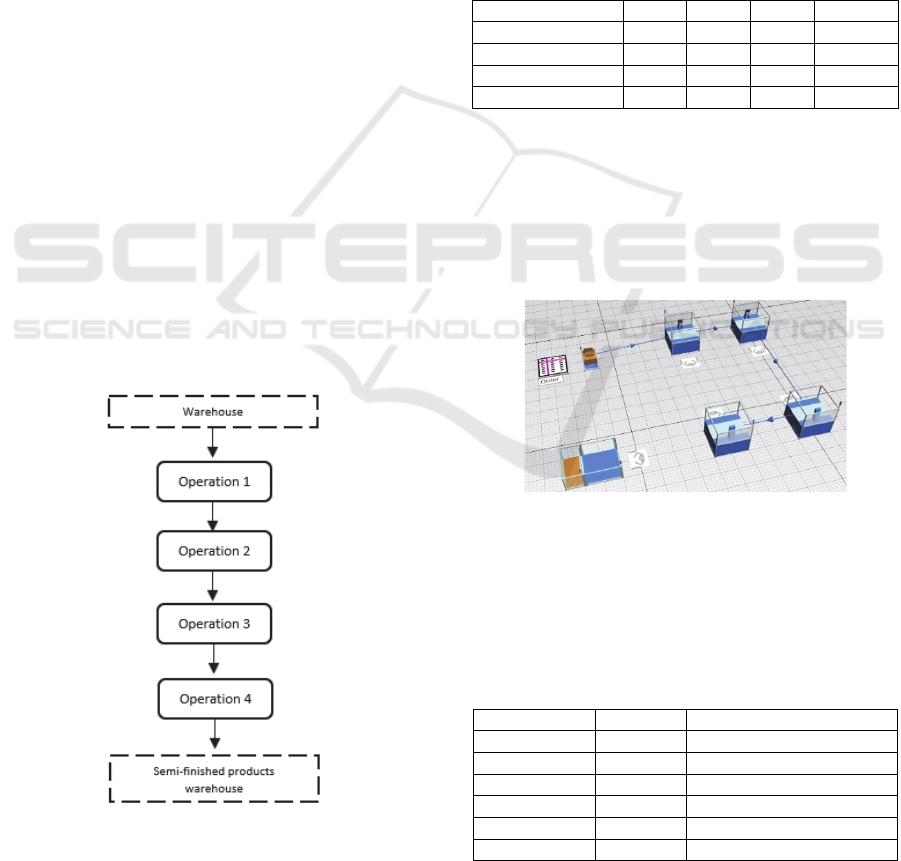

Figure 4: Schematic diagram of a analysed production

process.

The analysis of indicators refers to the production

of one of the components of the electrical installation

box. The production of a component consists of four

activities, after which it is transferred to the semi-

finished products warehouse. The diagram of the

process is shown in Figure 4.

The study was conducted on three different

product variants (A, B and C) in a specific number of

orders (11 pieces A, 4 pieces B and 7 pieces C), and

the analysis covered part of one shift - 3 hours and 15

minutes. Table 2 presents unit processing times of

elements at all workstations and the set-up times

between orders. The process is handled by two

workers.

Table 2: Times of material processing.

A B C Set-up

O

p

eration 1 0:04 0:06 0:07 0:00

O

p

eration 2 0:20 0:24 0:20 6:00

O

p

eration 3 0:49 0:52 0:45 2:50

Operation 4 0:45 0:45 0:55 9:48

Source: own study.

The research was carried out using the Siemens

product - Tecnomatix Plant Simulation, which is one

of the tools available on the market for creating

simulation models. It combines technological fields,

production engineering and logistics. A simulation

model is shown in Figure 5.

Figure 5: Simulation model of the analysed process.

The simulation resulted in six different variants of

the production plan. The number of semi-finished

products produced in individual experiments is

presented in Table 3. The results of detailed indicators

are presented in subsequent points of the study.

Table 3: Times of material processing.

Sequence Semi-finished products

Simulation 1 ABC 34

Simulation 2 ACB 35

Simulation 3 BAC 37

Simulation 4 BCA 33

Simulation 5 CAB 40

Simulation 6 CBA 33

Source: own study.

MODELSWARD 2020 - 8th International Conference on Model-Driven Engineering and Software Development

96

The highest production efficiency (40 units) was

achieved in the fifth production plan (CAB

sequence), while the lowest production value (33

units) was achieved in scenarios 4 and 6 (BCA and

CBA).

Simulation studies were conducted for selected

indicators in each of the four groups: production,

maintenance, inventory and quality. The choice of

indicators consisted in identifying one indicator from

each group and testing it.

4.1 Production KPI - Worker

Efficiency

The analysed process is handled by two employees -

one responsible for material processing (operations 1-

3) and one responsible for the finishing of semi-

finished products (operation 4) and their transport to

the warehouse. The results of their performance are

presented in Table 4 and Table 5.

Table 4: Statistics on the workload of worker 1.

Sim 1 Sim 2 Sim 3

Working 25,20% 31,41% 29,06%

Setting-up 31,03% 25,34% 30,61%

Trans

p

ortin

g

0% 0% 0%

En-route to

j

ob 3,72% 3,76% 3,89%

Waiting 40,06% 39,49% 36,44%

Sim 4 Sim 5 Sim 6

Working 33,42% 29,96% 26,26%

Settin

g

-u

p

29% 30,90% 30,82%

Trans

p

ortin

g

0% 0% 0%

En-route to

j

ob 3,72% 4,19% 3,72%

Waiting 33,86% 34,95% 39,21%

Source: own study.

Table 5: Statistics on the workload of worker 2.

Sim 1 Sim 2 Sim 3

Workin

g

14,46% 15,02% 14,83%

Setting-up 28,92% 28,92% 28,92%

Transporting 1,16% 1,20% 1,26%

En-route to

j

ob 1,21% 1,24% 1,31%

Waitin

g

54,25% 53,63% 53,68%

Sim 4 Sim 5 Sim 6

Working 17,68 17,37% 13,89%

Setting-up 27,46 28,92% 30,92%

Transporting 1,13 1,37% 1,13%

En-route to

j

ob 1,21 1,41% 1,21%

Waitin

g

52,53% 50,94% 52,86%

Source: own study.

The simulation shows that worker 1 achieves the

best work performance in the simulation scenarios 4

and 5. Worker 2 achieves the best percentage of work

in the fifth scenario.

4.2 Maintenance KPI - Mean Time to

Repair

Parameters of the tested model concerning

Maintenance indicators do not allow for their random

generation - they were defined in the project

assumptions and are generated in a fixed form during

the simulation. The MTTR indicators are shown in

Table 6.

Table 6: Mean time to repair times in simulated model.

MTTR

(

in minutes

)

Operation 1 0:30

Operation 2 6:10

O

p

eration 3 1:10

O

p

eration 4 12:00

Source: own study.

Simulation software allows to determine the

constants or resulting from selected distributions (e.g.

Gamma) mean times to repair.

4.3 Inventory KPI - Inventory Turns

Inventory turns is specified as the ratio of the

throughput (TH) to average inventory. It is commonly

used to measure the efficiency of inventory, and

represents the average number of times the inventory

stock is replenished or turned over (ISO 22400-

2:2014). Inventory turns results are presented in

Table 7. Average inventory in this study is 39,3.

Table 7: First pass yield ratio.

Inventory turns

Simulation 1 0,865

Simulation 2 0,891

Simulation 3 0,941

Simulation 4 0,839

Simulation 5 1,018

Simulation 6 0,839

Source: own study.

The highest inventory turns indicator has been

achieved in Scenarios 3 and 5.

4.4 Quality KPI - First Pass Yield

First pass yield is a mathematical formula used to

measure quality and efficiency in production. It

shows in particular how many elements go through

the production process without any problems. The

indicator is presented in Table 8.

Determination of ISO 22400 Key Performance Indicators using Simulation Models: The Concept and Methodology

97

Table 8: First pass yield indicator ratio.

First

p

ass

y

iel

d

Simulation 1 89,5%

Simulation 2 89,7%

Simulation 3 92,5%

Simulation 4 86,8%

Simulation 5 93%

Simulation 6 89,2%

Source: own study.

In simulation 1 an FPY of 89,5%, for example,

tells that 89,5% of items are moving through the

system without any issues. 10,5% percent of items are

scraps or reworks, which can be a time and cost

burden on final production. The higher the FPY, the

more efficient your production processes. In this

study, the highest percentage of FPY can be observed

in the simulation 5 (CAB sequence) – 93%.

5 CONCLUSIONS

The article presents a proprietary methodology for

determining the level of key performance indicators

using simulation models.

The wide availability of simulation tools and

powerful computers creates appropriate conditions

for the extensive use of simulation methods in

industry. Simulation models are used to reduce the

risk of failure when introducing significant changes

to the existing generation systems. After the model is

generated, a simulation analysis is carried out to

determine the individual components of the process.

Siemens Plant Simulation software was used to

develop the models.

In order to obtain correct analysis results, it is

necessary to define the basic properties of the system

correctly. The collected information was used to build

virtual manufacturing processes and determine their

basic tasks. Simulation models were developed in

accordance with the adopted assumptions concerning,

among others, the size of production batches,

simulation times and performance of individual

operations, as well as the availability of workstations.

Out of several production scenarios, the highest

efficiency in all measurements was shown by the fifth

scenario with the CAB sequence.

The methodology will be still tested and possibly

extended in the course of further research. The next

field of research will be testing methodology in pull

production systems (Pull System).

ACKNOWLEDGEMENTS

The research was funded by Project PROM -

International scholarship exchange of PhD candidates

and academic staff" is financed from the European

Social Fund under the Operational Programme

Knowledge Education Development, non-

competitive project entitled International scholarship

exchange for PhD candidates and academic staff,

contract number POWR.03.03.00-00-PN13/18.

REFERENCES

Antczak, A., Gębczyńska, A., 2016. Production process

efficiency analysis with use of key performance

indicators (kpi) on the example of XYZ company.

Scientific Papers. Organizacja i Zarządzanie

/Politychnika Śląska, (92), 9-20.

Halicka, K., 2016. Innovative Classification of Methods of

The Future-Oriented Technology Analysis.

Technological and Economic Development of

Economy, 22(4), 574-597.

IEC 62264, 2002. Enterprise-control System Integration,

Part 1. Models and Terminology, Part 2: Model Object

Attributes.

ISO 22400-1:2014, 2014, Automation systems and

integration — Key Performance Indicators (KPIs) for

manufacturing operations management; Part 1:

Overview, concepts, and terminology. International

Organization for Standardization.

ISO 22400-2:2014, 2014. Automation systems and

integration – Key performance indicators (KPIs) for

manufacturing operations management – Part 2:

Definitions and descriptions of KPIs. International

Organization for Standardization.

Kibira, D., Brundage, M. P., Feng, S., Morris, K. C., 2018.

Procedure for selecting key performance indicators for

sustainable manufacturing. Journal of Manufacturing

Science and Engineering, 140(1), 011005.

Kikolski, M., 2016. Identification of production bottlenecks

with the use of Plant Simulation software. Ekonomia i

Zarzadzanie, 8(4), 103-112.

Kikolski, M., 2019. Sample measurement of the ISO 22400

standard key performance indicators with the use of

simulation models. In 2019 IEEE Technology &

Engineering Management Conference (TEMSCON)

(pp. 1-5). IEEE.

Kikolski, M., 2017. Study of production scenarios with the

use of simulation models. Procedia Engineering, 182,

321-328.

Kikolski, M., Ko, C. H., 2018. Facility layout design–

review of current research directions. Engineering

Management in Production and Services, 10(3), 70-79.

Law, A. M., 2008. How to build valid and credible

simulation models. Proceedings of the 40th Conference

on Winter Simulation, 39-47.

MODELSWARD 2020 - 8th International Conference on Model-Driven Engineering and Software Development

98

Rakar, A., Zorzut, S., Jovan, V., 2004. Assessment of

production performance by means of KPI. Proceedings

of the Control, 6-9.

Rydzewska-Włodarczyk, M., Sobieraj, M., 2015.

Measuring process efficiency with key performance

indicators. Scientific Papers of the University of

Szczecin, 864, 333-347.].

Usman, M., 2018. An Implementation of KPI-ML to a

Multi-Robot Line Simulator (Master's thesis).

Zwierzyński, P., Ahmad, H., 2018. Seru production as an

alternative to a traditional assembly line. Engineering

Management in Production and Services, 10(3), pp. 62-

69.

Determination of ISO 22400 Key Performance Indicators using Simulation Models: The Concept and Methodology

99