Solution Concentration and Temperature Measurements by

Long-path Optical Coherence Tomography

Tatsuo Shiina

Graduate School of Engineering, Chiba University, 1-33 Yayoi-cho, Inage-ku, Chiba-shi, 263-8522, Japan

Keywords: OCT, Industrial, Temperature, Concentration.

Abstract: Long path time domain OCT was developed and applied to evaluate a certain solution under the consideration

of concentration and temperature. Long path TD-OCT has the measurement range of 100mm and the

resolution of position decision of 1m. Optical characteristics of the solution is represented as group

refractive index by Long path TD-OCT, and it depends on solution concentration and temperature. In this

study, the experimental result of the diluted alcohol solution was compared with the plural theoretical models.

As a result, the measurement accuracy was confirmed with the refractive index error of less than 0.0001. Long

path TD-OCT has potential to evaluate the target solution with volume, and the experiment was proceeded to

monitor the spatial fluctuation process. As a result, the unique phenomenon was observed in the model

experiment of partially different refractive index sample. The OCT signal had the change of knife-edge effect

at the boundary of refractive index. More fundamental experiment was conducted to observe the phenomenon

precisely. Now the theoretical approach was started to understand the phenomenon.

1 INTRODUCTION

In industrial scene, the transparent materials often

have needs to measure their exterior and interior

characteristics, that is, flatness, uniformity, thickness,

crack, void, structure and concentration. The

transparent materials are difficult to take a camera

image. Off course, up to now, various kinds of

measurement methods are invented for these

materials. By utilizing the polarization, birefringence,

and other optical characteristics are helpful to get

information of these transparent materials. Laser

devices are powerful tool to deduce these

characteristics. Furthermore, it has the highest

accuracy to get the precise measurement.

The traditional high-precision measurement

technology is optical interference technology in

industrial field.(Yoshizawa 2015) Laser inter-

ferometer, laser displacement meter, and white-light

interferometer have been commercialized. In these

high-precision optical measurement devices, long

path measurement is one of the industrial

applications. Combinational lens such as camera lens

is essential to evaluate and analyse their lenses

matching to optimize their performance. In the case

of crystal growth and material compounding

operation, the feedbacks from the interior condition

sensing to the temperature and concentration controls

are important. On the other hand, the long path

measurement on the laser and white-light

interferometers utilizes linear motion, and they are

lack of repeatability. Furthermore, these apparatuses

are large and expensive. As a result, they have

restriction to use.

The optical coherence tomography : OCT

technology is the low coherent interferometer and

obtains the cross-sectional image by non-invasive and

non-destructive measurement, Mainly it is used in

ophthalmology.(Danielson 1991, Huang 1991,

Brezinski 1999) It is developed and commercialized

in medical field at first, and recently it is adapted to

the industrial use.(Song 2012) The combination of

super luminescent diode : SLD and optical fiber

interferometer adds the flexibility of measurement to

the device and also compactness. In this study, a

portable OCT scanner has been developed for

industrial use. (Shiina 2003, 2009, 2014, Yoshizawa

2015) The long path TD-OCT was improved to take

a measurement range of up to 100mm with 5-digit

accuracy. In this study, this technique was applied to

the refractive index measurement of a solution. To

expand the measurement to the concentration change

and erratic distribution of solution due to the

temperature, the another material was inserted into

Shiina, T.

Solution Concentration and Temperature Measurements by Long-path Optical Coherence Tomography.

DOI: 10.5220/0009159801510156

In Proceedings of the 8th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2020), pages 151-156

ISBN: 978-989-758-401-5; ISSN: 2184-4364

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

151

the solution. As a result, the unique diffraction-like

phenomenon from knife-edge was observed. In this

report, the high precision experiment was explained

and mentioned to the new approach for the spatial

fluctuation measurement of the solution, too.

2 EXPERIMENTAL SET-UP

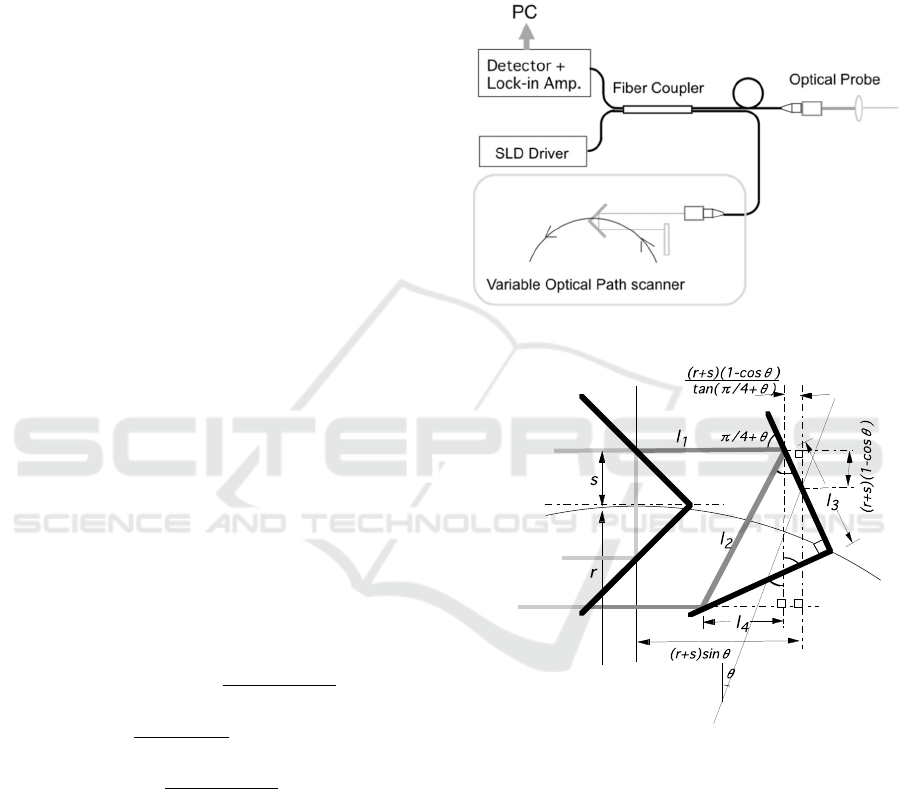

2.1 OCT Setup

The SLD light source of 800nm-band is installed into

the long path TD-OCT. The low coherence

interferometer changes its reference path length, and

interior information of the specimen is visualized.

Therefore, it is important to scan precisely the optical

path change. The optical setup of the long path TD-

OCT is illustrated in Fig.1. The interferometer

consists of an optical fiber coupler. SLD beam

(Anritsu Co. Ltd) is divided by the coupler, one goes

to the reference path and the other goes to the

measurement path, which has the optical probe to

focus it to the specimen. Both of reflected beam are

combined and cause the interference within the same

coupler, and detected by the photodiode. The

interference signal is detected as the Gaussian

envelope through amplifiers and filter circuits.

The long path TD-OCT utilizes the rotational

optical path change mechanism. The rotation radius

and speed decide the measurement range and scan

rate, respectively. This scanning mechanism consists

of a rotating corner reflector and a fixed mirror. The

optical path change is represented by equation (1).

(1)

Figure 2 shows the geometrical arrangement of

the mechanism with the optical path of l

1

– l

4

.

θ

is

rotation angle [deg], r is rotation radius, s is the offset

length from the optical axis. The fixed mirror reflects

the thrown beam to the same path. The optical path

change becomes the approximately linear motion.

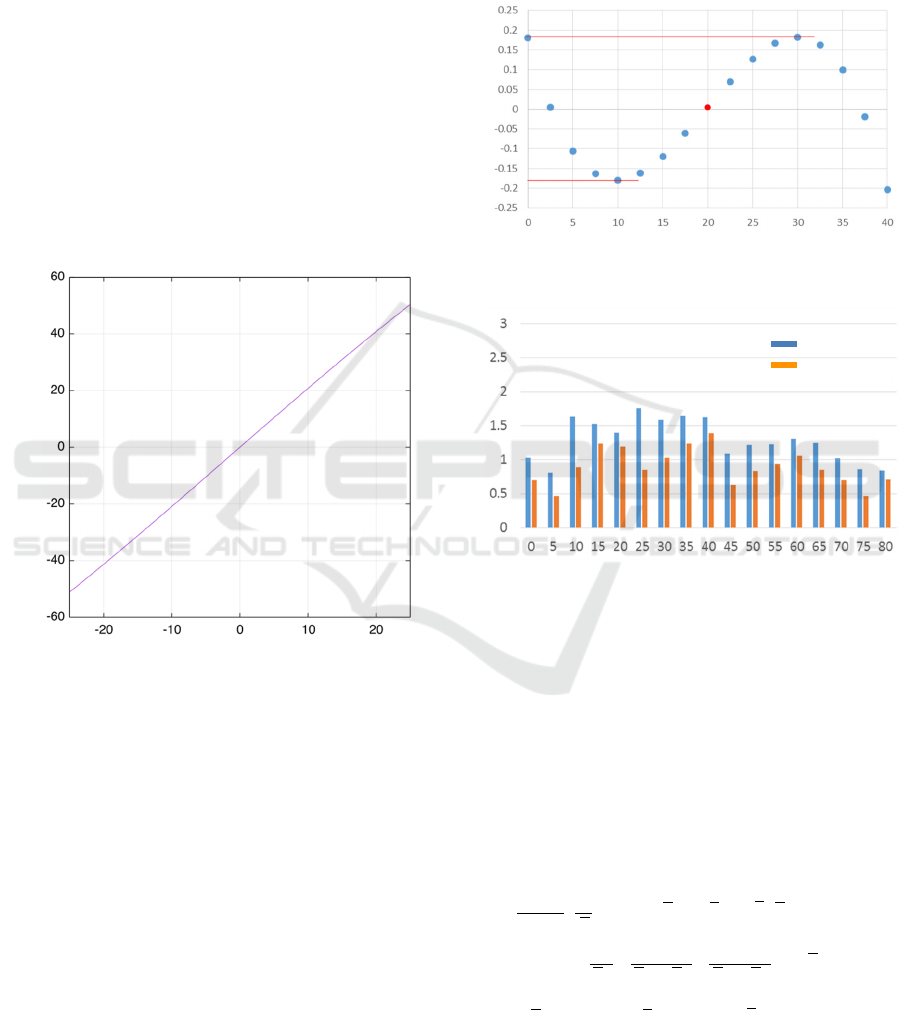

The optical path change of the rotation radius of

60mm is shown in Fig.3. The actual motion has the

distortion from the linear motion. The distortion is

about 1 – 2% within the rotation angle of +/-20

degrees.

The long path industrial OCT has a rotation disk

of 60mm radius, of which maximum measurement

range reaches 100mm. Here it is restricted to 80mm

by the reflector size. The rotation speed is 200rpm. A

servo motor is installed to stabilize the rotation.

Figure 1: Structure of long path industrial OCT.

Figure 2: Optical path change by rotating reflector.

2.2 Accuracy Improvement

The rotational optical path scanning mechanism has

the approximated linear motion. It has a small

distortion from linear change. The larger the rotation

angle is from the center position that the refractor

faces to the incident beam, the distortion becomes

larger. Furthermore, the distortion is not symmetry

right and left at the center position because of the

fixed mirror and the incident beam arrangement.

Then linear transformation from the distortion curve

was conducted by taking a balance of the distortion.

Here, the 3

rd

approximation curve, which represented

l

All

= l

1

+

l

2

+

(l

1

− l

4

) − 2s

= 2l

1

+ l

2

(1 − sin 2

θ

) − 2s

l

1

= (r + s)sin

θ

−

(r + s)(1− cos

θ

)

tan(

π

/4+

θ

)

l

2

=

l

3

cos(

π

/4+

θ

)

l

3

= 2s+

(r + s)(1− cos

θ

)

sin(

π

/4+

θ

)

l

4

= l

2

sin(2

θ

)

PHOTOPTICS 2020 - 8th International Conference on Photonics, Optics and Laser Technology

152

as equation (2), is adapted to the balanced distortion

curve experimentally obtained as shown in Fig.4.

y =−0.00010456x

3

+ 0.0035485x

2

+ 2.0526x +13.845

(2)

Even if the servo motor was installed into the long

path TD-OCT, the rotation jitter still remained.

Standard deviation of 10 times measurement at each

path length is investigated in Fig.5. The blue bars

indicate the normal average of 10 times

measurements. The servo motor accelerates or

decelerates to keep its rotation speed, and such force

influences to the positioning of the reflector. Such an

accidental fluctuation was trimmed from the results,

and took an average to minimize the standard

deviation. It is represented as red bars. The total error

restricted within 1μm.

Rotation Angle [deg.]

Figure 3: Optical path difference of long path TD-OCT.

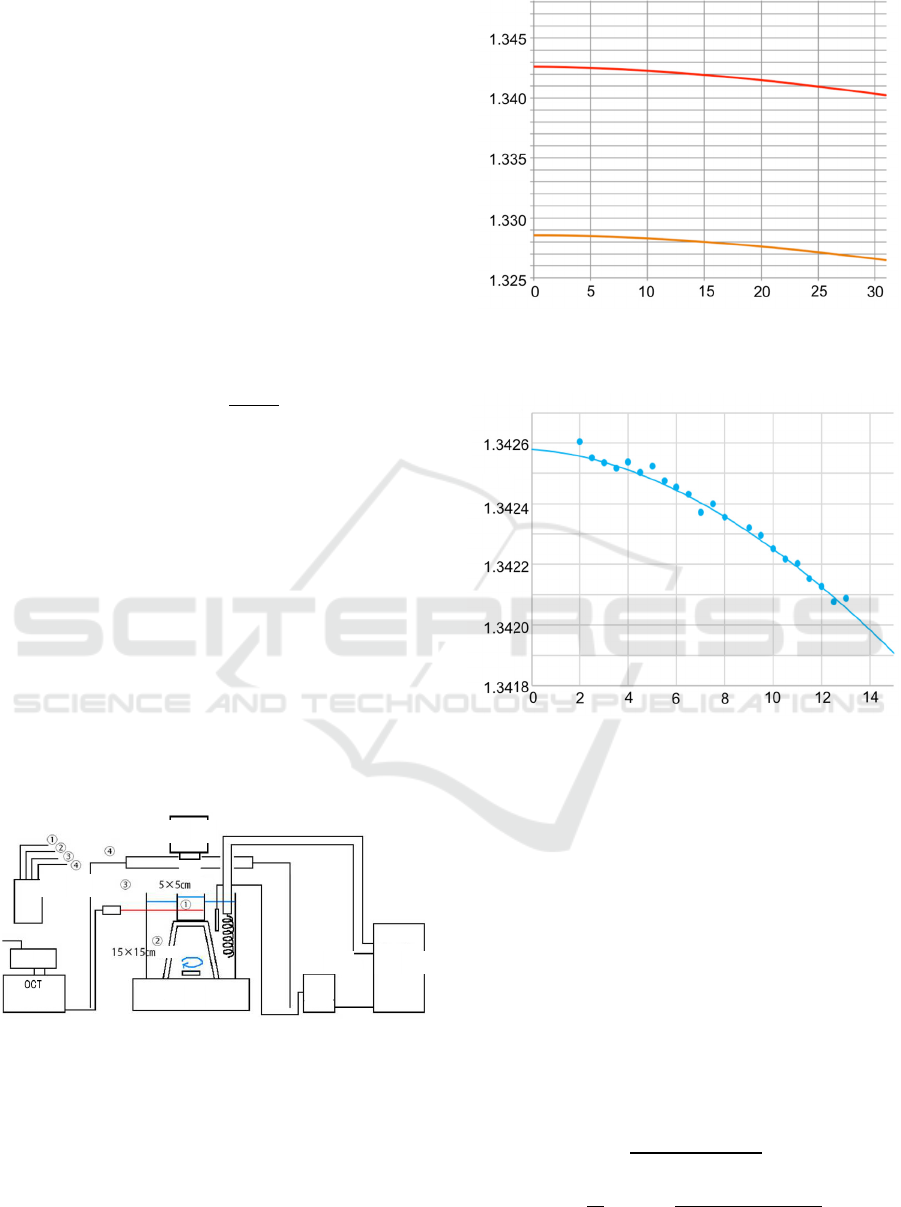

The refractive index measurement is the purpose

of the long path TD-OCT. The experimental set up is

shown in Fig.6. The measurement target is 5cm x 5cm

water tank (small tank). 15cm x 15cm water tank

(large tank) is the temperature control tank, which has

a cooler terminal. In the measurement, water

temperature is lowered, and the refractive index,

which depend on the temperature, was calculated by

measuring the optical path change between the inside

glass walls of the small tank. To stabilize the

controlled temperature inside the small tank, a stirrer

rotates the water in the large tank slowly. a thermo-

camera was also installed to monitor the temperature

distribution of the small.

The OCT measurement probe was set to enter the

small tank within the measurement range. The

interference signals of the small tank were obtained at

four positions from its glass walls (each side of the

walls). The refractive index was calculated by the

optical path length between the inner water-sides of

the small tank walls. The temperature was controlled

from the 25 to 2 degrees at the step of 0.5 degrees.

Rotation Angle [deg.]

Figure 4: Deviation balance on optical path difference.

Figure 5: Measurement errors on each optical path

difference.

3 EXPERIMENTAL RESULTS

3.1 Water Refractive Index

The refractive index depends on material density,

temperature, and incident wavelength. Absolute

refractive index equation shown as equation (3) is a

regression formula due to the above parameters based

on Lorentz-Lorentz equation.

n

2

+1

n

2

+ 2

⋅

1

D

= a

0

+ a

1

D + a

2

T + a

3

λ

2

T

+

a

4

λ

2

+

a

5

λ

2

−

λ

UV

2

+

a

6

λ

2

−

λ

IR

2

+ a

7

D

2

D = D / D

0

, T = T / T

0

,

λ

=

λ

/

λ

0

(3)

where n is the absolute refractive index of pure water,

𝐷

is density scale represented by the ratio between the

Optical Path Error [μ m]

Normal

Correction

Optical path Length [mmj]

Optical Path Difference [mm]

Solution Concentration and Temperature Measurements by Long-path Optical Coherence Tomography

153

pure water density D and the standard density D

0

[kg/m

3

], 𝑇

is temperature scale represented by the

ratio between the pure water temperature T [K] and

the standard temperature T

0

(=273.15K). 𝜆

̅

is

wavelength scale represented by the ratio between the

wavelength in vacuum λ and the standard wavelength

λ

0

(=0.589μm). a

0

– a

7

are optimized coefficients and

λ

UV

and

λ

IR

are UV / IR resonances. [7]

The OCT light source (here, SLD light source)

has wide spectrum. The SLD light disperses in a

material, and difference of speed (group index) due to

the refractive index occurs. That is, the refractive

index estimated by the OCT system becomes group

index of refraction . It is expressed as equation

(4).

(4)

Figure 7 shows the absolute index calculated by

the equation (3) and the group index calculated by the

equation (4) against the wavelength of 859.681nm,

which is same as the experiment. The experimental

results were compared with this group index.

The water group refractive index was obtained by

the experiment as shown in Fig.8. The measurement

was conducted by lowering the temperature from the

room temperature to 2 degrees. In the figure, the

results are represented as average with 10 times

measurements. The result well matched with the

theoretical value of group index. The maximum

errors from the theoretical curve was 0.00070. It gets

the five-digit accuracy. The maximum error occurred

on the longest path difference. It is caused by the 3

rd

approximation curve we used.

Figure 6: Water refractive index measurement by long-path

TD-OCT. The thormo meter minotered at each position

signed with the same numbers.

Figure 7: Refractive index and group refractive index of

water at each temperature.

Figure 8: Change of water group refractive index.

3.2 Refractive Index of Diluted Ethanol

Next step, group refractive index of diluted ethanol

was measured. Ethanol concentration was 20, 40, 60,

80 and 100% by diluting them with pure water. The

result is shown in Fig.9. The refractive index of the

concentration of 60 – 80% becomes higher than that

of the concentration of 100%. In the ethanol

concentration of 60 – 80% is not the sum of ethanol

and water volumes. Because the water molecules get

into the intervals among the ethanol molecules, the

density becomes high and the refractive index

becomes high, too. The experimental results indicate

its characteristics. The theoretical curve was obtained

by the Oster’s law shown as equation (5).

𝑛1

𝑛1

2𝑛

1

𝑛

1𝑐

𝜌

𝜌

𝑛

1

𝑛

1

2𝑛

1

𝑛

(5)

n

g

n

g

= n(

λ

) −

λ

dn(

λ

)

d

λ

Cooler

Thermo

Camera

SLD

Stirrer

Thermo-

meter

Thermo

Controller

Temperature [deg]

Refractive Index

Group Refractive Index

Temperature [deg]

● Experiment

-- Calculation

Group Refractive Index

Refractive / Group Refractive Index

PHOTOPTICS 2020 - 8th International Conference on Photonics, Optics and Laser Technology

154

𝑐

𝜌

𝜌

𝑛

1

𝑛

12𝑛

1

𝑛

Where n, n

1

, n

2

are refractive index of diluted ethanol,

water and ethanol, respectively. 𝜌, 𝜌

, 𝜌

are density

of diluted ethanol, water and ethanol, respectively. C

is ethanol density. The experimental results well

matched with the theory. Their accuracy was 4-digits.

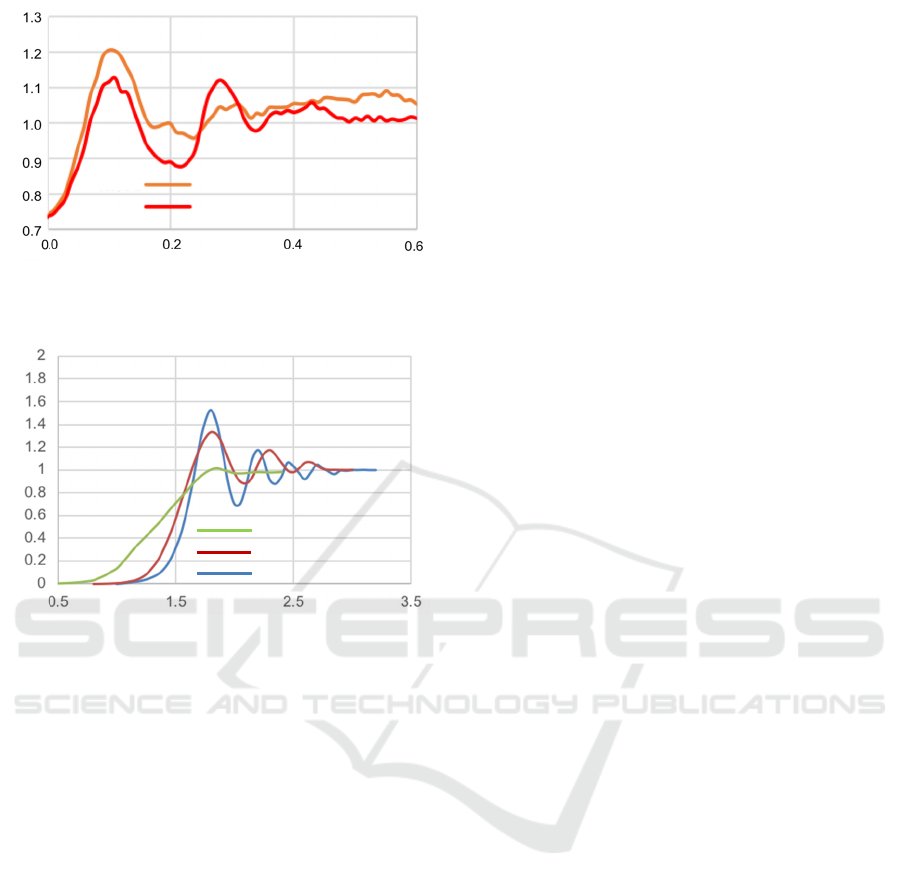

Figure 9: Group refractive index of diluted alcohols at each

temperature.

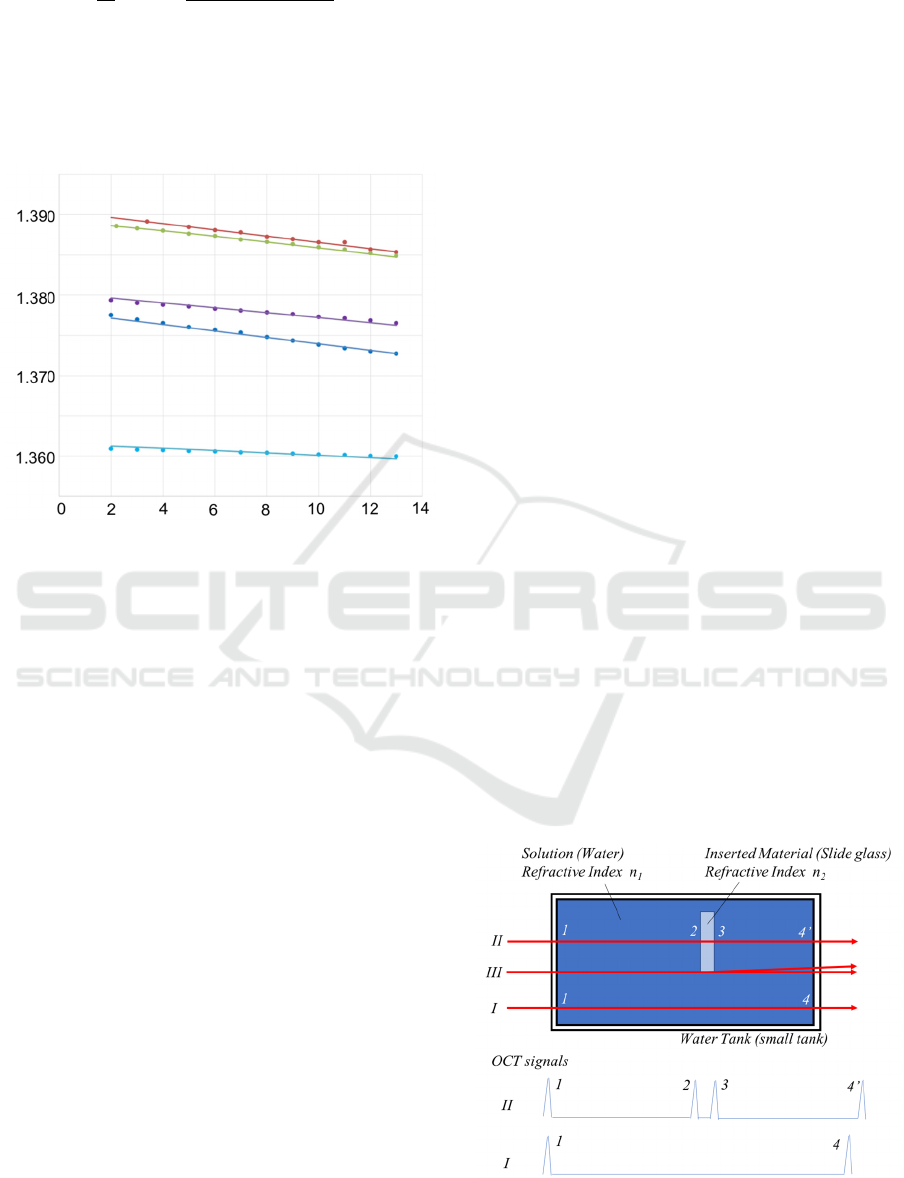

4 NEW APPROACH

4.1 Material Insertion

The purpose of this study is to visualize the

concentration change and erratic distribution of

solution due to the temperature. Such an effect can be

captured in the OCT signal, that is, the difference of

the optical path length in the solution. Figure 10

shows the experiment and the supposed OCT signals.

The slide glass was inserted into the water tank. When

the OCT beam is scanned on the glass inserted part

( II ), the OCT signal has longer interval between the

tank former signal ( 1 ) and tank rear signal ( 4’ ) than

the interval ( 1 - 4 ) on the water only part ( I ). It

looked that the tank rear signal simply shifted due to

the refractive index and the thickness of the inserted

slide glass. The boundary part ( III ) caused the

diffraction due to the knife-edge effect. The OCT

beam propagates with a certain divergence, and it is

reflected by the tank interior glass. The beam will not

be able to return to the OCT probe because of the

divergence.

The actual result did not like that. Figure 11 shows

the result. They are the OCT signals from the front

( 2 ) and rear ( 3 ) surfaces of the inserted slide glass.

The boundary never shifted simply, but the unique

diffraction-like phenomenon from knife-edge ware

appeared. The rear surface signal of the inserted slide

glass had more clear vibration than the front surface

signal. OCT is a point measurement, and its probe get

a reflected intensity from a point of the material

boundary. Diffraction phenomenon is an intensity

distribution with beam divergence. To observe its

distribution, the receiving aperture should have a

certain shift from the incident beam position in

perpendicular to the beam propagation. The OCT

probe is an inline optics, that is, common use for

transmitter and receiver. Why such a phenomenon

appeared ? What is the meaning of the signals ?

4.2 Fundamental Consideration

To make this phenomenon clear, the water tank was

removed and put the fixed mirror plate. the inserted

slide glass was replaced with a movable thin mirror,

too. In this set up, the movable mirror and the fixed

mirror plate act as knife-edge ( 2 or 3 ) and reflecting

target ( 4’ ), respectively. The result is shown in

Fig.12. It is the OCT signals from the fixed mirror.

Depending on the movable mirror positions, more

clear diffraction pattern was appeared. It has

completely same vibration with the diffraction pattern

from a knife-edge. Its degree depends on the beam

divergence. The degree of the vibration was changed

due to the beam divergence conditions. It is

considered that the diffracting wave front effected by

its divergence will be return to the OCT probe and

cause the interference signal. Now this fundamental

experiment was repeated with some variations and

theoretical approach was started to explain this

phenomenon.

Figure 10: Spatial fluctuation of concentration in a solution

volume.

Temperature [deg]

20%

40%

60%

80%

100%

Group Refractive Index

Solution Concentration and Temperature Measurements by Long-path Optical Coherence Tomography

155

Figure 11: Interference intensity vibrations on slide glass

measurement.

Figure 12: Interference intensity vibrations on mirror

measurement.

5 CONCLUSIONS

In this study, the high precision long path TD-OCT

system was developed to measure the refractive index

due to the temperature. Its accuracy was 5 digits for

water and 4 digits for ethanol solution. This approach

will link to the observation of local and temporal

change of the solution concentration. In this

measurement, the target solution can be treated in a

large volume. It will be able to visualize the spatial

and temporal phase transition of a solution,

fluctuation of concentration or temperature

distribution of solution, and mixing condition in some

solutions.

At its initial stage that the fluctuation was

modelled with the slide glass in a water, the unique

phenomenon was observed. At the boundary

condition, that is, at the case that the beam partially

interrupted by the movable thin mirror, which is act

as the knife-edge, the diffraction patterns were

observed. Their diffraction patterns are quite similar

to that of the knife-edge diffraction. The beam

propagated to the slide glass or the fixed mirror and

reflected to the OCT probe. In general, the diffraction

from the knife-edge can be observed on the screen

perpendicular to the optical axis. The diffracted beam

has a divergence and it cannot return to the same path

with the going way. The OCT probe transmits and

receives the beam on the in-line optical path. The

observed pattern was captured at that conditions. It

was confirmed that the small beam divergence will

cause the phenomenon. The theoretical analyses will

help to understand the situation.

The observed unique pattern will have valuable

information between the solution and the inserted

material. It represents the small angle divergence. The

OCT image will have the enhance effect to the

boundary between their materials. The small-angle

scattering on X-ray regions is suggestive. Is it

possible to deduce such fruitful information from the

pattern? Now such consideration is started.

REFERENCES

Brezinski M. E. and Fujimoto J. G., 1999, “Optical

Coherence Tomography: High-Resolution Imaging in

Nontransparent Tissue”, IEEE J. Quant. Electron., Vol.

5, No. 4, pp.1185-1192.

Danielson B. L. and Boisrobert C. Y. 1991, “Absolute

optical ranging using low coherence interferometry”,

App. Opt. Vol. 30, No.21 pp.2975-2979.

Harvey A. H., Gallagher J. S., and J. M. H. L.,

1998, ”Revised Formulation for the Refractive Index of

Water and Steam as a Function of Wavelength,

Temperature and Density”, J. Phys. Chem. Ref. Data,

Vol.27, pp.761-774.

Huang D., Swanson E. A., Lin C. P., Schuman J. S., Stinson

W. G., Chang W., Hee M. R., Flotte T., Gregory K.,

Puliafito C. A., J. G. Fujimoto, 1991, “Optical

Coherence Tomography”, Science, Vol. 254, pp.1178-

1181.

Shiina T., Moritani Y., Ito M., and Okamura Y.,

2003, "Long optical path scanning mechanism for

optical coherence tomography", Applied Optics, Vol.42,

No. 19, pp.3795-3799.

Shiina T., Miyazaki H., and Honda T., 2009, “Factory built-

in type simplified OCT system for industrial

application”, IEEJ C、Vol.129, No.7, pp.1276-1281,

(Japanese)

Shiina T., 2014, “Optical Coherence Tomography for

industrial application” Handbook of Optical Metrology

2

nd

Edition, CRC Press, Chapter 30, pp.769 – 790..

Shiina T., PCT/JP2010/070844

Song G. and Harding K G, 2012, “OCT for industrial

applications”, Proc. Of SPIE, 8536.

Yoshizawa t. Eds, 2015, Handbook of optical metrology:

principles and applications, second edition, CRC Press.

Slide Glass Insertion distance [mm]

Interference Intensity [a.u.]

Front Surface Signal

Rear Surface Si

g

nal

Knife Edge Insertion Distance [mm]

Interference Intensity [a.u.]

Collimated (<0.3mrad)

Divergence(1.0mrad)

Divergence(1.4mrad)

PHOTOPTICS 2020 - 8th International Conference on Photonics, Optics and Laser Technology

156