Assessment of Computational Cell Model Benefits for Optimization of

Microfluidic Devices

Al

ˇ

zbeta Bohinikov

´

a

1 a

, In

ˆ

es Maia

2,3 b

, Monika Smie

ˇ

skov

´

a

1 c

, Al

ˇ

zbeta Bug

´

a

ˇ

nov

´

a

1 d

,

Ana S. Moita

2 e

, Ivan Cimr

´

ak

1 f

and Rui A. Lima

3,4 g

1

Cell-in-Fluid - Biomedical Modeling and Computation Group, University of Zilina, Slovakia

2

IN+ Center for Innovation, Technology and Policy Research, Instituto Superior T

´

ecnico, Universidade de Lisboa,

Av. Rovisco Pais, 1049-001 Lisboa, Portugal

3

Metrics, Mechanical Engineering Department, University of Minho, Campus de Azur

´

em, 4800-058 Guimar

˜

aes, Portugal

4

CEFT, Faculdade de Engenharia da Universidade do Porto (FEUP), R. Dr. Roberto Frias, 4200-465 Porto, Portugal

Keywords:

Computational Cell Model, Microfluidic Devices, Cell Deformation.

Abstract:

This article describes the overview of the steps required to derive and validate a new model on cell behaviour

in microfluidic devices, from the experimental approach to the computational model. The paper identifies

the challenges of the biological side of the experiments and shows where computational power can be useful.

It also emphasizes the necessity for the collaboration between the experimental and computational research

groups. Computations can offer great insides into the mechanics of cells, however, interesting applications

mainly arise from combining nunerics with experiments. Well calibrated and verified model can be used to

improve the performance of a given microfluidic device by testing various geometries and thus lowering the

number of devices that need to be produced. Choosing several designs of microfluidic devices one tries to

demonstrate the wide range of possible uses of the microfluidic technology and how the computations can

enrich them.

1 INTRODUCTION

There is a rising necessity for interdisciplinary co-

operation in solving problems in microfluidics. Mi-

crofluidic devices have a broad spectrum of use, rang-

ing from devices for sorting cells based on their me-

chanical properties to devices designed to detect spe-

cific cells or even to study mechanical properties of

individual cells (Sajeesh and Sen, 2014). Especially,

the use for clinical purposes can have a great influ-

ence on the early diagnosis of metastatic cancer and

thus can help patients to get personalized treatment

(Zhang and Nagrath, 2013).

There is a variety of microfluidic devices based

a

https://orcid.org/0000-0001-8058-7929

b

https://orcid.org/0000-0001-7986-8934

c

https://orcid.org/0000-0002-3633-1798

d

https://orcid.org/0000-0001-6772-2970

e

https://orcid.org/0000-0001-9801-7617

f

https://orcid.org/0000-0002-0389-7891

g

https://orcid.org/0000-0003-3428-637X

on their intended use. When interested in measuring

the biophysical properties of single cells, most com-

mon are devices with narrow channels and obstacles,

where transition times and deformation coefficients

can be measured.

A microfluidic device consisting of a straight

channel with constriction (150×10×10µm) was used

in (Hou et al., 2009). The study aimed to deter-

mine differences between cancer line cells MCF-

10A (benign breast epithelial cell) and MCF-7 (non-

metastatic tumor breast cell). This work was the in-

spiration behind the production of the microfluidic

channels described in Section 3.3.

Other types of devices, such as ones used in

(Lima et al., 2008) and (Pinho et al., 2013), focused

on global properties of the dense blood suspensions.

There is large number of microfluidic devices being

developed for in vitro cancer diagnosis (Chen et al.,

2012).

The need to improve these devices is ever increas-

ing (Shields IV et al., 2015). This process is costly

and time consuming. Computational models of cells

280

Bohiniková, A., Maia, I., Smiešková, M., Bugá

ˇ

nová, A., Moita, A., Cimrák, I. and Lima, R.

Assessment of Computational Cell Model Benefits for Optimization of Microfluidic Devices.

DOI: 10.5220/0009173202800287

In Proceedings of the 13th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2020) - Volume 1: BIODEVICES, pages 280-287

ISBN: 978-989-758-398-8; ISSN: 2184-4305

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

and their flow in microfluidic devices can help im-

prove their design and save time by lowering the

amount of necessary lab experiments.

To help with this process, we started a collab-

oration between Cell-in-fluid Biomedical Modelling

& Computations Group (CifBMCG), the Laboratory

of Interfacial plus Microscale Phenomena from IN+,

Centre for Innovation, Technology and Policy Re-

search in Instituto Superior T

´

ecnico, Universisadede

de Lisboa and Metrics research center, from Univer-

sity of Minho. Here we present the main goals of the

research project behind this collaboration and some

initial results gathered.

1.1 ESPResSo and PyOIF

Simulation model used for this work is being devel-

oped by our research group at the University of Zilina.

All the computations are run on ESPResSo (Weik

et al., 2019) software with an open source license.

We developed the python module PyOIF

1

that allows

modelling of blood as a fluid with immersed elastic

objects, which represent blood cells. More informa-

tion can be found in (Cimr

´

ak et al., 2014).

There are two main parts of the model, namely the

model of the fluid and the model of the elastic object,

that are coupled by dissipative forces. More details

can be found in (Bu

ˇ

s

´

ık and Cimr

´

ak, 2017).

The fluid is modelled using the lattice-Boltzmann

method. The space, through which the fluid moves

is represented by a lattice of discrete points. With

this method, the points are fixed throughout the whole

simulation. During the simulation, fictitious fluid

particles move and encounter other particles, which

transfer information about their velocity and direc-

tion. Information about the number and speed of the

particles passing through each of the fixed lattices is

stored. In-depth description of this method can be

found in (Cimr

´

ak and Jan

ˇ

cigov

´

a, 2018).

1.2 Computational Model of Elastic Cell

The model of elastic cells is represented by an approx-

imation of the cell membrane surface. Five elastic

moduli are responsible for the elastic behaviour of the

cell. Next section provides a brief overview of these

parameters. More details are presented in (Cimr

´

ak

and Jan

ˇ

cigov

´

a, 2018).

The stretching modulus is responsible for the

rigidity of the cell. Once the cell membrane is

stretched, this modulus reacts and develops resistance

against the stretching force to achieve the original re-

laxed state of the cell. The edges of the triangles can

1

http://cellinfluid.fri.uniza.sk/resources-espresso/

be thought of as springs trying to stay in their original

relaxed length.

The bending parameter aims to maintain the shape

of the object by preservation of the angles. The trian-

gle mesh has a prescribed relaxed state and this mod-

ulus maintains the angles between neighboring trian-

gles.

Local area conservation parameter manages

preservation of individual triangle area. When the cell

deforms by pressing forces and the areas of the trian-

gles change, this parameter is responsible for apply-

ing forces to achieve the original area.

The three parameters described above are related

to local regulation of the cell shape. The follow-

ing two parameters will guarantee the conservation of

global properties such as the global cell surface and

the cell volume.

Global area conservation preserves constant sur-

face of the whole object. If the surface of the cell

is larger than desired, this parameter acts to decrease

this surface. On the opposite, if it is smaller, this pa-

rameter increases it. There is a control system for

the surface of the cell. When the relative changes are

too large (larger than 3%), the simulation stops with a

warning.

The global volume conservation parameter is sim-

ilar to the global area conservation parameter, but in-

stead of surface, it is responsible for global volume.

It maintains constant volume of the cell during the

simulation. Similarly as for the global area conser-

vation parameter, there is control system which stops

the simulation with a warning in case the cell volume

becomes larger than 3%.

The model of RBCs was calibrated using the

stretching experiment (Dao et al., 2003), where silica

beads were attached to the cell and afterwards the cell

was stretched with different forces and the change in

cells radial and axial size was measured. The model

was also validated with experimental data of RBC de-

forming in a flow (Koval

ˇ

c

´

ıkov

´

a, 2019).

When setting up simulations of real biological ex-

periments, the most important is to set the parame-

ters as closely as possible to the experimental environ-

ment. Apart from channel geometry and visco-elastic

properties of the fluid, which are set based on the ex-

periments, and elastic parameters of the cell that are

set based on the calibration, one must also consider

the flow of the fluid in the channel. This informa-

tion is quite challenging to obtain from the biological

experiments, especially in narrow channels, such as

the ones used in 3.3. This is because at low volumet-

ric rate, the suspension might not even pass trough

and at higher rates the flow may become too fast to

be captured for instance by an high-speed camera (it

Assessment of Computational Cell Model Benefits for Optimization of Microfluidic Devices

281

can be out of the range of camera capture capacities).

Running simulation with the volumetric flow rate of

was 2.5µL/s resulted in higher velocities than those

measured from the biological experiment. Thus we

established the simulation flow by comparing the cell

velocities.

2 BIOLOGICAL EXPERIMENTS

The biological experiments for this work were carried

out and recorded at Metrics research center in Univer-

sity of Minho, in cooperation with the Laboratory of

Interfacial plus Microscale Phenomena from IN+, in

University of Lisbon. Different types of microfluidic

channels were tested to present various typical cases

addressed in microfluidic technology. The details on

the properties and origins of cells used for these ex-

periments are outlined in Section 2.2.

2.1 Experimental Setup

The flow of the working fluid was analyzed with a

system constituted by an inverted microscope (IX71,

Olympus) and a high-speed camera (FASTCAM SA3,

Photron). The microfluidic devices were placed on

the stage of the inverted microscope and a syringe

pump (CetoniNEMESYS Syringe Pump) was used to

produce a constant flow rate.

Figure 1: Experimental setup.

2.2 Biological Material

The working fluid used in the experiments was a sus-

pension of human red blood cells (RBCs) in dex-

tran 40 (Dx40) with a hematocrit (Hedct) of 0.2

%. In brief, blood from healthy individuals was

obtained from Instituto Portugu

ˆ

es do Sangue e da

Transplantac¸

˜

ao (IPST). The RBCs were separated

from bulk blood by centrifugation (1500 rpm for 15

min) and then the plasma was removed by aspira-

tion. The RBCs were then washed with a physiolog-

ical saline solution and the process was repeated two

more times. Lastly, the RBCs were diluted with Dx40

to make up the required concentration.

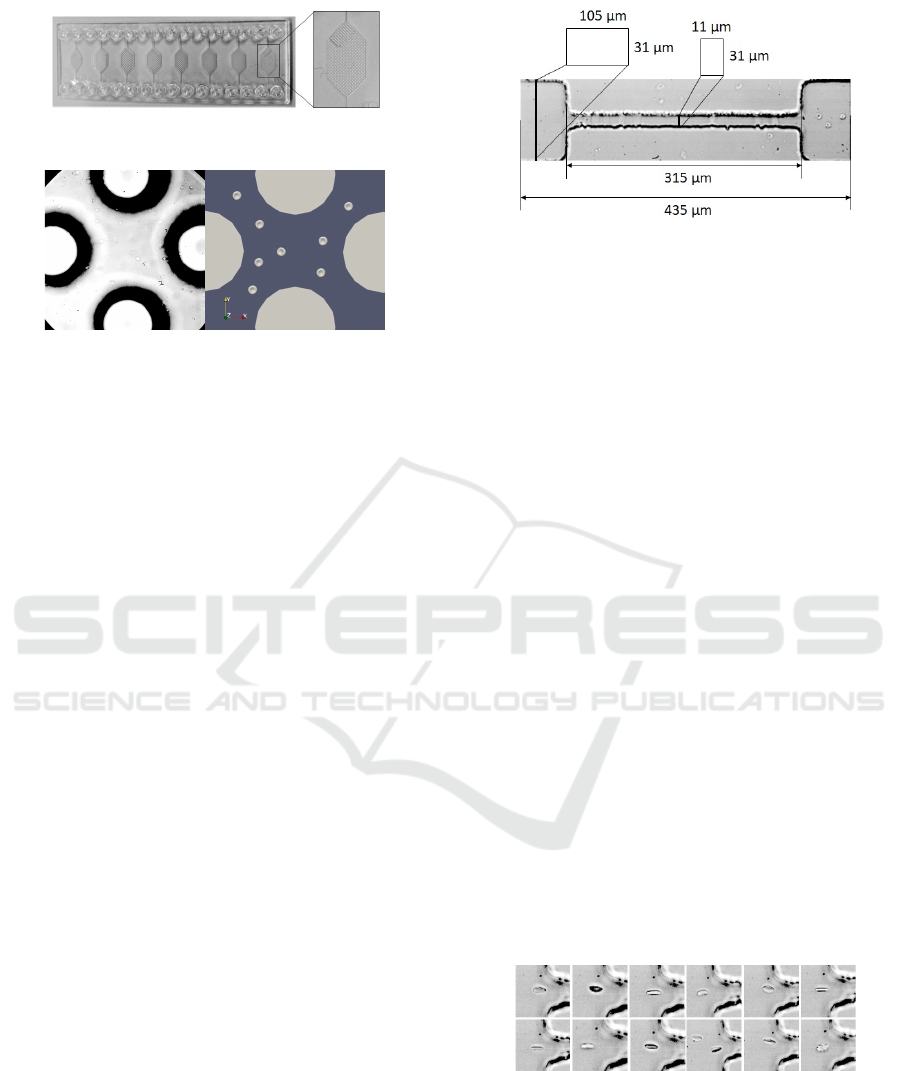

2.3 Microfluidic Devices

In this study, four different types of channels are ad-

dressed. Spiral sorter chip and Pillar chip were ob-

tained from microfluidic ChipShop. The other two

chips were produced in Metrics research centre in the

University of Minho. The production process of the

latter two is described in Section 2.3.1. For each type

of microchannel, the potential use and how can the

computational model be used are outlined.

2.3.1 Production of Microfluidic Devices

The microchannels used in this work were produced

by a soft lithographic technique. Firstly, to fabricate

the master moulds, the geometries were drawn in Au-

toCAD to produce a high-resolution photomask. The

mould was then fabricated on a silicon wafer with an

ultrathick photoresist (SU-8 50; Kayaku MicroChem,

Japan). The polydimethylsiloxane (PDMS) prepoly-

mer was prepared by mixing a commercial prepoly-

mer and a curing agent (Silpot 184; Dow Corning,

USA) at a 10:1 weight ratio. The mixture was de-

gassed under vacuum and the PDMS was poured into

the SU-8 photo-resist master mould and cured in an

oven for about 2 h at 70

◦

C. After both master and

PDMS were cooled to room temperature, the PDMS

was peeled from the master. The input and output

ports are made using micro-pipette tips. Lastly, the

PDMS was washed with ethanol and spin-coated over

a clean glass slide. The microchannels were manu-

factured considering three different heights, namely

31µm, 25µm and 12µm. The geometry of the mi-

crochannel with the tallest height is presented in Fig-

ure 5.

3 MICROFLUIDIC DEVICES

DESIGNS AND POTENTIAL OF

COMPUTATIONAL CELL

MODEL

3.1 Spiral Sorter

One of the short term goals of the CifBMCG is to de-

sign and construct geometry for special spiral chan-

nels utilizing inertial effects for cell sorting. Such a

BIODEVICES 2020 - 13th International Conference on Biomedical Electronics and Devices

282

device can be used for ultra-fast cancer cells filtering

without labelling from blood (Warkiani et al., 2014).

The technique utilizes the natural Dean vortex

flows present in the continual flow inside curvilinear

microchannels along with inertial lifting forces that

concentrate larger cancer cells against the inner wall.

By using spirals and circular cross-section, unlike the

traditional rectangular cross-section, the position of

the Dean’s vortex core can be altered to achieve sepa-

ration. Smaller hematologic components are trapped

in Dean’s vortices slanted toward the outer walls of

the duct and finally removed at the outer outlet, while

larger cancer cells accumulate at the inner wall of the

channel and collect from the inner outlet.

The plan is to start with a single spiral micro-

channel with one input and two outputs. This arrange-

ment could successfully isolate two types of cells with

different mechanical properties. Simulations can be

used to suggest how to position the outputs in order to

achieve better purity in the filtering process. Running

biological experiments with healthy and sick RBCs

pushed trough the different channels in the microflu-

idic device in Figure 2 can be used to validate the

model in this novel geometry. Afterwards, the simu-

lations can be used to design improved devices which

then can be produced and tested. Next step could be

to use this device to sort cancer cells from the blood.

Figure 2: Spiral sorter chip.

3.2 Pillar Channels

There are many biological studies focusing on the

flows in different geometries that can be characterized

by the common property of having arrays of periodic

pillars.

Cell-in-fluid research group already carried out

simulation studies of channels inspired by such bi-

ological experiments (Nagrath et al., 2007), (Huang

et al., 2004), (Inglis et al., 2006), (Gleghorn et al.,

2010). However, the simulation results could only

be compared with data collected from the literature,

which did not include all the required information to

fully validate the numerical model.

Our previous studies concerned the trajectories

and rotation of the cells (Bachrat

´

y et al., 2017),

(Slav

´

ık et al., 2017) and (Koval

ˇ

c

´

ıkov

´

a et al., 2018).

Since computational power is somewhat limited, only

part of the microfluidic devices was simulated, with

periodic borders. This means that one can only ob-

tain local information on the behaviour of the cells

and then extrapolate conclusions for the overall be-

haviour. This was studied in (Chovanec et al., 2019).

In order to further develop our research in this area

a microfluidic chip with several channels with differ-

ent pillar geometries was now chosen (see Figure 3).

The flow in one of the channels of this microfluidic

chip was recorded using the high-speed camera (as

aforementioned), from which data can be obtained in

post-processing processes, according to the following

three steps process.

• Video Processing - Currently, there are various

software packages available that can be used for

tracking cell trajectories and obtaining informa-

tion about the cell deformations, such as ImageJ.

However, using these is either a manual or semi-

manual process. There are also limitations con-

cerning the shape of trajectories, as ImageJ can

only track straight trajectories, for example. One

of the goals is to automatize this step. First steps

towards achieving this goal have already been

taken, see (Kaj

´

anek and Cimr

´

ak, 2019).

• Simulations - We will simulate part of the device,

that can be seen on the recordings from the ex-

periment, see Figure 5. Comparing the cell trajec-

tories from simulations with the trajectories of ac-

tual cells will serve as validation of the model. Af-

terwards, it is possible to perform a computational

study with different geometries from the chip and

then carrying out reverse comparison where we

should confirm that the cell behaviour predicted

by our model is similar to that of the real cells.

With this double verification, we can further study

other possible geometries and further optimize the

model, for example, to achieve higher collision

rates with the pillars or introduce other types of

cells.

• Statistical Analysis - Using machine learning

techniques, specifically convolutional neural net-

works, we aim to predict cell behaviour within

large microfluidic devices. Simulations of whole

microfluidic devices require excess computational

power, which is limited. To overcome this, we

plan to use both the information obtained from

videos of biological experiments and data from

simulations in order to compare the results of

our techniques, building on the work started in

(Chovanec et al., 2019).

Assessment of Computational Cell Model Benefits for Optimization of Microfluidic Devices

283

Figure 3: Pillar chip.

Figure 4: Capture from the video recording of the experi-

ment on the left side. Example of cell seeding in simulation

with the pillar geometry on the right.

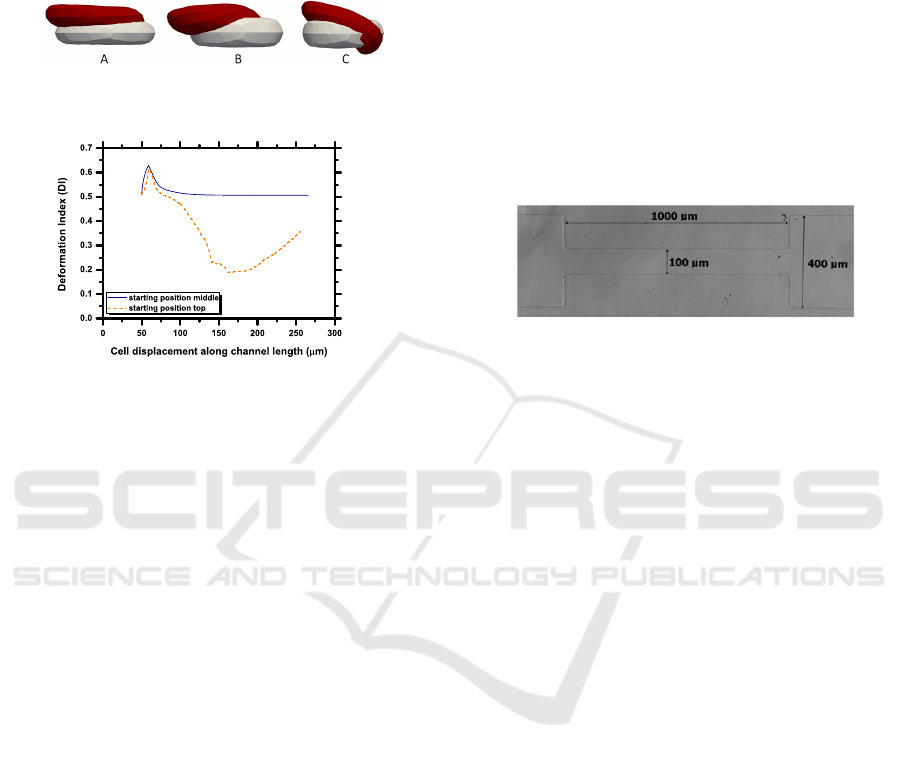

3.3 Channels with Constriction

With these types of channels, the objective is to study

the deformation of individual cells. As a starting

point, we looked at the deformation of a healthy RBC.

Further experiments will be carried out, once there are

other types of cells available. Particular emphasis is

expected to be given to studies on the deformation of

cells with a nucleus. This could be then used to study

the flow of rare cells, such as the circulating tumour

cells, in the microfluidic devices and optimize their

geometry to achieve the desired properties.

Production of these devices is described in Section

2.3.1. The Metrics research centre in the University of

Minho already produced similar geometries in (Boas

et al., 2018). The objective now is to go smaller and

achieve the flow of cells in one layer which should

allow for a better focus of the video recordings.

Several videos were captured, however, there were

some challenges with the volumetric flow rate, as

mentioned in Section 2.1. We analyzed one of these

videos where the volumetric flow rate on the pump

was set to 2.5 µL/s. Once the simulations finish we

plan to compare the numerical and experimental re-

sults by looking at the time required for the cell to

pass through the channel and at the deformation in-

dex (DI). Figures 7 and 8 depict the partial results

gathered so far.

Furthermore, several sections were selected from

the channel and will be used to qualitatively compare

the shape of the cell deformation obtained from the

experiments and the numerical results.

Figure 5: Dimensions of the channel with constriction.

3.3.1 Data Processing

As aforementioned the quantitative data was extracted

from video recordings of the experiments, using Im-

ageJ (Schneider et al., 2012). For each cell, defor-

mation index, velocity, constriction time and average

velocity in constriction were measured. To obtain the

DI a boxing rectangle was created for each frame. DI

was computed as |x − y|/(x +y), where x is the width

and y is the length of the rectangle. There are other

options to determine the DI, but this was chosen due

to simplicity in terms of how easy it is to compare the

experimental data with the numerical results in this

case.

3.3.2 Comparison between Numerical and

Experimental Results

Due to the difficulties with the reliability of the volu-

metric flow rate, as already discussed in Section 2.1,

the flow velocity was evaluated instead and used to set

up the fluid flow in the simulation. The parameter of

fluid force density was set to 0.0003.

The position of the biological cells was analyzed

when entering the narrow part of the channel. From

16 cells detected in the video, 12 passed through the

whole length. 5 cells entered in the middle and 6 from

the top. Upon entering, most of the cells were rotated

vertically in the flow direction, see Figure 6.

Figure 6: All 12 cells at the entrance of the constriction.

Figure 7 depicts the difference between the cell

deformation when the cell is starting centred (the grey

cell) in the middle and when the cell is moved 5µm

to the left (the red cell). The simulation is still run-

ning and our results go up to one-third of the con-

striction. So we show the difference at the entrance

BIODEVICES 2020 - 13th International Conference on Biomedical Electronics and Devices

284

(Figure 7 A), then 20 µm (Figure 7 B) into the con-

striction and then in the middle (Figure 7 C). The dif-

ference in the DI changes, depending on the starting

point is depicted in Figure 8.

Figure 7: Deformation of cells with different starting posi-

tions.

Figure 8: DI of cells with different starting positions.

At the moment limited information could be ob-

tained from the simulations. To save time, the cells

with 10µm in size were positioned before the constric-

tion. We can compare the DI at the beginning of the

constriction (at position 66 µm from the beginning of

the channel). The average DI of biological cells is

0.65, while for the cell from the simulation, it is 0.58.

The difference can be explained by the fact that the

DI from simulation comes from one cell position at a

certain place and the experimental value is obtained

as an average of several cells.

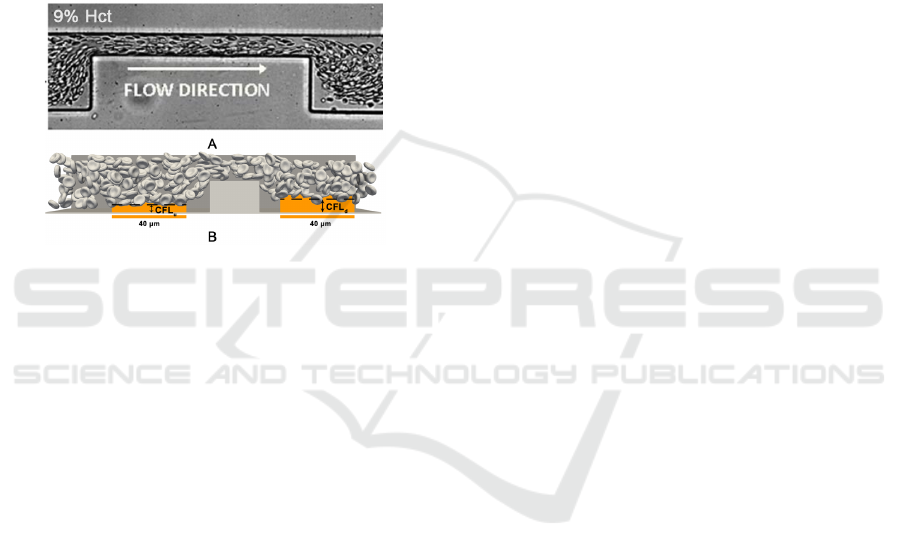

3.4 Channels for Observing CFL

The cell-free layer (CFL) is a hemodynamic phe-

nomenon that contributes to the rheological proper-

ties of blood flowing in microvessels. Due to the

high shear stresses developed around the wall and the

parabolic velocity profile, deformable RBCs in nar-

rower vessels tend to migrate toward the centre of the

vessel. This results in the formation of two phases,

the central cell concentrated phase and the cell-free

liquid phase. To the contrary, white blood cells and

platelets that are more rigid than RBCs, as well as

more infected RBCs, are localized closer to CFL.

Several factors, such as cell deformability, hema-

tocrit, blood flow rate and vascular geometry, affect

the thickness of the resulting CFL. The computational

study performed in (Smie

ˇ

skov

´

a and Bachrat

´

a, 2019),

simulated blood flow in a straight channel with dif-

ferent hematocrit values ranging from 5 to 15% with

cells of different stiffness. When examining the im-

pact of the geometry, it is possible to use the mi-

crochannels with narrower parts. Section 3.4.1 dis-

cusses several challenges we encountered with these

in-silico experiments.

New microfluidic chips are now being produced

at Metrics in the University of Minho, with different

geometries. Our goal is to gather data from these de-

vices at different levels of flow and hematocrits and

access more detailed information in order to improve

our model for these types of more dense flows. For

now, we obtained data from channel design shown in

Figure 9.

Figure 9: Dimensions of channels for observing CFL. The

height of the channel is 30µm.

3.4.1 Simulating Dense Blood Suspensions -

Challenges

Simulations of real biological experiments require the

use of large-scale computations. It is necessary to

choose the degree of simulation complexity based

on biological phenomena. One way to simplify the

model is to reduce the discretization of the cell mem-

brane. This has a more pronounced effect at higher

hematocrits.

The advantage of PyOIF is the possibility to sim-

ulate periodic properties of the flow in all three di-

rections. Application of periodic boundary condi-

tions is advantageous for microchannels with a peri-

odic obstacle field (Bu

ˇ

s

´

ık et al., 2016) or direct mi-

crochannels without obstacles (Qi and Shaqfeh, 2017;

Smie

ˇ

skov

´

a and Bachrat

´

a, 2019).

A different situation occurs in the case of chan-

nels with complex segmented geometry. In (Pinho

et al., 2013), a continuous microfluidic device for par-

tial red blood cell (RBC) extraction and subsequent

measurement of RBC deformability was presented.

First part of this device, a constriction with different

heights (25%, 50% and 75% of the channel height)

was placed and the effect of the constriction on the

CFL thickness and the effectiveness of the subsequent

separation were examined.

Simulating this part of the microfluidic device

with the original dimensions (2500×100×51 / 300×

25(50,75) × 51 / 100 × 100 × 51) and with a hemat-

ocrit of about 9% would represent a seeding of 12900

to 13700 cells. A possible solution to this type of

Assessment of Computational Cell Model Benefits for Optimization of Microfluidic Devices

285

problem is to divide the entire simulated channel into

two consecutive simulations. The first simulation box

would have a cuboid shape and would represent a

straight part of the channel before the constriction.

When the steady-state CFL thickness is reached, the

actual cell positions and forces acting on all compu-

tational nodes would be stored. This data would be

an input to the second simulation box containing the

constriction, providing an approximation of the hy-

drodynamic properties. The open question remains,

i.e. the effect of such an approximation on the results,

as well as the reduction of computational power or

efficiency of such an approach.

Figure 10: Comparison of the screenshot (A) from a biolog-

ical experiment (Pinho et al., 2013) and (B) a computational

model to investigate the effect of CFL enhancement after in-

sertion of the contraction region into a direct microchannel.

4 CONCLUSIONS

The work presented here addresses a strategy com-

bining an experimental and a numerical approach

to develop microfluidic devices focusing diagnos-

tics based on cell deformation and fluid flow be-

haviour. Microfluidic devices can get blocked with ei-

ther cells, micro-particles or even some material from

the microfluidic channel itself. Saving the data from

recorded video takes time, and it is not certain to ob-

tain the desired data at proper conditions. Experimen-

tal data is therefore of paramount importance to de-

vise and validate a numerical model, but all the afore-

mentioned issues limit the number of experiments that

can be performed. Here is where computational tools

can provide help. Before even starting an experiment

there is a possibility to run several experimental set

up scenarios and based on the analyses of those, it is

easier to establish the plan of experiments to perform.

An important part of the development of the compu-

tational model is the calibration and verification of its

functionality. This process is required for different

types of cells used in the biological experiments, such

as cell RBC, various types of CTC and many others.

For these purposes more simple designs of microflu-

idic channels can be used as proposed in our paper. It

is important to know all the essential parameters of a

given biological experiment. When conducting fluid

flow simulations, it is essential to know the flow in-

formation (Slav

´

ık et al., 2017), fluid density and vis-

cosity, channel shape and size.

This work presents several types of microfluidic

devices and gives a brief overview of most of the steps

necessary to gather data from biological experiments

and how to set up simulations using the open-source

software Espresso with extension PyOIF. The main

focus is towards the development of new microfluidic

devices allowing the study of cell deformation and

deepen the knowledge on this topic, for future use in

alternative diagnostics. Partial results of a simulation

are shown and compared with experimental data ob-

tained for the channels with narrow constriction. This

procedure shows the usefulness of the calibrated RBC

model for healthy RBC. Finally, we outline the possi-

ble applications of the simulation tool for optimizing

designs of some of these devices.

ACKNOWLEDGEMENTS

This work was supported by the Slovak Research

and Development Agency (contract number APVV-

15-0751) and by the Ministry of Education, Science,

Research and Sport of the Slovak Republic (contract

No. VEGA 1/0643/17). Authors are also grateful

to Fundac¸

˜

ao para a Ci

ˆ

encia e Tecnologia (FCT) for

partially financing the research under the framework

of project UTAP-EXPL/CTE/0064/2017 and project

n

o

030171 financed by LISBOA-01-0145-FEDER-

030171 / PTDC/EME-SIS/30171/2017 which also

provided a fellowship. Finally authors also grate-

ful to FCT for the IF 2015 recruitment program (IF

00810-2015) and exploratory project associated with

this contract.

REFERENCES

Bachrat

´

y, H., Koval

ˇ

c

´

ıkov

´

a, K., Bachrat

´

a, K., and Slav

´

ık, M.

(2017). Methods of exploring the red blood cells ro-

tation during the simulations in devices with periodic

topology. In 2017 International Conference on Infor-

mation and Digital Technologies (IDT), pages 36–46.

IEEE.

Boas, L., Faustino, V., Lima, R., Miranda, J., Minas, G.,

Fernandes, C., and Catarino, S. (2018). Assessment

of the deformability and velocity of healthy and ar-

tificially impaired red blood cells in narrow poly-

BIODEVICES 2020 - 13th International Conference on Biomedical Electronics and Devices

286

dimethylsiloxane (pdms) microchannels. Microma-

chines, 9(8):384.

Bu

ˇ

s

´

ık, M. and Cimr

´

ak, I. (2017). The calibration of fluid-

object interaction in immersed boundary method. In

EPJ Web of Conferences, volume 143, page 02013.

EDP Sciences.

Bu

ˇ

s

´

ık, M., Jan

ˇ

cigov

´

a, I., T

´

othov

´

a, R., and Cimr

´

ak, I.

(2016). Simulation study of rare cell trajectories and

capture rate in periodic obstacle arrays. Journal of

Computational Science, 17:370–376.

Chen, J., Li, J., and Sun, Y. (2012). Microfluidic approaches

for cancer cell detection, characterization, and separa-

tion. Lab on a Chip, 12(10):1753–1767.

Chovanec, M., Bachrat

´

y, H., Jasen

ˇ

c

´

akov

´

a, K., and

Bachrat

´

a, K. (2019). Convolutional neural networks

for red blood cell trajectory prediction in simulation

of blood flow. In International Work-Conference on

Bioinformatics and Biomedical Engineering, pages

284–296. Springer.

Cimr

´

ak, I., Gusenbauer, M., and Jan

ˇ

cigov

´

a, I. (2014).

An espresso implementation of elastic objects im-

mersed in a fluid. Computer Physics Communications,

185(3):900–907.

Cimr

´

ak, I. and Jan

ˇ

cigov

´

a, I. (2018). Computational Blood

Cell Mechanics: Road Towards Models and Biomedi-

cal Applications. CRC Press.

Dao, M., Lim, C. T., and Suresh, S. (2003). Mechanics of

the human red blood cell deformed by optical tweez-

ers. Journal of the Mechanics and Physics of Solids,

51(11-12):2259–2280.

Gleghorn, J. P., Pratt, E. D., Denning, D., Liu, H., Bander,

N. H., Tagawa, S. T., Nanus, D. M., Giannakakou,

P. A., and Kirby, B. J. (2010). Capture of circulat-

ing tumor cells from whole blood of prostate cancer

patients using geometrically enhanced differential im-

munocapture (gedi) and a prostate-specific antibody.

Lab on a chip, 10(1):27–29.

Hou, H. W., Li, Q., Lee, G., Kumar, A., Ong, C., and Lim,

C. T. (2009). Deformability study of breast cancer

cells using microfluidics. Biomedical microdevices,

11(3):557–564.

Huang, L. R., Cox, E. C., Austin, R. H., and Sturm,

J. C. (2004). Continuous particle separation

through deterministic lateral displacement. Science,

304(5673):987–990.

Inglis, D. W., Davis, J. A., Austin, R. H., and Sturm,

J. C. (2006). Critical particle size for fractionation

by deterministic lateral displacement. Lab on a Chip,

6(5):655–658.

Kaj

´

anek, F. and Cimr

´

ak, I. (2019). Evaluation of detec-

tion of red blood cells using convolutional neural net-

works. In 2019 International Conference on Informa-

tion and Digital Technologies (IDT), pages 198–202.

IEEE.

Koval

ˇ

c

´

ıkov

´

a, K. (2019). Discretization of simulation

elements–feasibility limits and accuracy of results. In

2019 Proceedings of MIST Conference on Mathemat-

ics in Science and Technologies (2019, In press).

Koval

ˇ

c

´

ıkov

´

a, K., Slav

´

ık, M., Bachrat

´

a, K., Bachrat

´

y, H.,

and Bohinikov

´

a, A. (2018). Volumetric flow rate in

simulations of microfluidic devices. In EPJ Web of

Conferences, volume 180, page 02046. EDP Sciences.

Lima, R., Ishikawa, T., Imai, Y., Takeda, M., Wada, S., and

Yamaguchi, T. (2008). Radial dispersion of red blood

cells in blood flowing through glass capillaries: the

role of hematocrit and geometry. Journal of biome-

chanics, 41(10):2188–2196.

Nagrath, S., Sequist, L. V., Maheswaran, S., Bell, D. W., Ir-

imia, D., Ulkus, L., Smith, M. R., Kwak, E. L., Digu-

marthy, S., Muzikansky, A., et al. (2007). Isolation

of rare circulating tumour cells in cancer patients by

microchip technology. Nature, 450(7173):1235.

Pinho, D., Yaginuma, T., and Lima, R. (2013). A microflu-

idic device for partial cell separation and deformabil-

ity assessment. BioChip Journal, 7(4):367–374.

Qi, Q. M. and Shaqfeh, E. S. (2017). Theory to predict

particle migration and margination in the pressure-

driven channel flow of blood. Physical Review Fluids,

2(9):093102.

Sajeesh, P. and Sen, A. K. (2014). Particle separation and

sorting in microfluidic devices: a review. Microflu-

idics and nanofluidics, 17(1):1–52.

Schneider, C. A., Rasband, W. S., and Eliceiri, K. W.

(2012). Nih image to imagej: 25 years of image anal-

ysis. Nature methods, 9(7):671.

Shields IV, C. W., Reyes, C. D., and L

´

opez, G. P. (2015).

Microfluidic cell sorting: a review of the advances in

the separation of cells from debulking to rare cell iso-

lation. Lab on a Chip, 15(5):1230–1249.

Slav

´

ık, M., Bachrat

´

a, K., Bachrat

´

y, H., and Koval

ˇ

c

´

ıkov

´

a,

K. (2017). The sensitivity of the statistical charac-

teristics to the selected parameters of the simulation

model in the red blood cell flow simulations. In 2017

International Conference on Information and Digital

Technologies (IDT), pages 344–349. IEEE.

Smie

ˇ

skov

´

a, M. and Bachrat

´

a, K. (2019). Validation of bulk

properties of red blood cells in simulations. In 2019

International Conference on Information and Digital

Technologies (IDT), pages 417–423. IEEE.

Warkiani, M. E., Guan, G., Luan, K. B., Lee, W. C., Bhagat,

A. A. S., Chaudhuri, P. K., Tan, D. S.-W., Lim, W. T.,

Lee, S. C., Chen, P. C., et al. (2014). Slanted spiral

microfluidics for the ultra-fast, label-free isolation of

circulating tumor cells. Lab on a Chip, 14(1):128–

137.

Weik, F., Weeber, R., Szuttor, K., Breitsprecher, K.,

de Graaf, J., Kuron, M., Landsgesell, J., Menke, H.,

Sean, D., and Holm, C. (2019). Espresso 4.0 – an

extensible software package for simulating soft mat-

ter systems. The European Physical Journal Special

Topics, 227(14):1789–1816.

Zhang, Z. and Nagrath, S. (2013). Microfluidics and can-

cer: are we there yet? Biomedical microdevices,

15(4):595–609.

Assessment of Computational Cell Model Benefits for Optimization of Microfluidic Devices

287